A review of construction and test operation for full scale low speed wind tunnels overseas

-

摘要: 从介绍美国和俄罗斯建设特大型低速风洞的背景出发, 重点阐述了国外特大型低速风洞开展的试验研究情况, 包括运用的试验流程、完成的试验型号、使用的试验技术等, 尤其是针对特大型低速风洞而设计的特殊试验技术, 研判了特大型低速风洞试验技术未来的发展趋势. 研究结果表明, 特大型低速风洞的建设主要是为了满足型号试验任务和技术发展的需要, 试验流程突出大模型的安装和试验故障的处理, 试验型号以固定翼飞机、旋翼飞机等各类飞机为主, 也兼顾多种航天飞行器的低速试验研究, 还积极承揽能源、交通及建筑类的试验任务, 并在基础空气动力学问题研究方面发挥了重要的作用. 在试验技术方面, 特大型低速风洞既采用了常规的测力、测压和测速等试验技术, 也发展了全尺寸模型、倾转试验台、特大攻角、模型自由飞行、非接触光学测量、恶劣环境模拟等特殊的试验技术, 试验技术总体呈现向提交高精度数据、组合利用多种测试手段、深度赋能大数据、多学科一体化、虚拟现实与增强现实相结合等方向发展. 最后, 提出了特大型低速风洞分步发展试验技术、打造专业试验平台、突出试验细节尺度优势等几点启示.Abstract: The construction background of three full scale low speed wind tunnels in the United States and Russia is briefly introduced. Then, emphasis on tests performed in these wind tunnels are presented, including test operation mode, test model types, test technologies, etc, especially for special test techniques of the full scale wind tunnel. The future development trend of the test techniques is concluded. Research results show that the construction need of full scale wind tunnel is mainly originated from large model aerodynamic test and some related technology development. During model test process, more special attentions are paid to the installation of very large model and the treatment of test failure. The models tested in full scale wind tunnel mainly include airplanes, aerospace vehicles, and energy infrastructures. Additionally, fundamental aerodynamic problem such as rotor flow, acoustic noise can also be resolved in such kind of wind tunnel. As far as the test technique is concerned, conventional measurement method such as force balance, pressure transducer and hot wire anemometer can be used. More importantly, special test techniques developed for full scale model tilting test apparatus, test benches with very large angle of attack, model free flight mechanism, non-intrusive optical measurement and bad weather simulation facility are also been described. The general development trend of test technique is obtained, including going along a direction of providing data with high precision, combining and utilizing various test methods, enabling development with big data in depth, integrating multidiscipline research, developing virtual and augmented reality, etc. Finally, some enlightenments and suggestions are put forward, such as developing test techniques step by step, building professional experimental stand, and highlighting the advantages of large scale and detailed measurements.

-

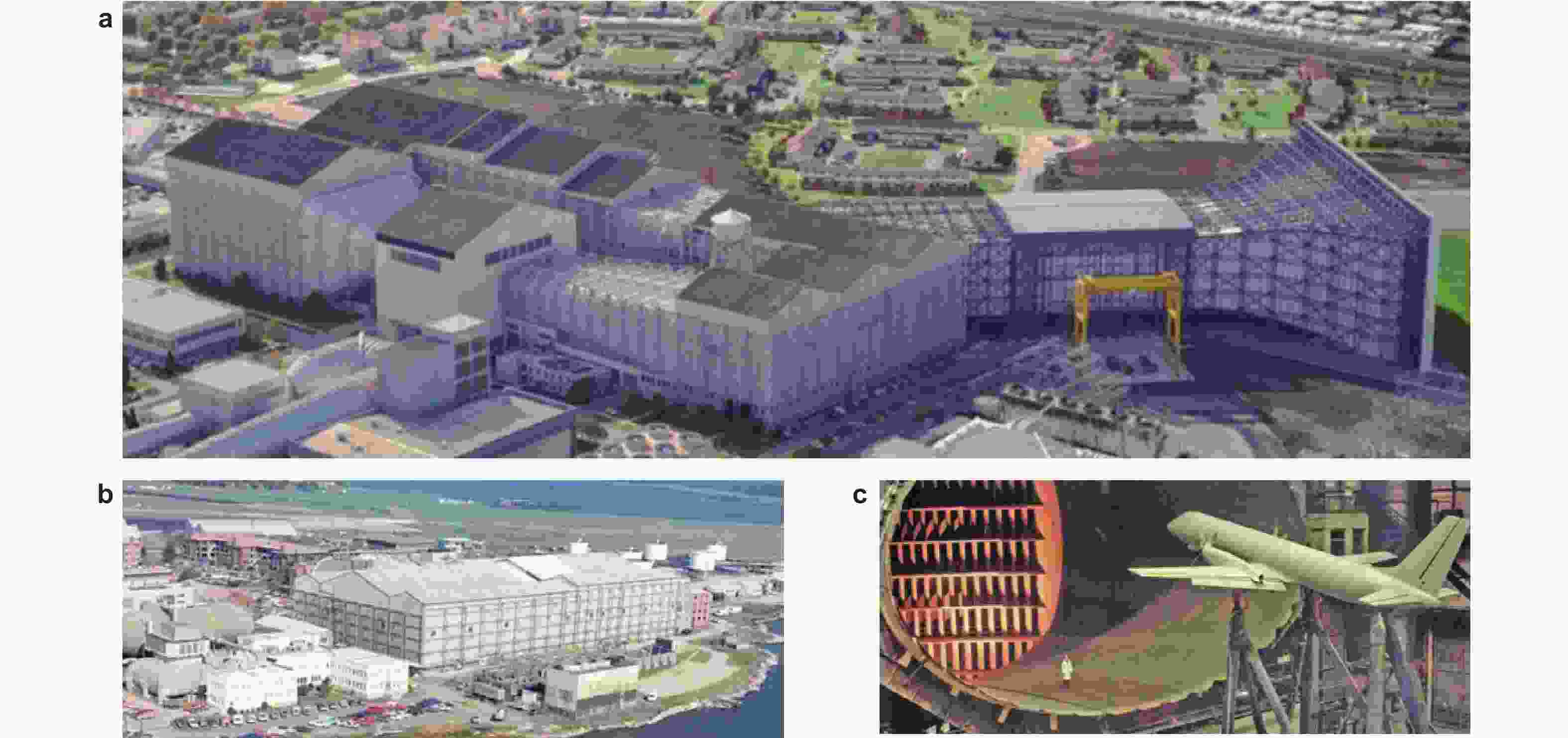

图 1 国外三座特大型低速风洞. (a)NFAC风洞 (Kenneth 2020); (b)LFST风洞(Joseph 2014); (c)T-101风洞(Chernyshev 2018)

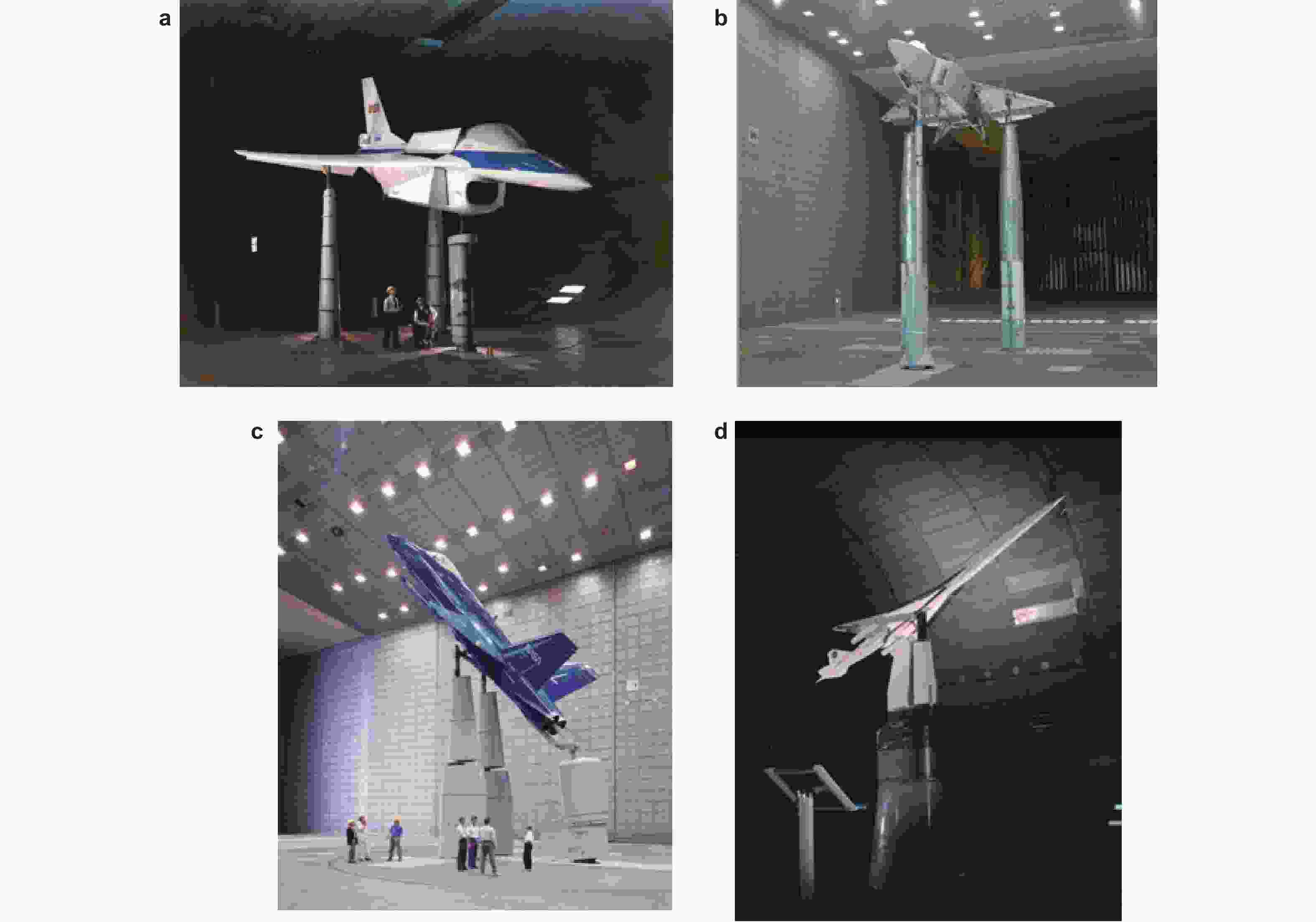

图 2 四种飞机型号在NFAC的两个试验段开展试验 (Kenneth 2020). (a) E-7, (b)联合攻击机 (JSF), (c) F-18, (d) 高速民用运输机 (HSCT)

图 3 三种典型的倾转旋翼机. (a) XV-3 (David et al. 1959), (b) XV-15联合攻击机(Martin et al. 2020), (c) V-22的1/4缩比模型(Acree & Jr 2016)

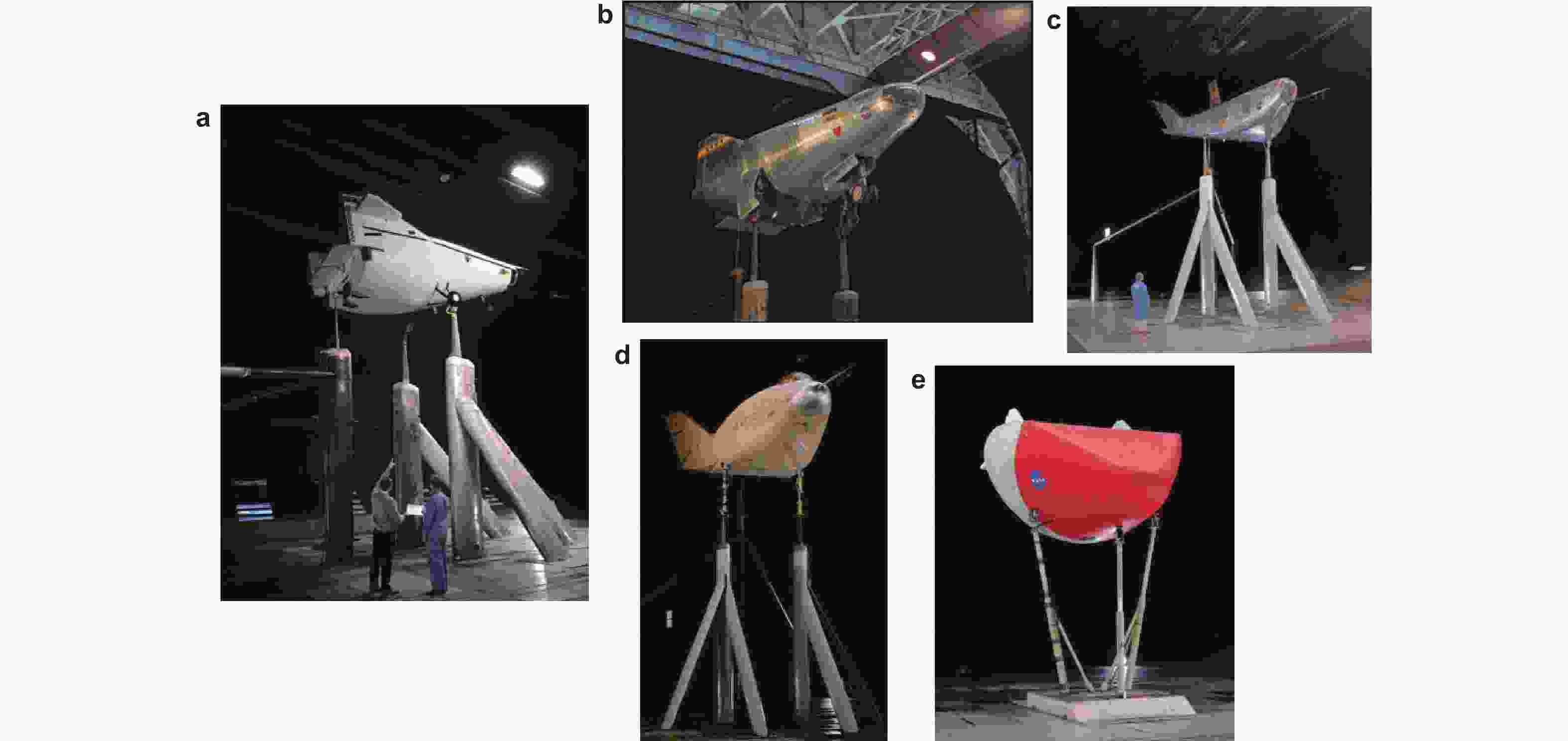

图 4 五种典型的升力体飞行器 (Kenneth 2020).(a) M2-F1, (b) M2-F2, (c) HL-10, (d) X-24A, (e) M1-L

图 5 航天飞机模型在40英尺 × 80英尺风洞中试验 (Kenneth 2020)

图 6 高速充气式气动减速器 (HIAD) 进行试验 (Kenneth 2020)

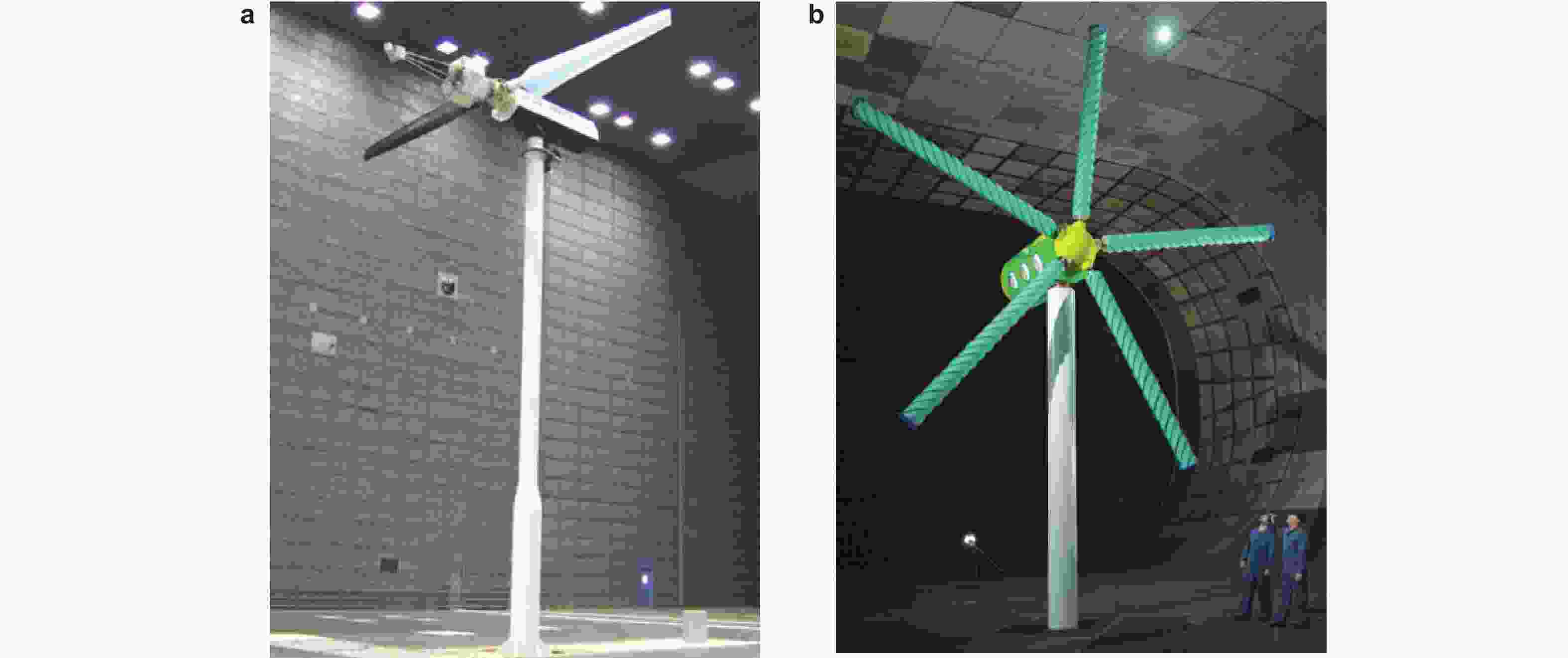

图 7 NREL开展的两种风力机试验. (a)水平轴风力机 (Schreck & Robinson 2005), (b)梅卡罗螺旋马格努斯风力机(Kenneth 2020)

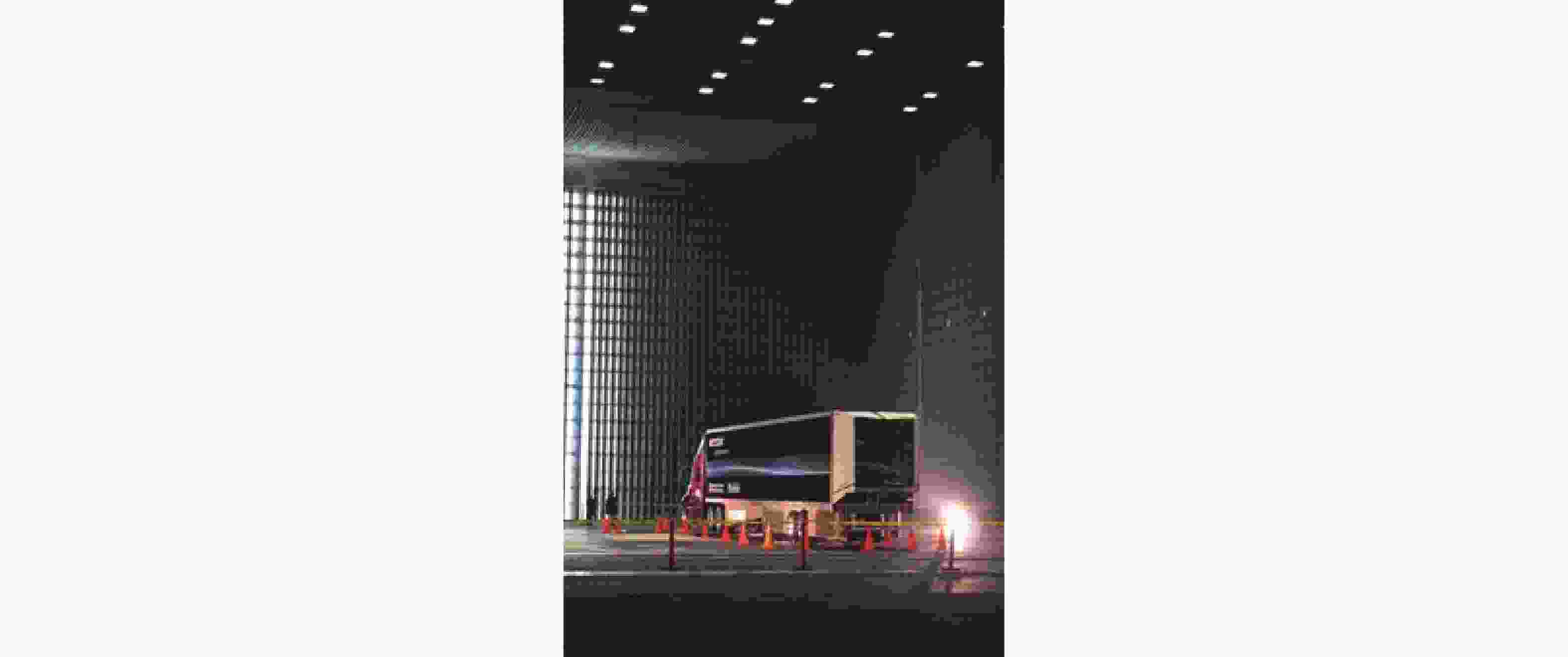

图 8 Navistar卡车在80英尺 × 120英尺试验段开展试验(Kenneth 2020)

图 9 室外空气动力学研究设备 (OARF)(Felker et al. 1986)

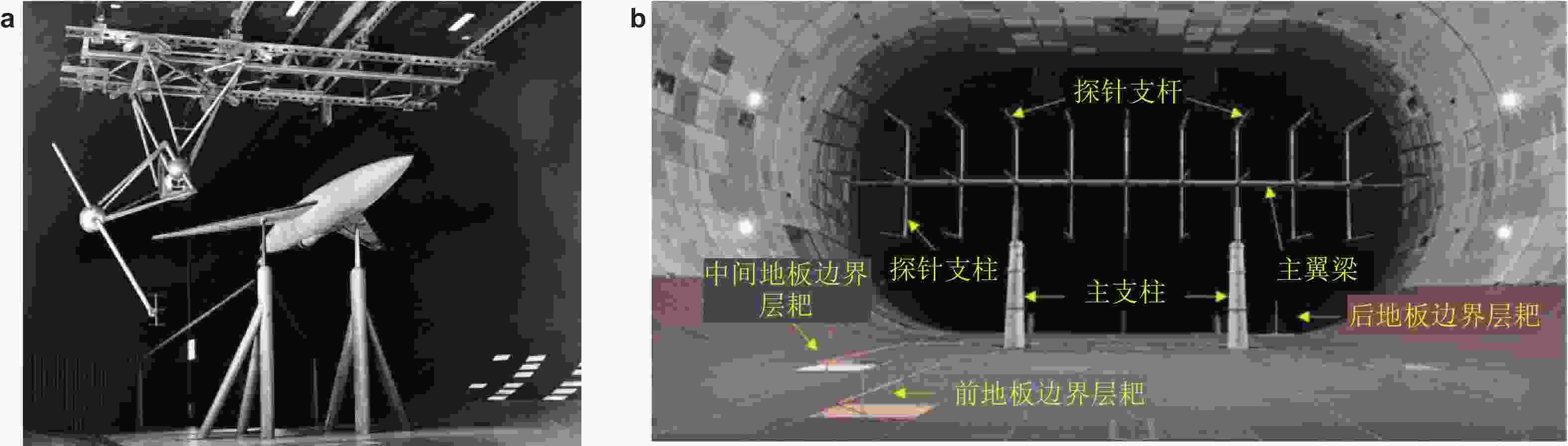

图 10 NFAC使用的两种流场校测装置. (a) 40英尺 × 80英尺风洞(Kenneth 2020), (b) 80英尺 × 120英尺风洞(Lukacovic & Sayles 2024)

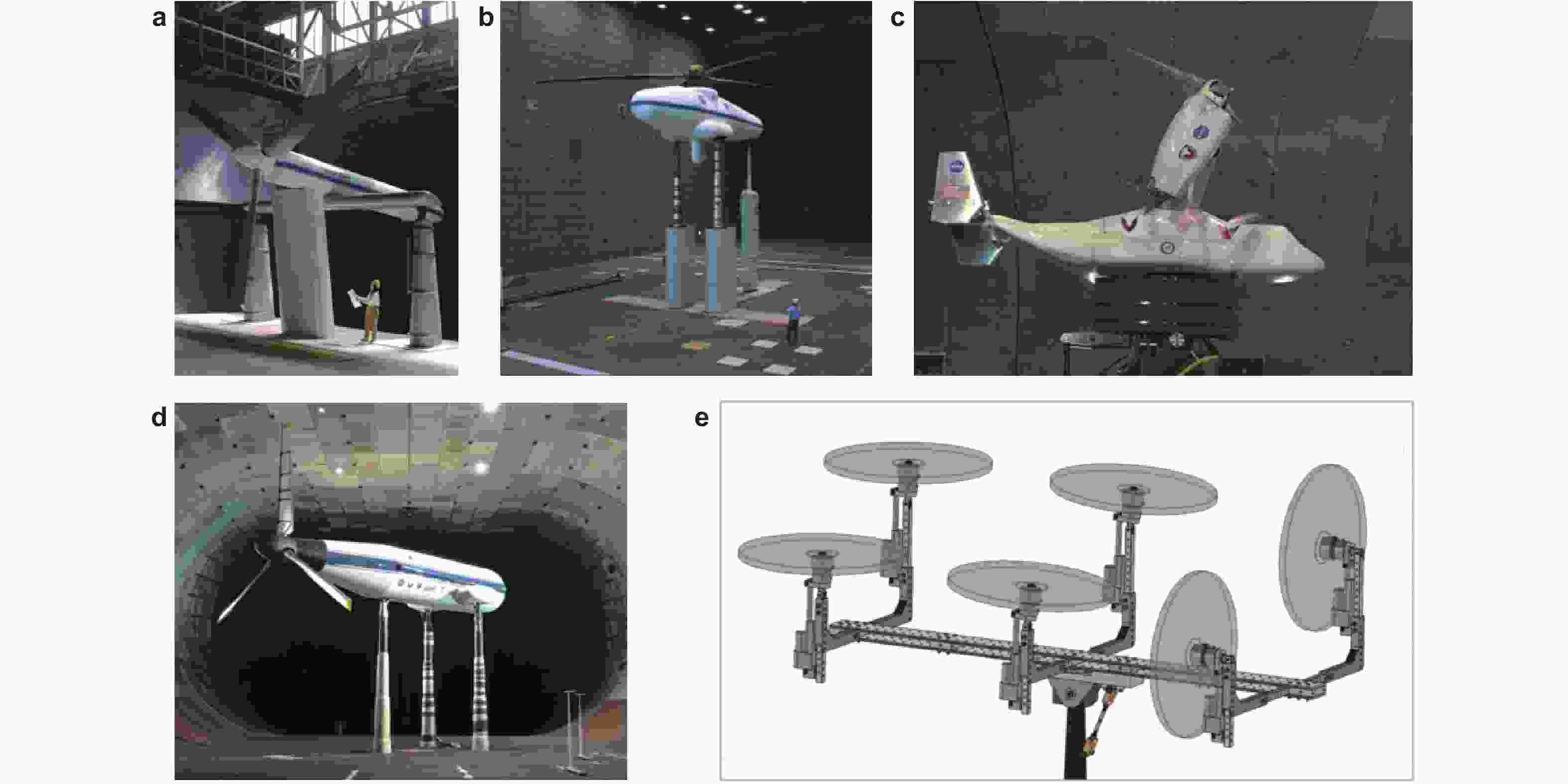

图 11 倾转试验台技术的发展演变. (a) PTR (Kenneth 2020), (b) LRTA (Johannes 2007), (c) TRAM (Megan 2002), (d) TTR (Acree et al. 2019), (e) MTB (Sarah 2023)

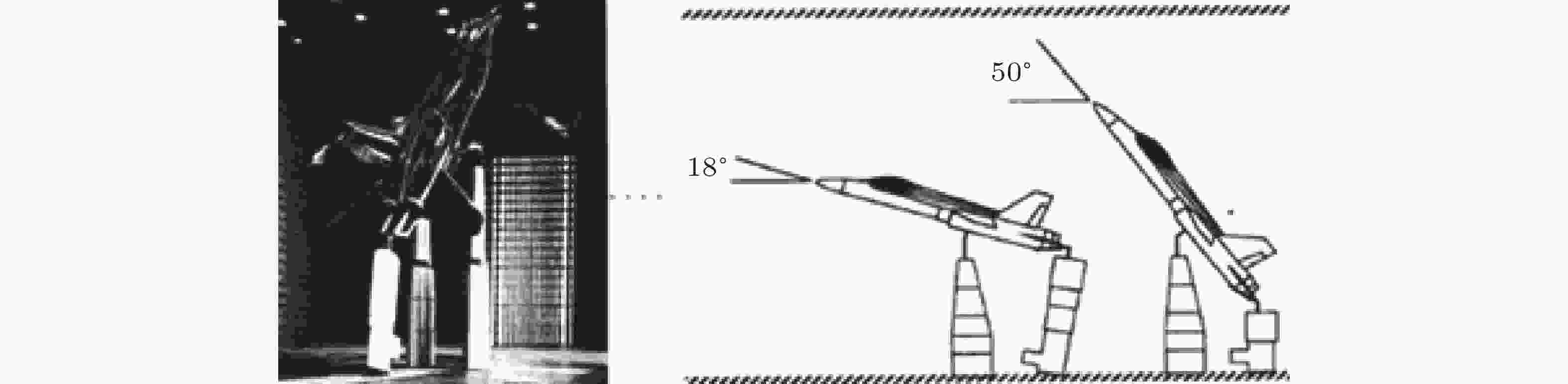

图 12 F/A-18飞机在80英尺 × 120英尺试验段的特大攻角布置(Larry & Kevin 1992)

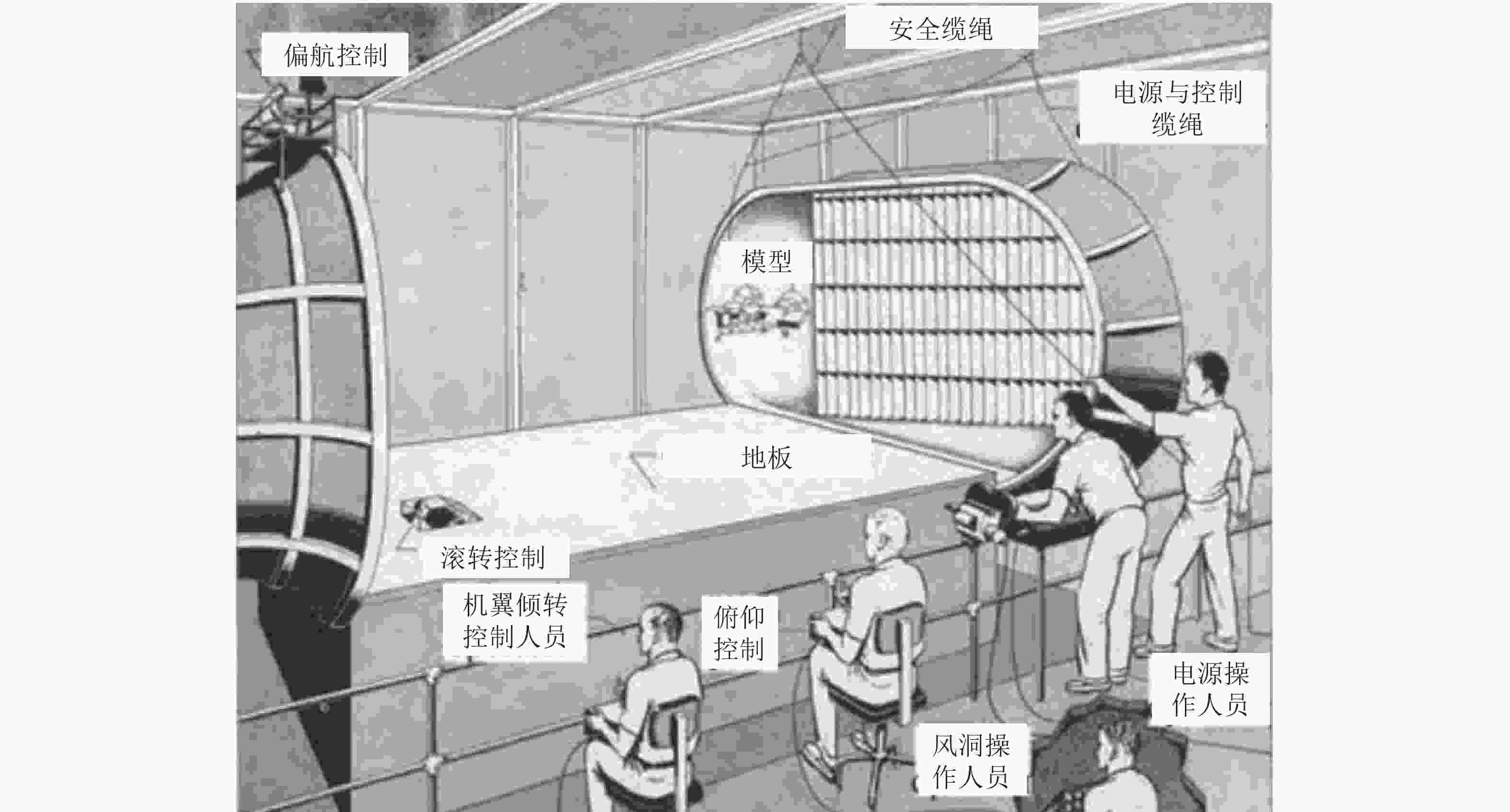

图 13 风洞中的自由飞行试验装置简图(John 1963, 张卫国 等 2024)

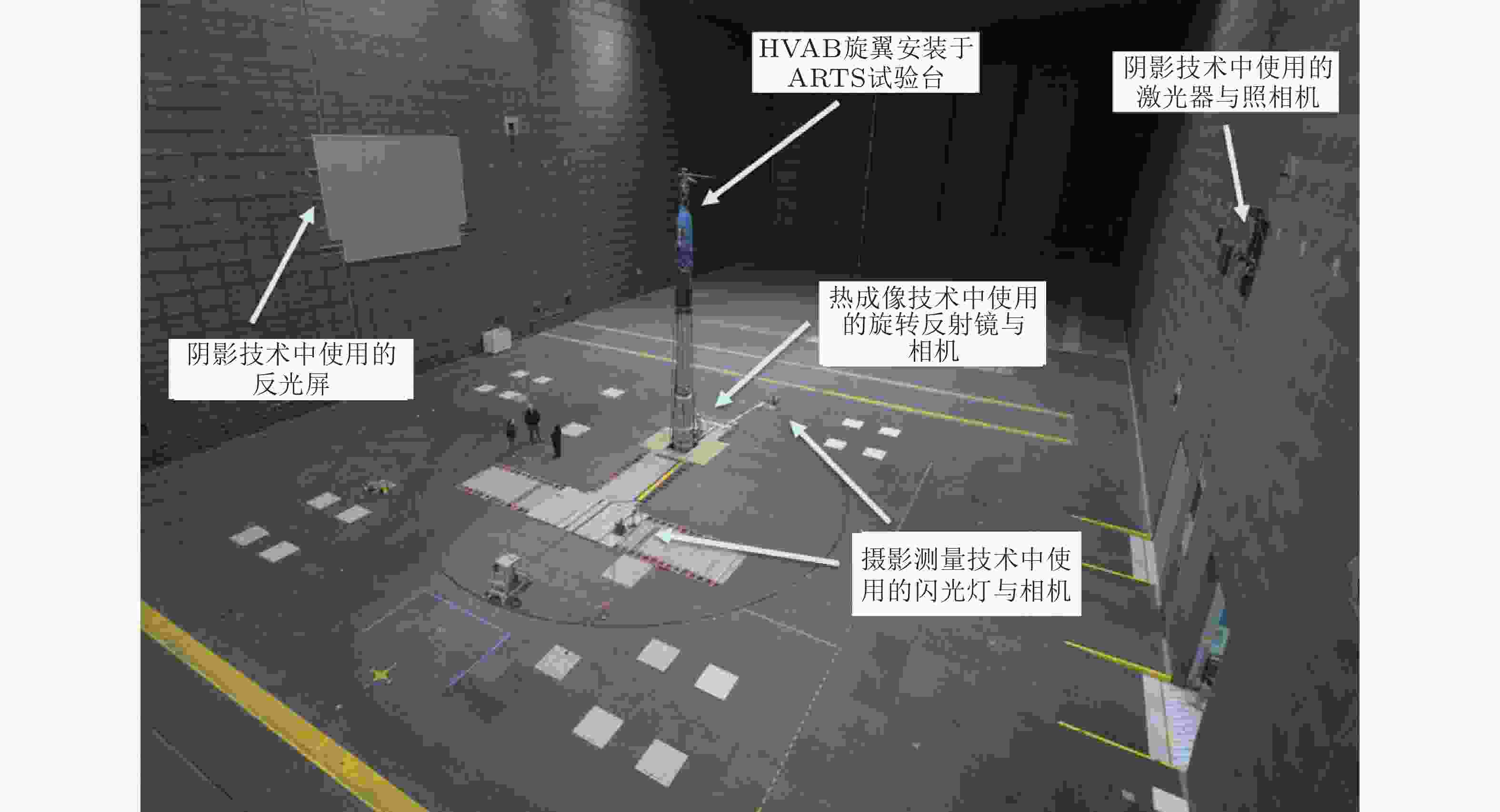

图 14 某旋翼在80英尺 × 120英尺试验段的光学综合测量试验(Norman et al. 2023)

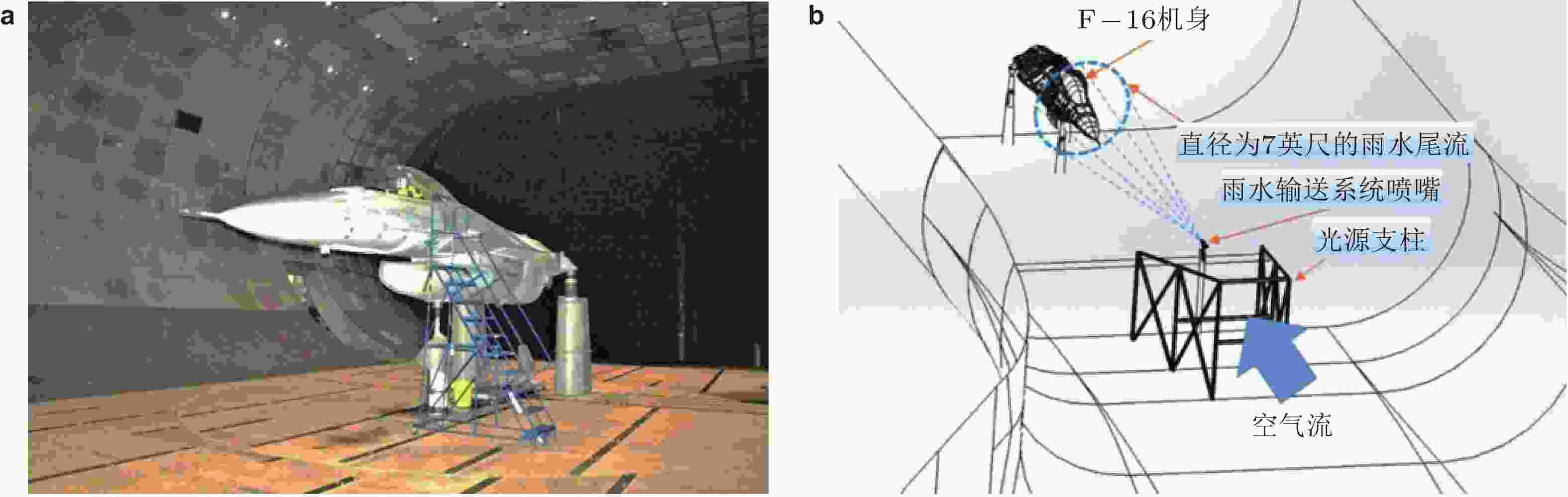

图 15 40英尺 × 80英尺试验段发展的降雨模拟试验技术布局图(Goulding et al. 2022). (a) F-16飞机等待测试, (b)试验技术系统组成

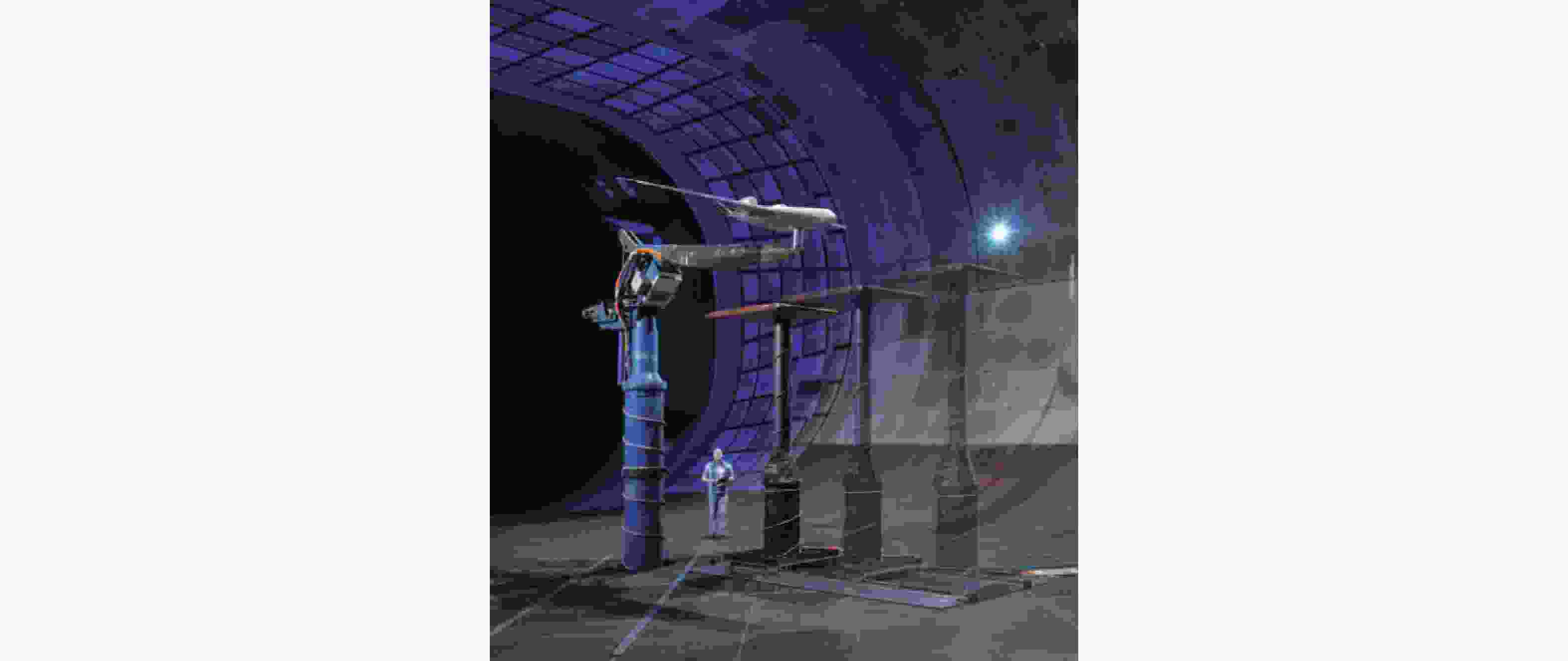

图 16 混合翼身组合体 (HWB) 模型安装于40英尺 × 80英尺风洞(Nathan et al. 2017)

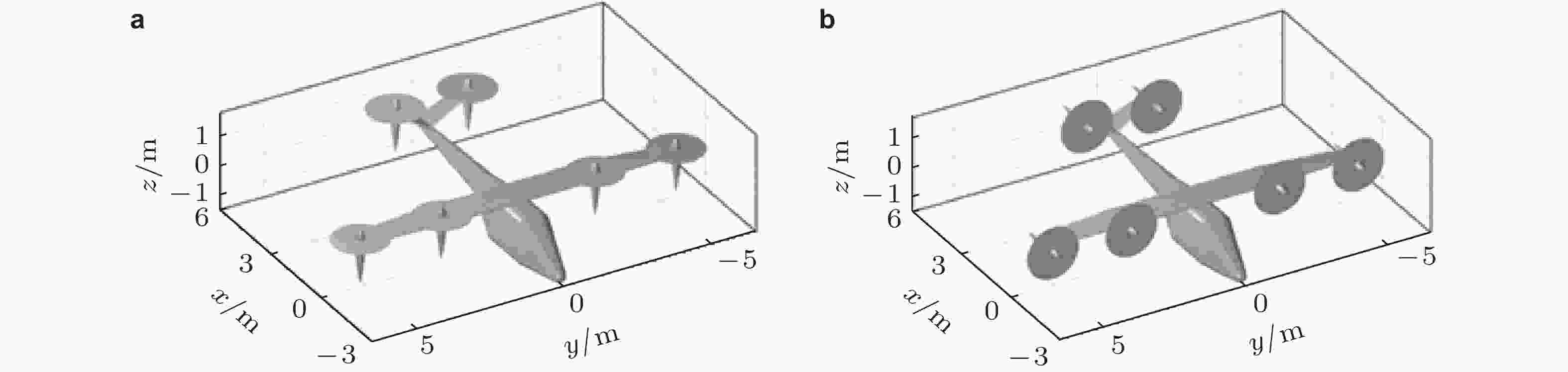

图 17 电动垂直起降飞行器 (eVTOL). (a)垂直起飞构型, (b)巡航构型(Wang et al. 2025)

图 18 波多黎各大学马圭斯大学高性能计算与可视化实验室建设的虚拟风洞(David et al. 2021)

表 1 NFAC风洞建设初期开展的部分型号试验

序号 型号名称 试验年份 试验内容 1 道格拉斯XSB2D-1战斗机 1944 NFAC试验的首架飞机, 主要是评估气动特性, 以估算飞机起飞跑道长度 2 道格拉斯A-26轰炸机 1945 双发中置翼飞机, 主要是为了减少高速飞行时的操纵力, 提高飞行稳定性 3 共和F-84A战斗机 1948 解决飞机的纵向稳定性问题, 被美国空军广泛应用 4 北美F-86A战斗机 1951 初期主要开展气动性能改进试验, 后期开展了诸多边界层控制试验 5 洛克希德F-94C截击机 1952 测定不同攻角下的气动特性, 评估飞机的不规则表面和部件阻力 表 2 NFAC各个时期开展的几种典型直升机型号试验

序号 型号名称 时期 试验内容 1 XV-1 NACA时期

(1944—1958)验证推力转向式旋翼机在垂直起降和巡航飞行中的可行性和性能 2 喷气襟翼旋翼机 NASA单试验段时期

(1958—1980)评估喷气襟翼旋翼对直升机升力和操控性能的提升效果 3 西科斯基高速旋翼 开展高速旋翼系统试验, 以研究新型旋翼设计对直升机性能提升的影响 4 S-76直升机 对采用弹性轴承的直升机S-76开展了试验, 验证飞行性能、安全性和舒适性 5 UH-60直升机 NASA双试验段时期

(1987—2003)对直升机四桨叶旋翼开展了空速达85节条件下的独立桨叶控制试验 6 DARPA/西科斯基

主动旋翼AEDC时期

(2006至今)测试了通过主动旋翼改装的旋翼机, 验证独立桨叶控制技术降低旋翼机噪声和振动的效果 表 3 NFAC双试验时期开展的倾转旋翼机试验

序号 型号名称 试验年份 试验内容 1 XV-15 1996、1998 验证XV-15在直升机和巡航模式下的性能, 以及旋翼气动性能和噪声特性 2 V-22 1987、1990 对V-22倾转旋翼机的旋翼和机翼进行了气动性能试验, 验证设计性能 3 倾转旋翼气动声学

模型 (TRAM)2000 开展旋翼气动声学模型试验以研究倾转旋翼机气动噪声特性, 提出控制方法 -

[1] 陈呈, 赵丹, 王岳青, 等. 2021. NNW-TopViz流场可视分析系统. 航空学报, 42(9): 625747, 1-12 (Cheng C, Zhao D, Wang Y Q, et al. 2021. NNW-TopViz visualization analysis system for flow field. Acta Aeronautica et Astronautica Sinaica, 42(9): 625747, 1-12).Cheng C, Zhao D, Wang Y Q, et al. 2021. NNW-TopViz visualization analysis system for flow field. Acta Aeronautica et Astronautica Sinaica, 42(9): 625747, 1-12 [2] 刘赟, 黄心跃, 张苗苗, 等. 2024. 4 m × 3 m风洞大迎角机构上位机软件. 兵工自动化, 43(7): 79-81, 96 (Liu Y, Huang X Y, Zhang M M, et al. 2024. Upper computer software for high angle of attack mechanism in 4 m × 3 m wind tunnel. Ordnance Industry Automation, 43(7): 79-81, 96).Liu Y, Huang X Y, Zhang M M, et al. 2024. Upper computer software for high angle of attack mechanism in 4 m × 3 m wind tunnel. Ordnance Industry Automation, 43(7): 79-81, 96 [3] 刘政崇, 廖达雄, 董谊信. 2003. 高低速风洞气动与结构设计. 国防工业出版社: 北京 (Liu Z C, Liao D X, Dong Y X. 2003. Aerodynamic and structural design for low speed and high speed wind tunnel. National Defense Industry Press: Beijing).Liu Z C, Liao D X, Dong Y X. 2003. Aerodynamic and structural design for low speed and high speed wind tunnel. National Defense Industry Press: Beijing [4] 王振羽, 伍荣林. 1985. 风洞设计原理. 北京航空学院出版社: 北京 (Wang Z Y, Wu R L. 1985. Wind tunnel design principle. Beijing Aeronautics College Press: Beijing).Wang Z Y, Wu R L. 1985. Wind tunnel design principle. Beijing Aeronautics College Press: Beijing [5] 张德久, 徐剑英, 谢明伟, 等. 2024. 大型低速风洞尾撑机构研制. 兵工自动化, 43(2): 35-39 (Zhang D J, Xu J Y, Xie M W, et al. 2024. Development of tail support mechanism for large low speed wind tunnel. Ordnance Industry Automation, 43(2): 35-39).Zhang D J, Xu J Y, Xie M W, et al. 2024. Development of tail support mechanism for large low speed wind tunnel. Ordnance Industry Automation, 43(2): 35-39 [6] 战培国. 2017. 美国全尺寸风洞中的PIV系统. 航空科学技术, 28(11): 1-4 (Zhan P G. 2017. PIV system in national full-scale aerodynamics complex of American. Aeronautical Science & Technology, 28(11): 1-4).Zhan P G. 2017. PIV system in national full-scale aerodynamics complex of American. Aeronautical Science & Technology, 28(11): 1-4 [7] 张卫国, 唐敏, 武杰, 等. 2024. 倾转旋翼机风洞试验综述. 航空学报, 45(9): 530114 (Zhang W G, Tang M, Wu J, et al. 2024. Overview of wind tunnel test research on tiltrotor aircraft. Acta Aeronautica et Astronautica Sinica, 45(9): 530114).Zhang W G, Tang M, Wu J, et al. 2024. Overview of wind tunnel test research on tiltrotor aircraft. Acta Aeronautica et Astronautica Sinica, 45(9): 530114 [8] Acree C W, Jr. 2016. Assessment of JVX proprotor performance data in hover and airplane-mode flight conditions. NASA/TM-2016-219070. [9] Acree C W, Sheikman A L, Norman T R. 2019. High-speed wind tunnel tests of a full-scale proprotor on the tiltrotor test rig. Vertical Flight Society’s 75th Annual Forum & Technology Display. [10] Austin D O, Peter A C, Norman W S. 2020. Hover validation and acoustic baseline blade set definition. NASA/TM–2020–5002153. [11] Askins P A, Zell P T, Ross J C. 1997. Aerodynamic decelerator testing in the national full-scale aerodynamics complex. 14th Aerodynamic Decelerator Systems Technology Conference. [12] Bedrzhitsky E I, Roukavets V P. 1996. Historical review of the creation and improvement of aerodynamic test facilities at TsAGI. NATO-AGARD/RTO. [13] Boettcher K, Lehr C, Aurich D, et al. 2023. Methodology for real-time sensor measurement based augmented reality laboratory experiment in a wind tunnel. 20th International Conference on Remote Engineering and Virtual Instrumentation. [14] Califano N, Murakami D. 2020. 3D localization of defects in facility inspection. 33th Florida Conference on Recent Advances in Robotics. [15] Chernyshev S L. 2018. To the 100th anniversary of TsAGI. TsAGI Science Journal, 49(4): 299–307. [16] Clifton H W, Nathan J B, Paul T S, et al. 2004. Aeroacoustic study of a 26%-scale semispan model of a Boeing 777 wing in the NASA Ames 40- by 80-foot wind tunnel. NASA/TP–2004-212802. [17] Colin P B, Drew L. 1998. From the 30 by 60 to the langley full scale tunnel. AIAA 1998-16067. [18] Corsiglia V R, Schwind R G, Chigier N A. 1973. Rapid scanning, three-dimensional, hot-wire anemometer surveys for wing tip vortices in the Ames 40- by 80-foot wind tunnel. AIAA Paper, 73-681. [19] Datta A, Yeo H, Norman T R. 2013. Experimental investigation and fundamental understanding of a full-scale slowed rotor at high advance ratios. Journal of the American Helicopter Society, 58(2). [20] David G. 1954. Tests of the Northrop XB-62 missile in the Ames 40 by 80 foot wind tunnel. NACA RM SA54129. [21] David G K, Richard K G, Mark W K. 1959. Full-scale wind-tunnel investigation of the longitudinal characteristics of a tilting-rotor convertiplane. N89-70796. [22] David P, Jean S, Christian J L, et al. 2021. Design of a virtual wind tunnel for CFD visualization. AIAA Scitech 2021 Forum. [23] Dennis O M, Terrence A T, Alexander F M, et al. 2024. Effect of the proposed closure of NASA’s subsonic wind tunnel: An assessment of alternatives. IDA Paper, 3858. [24] Edgar R E. 1994. An LDV investigation of support structure influence on the flow field near the wingtip of a STOVL configuration in hover. Master of science in aeronautical engineering from the naval postgraduate school september 1994. [25] Edward T S, Laura K K, James T H. 2018. Measurements of parachute dynamics in the world’s largest wind tunnel by stereo photogrammetry. 2018 Aerodynamic Measurement Technology and Ground Testing Conference. [26] Felker F F, Young L A, Signor D B. 1986. Performance and loads data from a hover test of a full-scale advanced technology XV-15 rotor. NASA-TM-86854. [27] Goulding P W, Nykamp C M. 2023. The path to mars runs through the national full-scale aerodynamics complex. AIAA SCITECH 2023 FORUM. [28] Goulding P W, Nykamp C M, Lukacovic K S, et al. 2022. Development of a rain simulation capability in the national full-scale aerodynamics complex 40- by 80-foot wind tunnel. AIAA SCITECH 2022 Forum TR 006442. [29] Goulding P W, Tupis A R. 2017. Developing a semi-span wall interference correction capability in the national full-scale aerodynamics complex 40-by 80-foot wind tunnel. AIAA SciTech Forum-55th AIAA Aerospace Sciences Meeting. [30] Hicks B. 2024. AEDC expert takes home AIAA honors. Arnold Air Force Base. [31] Hunt R, Sacco J. 2020. Activation and operation of the national full-scale aerodynamics complex. AIAA, 2000-1076. [32] James H S, Natasha L S, Benny K C. 2021. Aeroacoustic measurements from the aerodynamic and acoustic rotorprop test (AART) in the national full-scale aerodynamics complex (NFAC) 40- by 80-foot wind tunnel. The Vertical Flight Society’s 77th Annual Forum & Technology Display. [33] Johannes M A. 2007. Analysis of calibration data for the multi-component rotor balance installed in the NFAC large rotor test apparatus. AIAA 2007-146. [34] Van Aken J M, Yang L. 2009. Development of a new state-of-the-art data acquisition system for the national full-scale aerodynamics complex wind tunnels. AIAA 2009-1346. [35] John P C. 1963. Free and semi-free model flight-testing techniques used in low-speed studies of dynamic stability and control. NASA TM 450785. [36] Joseph R C. 2014. Cave of the winds the remarkable history of the Langley full-scale wind tunnel. NASA/SP-2014-614. [37] Kelly M W. 1974. Large-scale wind-tunnel studies of several VTOL types. NASA Report. [38] Kenneth W M. 2020. The world’s largest wind tunnels their history, contributions to aeronautics, and importance to flight: A history of the NASA Ames 40- by 80-foot and 80- by 120-foot wind tunnels. NASA/SP-20205009237. [39] Kenneth W M, Paul T S, William T E. 1979. Improving large-scale testing capability by modifying the 40- by 80-ft wind tunnel. J. Aircraft, 16(8): 571-575. [40] Kreshock A R, Thornburgh R P. 2024. Ground vibration testing of the TiltRotor aeroelastic stability testbed. NASA/TM−20240004747. [41] Larry A Y. 1998. Tilt rotor aeroacoustic model (TRAM): A new rotorcraft research facility. AHS International Meeting on Advanced Rotorcraft Technology and Disaster Relief, Gifu, Japan, April 21-23. [42] Larry A M, Kevin D J. 1992. Full-scale high angle-of-attack tests of an F/A-18. AIAA, 92-2676. [43] Laura K K, Justin L, Alan C. 2013. Photogrammetry of a hypersonic inflatable aerodynamic decelerator. AIAA 2013-1284. [44] Lauren N W, Hannah T D. 2021. Upwind buildings effects on test section performance of the NFAC 80-by 120-foot wind tunnel. AIAA SciTech Forum. [45] Lowrance R K, Meyer R D. 2010. Distributed data system for the national full-scale aerodynamics complex wind tunnels. AIAA-2010-1729. [46] Lukacovic K S, Sayles E L. 2024. Summary of the national full-scale aerodynamics complex 40- by 80-foot wind tunnel flow characterization study methods and results. AIAA SCITECH 2024 Forum. [47] Martin D M, Demo J G, Daniel C D. 2000. The history of the XV-15 tilt rotor research aircraft: From concept to flight. NASA SP-2000-4517. [48] Masataro A, Shohei M, Yuta S, et al. 2025. Aeroelastic CRM-HL wind tunnel testing for verification and validation study on stall speed determination by analysis: Modeling and testing plan. AIAA 2025-1282. [49] Megan S M. 2002. Full-span tiltrotor aeroacoustic model (FS TRAM) overview and initial testing. American Helicopter Society Aerodynamics, Acoustics, and Test and Evaluation Technical Specialists’ Meeting. [50] Natasha L S, Carlos M. 2019. Acoustic testing of the tiltrotor test rig in the national full-scale aerodynamics complex 40- by 80-foot wind tunnel. ARC-E-DAA-TN67821. [51] Natasha L S, Lauren W, Jeremy J B, et al. 2025. Acoustic testing of the Joby aviation propeller in the national full-scale aerodynamics complex 40- by 80-foot wind tunnel. AIAA SCITECH 2025 Forum. [52] Nathan J B, William C H. 2012. Acoustic surveys of a scaled-model CESTOL transport aircraft in static and forward speed conditions. AIAA 2012-2231. [53] Nathan J B, William C H, Kevin R E. 2017. Phased acoustic array measurements of a 5.75% hybrid wing body aircraft. International Journal of Aeroacoustics, 16(4–5) 326–357. [54] Norman T R, Heineck J T, Schairer E T, et al. 2023. Fundamental test of a hovering rotor: Comprehensive measurements for CFD validation. N230004378. [55] Northrup C J. 2021. Replacement plan for the fan blades on the wind tunnel drive in the national full-scale aerodynamics complex. AIAA SCITECH 2021 FORUM. [56] Nykamp C M, Bartow W B, Goulding P W, et al. 2019. Computational assessment of facility wall loads for large parachute testing in the national full-scale aerodynamics complex 80-by 120-foot wind tunnel. AIAA Aviation 2019 Forum. [57] Paul T S, Stephen C N. 1975. Directional microphone array for acoustic studies of wind tunnel models. J. Aircraft, 12: 3. [58] Patrick W G, Christopher M N. Expanding the wall interference effect correction capability in the national full-scale aerodynamics complex 80- by 120-foot wind tunnel for semi-span and automotive applications. 2018 AIAA Aerospace Sciences Meeting. [59] Peter T Z. 1989. Performance and test section flow characteristics of the national full-scale aerodynamics complex 40- by 80-foot wind tunnel. NASA Technical Memorandum 101065. [60] Peter T Z. 1993. Performance and test section flow characteristics of the national full-scale aerodynamics complex 80- by 120-foot wind tunnel. NASA Technical Memorandum 103920. [61] Ralph L M. 1950. Tests of a northrop XSSM-A-3 missile in the ames 40- by 80-foot wind tunnel-stability and control. NACA RM SA50D05. [62] Robert N, Rohit J, Jennifer A, et al. 2021. HVAB rotor hover computational prediction: A comparative study using OVERFLOW and HPCMP CREATE™-AV helios. AIAA Scitech 2021 Forum. [63] Rohit J. 2018. Effect of facility walls and blade aeroelasticity on PSP rotor hover performance predictions. 2018 AIAA Aerospace Sciences Meeting. [64] Rohit J. 2024. CFD-CSD pre-test hover predictions validation for the HVAB rotor. AIAA SCITECH 2024 Forum. [65] Rose M C, Kambiz S, Jason O, et al. 2005. DOE’s effort to reduce truck aerodynamic drag through joint experiments and computations. Sae Technical Paper Series, 2005-01-3511. [66] Rossow V J, Fong R K, Wright M S, et al. 1996. Vortex wakes of two transports measured in 80 by 120 foot wind tunnel. Journal of Aircraft, 33: 2 March-April. [67] Sarah C. 2023. Multirotor test bed load and stress analysis. NASA/TM–20230000313. [68] Schreck, Robinson M. 2005. Unsteadiness in HAWT blade aerodynamic forces and flow field structures during rotational augmentation S. AIAA 2005-776. [69] Stephen L, Drew L, Jeffrey J, et al. 2002. Performance automotive applications of pressure-sensitive paint in the langley full scale tunnel. Proceedings of the 2002 SAE Motorsports Engineering Conference and Exhibition. [70] Wang S, Pereira L T, Ragni D. 2025. Design exploration of UAM vehicles. Aerospace Science and Technology, 160: 110058. [71] Warmbrodt W, Smith C A, Johnson W. 1985. Rotorcraft research testing in the national full-scale aerodynamics complex at NASA ames research center. NASA-TM-86687. -

下载:

下载: