Design strategies for non-positive Poisson’s ratio mechanical metamaterials and their cushioning and energy absorption characteristics

-

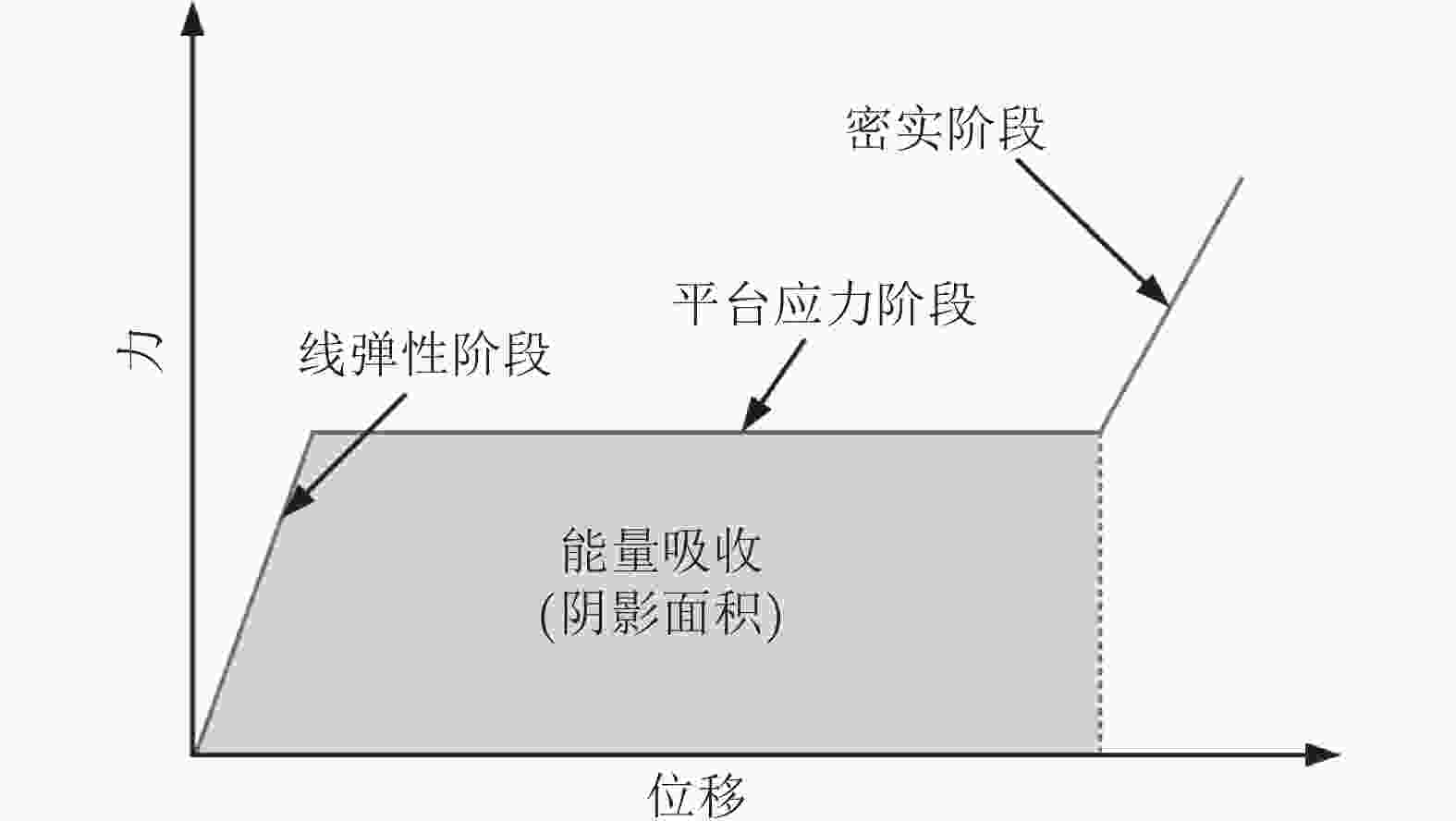

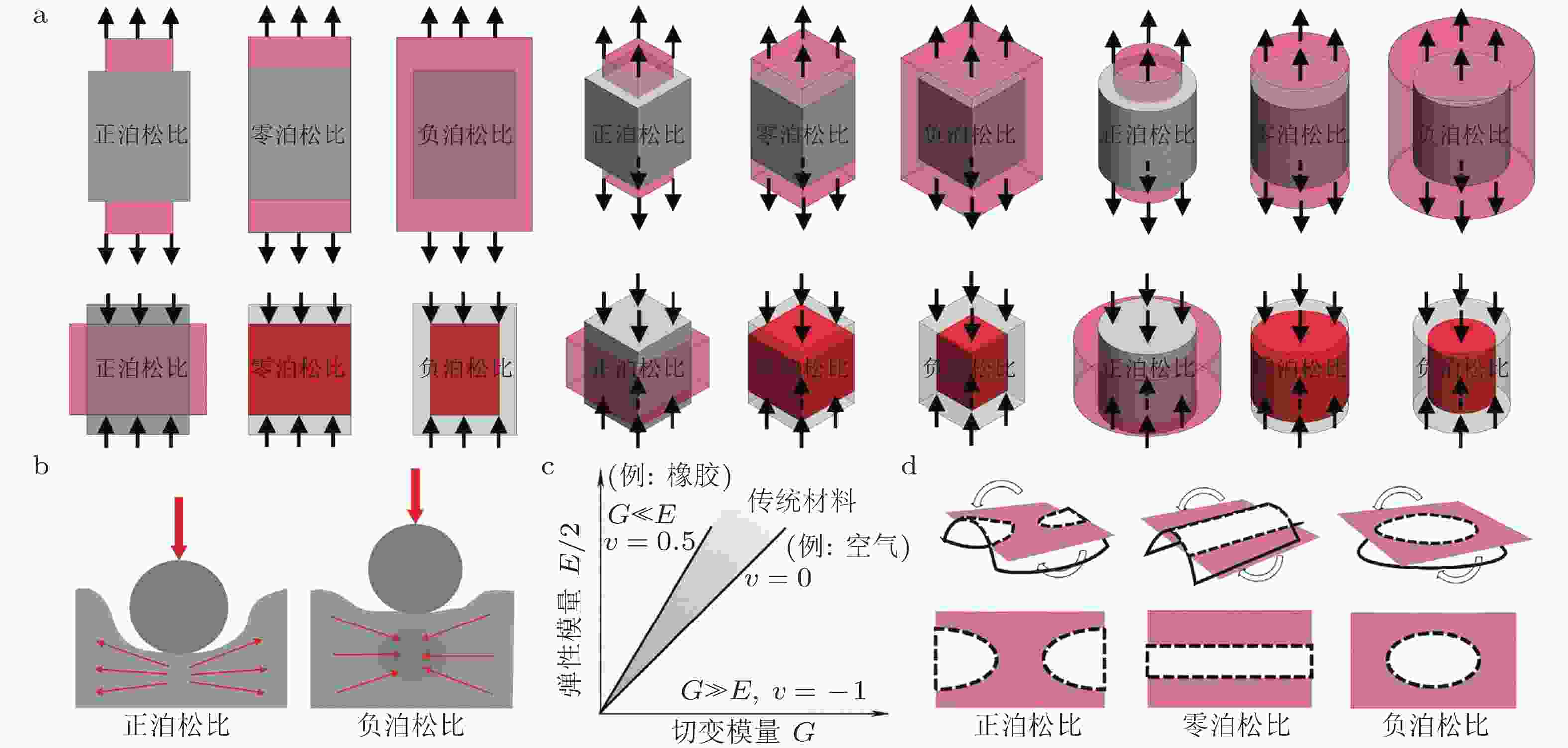

摘要: 非正泊松比力学超材料是一类通过构型设计在宏观尺度上展现零/负泊松比效应的结构型功能材料. 因其在横向变形调控、尺寸稳定性和能量吸收等方面的独特优势, 在航空航天、海洋工程、交通运输、可穿戴防护装备和生物医学等领域展现出广泛的应用前景. 近年来, 随着微结构设计、先进材料制备技术和多材料集成手段的不断演进, 非正泊松比力学超材料在构型多样性、响应调控性与结构功能一体化等方面取得了显著进展. 本文从激活结构横向变形行为的主导机理出发, 系统梳理了非正泊松比力学超材料的典型设计策略. 负泊松比超材料围绕内凹几何、旋转体系 (旋转刚体/桁架、手性/反手性)、剪纸/折纸、弹性不稳定诱导与刚体联动等机制组织. 零泊松比超材料归纳为类矩形/平行四边形、半内凹、正/负泊松比单元组合与刚柔复合等几何范式. 围绕非正泊松比力学超材料在缓冲吸能应用中的关键性能, 重点讨论了多平台响应设计、梯度构型调控、多材料耦合与智能材料介入等性能增强途径. 在结构集成层面, 本文还探讨了模块化组装、夹层结构设计与本征三维结构设计等技术路径. 最后, 结合非正泊松比力学超材料在设计制备、性能调控与系统集成中的研究进展, 梳理了当前面临的核心技术瓶颈, 明确了亟需突破的关键方向, 并提出了面向多尺度制造、多场响应集成与工程化应用的未来发展路径.Abstract: Non-positive Poisson’s ratio mechanical metamaterials are a class of architected functional materials that exhibit negative or zero Poisson’s ratio effect at the macroscopic scale through configuration design. Their distinctive capabilities in controlling transverse deformation, maintaining dimensional stability, and enhancing energy absorption confer significant potential for applications in aerospace, marine engineering, transportation, wearable protective equipment, and biomedicine. In recent years, continuous advancements in microstructural design, advanced material fabrication techniques, and multi-material integration methods have driven significant progress in non-positive Poisson’s ratio mechanical metamaterials, particularly in configuration diversity, mechanical response tunability, and multifunctional integration. Guided by the dominant mechanisms that activate transverse deformation, this paper systematically surveys the typical design strategies of non-positive Poisson’s ratio mechanical metamaterials. For negative Poisson’s ratio architectures, the discussion is organized around re-entrant geometries, rotating systems (rotating rigid-body/truss and chiral/anti-chiral configurations), kirigami/origami schemes, elastic instability-induced mechanisms, and rigid-body linkages. Zero Poisson’s ratio architectures are categorized into geometric paradigms, including rectangular/parallelogram-like, semi-re-entrant, positive/negative Poisson’s ratio unit combinations, and rigid-flexible composites. Focusing on performance requirements in cushioning and energy absorption, enhancement strategies include multi-plateau response designs, graded structural architectures, multi-material coupling, and the incorporation of smart materials. At the level of structural integration, technical pathways such as modular assembly, sandwich structure, and intrinsically three-dimensional architectures are reviewed. Finally, by synthesizing recent research progress on non-positive Poisson’s ratio mechanical metamaterials in terms of design and fabrication, performance regulation, and system integration, the current core technical bottlenecks are identified, the key directions for breakthroughs are clarified, and future development pathways for multiscale manufacturing, multifield response integration, and engineering applications are proposed.

-

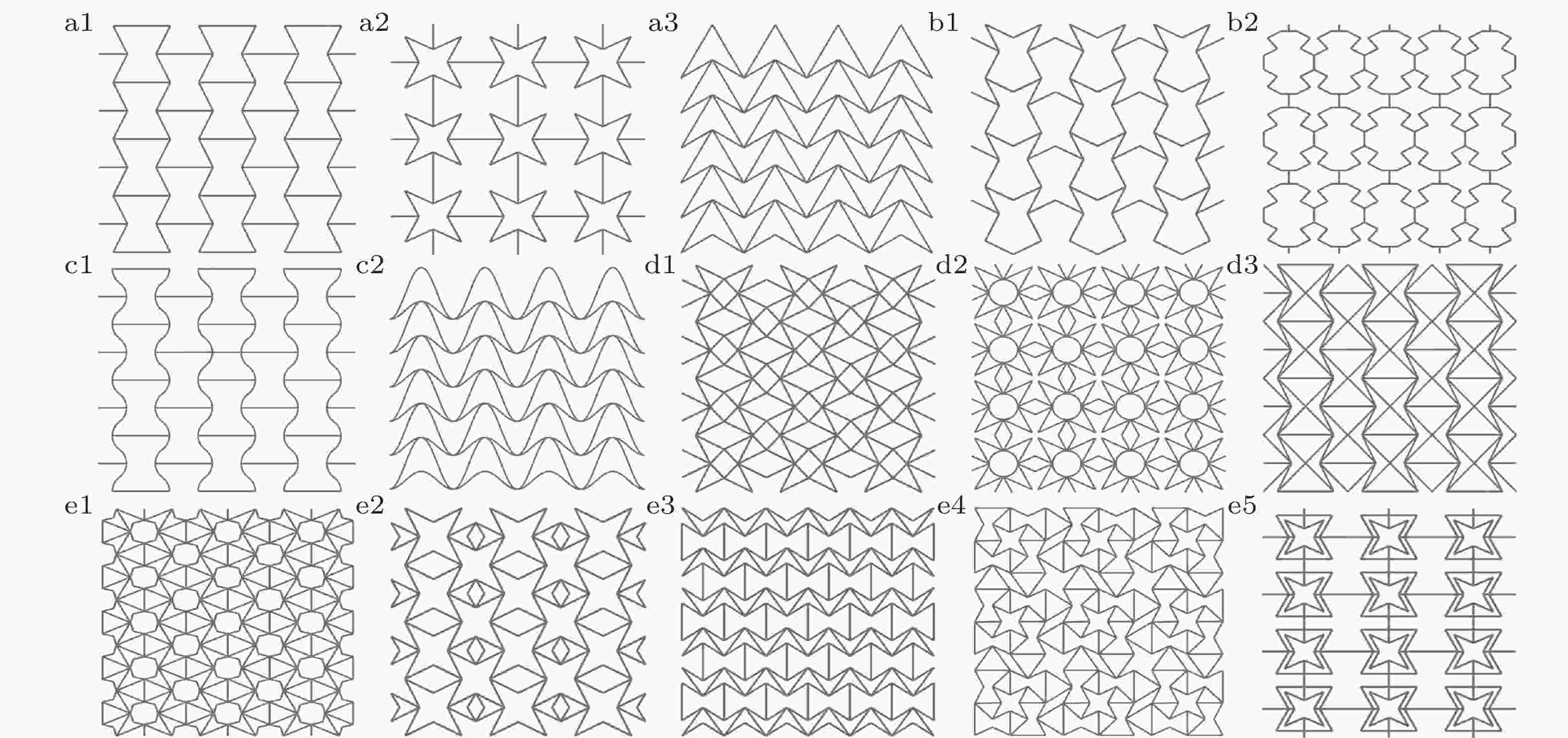

图 1 基于内凹机制的负泊松比蜂窝设计策略. (a) 典型内凹蜂窝 (从左至右分别为 (a1) 内凹六边形蜂窝、(a2) 内凹星形蜂窝和 (a3) 内凹双箭头蜂窝); (b) 其他内凹蜂窝 (从左至右分别为 (b1) 半内凹八边形蜂窝和 (b2) 多内凹角蜂窝); (c)“化直为曲”内凹蜂窝 (从左至右分别为 (c1) 内凹曲臂蜂窝和 (c2) 内凹双U形蜂窝); (d) 嵌入支撑单元的内凹蜂窝 (从左至右分别为 (d1) 星形−菱形蜂窝、(d2) 星形−圆形蜂窝和 (d3) 内凹−三角形蜂窝); (e) 通过经典构型组合重构得到的内凹蜂窝 (从左至右分别为 (e1) 和 (e2) 星形−双箭头蜂窝、(e3) 内凹−双箭头蜂窝、(e4) 和 (e5) 内凹−星形蜂窝)

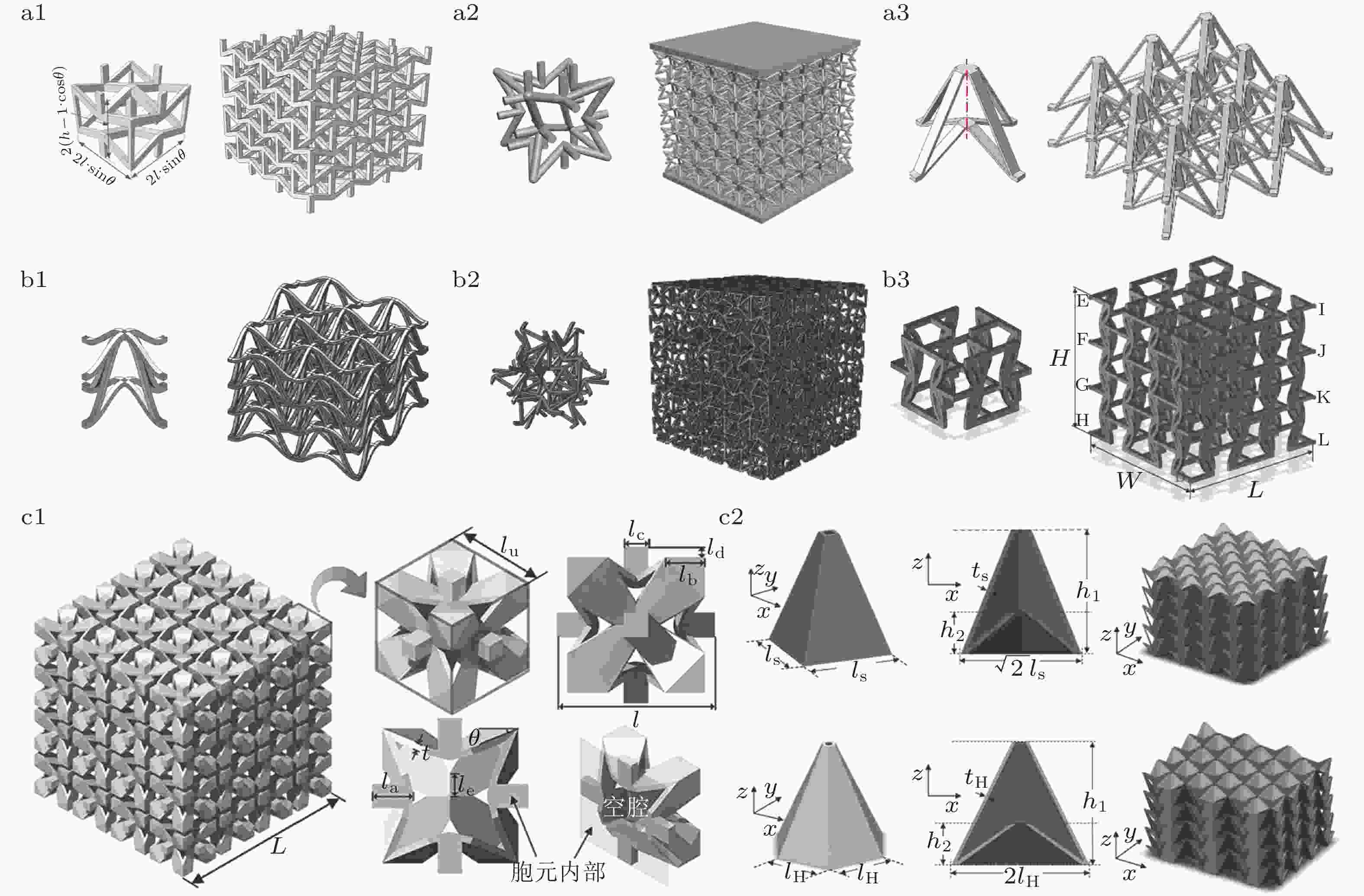

图 2 基于内凹机制的负泊松比点阵超材料设计策略. (a) 典型内凹点阵 (从左至右分别为 (a1) 内凹六边形点阵 (王信涛 2018)、(a2) 内凹星形点阵 (薛玉祥 2021) 和 (a3) 内凹双箭头点阵 (Wang et al. 2018b)); (b) 其他内凹点阵 (从左至右分别为 (b1) 双U形点阵 (Yang & Ma 2021)、(b2) 内凹−星形点阵 (王玮婧 等 2024) 和 (b3) 曲壁内凹点阵 (Jiang et al. 2022)); (c) 本征三维负泊松比内凹点阵 (从左至右分别为 (c1) 三维内凹薄板点阵 (Wang et al. 2022) 和 (c2) 三维双箭头薄板点阵 (Guo et al. 2022))

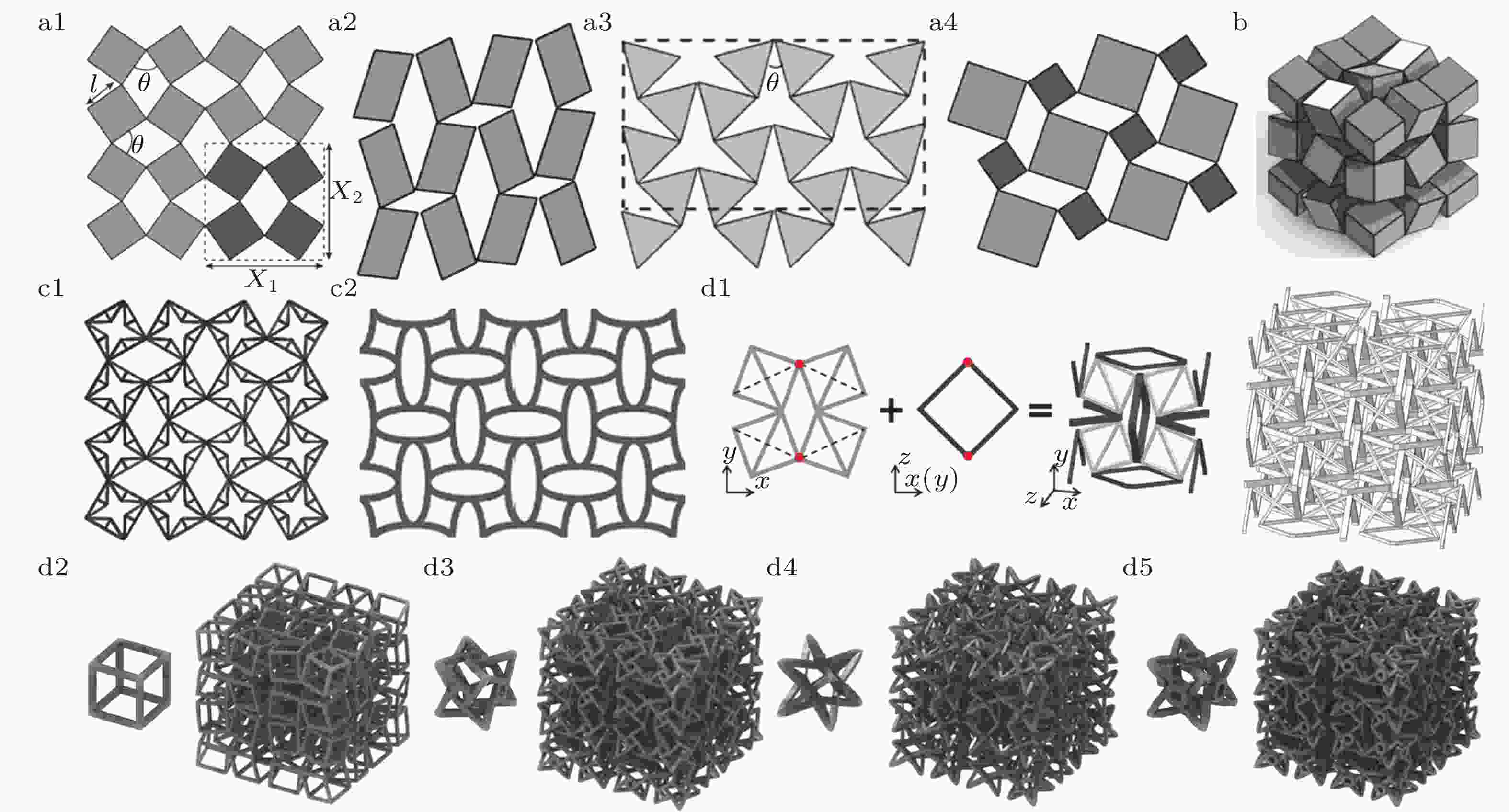

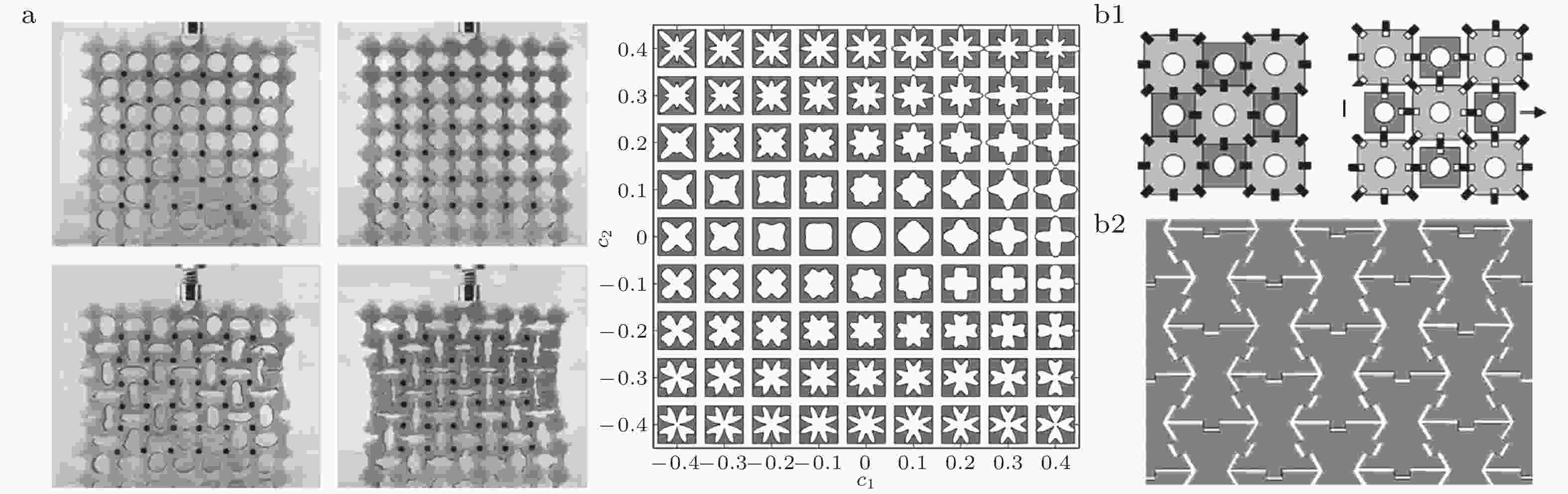

图 3 基于旋转机制的负泊松比超材料设计策略 (旋转刚体/旋转桁架). (a) 二维旋转刚体结构 (Grima & Evans 2000)(从左至右分别为 (a1) 旋转方形结构、(a2) 旋转矩形结构、(a3) 旋转三角形结构和 (a4) 旋转混杂四边形结构); (b) 三维旋转立方体结构 (Andrade et al. 2018); (c) 二维旋转桁架结构 (从左至右分别为 (c1) 旋转−星形结构 (Li et al. 2021) 和 (c2) 旋转−内凹六边形结构 (Hao et al. 2022)); (d) 三维旋转桁架点阵 (Gao et al. 2021, Yang et al. 2025)(分别为 (d1) 旋转桁架点阵、(d2) 旋转六面体点阵、(d3) 旋转手性点阵、(d4) 旋转内凹点阵和 (d5) 复合旋转点阵)

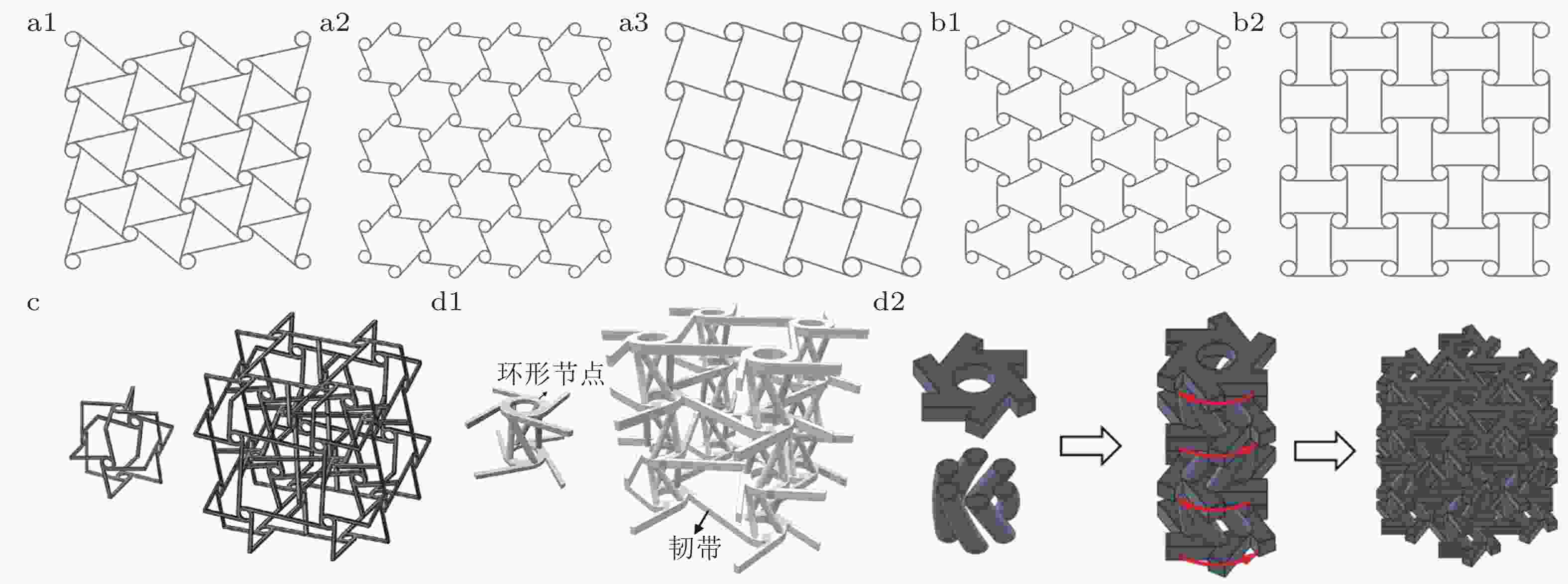

图 4 基于旋转机制的负泊松比超材料设计策略 (手性/反手性). (a) 二维手性蜂窝 (从左至右分别为 (a1) 二维六手性蜂窝、(a2) 二维三手性蜂窝和 (a3) 二维四手性蜂窝); (b) 二维反手性蜂窝 (从左至右分别为 (b1) 二维反三手性蜂窝和 (b2) 二维反四手性蜂窝); (c) 伪三维四手性点阵 (Fu et al. 2017); (d) 本征三维手性点阵 (从左至右分别为 (d1) 本征三维四手性点阵 (Fu et al. 2018) 和 (d2) 本征三维六手性点阵 (Jiao & Yan 2021))

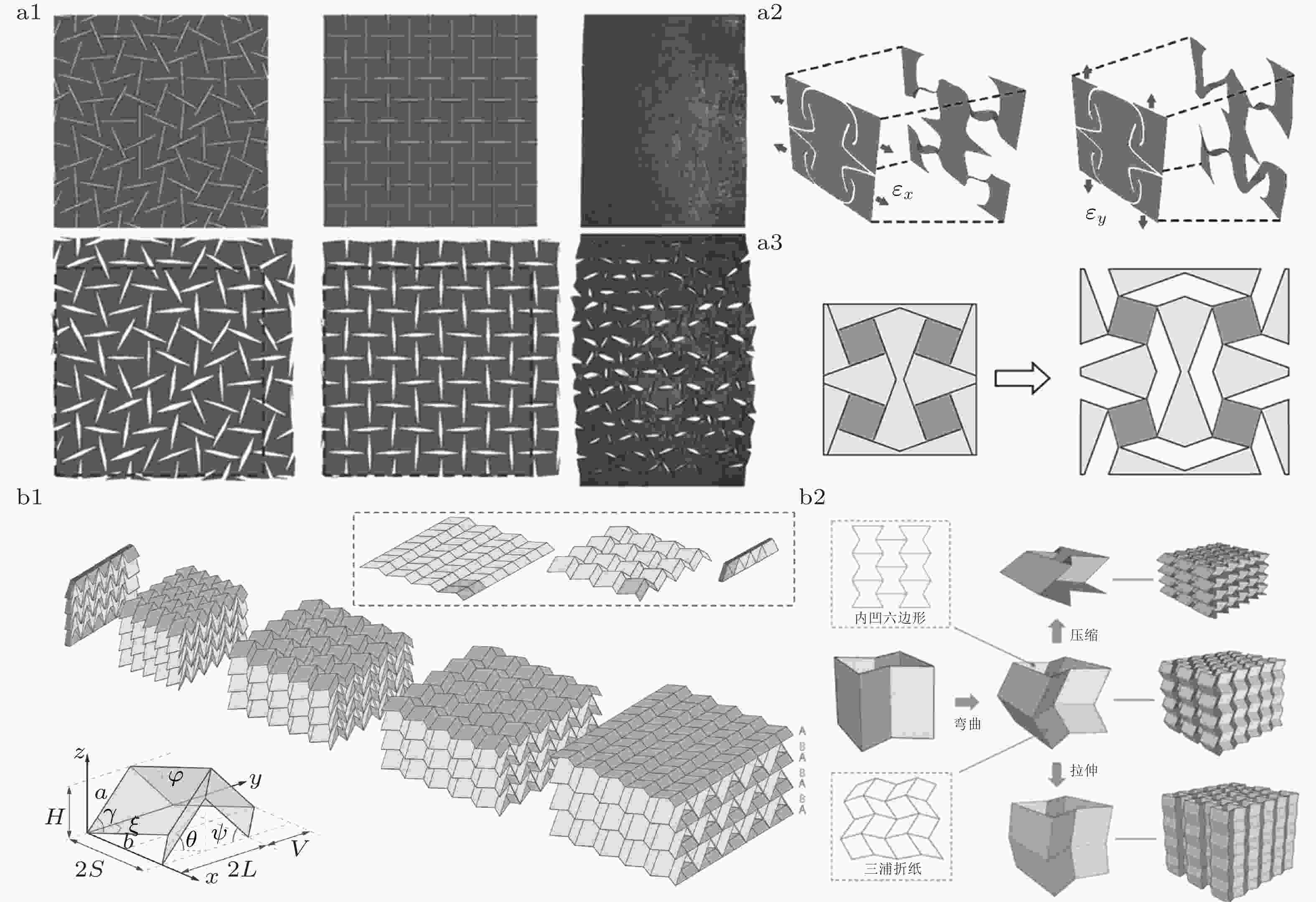

图 5 基于剪纸/折纸机制的负泊松比超材料设计策略. (a) 剪纸负泊松比超材料 (从左至右分别为 (a1) 有序/无序剪纸超材料 (Grima et al. 2016)、(a2) 弧形剪纸超材料 (Song et al. 2025) 和 (a3) 方形剪纸超材料 (Rafsanjani & Pasini 2016)); (b) 折纸负泊松比超材料 (从左至右分别为 (b1) 三浦折纸超材料 (Schenk & Guest 2013) 和 (b2) 内凹折纸超材料 (Li et al. 2022))

图 6 其他机制的负泊松比超材料设计策略. (a) 基于弹性不稳定性屈曲设计的负泊松比超材料 (Overvelde & Bertoldi 2014); (b) 基于刚体联动机制设计的负泊松比超材料 (分别为 (b1) 嵌锁联动结构 (Evans & Alderson 2000) 和 (b2) 内凹联动结构 (Ravirala et al. 2007))

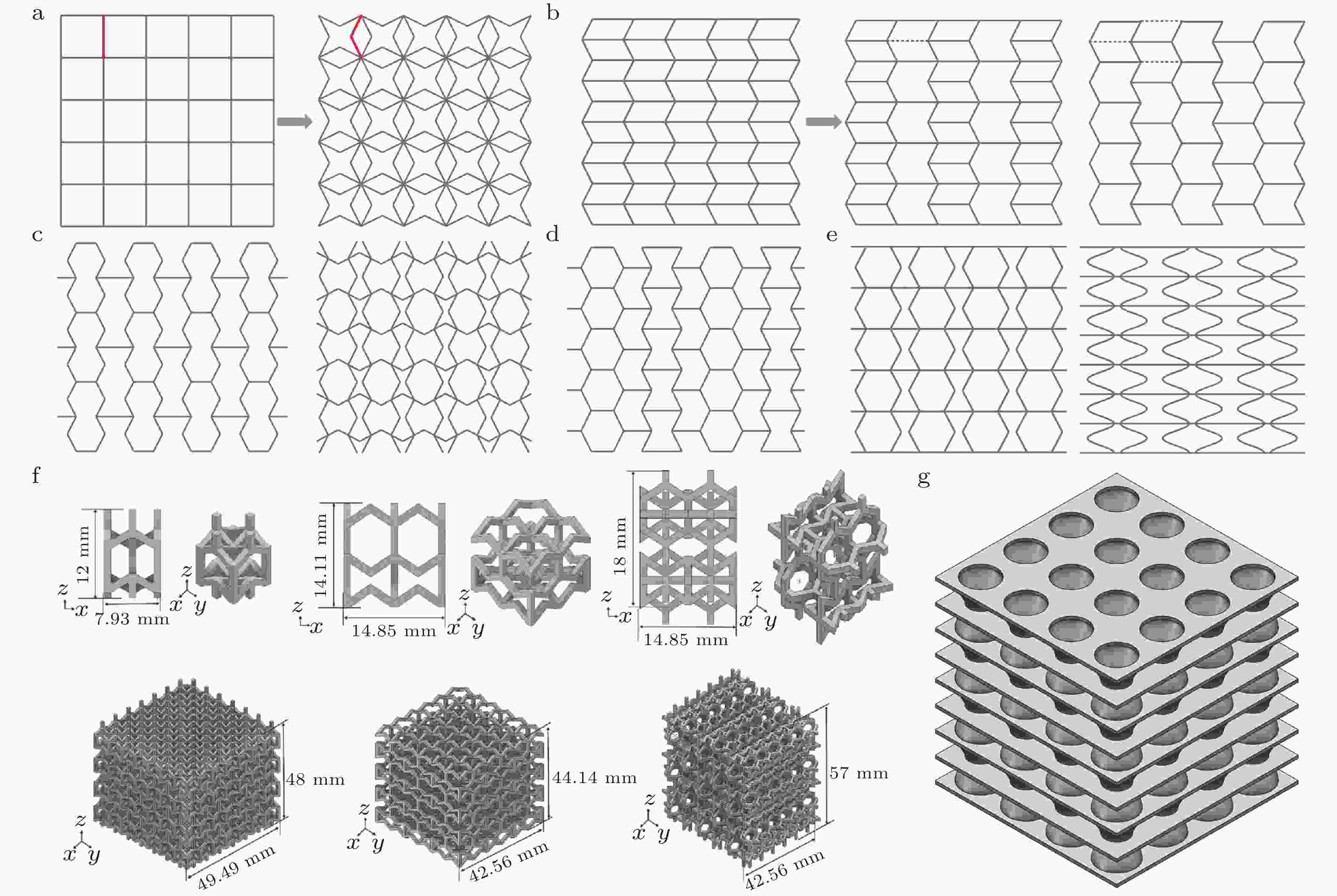

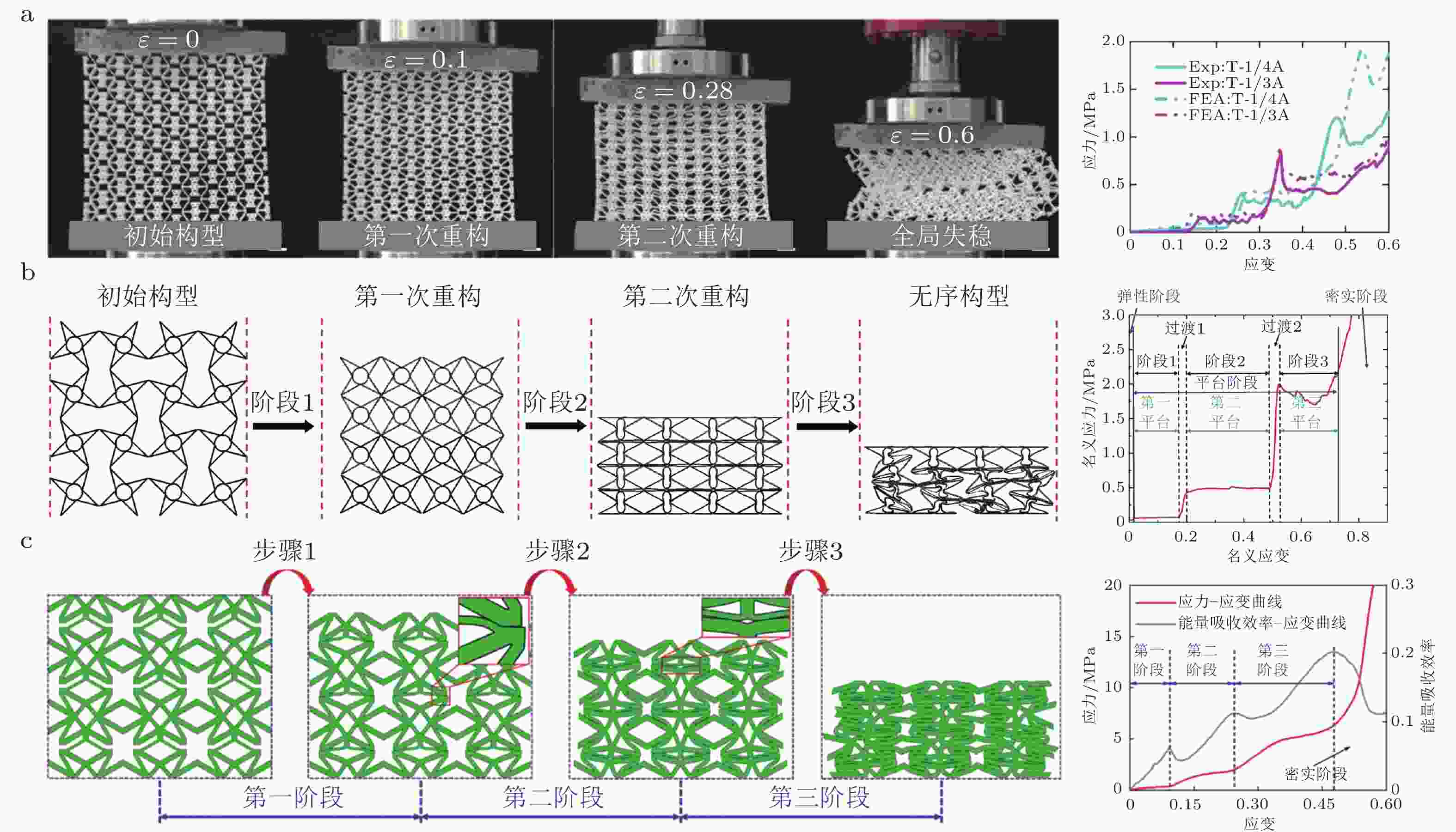

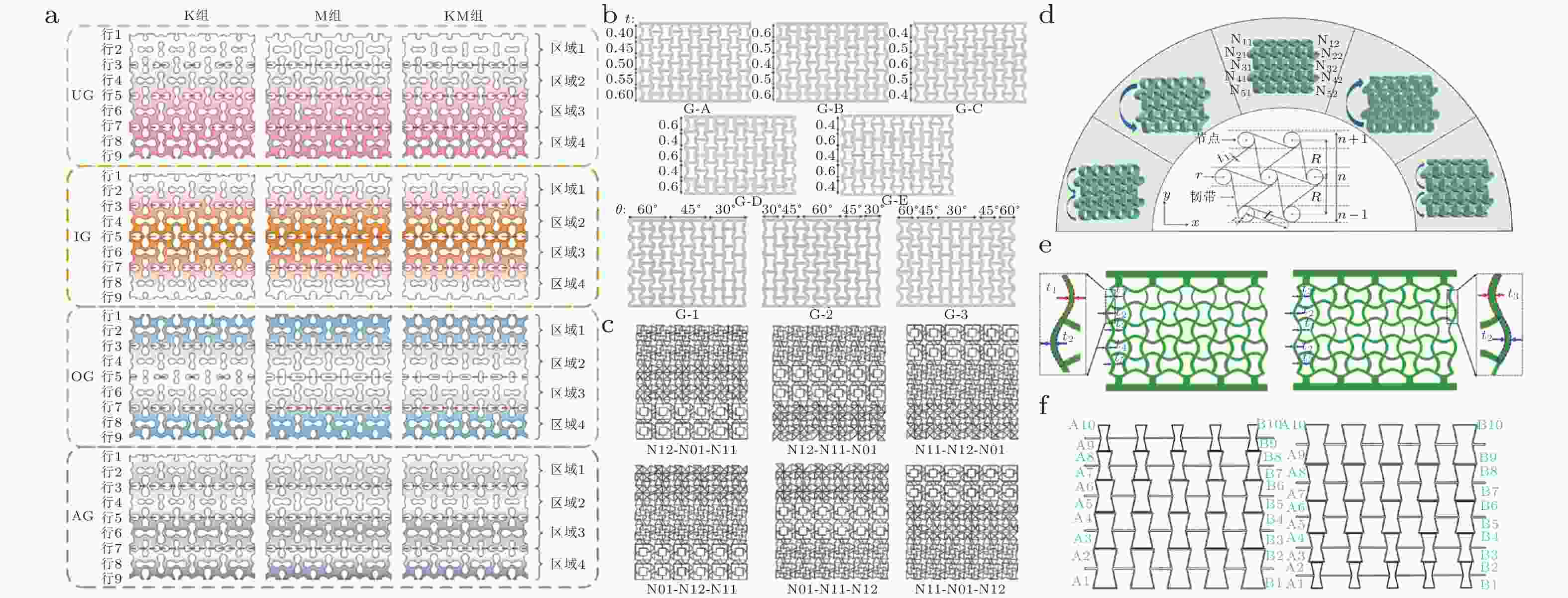

图 7 零泊松比超材料设计策略. (a) 类矩形设计策略; (b) 类平行四边形设计策略; (c) 半重入设计策略; (d) 正/负泊松比单元组合设计策略; (e) 刚柔串联设计策略; (f) 伪三维零泊松比超材料设计策略 (Sahariah et al. 2023); (g) 本征三维零泊松比超材料设计策略

图 9 非正泊松比超材料特性. (a) 变形机制 (杨航 2023); (b) 压痕阻性; (c) 剪切特性 (于靖军 等 2018); (d) 面外变形特性 (Lin et al. 2025)

图 10 具有多平台响应特性的负泊松比缓冲吸能超材料设计策略. (a) 多尺度自相似设计 (Yu et al. 2024); (b) 多变形机制耦合设计 (Lu et al. 2022); (c) 子结构嵌套设计 (Wang & Liu 2024)

图 11 梯度负泊松比缓冲吸能超材料. (a) 花生型梯度结构 (Zhang et al. 2025c); (b) 内凹曲壁梯度结构 (Wang et al. 2023); (c) 梯度内凹−星形结构; (d) 梯度手性结构 (Chen et al. 2024c); (e) 梯度曲壁结构 (Zhang et al. 2022b); (f) 梯度内凹结构 (Zhang et al. 2025b)

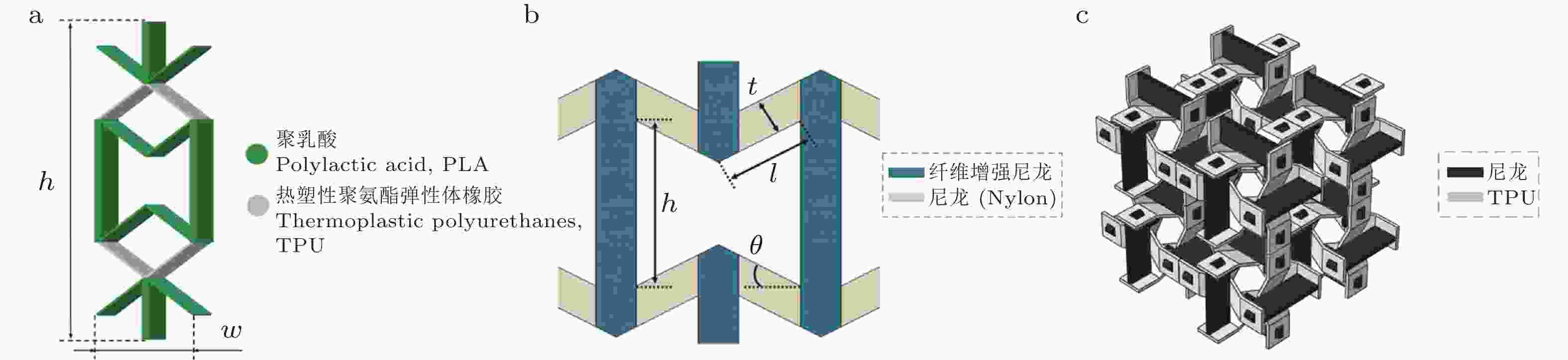

图 12 多材料负泊松比缓冲吸能超材料. (a) 双材料多稳态拉胀蜂窝 (Wu et al. 2024); (b) 双材料内凹六边形结构 (Günaydın et al. 2022); (c) 双材料拼装式内凹薄板点阵

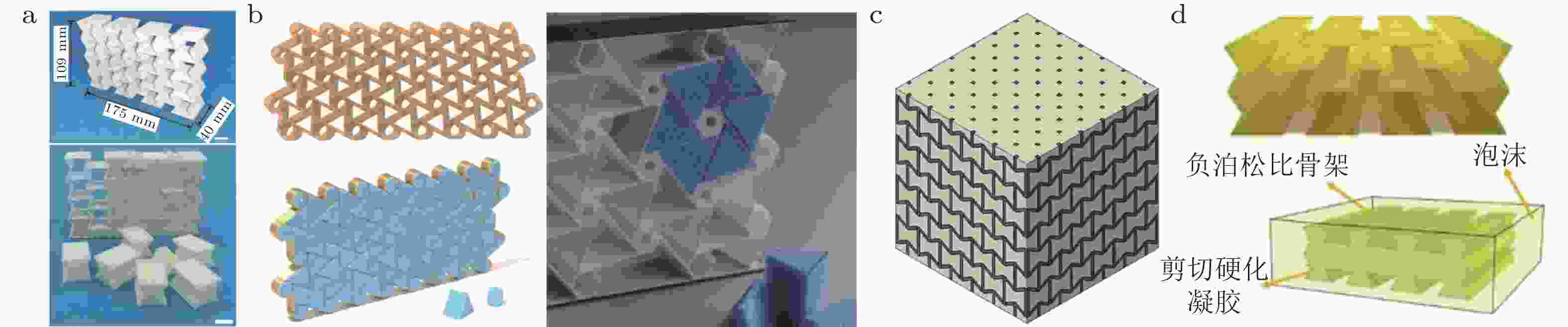

图 13 填充型多材料负泊松比缓冲吸能超材料. (a) 填充PU泡沫的内凹六边形蜂窝 (Luo et al. 2022); (b) 填充PU泡沫的手性蜂窝 (Airoldi et al. 2020, Chen et al. 2024a); (c) 填充剪切增稠流体的三维内凹点阵 (Hu et al. 2024); (d) 填充剪切硬化凝胶的柔性复合结构 (Wu et al. 2022)

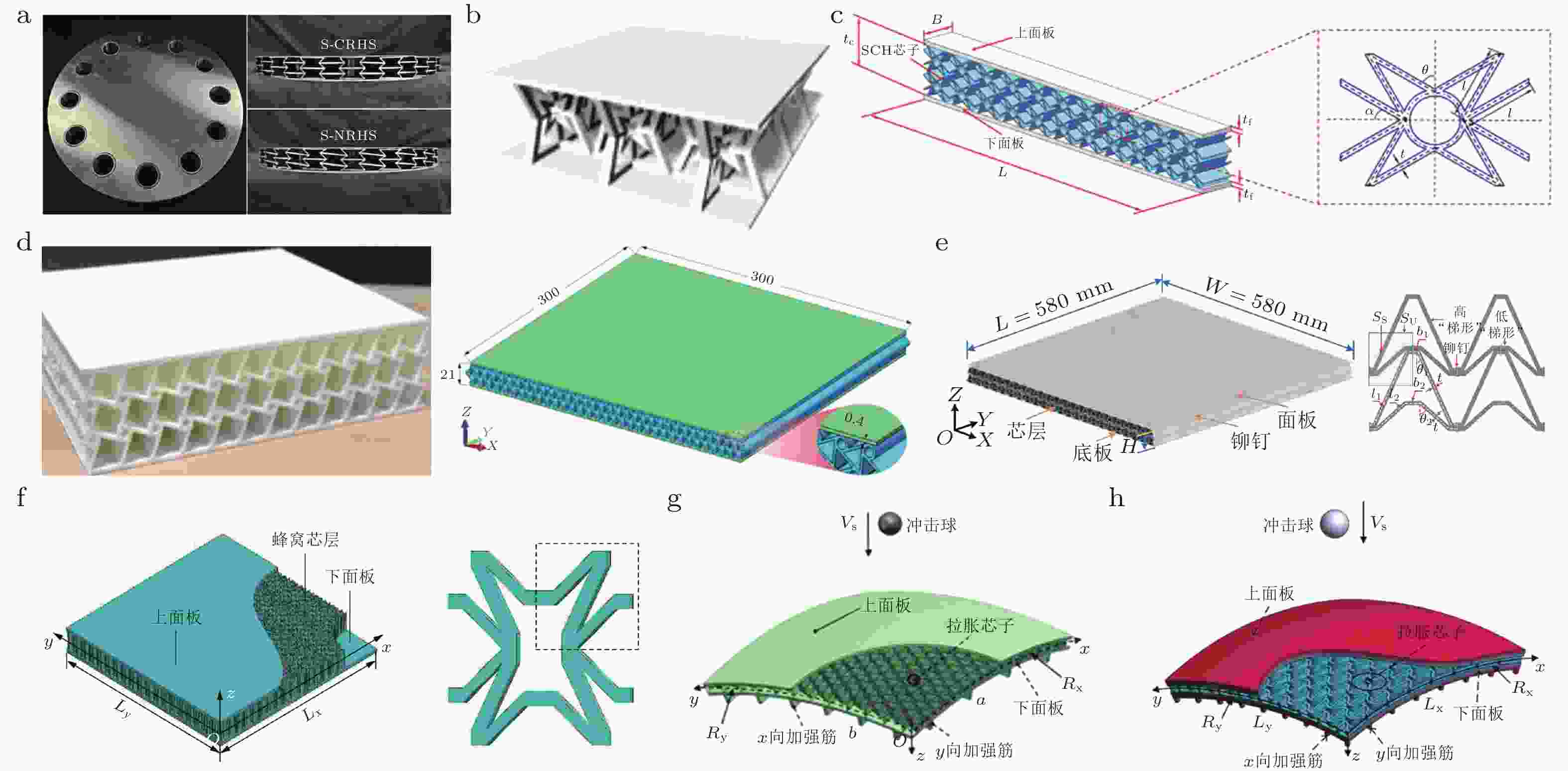

图 14 基于夹层结构集成的负泊松比缓冲吸能超材料. (a) 内凹六边形夹芯板 (Jiang et al. 2025); (b) 内凹−星形夹芯板 (Qu et al. 2025); (c) 星形−圆形夹芯板 (Lu et al. 2023); (d) 手性蜂窝夹芯板 (Chen et al. 2024b, Sadikbasha & Pandurangan 2023); (e) 双箭头夹芯板 (廖瑜 等 2025); (f) 星形夹芯板 (余阳和付涛 2023); (g) 功能梯度负泊松比多孔材料夹芯壳 (Fu et al. 2023); (h) 曲壁内凹蜂窝夹芯壳 (Fu et al. 2024)

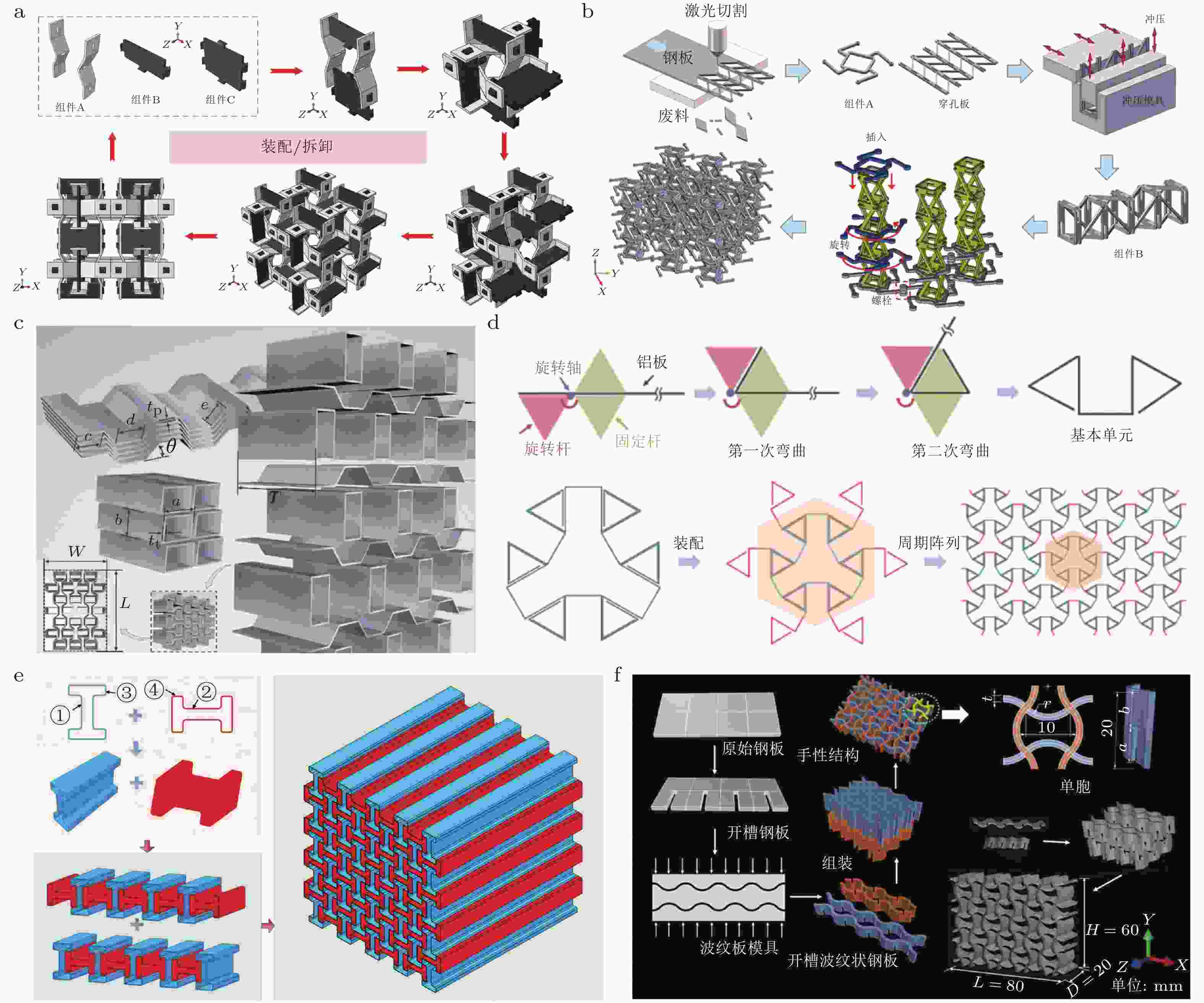

图 15 模块化负泊松比缓冲吸能超材料. (a) 拼装式内凹薄板点阵超材料; (b) 拼装式压扭超材料 (Wei et al. 2025); (c) 拼装式波纹板−矩形超材料 (Jiang et al. 2023); (d) 自锁手性蜂窝 (Niu et al. 2025); (e) 拼装式缺失肋结构 (Zhu et al. 2025); (f) 拼装式手性结构 (Zhang et al. 2022c)

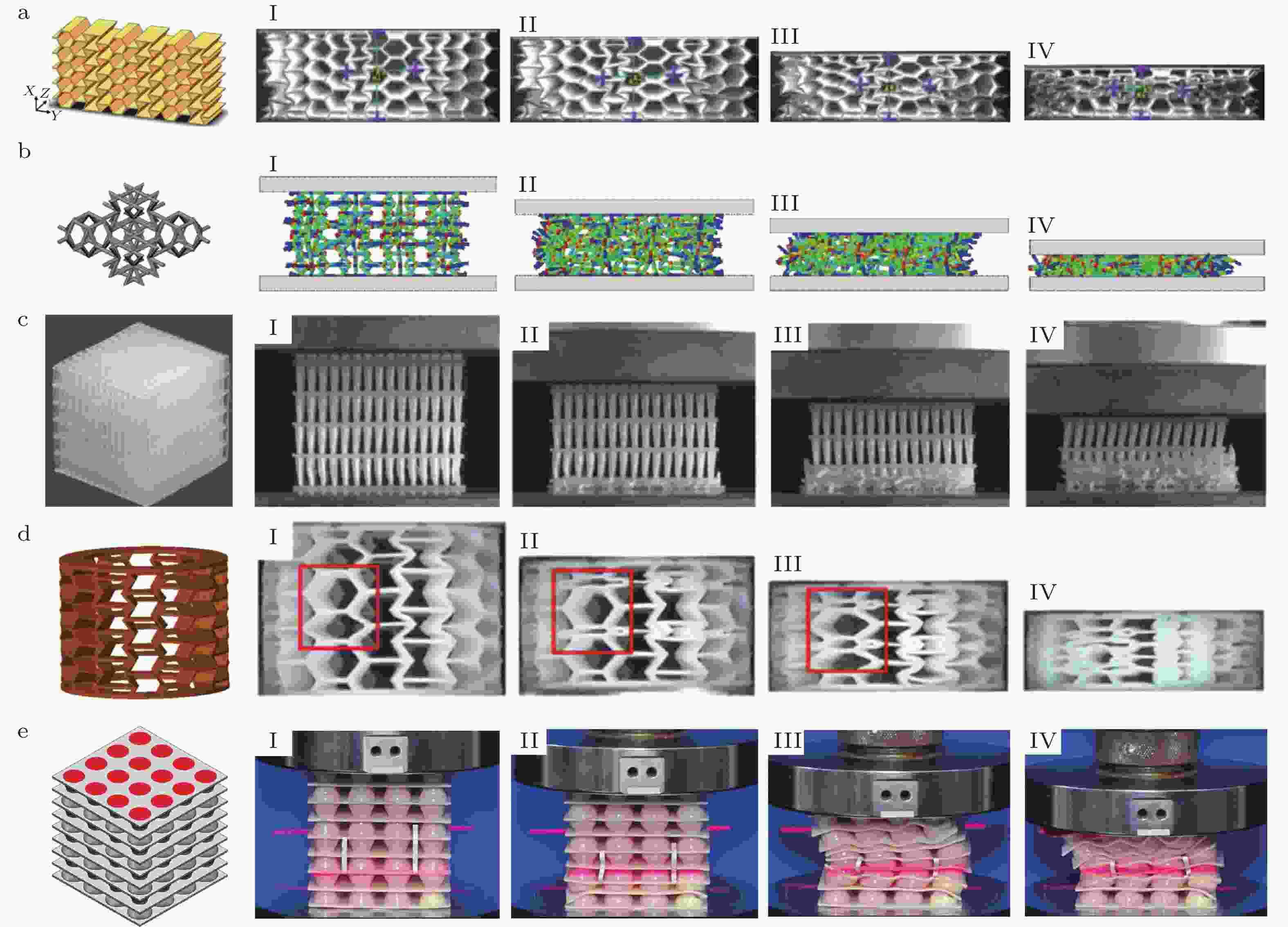

图 16 零泊松比缓冲吸能力学超材料及其变形过程. (a) AuxHex蜂窝 (Xu et al. 2019); (b) 三维AuxHex点阵 (Guo et al. 2020b); (c) 类乌贼骨结构 (Mao et al. 2021); (d) AuxHex圆柱结构 (Liu et al. 2020); (e) 零泊松比薄壳点阵

-

[1] 廖瑜, 石少卿, 夏菲, 等. 2025. 双梯形负泊松比蜂窝夹心结构抗爆力学性能研究. 工程力学, 42: 244-261 (Liao Y, Shi S Q, Xia F, et al. 2025. Study on anti-explosion mechanical properties of double trapezoidal negative Poisson’s ratio auxetic sandwich honeycomb structure. Engineering Mechanics, 42: 244-261).Liao Y, Shi S Q, Xia F, et al. 2025. Study on anti-explosion mechanical properties of double trapezoidal negative Poisson’s ratio auxetic sandwich honeycomb structure. Engineering Mechanics, 42: 244-261 [2] 王钦泽, 韩宾, 郑培远, 等. 2024. 负刚度扭转超结构力学性能研究. 应用数学和力学, 45: 1082-1095 (Wang Q Z, Han B, Zheng P Y, et al. 2024. Research on mechanical properties of negative stiffness torsion metastructures. Applied Mathematics and Mechanics, 45: 1082-1095).Wang Q Z, Han B, Zheng P Y, et al. 2024. Research on mechanical properties of negative stiffness torsion metastructures. Applied Mathematics and Mechanics, 45: 1082-1095 [3] 王玮婧, 张伟明, 郭孟甫, 等. 2024. 内凹-星型三维负泊松比结构设计及冲击吸能特性. 振动与冲击, 43: 75-83 (Wang W J, Zhang W M, Guo M F, et al. 2024. Design and impact energy absorption characteristics of concave-star three dimensional negative Poisson’s ratio structures. Journal of Vibration and Shock, 43: 75-83).Wang W J, Zhang W M, Guo M F, et al. 2024. Design and impact energy absorption characteristics of concave-star three dimensional negative Poisson’s ratio structures. Journal of Vibration and Shock, 43: 75-83 [4] 王信涛. 2018. 三维有序负泊松比结构的设计、制备与力学性能表征[博士学位论文]. 哈尔滨: 哈尔滨工业大学 (Wang X T. 2018. The design, fabrication and mechanical characterization of three-dimensional periodic auxetic cellular structures [PhD Thesis]. Harbin: Harbin Institute of Technology).Wang X T. 2018. The design, fabrication and mechanical characterization of three-dimensional periodic auxetic cellular structures [PhD Thesis]. Harbin: Harbin Institute of Technology [5] 薛玉祥. 2021. 三维负泊松比星型结构冲击动力学研究[硕士学位论文]. 广州: 广州大学 (Xue Y X. 2021. Study on the impact dynamics of three-dimensional negative Poisson’s ratio star-shaped structure [Master Thesis]. Guangzhou: Guangzhou University).Xue Y X. 2021. Study on the impact dynamics of three-dimensional negative Poisson’s ratio star-shaped structure [Master Thesis]. Guangzhou: Guangzhou University [6] 杨航. 2023. 可编程机械超材料的结构设计及力学行为研究[博士学位论文]. 哈尔滨: 哈尔滨工业大学 (Yang H. 2023. Structure design and mechanical behavior of programmable mechanical metamaterials [PhD Thesis]. Harbin: Harbin Institute of Technology).Yang H. 2023. Structure design and mechanical behavior of programmable mechanical metamaterials [PhD Thesis]. Harbin: Harbin Institute of Technology [7] 于靖军, 谢岩, 裴旭. 2018. 负泊松比超材料研究进展. 机械工程学报, 54: 1-14 (Yu J J, Xie Y, Pei X. 2018. State-of-art of metamaterials with negative Poisson’s ratio. Journal of Mechanical Engineering, 54: 1-14).Yu J J, Xie Y, Pei X. 2018. State-of-art of metamaterials with negative Poisson’s ratio. Journal of Mechanical Engineering, 54: 1-14 [8] 余阳, 付涛. 2023. 低速冲击下负泊松比蝴蝶形蜂窝夹芯板的动力响应. 爆炸与冲击, 43: 84-95 (Yu Y, Fu T. 2023. Dynamic response of a sandwich panel cored by butterfly-shaped honeycombs with negative Poisson’s ratio to low-velocity impact. Explosion and Shock Waves, 43: 84-95).Yu Y, Fu T. 2023. Dynamic response of a sandwich panel cored by butterfly-shaped honeycombs with negative Poisson’s ratio to low-velocity impact. Explosion and Shock Waves, 43: 84-95 [9] 张宝庆, 蒋森. 2025. 旋转型负泊松比星形蜂窝结构能量吸收特性研究. 固体力学学报, 46: 129-148 (Zhang B Q, Jiang S. 2025. Study on energy absorption characteristics of rotating star-shaped honeycomb structure with negative Poisson’s ratio. Chinese Journal of Solid Mechanics, 46: 129-148).Zhang B Q, Jiang S. 2025. Study on energy absorption characteristics of rotating star-shaped honeycomb structure with negative Poisson’s ratio. Chinese Journal of Solid Mechanics, 46: 129-148 [10] 赵淳铮, 王昕, 李振, 等. 2024. 可调控热膨胀力学超材料设计制备与表征评测研究进展. 复合材料学报, 41: 4589-4605 (Zhao C Z, Wang X, Li Z, et al. 2024. Research progress in the design, manufacturing, characterization, and evaluation of tailorable thermal expansion mechanical metamaterials. Acta Materiae Compositae Sinica, 41: 4589-4605).Zhao C Z, Wang X, Li Z, et al. 2024. Research progress in the design, manufacturing, characterization, and evaluation of tailorable thermal expansion mechanical metamaterials. Acta Materiae Compositae Sinica, 41: 4589-4605 [11] Airoldi A, Novak N, Sgobba F, et al. 2020. Foam-filled energy absorbers with auxetic behaviour for localized impacts. Materials Science and Engineering: A, 788: 139500. doi: 10.1016/j.msea.2020.139500 [12] Alderson A, Alderson K L, Attard D, et al. 2010. Elastic constants of 3-, 4- and 6-connected chiral and anti-chiral honeycombs subject to uniaxial in-plane loading. Composites Science and Technology, 70: 1042-1048. doi: 10.1016/j.compscitech.2009.07.009 [13] Alderson K L, Webber R S, Evans K E. 2000. Novel variations in the microstructure of auxetic ultra-high molecular weight polyethylene. Part 2: Mechanical properties. Polymer Engineering & Science, 40: 1906-1914. doi: 10.1002/pen.11322 [14] Andrade C, Ha C S, Lakes R S. 2018. Extreme cosserat elastic cube structure with large magnitude of negative Poisson’s ratio. Journal of Mechanics of Materials and Structures, 13: 93-101. doi: 10.2140/jomms.2018.13.93 [15] Bauer J, Schroer A, Schwaiger R, et al. 2016. Approaching theoretical strength in glassy carbon nanolattices. Nature Materials, 15: 438-443. doi: 10.1038/nmat4561 [16] Baughman R H, Stafstrom S, Cui C, et al. 1998. Materials with negative compressibilities in one or more dimensions. Science, 279: 1522-1524. doi: 10.1126/science.279.5356.1522 [17] Bertoldi K, Reis P M, Willshaw S, et al. 2010. Negative Poisson’s ratio behavior induced by an elastic instability. Advanced Materials, 22: 361-366. doi: 10.1002/adma.200901956 [18] Chen C Q, Airoldi A, Caporale A M, et al. 2024a. Impact response of composite energy absorbers based on foam-filled metallic and polymeric auxetic frames. Composite Structures, 331: 117916. doi: 10.1016/j.compstruct.2024.117916 [19] Chen C Q, He Y L, Xu R, et al. 2024b. Dynamic behaviors of sandwich panels with 3D-printed gradient auxetic cores subjected to blast load. International Journal of Impact Engineering, 188: 104943. doi: 10.1016/j.ijimpeng.2024.104943 [20] Chen C Q, Jiang L, Wang H R, et al. 2024c. Quasi-static and dynamic responses of gradient hexachiral auxetics: Experimental and numerical analysis. Materials Today Communications, 41: 110670. doi: 10.1016/j.mtcomm.2024.110670 [21] Chen Y, Fu M H. 2018. Mechanical properties of a novel zero Poisson’s ratio honeycomb. Advanced Engineering Materials, 20: 1700452. doi: 10.1002/adem.201700452 [22] Cui H, Hensleigh R, Yao D, et al. 2019. Three-dimensional printing of piezoelectric materials with designed anisotropy and directional response. Nature Materials, 18: 234-241. doi: 10.1038/s41563-018-0268-1 [23] De Jong M, Chen W, Angsten T, et al. 2015. Charting the complete elastic properties of inorganic crystalline compounds. Scientific Data, 2: 150009. doi: 10.1038/sdata.2015.9 [24] Del Broccolo S, Laurenzi S, Scarpa F. 2017. AuxHex-A Kirigami inspired zero Poisson’s ratio cellular structure. Composite Structures, 176: 433-441. doi: 10.1016/j.compstruct.2017.05.050 [25] Ding L, Zhang D, Lin Y, et al. 2024. Improving energy absorption of rotating triangle auxetic metamaterials through multistage perforations. Materials Today Communications, 41: 110746. doi: 10.1016/j.mtcomm.2024.110746 [26] Dong Y, Huang N. 2024. Multifield and higher-order analysis of sandwich smart curved beams made of graphene origami auxetic metamaterial. Mechanics of Advanced Materials and Structures, 31: 1-19. doi: 10.1080/15376494.2024.2302247 [27] Donoghue J, Alderson K, Evans K. 2009. The fracture toughness of composite laminates with a negative Poisson’s ratio. Physica Status Solidi B, 246: 2011-2017. doi: 10.1002/pssb.200982031 [28] Esmaeili A, Karimi M, Heidari-Rarani M, et al. 2024. A new design of star auxetic metastructure with enhanced energy-absorption under various loading rates: Experimental and numerical study. Structures, 63: 106457. doi: 10.1016/j.istruc.2024.106457 [29] Etemadi E, Bashtani M, Hu H. 2024. Novel auxetic metamaterials inspired from geometry patterns of an Iranian Mosque with improved energy absorption capability. Materials Today Communications, 41: 110470. doi: 10.1016/j.mtcomm.2024.110470 [30] Evans K E. 1991. Auxetic polymers: A new range of materials. Endeavour, 15: 170-174. doi: 10.1016/0160-9327(91)90123-S [31] Evans K E, Alderson A. 2000. Auxetic materials: Functional materials and structures from lateral thinking! Advanced Materials, 12: 617-628. doi: 10.1002/(SICI)1521-4095(200005)12:9%3C617::AID-ADMA617%3E3.0.CO;2-3 [32] Fan J, Zhang L, Wei S, et al. 2021. A review of additive manufacturing of metamaterials and developing trends. Materials Today, 50: 303-328. doi: 10.1016/j.mattod.2021.04.019 [33] Fu M H, Zheng B B, Li W H. 2017. A novel chiral three-dimensional material with negative Poisson’s ratio and the equivalent elastic parameters. Composite Structures, 176: 442-448. doi: 10.1016/j.compstruct.2017.05.027 [34] Fu M, Liu F, Hu L. 2018. A novel category of 3D chiral material with negative Poisson’s ratio. Composites Science and Technology, 160: 111-118. doi: 10.1016/j.compscitech.2018.03.017 [35] Fu T, Hu X, Yang C. 2023. Impact response analysis of stiffened sandwich functionally graded porous materials doubly-curved shell with re-entrant honeycomb auxetic core. Applied Mathematical Modelling, 124: 553-575. doi: 10.1016/j.apm.2023.08.024 [36] Fu T, Wang X, Hu X, et al. 2024. Impact dynamic response of stiffened porous functionally graded materials sandwich doubly-curved shells with arc-type auxetic core. International Journal of Impact Engineering, 191: 105000. doi: 10.1016/j.ijimpeng.2024.105000 [37] Gao Y, Wei X, Han X, et al. 2021. Novel 3D auxetic lattice structures developed based on the rotating rigid mechanism. International Journal of Solids and Structures, 233: 111232. doi: 10.1016/j.ijsolstr.2021.111232 [38] Gibson L J, Ashby M F, Schajer G, et al. 1982. The mechanics of two-dimensional cellular materials. Proceedings of the Royal Society of London. A. Mathematical and Physical Sciences, 382: 25-42. doi: 10.1098/rspa.1982.0087 [39] Gömöry F, Solovyov M, Šouc J, et al. 2012. Experimental realization of a magnetic cloak. Science, 335: 1466-1468. doi: 10.1126/science.1218316 [40] Gong X, Huang J, Scarpa F, et al. 2015. Zero Poisson’s ratio cellular structure for two-dimensional morphing applications. Composite Structures, 134: 384-392. doi: 10.1016/j.compstruct.2015.08.048 [41] Greaves G N, Greer A L, Lakes R S, et al. 2011. Poisson’s ratio and modern materials. Nature Materials, 10: 823-837. doi: 10.1038/nmat3134 [42] Grima J N, Evans K E. 2000. Auxetic behavior from rotating squares. Journal of Materials Science Letters, 19: 1563-1565. doi: 10.1023/A:1006781224002 [43] Grima J N, Gatt R, Farrugia P S. 2008. On the properties of auxetic meta-tetrachiral structures. Physica Status Solidi B, 245: 511-520. doi: 10.1002/pssb.200777704 [44] Grima J N, Mizzi L, Azzopardi K M, et al. 2016. Auxetic perforated mechanical metamaterials with randomly oriented cuts. Advanced Materials, 28: 385-389. doi: 10.1002/adma.201503653 [45] Grima J N, Oliveri L, Attard D, et al. 2010. Hexagonal honeycombs with zero Poisson’s ratios and enhanced stiffness. Advanced Engineering Materials, 12: 855-862. doi: 10.1002/adem.201000140 [46] Günaydın K, Rea C, Kazancı Z. 2022. Energy absorption enhancement of additively manufactured hexagonal and re-entrant (auxetic) lattice structures by using multi-material reinforcements. Additive Manufacturing, 59: 103076. doi: 10.1016/j.addma.2022.103076 [47] Guo M F, Yang H, Ma L. 2020a. Design and analysis of 2D double-U auxetic honeycombs. Thin-Walled Structures, 155: 106915. doi: 10.1016/j.tws.2020.106915 [48] Guo M F, Yang H, Ma L. 2020b. Design and characterization of 3D AuxHex lattice structures. International Journal of Mechanical Sciences, 181: 105700. doi: 10.1016/j.ijmecsci.2020.105700 [49] Guo M F, Yang H, Ma L. 2022. 3D lightweight double arrow-head plate-lattice auxetic structures with enhanced stiffness and energy absorption performance. Composite Structures, 290: 115484. doi: 10.1016/j.compstruct.2022.115484 [50] Guo Y, Zhang J, Chen L, et al. 2020c. Deformation behaviors and energy absorption of auxetic lattice cylindrical structures under axial crushing load. Aerospace Science and Technology, 98: 105662. doi: 10.1016/j.ast.2019.105662 [51] Hao J, Han D, Zhang X G, et al. 2022. Novel dual-platform lightweight metamaterials with auxeticity. Engineering Structures, 270: 114891. doi: 10.1016/j.engstruct.2022.114891 [52] He H, Wei X, Yang B, et al. 2022. Ultrastrong and multifunctional aerogels with hyperconnective network of composite polymeric nanofibers. Nature Communications, 13: 4242. doi: 10.1038/s41467-022-31957-2 [53] Hou Y, Quan J, Thai B Q, et al. 2022. Ultralight biomass-derived carbon fibre aerogels for electromagnetic and acoustic noise mitigation. Journal of Materials Chemistry A, 10: 22771-22780. doi: 10.1039/D2TA06402B [54] Hu Q, Lu G, Tse K M. 2024. Dynamic responses of shear thickening fluid-filled lattice structures. International Journal of Impact Engineering, 189: 104954. doi: 10.1016/j.ijimpeng.2024.104954 [55] Huang J, Gong X, Zhang Q, et al. 2016. In-plane mechanics of a novel zero Poisson’s ratio honeycomb core. Composites Part B: Engineering, 89: 67-76. doi: 10.1016/j.compositesb.2015.11.032 [56] Jiang F, Yang S, Qi C. 2022. Quasi-static crushing response of a novel 3D re-entrant circular auxetic metamaterial. Composite Structures, 300: 116066. doi: 10.1016/j.compstruct.2022.116066 [57] Jiang W, Zhang X G, Han D, et al. 2023. Experimental and numerical analysis of a novel assembled auxetic structure with two-stage programmable mechanical properties. Thin-Walled Structures, 185: 110555. doi: 10.1016/j.tws.2023.110555 [58] Jiang Z, Rong J, Chen Z, et al. 2025. Deformation mechanisms and energy absorption characteristics of 3D-printed negative Poisson’s ratio sandwich structures subjected to underwater impulsive loading. International Journal of Impact Engineering, 203: 105355. doi: 10.1016/j.ijimpeng.2025.105355 [59] Jiao C, Yan G. 2021. Design and elastic mechanical response of a novel 3D-printed hexa-chiral helical structure with negative Poisson’s ratio. Materials & Design, 212: 110219. doi: 10.1016/j.matdes.2021.110219 [60] Kashani H, Ito Y, Han J, et al. 2019. Extraordinary tensile strength and ductility of scalable nanoporous graphene. Science Advances, 5: eaat6951. doi: 10.1126/sciadv.aat6951 [61] Kokkinis D, Schaffner M, Studart A R. 2015. Multimaterial magnetically assisted 3D printing of composite materials. Nature Communications, 6: 8643. doi: 10.1038/ncomms9643 [62] Lakes R. 1987. Foam structures with a negative Poisson’s ratio. Science, 235: 1038-1040. doi: 10.1126/science.235.4792.1038 [63] Lakes R, Elms K. 1993. Indentability of conventional and negative Poisson’s ratio foams. Journal of Composite Materials, 27: 1193-1202. doi: 10.1177/002199839302701203 [64] Larsen U D, Signund O, Bouwsta S. 1997. Design and fabrication of compliant micromechanisms and structures with negative Poisson’s ratio. Journal of Microelectromechanical Systems, 6: 99-106. doi: 10.1109/84.585787 [65] Lendlein A, Gould O E. 2019. Reprogrammable recovery and actuation behaviour of shape-memory polymers. Nature Reviews Materials, 4: 116-133. doi: 10.1038/s41578-018-0078-8 [66] Li C, Zhou Q, Li H, et al. 2024a. Dynamic crushing responses of enhanced auxetic re-entrant honeycomb based on additive manufacturing. Structures, 69: 107367. doi: 10.1016/j.istruc.2024.107367 [67] Li F, Lin D, Chen Z, et al. 2018. Ultrahigh piezoelectricity in ferroelectric ceramics by design. Nature Materials, 17: 349-354. doi: 10.1038/s41563-018-0034-4 [68] Li H, Bi K, Han Q, et al. 2025a. A state-of-the-art review on negative stiffness-based structural vibration control. Engineering Structures, 323: 119247. doi: 10.1016/j.engstruct.2024.119247 [69] Li L, He Q, Jing X, et al. 2023. Study on three-point bending behavior of sandwich beams with novel auxetic honeycomb core. Materials Today Communications, 35: 106259. doi: 10.1016/j.mtcomm.2023.106259 [70] Li Q X, Zhi X D, Fan F. 2022. Quasi-static compressive behaviour of 3D-printed origami-inspired cellular structure: Experimental, numerical and theoretical studies. Virtual and Physical Prototyping, 17: 69-91. doi: 10.1080/17452759.2021.1987051 [71] Li W, Zhong Y, Zhu Y, et al. 2024b. Enhancing the structural stiffness and energy absorption of re-entrant auxetic honeycombs using folded stiffeners. Thin-Walled Structures, 205: 112504. doi: 10.1016/j.tws.2024.112504 [72] Li X, Fan R, Fan Z, et al. 2021. Programmable mechanical metamaterials based on hierarchical rotating structures. International Journal of Solids and Structures, 216: 145-155. doi: 10.1016/j.ijsolstr.2021.01.028 [73] Li X, Li Z, Guo Z, et al. 2025b. A novel hybrid star honeycomb with individually adjustable second plateau stresses. Composite Structures, 356: 118881. doi: 10.1016/j.compstruct.2025.118881 [74] Lin H B, Liu H T. 2023. Mechanical properties and band gap characteristics of flexible skin based on multi-concave angle honeycomb. Materials Today Communications, 35: 106113. doi: 10.1016/j.mtcomm.2023.106113 [75] Lin Y X, Zhong Y F, Hien P L, et al. 2025. Gradient re-entrant honeycomb with quasi-ZPR and improved out-of-plane flexibility through tunable horizontal ligaments. Thin-Walled Structures, 213: 113241. doi: 10.1016/j.tws.2025.113241 [76] Lira C, Scarpa F, Tai Y H, et al. 2011. Transverse shear modulus of SILICOMB cellular structures. Composites Science and Technology, 71: 1236-1241. doi: 10.1016/j.compscitech.2011.04.008 [77] Liu H, Deng H, Bao J. 2025a. A deployable modular structure with zero thermal expansion for mesh reflector antennas and its structural performance. Structures, 71: 108000. doi: 10.1016/j.istruc.2024.108000 [78] Liu K, Han L, Hu W, et al. 2020. 4D printed zero Poisson’s ratio metamaterial with switching function of mechanical and vibration isolation performance. Materials & Design, 196: 109153. doi: 10.1016/j.matdes.2020.109153 [79] Liu R, Ji C, Mock J, et al. 2009. Broadband ground-plane cloak. Science, 323: 366-369. doi: 10.1126/science.1166949 [80] Liu W, Zhu H, Zhou S, et al. 2013. In-plane corrugated cosine honeycomb for 1D morphing skin and its application on variable camber wing. Chinese Journal of Aeronautics, 26: 935-942. doi: 10.1016/j.cja.2013.04.015 [81] Liu Z, Lv Q, Li D, et al. 2025b. A straight-arch-straight beam tandem quasi-zero stiffness structure. International Journal of Mechanical Sciences, 286: 109818. doi: 10.1016/j.ijmecsci.2024.109818 [82] Lu H, Wang X, Chen T. 2021. In-plane dynamics crushing of a combined auxetic honeycomb with negative Poisson’s ratio and enhanced energy absorption. Thin-Walled Structures, 160: 107366. doi: 10.1016/j.tws.2020.107366 [83] Lu H, Wang X, Chen T. 2022. Design and quasi-static responses of a hierarchical negative Poisson’s ratio structure with three plateau stages and three-step deformation. Composite Structures, 291: 115591. doi: 10.1016/j.compstruct.2022.115591 [84] Lu H, Wang X, Chen T. 2023. Quasi-static bending response and energy absorption of a novel sandwich beam with a reinforced auxetic core under the fixed boundary at both ends. Thin-Walled Structures, 191: 111011. doi: 10.1016/j.tws.2023.111011 [85] Lu Y, Luo Q, Tong L. 2025. Topology optimization for metastructures with quasi-zero stiffness and snap-through features. Computer Methods in Applied Mechanics and Engineering, 434: 117587. doi: 10.1016/j.cma.2024.117587 [86] Lu Y, Ma Y, Deng F, et al. 2024. Gradient wood-derived hydrogel actuators constructed by an isotropic-anisotropic structure strategy with rapid thermal-response, high strength and programmable deformation. Chemical Engineering Journal, 504: 158903. doi: 10.1016/j.cej.2024.158903 [87] Luo H C, Ren X, Zhang Y, et al. 2022. Mechanical properties of foam-filled hexagonal and re-entrant honeycombs under uniaxial compression. Composite Structures, 280: 114922. doi: 10.1016/j.compstruct.2021.114922 [88] Maldovan M. 2013. Sound and heat revolutions in phononics. Nature, 503: 209-217. doi: 10.1038/nature12608 [89] Mao A, Zhao N, Liang Y, et al. 2021. Mechanically efficient cellular materials inspired by cuttlebone. Advanced Materials, 33: 2007348. doi: 10.1002/adma.202007348 [90] Mirabolghasemi A, Akbarzadeh A, Rodrigue D, et al. 2019. Thermal conductivity of architected cellular metamaterials. Acta Materialia, 174: 61-80. doi: 10.1016/j.actamat.2019.04.061 [91] Mueller J, Raney J R, Shea K, et al. 2018. Architected lattices with high stiffness and toughness via multicore–shell 3D printing. Advanced Materials, 30: 1705001. doi: 10.1002/adma.201705001 [92] Muth J T, Dixon P G, Woish L, et al. 2017. Architected cellular ceramics with tailored stiffness via direct foam writing. Proceedings of the National Academy of Sciences, 114: 1832-1837. doi: 10.1073/pnas.1616769114 [93] Na H, Kang Y W, Park C S, et al. 2022. Hydrogel-based strong and fast actuators by electroosmotic turgor pressure. Science, 376: 301-307. doi: 10.1126/science.abm7862 [94] Ni X, Wong Z J, Mrejen M, et al. 2015. An ultrathin invisibility skin cloak for visible light. Science, 349: 1310-1314. doi: 10.1126/science.aac9411 [95] Nicolaou Z G, Motter A E. 2012. Mechanical metamaterials with negative compressibility transitions. Nature Materials, 11: 608-613. doi: 10.1038/nmat3331 [96] Niu H, Lu J, Qin R, et al. 2025. A self-locked chiral honeycomb: In-plane compression behavior and energy absorption. European Journal of Mechanics-A/Solids, 111: 105580. doi: 10.1016/j.euromechsol.2025.105580 [97] Ouyang S B, Zhong Y F, Hien P L, et al. 2025. Designing re-entrant nested star-shaped honeycombs for energy-absorbing and load-bearing capabilities. Engineering Structures, 335: 120258. doi: 10.1016/j.engstruct.2025.120258 [98] Overvelde J T B, Bertoldi K. 2014. Relating pore shape to the non-linear response of periodic elastomeric structures. Journal of the Mechanics and Physics of Solids, 64: 351-366. doi: 10.1016/j.jmps.2013.11.014 [99] Pan D, Tan S, Zhang Z, et al. 2025. The metastructures actuated by rotational motion with quasi-zero stiffness, negative stiffness, and bistability. Thin-Walled Structures, 207: 112700. doi: 10.1016/j.tws.2024.112700 [100] Pendry J B, Schurig D, Smith D R. 2006. Controlling electromagnetic fields. Science, 312: 1780-1782. doi: 10.1126/science.1125907 [101] Prall D, Lakes R S. 1997. Properties of a chiral honeycomb with a Poisson’s ratio of −1. International Journal of Mechanical Sciences, 39: 305-314. doi: 10.1016/S0020-7403(96)00025-2 [102] Qu Y C, Teng X C, Zhang Y, et al. 2025. A novel 3D composite auxetic sandwich panel for energy absorption improvement. Engineering Structures, 322: 119129. doi: 10.1016/j.engstruct.2024.119129 [103] Rafsanjani A, Pasini D. 2016. Bistable auxetic mechanical metamaterials inspired by ancient geometric motifs. Extreme Mechanics Letters, 9: 291-296. doi: 10.1016/j.eml.2016.09.001 [104] Ravirala N, Alderson A, Alderson K L. 2007. Interlocking hexagons model for auxetic behaviour. Journal of Materials Science, 42: 7433-7445. doi: 10.1007/s10853-007-1583-0 [105] Ritchie R O. 2011. The conflicts between strength and toughness. Nature Materials, 10: 817-822. doi: 10.1038/nmat3115 [106] Sadikbasha S, Pandurangan V. 2023. High velocity impact response of sandwich structures with auxetic tetrachiral cores: Analytical model, finite element simulations and experiments. Composite Structures, 317: 117064. doi: 10.1016/j.compstruct.2023.117064 [107] Sahariah B J, Baishya M J, Namdeo A, et al. 2023. A novel strategy to design lattice structures with zero Poisson’s ratio. Engineering Structures, 288: 116214. doi: 10.1016/j.engstruct.2023.116214 [108] Schaedler T A, Jacobsen A J, Torrents A, et al. 2011. Ultralight metallic microlattices. Science, 334: 962-965. doi: 10.1126/science.1211649 [109] Schenk M, Guest S D. 2013. Geometry of Miura-folded metamaterials. Proceedings of the National Academy of Sciences, 110: 3276-3281. doi: 10.1073/pnas.1217998110 [110] Schurig D, Mock J J, Justice B J, et al. 2006. Metamaterial electromagnetic cloak at microwave frequencies. Science, 314: 977-980. doi: 10.1126/science.1133628 [111] Schwartz J, Boydston A. 2019. Multimaterial actinic spatial control 3D and 4D printing. Nature Communications, 10: 791. doi: 10.1038/s41467-019-08639-7 [112] Shelby R A, Smith D R, Schultz S. 2001. Experimental verification of a negative index of refraction. Science, 292: 77-79. doi: 10.1126/science.1058847 [113] Sigmund O, Torquato S, Aksay I A. 1998. On the design of 1-3 piezocomposites using topology optimization. Journal of Materials Research, 13: 1038-1048. doi: 10.1557/JMR.1998.0145 [114] Sklan S R, Li B. 2018. Thermal metamaterials: Functions and prospects. National Science Review, 5: 138-141. doi: 10.1093/nsr/nwy005 [115] Smith C W, Grima J N, Evans K E. 2000. A novel mechanism for generating auxetic behaviour in reticulated foams: Missing rib foam model. Acta Materialia, 48: 4349-4356. doi: 10.1016/S1359-6454(00)00269-X [116] Song Z, Guo D, Liu Y, et al. 2025. Design of kirigami metamaterials with square-symmetric auxeticity under large stretching. Thin-Walled Structures, 213: 113268. doi: 10.1016/j.tws.2025.113268 [117] Sydney Gladman A, Matsumoto E A, Nuzzo R G, et al. 2016. Biomimetic 4D printing. Nature Materials, 15: 413-418. doi: 10.1038/nmat4544 [118] Tan X, Chu K, Chen Z, et al. 2024. Recent advances in self-healing hydrogel composites for flexible wearable electronic devices. Nano Research Energy, 3: e9120123. doi: 10.26599/NRE.2024.9120123 [119] Tang Y X, Zhong Y F, Zhu Y L, et al. 2025. Energy absorption characteristics and auxetic effect of novel elliptic-arc re-entrant honeycomb structures. Engineering Structures, 323: 119260. doi: 10.1016/j.engstruct.2024.119260 [120] Theocaris P, Stavroulakis G, Panagiotopoulos P. 1997. Negative Poisson’s ratios in composites with star-shaped inclusions: A numerical homogenization approach. Archive of Applied Mechanics, 67: 274-286. doi: 10.1007/s004190050117 [121] Toombs J T, Luitz M, Cook C C, et al. 2022. Volumetric additive manufacturing of silica glass with microscale computed axial lithography. Science, 376: 308-312. doi: 10.1126/science.abm6459 [122] Virk K, Monti A, Trehard T, et al. 2013. SILICOMB PEEK Kirigami cellular structures: Mechanical response and energy dissipation through zero and negative stiffness. Smart Materials and Structures, 22: 084014. doi: 10.1088/0964-1726/22/8/084014 [123] Wang H, Lu Z, Yang Z, et al. 2019. A novel re-entrant auxetic honeycomb with enhanced in-plane impact resistance. Composite Structures, 208: 758-770. doi: 10.1016/j.compstruct.2018.10.024 [124] Wang J, Luo X, Wang K, et al. 2022. On impact behaviors of 3D concave structures with negative Poisson’s ratio. Composite Structures, 298: 115999. doi: 10.1016/j.compstruct.2022.115999 [125] Wang N, Liu W, Tang A, et al. 2014. Strain isolation: A simple mechanism for understanding and detecting structures of zero Poisson’s ratio. Physica Status Solidi B, 251: 2239-2246. doi: 10.1002/pssb.201451376 [126] Wang Q, Tian X, Huang L, et al. 2018a. Programmable morphing composites with embedded continuous fibers by 4D printing. Materials & Design, 155: 404-413. doi: 10.1016/j.matdes.2018.06.027 [127] Wang S, Liu H T. 2023. Energy absorption performance of the auxetic arc-curved honeycomb with thickness and arc angle gradient based on additive manufacturing. Materials Today Communications, 35: 105515. doi: 10.1016/j.mtcomm.2023.105515 [128] Wang S, Liu H T. 2024. Quasi-static compression response of a novel multi-step auxetic honeycomb with tunable transition strain. Aerospace Science and Technology, 155: 109730. doi: 10.1016/j.ast.2024.109730 [129] Wang S, Liu H T, Cai G B. 2024a. Programmable mechanical responses of a hybrid star-rhombus honeycomb based on digital design method. Thin-Walled Structures, 205: 112399. doi: 10.1016/j.tws.2024.112399 [130] Wang W J, Yang H, Zhang W M, et al. 2025. Experimental study on the impact resistance of fill-enhanced mechanical metamaterials. International Journal of Mechanical Sciences, 285: 109799. doi: 10.1016/j.ijmecsci.2024.109799 [131] Wang W J, Zhang W M, Guo M F, et al. 2023. Energy absorption characteristics of a lightweight auxetic honeycomb under low-velocity impact loading. Thin-Walled Structures, 185: 110577. doi: 10.1016/j.tws.2023.110577 [132] Wang W J, Zhang W M, Guo M F, et al. 2024b. Impact resistance of assembled plate-lattice auxetic structures. Composite Structures, 338: 118132. doi: 10.1016/j.compstruct.2024.118132 [133] Wang X T, Wang B, Wen Z H, et al. 2018b. Fabrication and mechanical properties of CFRP composite three-dimensional double-arrow-head auxetic structures. Composites Science and Technology, 164: 92-102. doi: 10.1016/j.compscitech.2018.05.014 [134] Wang Y C, Lakes R. 2005. Composites with inclusions of negative bulk modulus: Extreme damping and negative Poisson’s ratio. Journal of Composite Materials, 39: 1645-1657. doi: 10.1177/0021998305051112 [135] Wei T, Lu F, Zhang C, et al. 2025. Energy absorption of 3D assembled auxetic meta-structure with compression-twisting effect. Structures, 73: 108482. doi: 10.1016/j.istruc.2025.108482 [136] Wojciechowski K W. 1989. Two-dimensional isotropic system with a negative Poisson ratio. Physics Letters A, 137: 60-64. doi: 10.1016/0375-9601(89)90971-7 [137] Wu L, Zhao F, Lu Z, et al. 2022. Impact energy absorption composites with shear stiffening gel-filled negative Poisson’s ratio skeleton by kirigami method. Composite Structures, 298: 116009. doi: 10.1016/j.compstruct.2022.116009 [138] Wu W, Hu W, Qian G, et al. 2019. Mechanical design and multifunctional applications of chiral mechanical metamaterials: A review. Materials & Design, 180: 107950. doi: 10.1016/j.matdes.2019.107950 [139] Wu X, Su Y, Shi J. 2020. In-plane impact resistance enhancement with a graded cell-wall angle design for auxetic metamaterials. Composite Structures, 247: 112451. doi: 10.1016/j.compstruct.2020.112451 [140] Wu X, Zhang S, Ding L, et al. 2024. Bi-material multistable auxetic honeycombs with reusable and enhanced energy-absorbing phases under in-plane crushing. Thin-Walled Structures, 201: 111988. doi: 10.1016/j.tws.2024.111988 [141] Xia X, Afshar A, Yang H, et al. 2019. Electrochemically reconfigurable architected materials. Nature, 573: 205-213. doi: 10.1038/s41586-019-1538-z [142] Xu C, Stiubianu G T, Gorodetsky A A. 2018. Adaptive infrared-reflecting systems inspired by cephalopods. Science, 359: 1495-1500. doi: 10.1126/science.aar5191 [143] Xu H, Liu H T, Li G F. 2025. In-plane characteristics of a multi-arc re-entrant auxetic honeycomb with enhanced negative Poisson’s ratio effect and energy absorption. European Journal of Mechanics-A/Solids, 109: 105473. doi: 10.1016/j.euromechsol.2024.105473 [144] Xu M, Xu Z, Zhang Z, et al. 2019. Mechanical properties and energy absorption capability of AuxHex structure under in-plane compression: Theoretical and experimental studies. International Journal of Mechanical Sciences, 159: 43-57. doi: 10.1016/j.ijmecsci.2019.05.044 [145] Yan Y, Xu S, Wang X, et al. 2025. A photothermal-responsive and glucose-responsive antibacterial hydrogel featuring tunable mechanical properties. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 708: 136029. doi: 10.1016/j.colsurfa.2024.136029 [146] Yang H, D’Ambrosio N, Liu P, et al. 2023. Shape memory mechanical metamaterials. Materials Today, 66: 36-49. doi: 10.1016/j.mattod.2023.04.003 [147] Yang H, Ma L. 2021. Impact resistance of additively manufactured 3D double-U auxetic structures. Thin-Walled Structures, 169: 108373. doi: 10.1016/j.tws.2021.108373 [148] Yang H, Yang L, Zheng X, et al. 2025. High-performance 3D auxetic metamaterials enabled by multiple auxetic mechanisms. International Journal of Mechanical Sciences, 287: 109981. doi: 10.1016/j.ijmecsci.2025.109981 [149] Yang S, Chalivendra V B, Kim Y K. 2017. Fracture and impact characterization of novel auxetic Kevlar®/Epoxy laminated composites. Composite Structures, 168: 120-129. doi: 10.1016/j.compstruct.2017.02.034 [150] Yeo S J, Oh M J, Yoo P J. 2019. Structurally controlled cellular architectures for high-performance ultra-lightweight materials. Advanced Materials, 31: 1803670. doi: 10.1002/adma.201803670 [151] Yu P, Zhang P, Ji Q, et al. 2024. A multi-step auxetic metamaterial with instability regulation. International Journal of Solids and Structures, 305: 113040. doi: 10.1016/j.ijsolstr.2024.113040 [152] Yu R, Luo W, Yuan H, et al. 2020. Experimental and numerical research on foam filled re-entrant cellular structure with negative Poisson’s ratio. Thin-Walled Structures, 153: 106679. doi: 10.1016/j.tws.2020.106679 [153] Yu X, Chen H, Lin H, et al. 2014. Continuously tuning effective refractive index based on thermally controllable magnetic metamaterials. Optics Letters, 39: 4643-4646. doi: 10.1364/OL.39.004643 [154] Yu X, Zhou J, Liang H, et al. 2018. Mechanical metamaterials associated with stiffness, rigidity and compressibility: A brief review. Progress in Materials Science, 94: 114-173. doi: 10.1016/j.pmatsci.2017.12.003 [155] Yuan C, Mu X, Dunn C K, et al. 2018. Thermomechanically triggered two-stage pattern switching of 2D lattices for adaptive structures. Advanced Functional Materials, 28: 1705727. doi: 10.1002/adfm.201705727 [156] Yue L, Liu H, Cheng Z, et al. 2024. Dynamic crushing behavior of a novel bi-directional gradient lattice structure under axial and oblique impact loadings. Thin-Walled Structures, 198: 111697. doi: 10.1016/j.tws.2024.111697 [157] Ze Q, Kuang X, Wu S, et al. 2020. Magnetic shape memory polymers with integrated multifunctional shape manipulation. Advanced Materials, 32: 1906657. doi: 10.1002/adma.201906657 [158] Zhang B, Zhang W, Zhang Z, et al. 2019a. Self-healing four-dimensional printing with an ultraviolet curable double-network shape memory polymer system. ACS Applied Materials & Interfaces, 11: 10328-10336. doi: 10.1021/acsami.9b00359 [159] Zhang C, Lu F, Mo W, et al. 2025a. Dynamic responses and energy absorption characteristics of windmill-shaped auxetic structure under impact loading. Structures, 75: 108670. doi: 10.1016/j.istruc.2025.108670 [160] Zhang D, Lim X J G, Li X, et al. 2022a. 3D-Printed porous thermoelectrics for in situ energy harvesting. ACS Energy Letters, 8: 332-338. doi: 10.1021/acsenergylett.2c02425 [161] Zhang H, Chen P, Lin G, et al. 2022b. A corrugated gradient mechanical metamaterial: Lightweight, tunable auxeticity and enhanced specific energy absorption. Thin-Walled Structures, 176: 109355. doi: 10.1016/j.tws.2022.109355 [162] Zhang Q, Sun Y. 2025. Energy absorption characteristic of auxetic metamaterials honeycombs and lattices with negative thermal expansion. Thin-Walled Structures, 208: 112824. doi: 10.1016/j.tws.2024.112824 [163] Zhang W, Chen J, Li X, et al. 2020. Liquid metal-polymer microlattice metamaterials with high fracture toughness and damage recoverability. Small, 16: 2004190. doi: 10.1002/smll.202004190 [164] Zhang W, Wang H, Lou X, et al. 2024. On in-plane crushing behavior of a combined re-entrant double-arrow honeycomb. Thin-Walled Structures, 194: 111303. doi: 10.1016/j.tws.2023.111303 [165] Zhang X, Vyatskikh A, Gao H, et al. 2019b. Lightweight, flaw-tolerant, and ultrastrong nanoarchitected carbon. Proceedings of the National Academy of Sciences, 116: 6665-6672. doi: 10.1073/pnas.1817309116 [166] Zhang Y, Ren X, Jiang W, et al. 2022c. In-plane compressive properties of assembled auxetic chiral honeycomb composed of slotted wave plate. Materials & Design, 221: 110956. doi: 10.1016/j.matdes.2022.110956 [167] Zhang Z, Gu Y W, Wu H A, et al. 2025b. Investigation on the energy absorption characteristics of novel graded auxetic re-entrant honeycombs. Composite Structures, 352: 118633. doi: 10.1016/j.compstruct.2024.118633 [168] Zhang Z, Lei Y P, Wang H. 2025c. Deformation and energy absorption characteristics of graded auxetic metamaterials featuring peanut-shaped perforations under in-plane compression. International Journal of Solids and Structures, 313: 113318. doi: 10.1016/j.ijsolstr.2025.113318 [169] Zheng X, Lee H, Weisgraber T H, et al. 2014. Ultralight, ultrastiff mechanical metamaterials. Science, 344: 1373-1377. doi: 10.1126/science.1252291 [170] Zhou C, Zhang F, Zhang X, et al. 2025. Hierarchical negative stiffness structures with improved resilience and energy absorption capability. Materials Today Communications, 42: 111371. doi: 10.1016/j.mtcomm.2024.111371 [171] Zhou J, Wang Y, Luo H, et al. 2024. Energy absorption of auxetic honeycomb with graded beam thickness based on Bezier curve. Aerospace Science and Technology, 155: 109619. doi: 10.1016/j.ast.2024.109619 [172] Zhou Y, Chen C, Zhu S, et al. 2019. A printed, recyclable, ultra-strong, and ultra-tough graphite structural material. Materials Today, 30: 17-25. doi: 10.1016/j.mattod.2019.03.016 [173] Zhu Y, Fu Y, Rui X, et al. 2025. On the design and crashworthiness of a novel auxetic self-locking energy absorption system. International Journal of Solids and Structures, 311: 113246. doi: 10.1016/j.ijsolstr.2025.113246 [174] Zouaoui M, Saifouni O, Gardan J, et al. 2022. Improvement of fracture toughness based on auxetic patterns fabricated by metallic extrusion in 3D printing. Procedia Structural Integrity, 42: 680-686. doi: 10.1016/j.prostr.2022.12.086 -

下载:

下载: