-

摘要: 力学超材料是一种有别于传统力学行为的工程材料, 它源于人工可编程的微结构以及材料的固有属性. 在过去的十年中, 随着计算性能和复杂微观结构制造能力的巨大进步, 力学超材料已经吸引了研究人员的广泛关注, 因为它能够实现自然界中不可能出现的多重物理属性. 该领域迅速崛起的趋势之一是将材料行为和单元结构与其他不同的多种物理因素(如电场或磁场)以及温度、光或化学反应等刺激相结合, 从而扩大按需主动调制力学响应的范围. 在本文中, 我们旨在概述有关超材料的力学和多物理性质调制的相关文献, 重点介绍双能级设计的新兴趋势, 着重讨论力学超材料在关键工程领域应用中的巨大潜力. 本文对该领域的发展趋势、挑战和未来路线进行了系统深入分析, 涵盖实时可重构性和功能编程、4D打印、纳米超材料、人工智能和机器学习、多物理折纸/剪纸、活性物质、软物质和保形超材料、复杂微结构制造、服役寿命效应和可扩展性等概念.Abstract: Mechanical metamaterials are engineered materials with unconventional mechanical behavior that originates from artificially programmed microstructures along with intrinsic material properties. With tremendous advancement in computational and manufacturing capabilities to realize complex microstructures over the last decade, the field of mechanical metamaterials has been attracting wide attention due to immense possibilities of achieving unprecedented multi-physical properties which are not attainable in naturally-occurring materials. One of the rapidly emerging trends in this field is to couple the mechanics of material behavior and the unit cell architecture with different other multi-physical aspects such as electrical or magnetic fields, and stimuli like temperature, light or chemical reactions to expand the scope of actively programming on-demand mechanical responses. In this article, we aim to abridge outcomes of the relevant literature concerning mechanical and multi-physical property modulation of metamaterials focusing on the emerging trend of bi-level design, and subsequently highlight the broad-spectrum potential of mechanical metamaterials in their critical engineering applications. The evolving trends, challenges and future roadmaps have been critically analyzed here involving the notions of real-time reconfigurability and functionality programming, 4D printing, nano-scale metamaterials, artificial intelligence and machine learning, multi-physical origami/kirigami, living matter, soft and conformal metamaterials, manufacturing complex microstructures, service-life effects and scalability.

-

图 1 材料和结构在超材料中相互作用. (a)在材料尺度上利用力学设计和人工微结构来提高性能(Schaedler & Carter 2016). 随着技术的进步, 功能结构的定义变得更加复杂, 并从宏观走向更精细的微观和纳米尺度. (b)跨尺度点阵结构的适用性和工程应用(Mukhopadhyay & Adhikari 2017a). (c)泊松比可编程的六边形晶格微结构: (i)正泊松比; (ii)负泊松比; (iii) ~ (v)零泊松比(Mukhopadhyay & Adhikari 2017b). (d)超平面弯曲的高斯曲率编程结构: (i)负; (ii)正(Mirzaali et al. 2021). (e) Sarrus模块化折纸设计: (i)描述Sarrus机制的立方单位; (ii) Sarrus连杆的装配; (iii) ~ (v)模块变换顺序; (vi) ~ (viii) Sarrus超材料(Yang & You 2020)的变形构型. (f)基于折纸/剪纸的模块材料: (i)一个典型的截断八面体; (ii) ~ (iii)由截断的八面体衍生的对称和非对称单胞; (iv)由对称单元格堆叠得到二维元表面; (v)承受压缩载荷时的超板材结构; (vi)受拉伸载荷(Sinha & Mukhopadhyay 2022c)时的板材超结构. (g)基于水弹折纸的管状超材料: (i)基于水弹折纸的折痕图; (ii)水弹管的3D视图; (iii)管状元结构的宏观图示; (iv)微观结构和远场驱动相关的形状变形; (v)基于微观结构的本构关系编程(Mukhopadhyay et al. 2020a)

图 3 多功能超材料总览 (a)电磁超材料: (i)由铜制分裂环谐振器和导线构成的2维周期阵列组成一种“左手材料”(LHM), 呈现出负折射(Shelby et al. 2001); (ii)圆形、方形、单环和多环结构的分裂环谐振器, 分裂环谐振器(SRR)是一种高导电性结构, 其电感由两个环之间的电容平衡; (iii)瑞士卷结构的透视图和俯视图, 瑞士卷结构内的电流是由结构的自身电容引起的, 能够形成完整交流电路; (iv)圆锥形瑞士卷的侧视图和俯视图, 圆锥形瑞士卷结构有助于电磁波在相对较大的距离上传输, 同时减少了阻尼; (v)用于制作手性瑞士卷结构的导电片展开结构和手性瑞士卷结构的俯视图, 导电片的每一层都填充有介质材料(Grimberg 2013). (b)光学超材料: (i)常规透镜聚焦光线; (ii)负折射率超材料; (iii)给出负电响应的等离子体纳米棒; (iv)提供负磁共振的分裂纳米环; (v)与双分裂纳米环配对的纳米棒, 产生负的磁和电响应; (vi)耦合纳米棒在特定情况下也能呈现负的磁和电响应; (vii)由双开口环组成的3D光学超材料单胞(Gardner et al. 2011). (c)声学超材料: (i)带有侧孔图案的管状结构, 显示出负有效模量, 单胞结构如侧图显示; (ii)测量相位和传输速度的实验装置(Lee et al. 2009b). (d)力学超材料: 显示出拉胀性和可逆变形的微观点阵(Schaedler & Carter 2016)

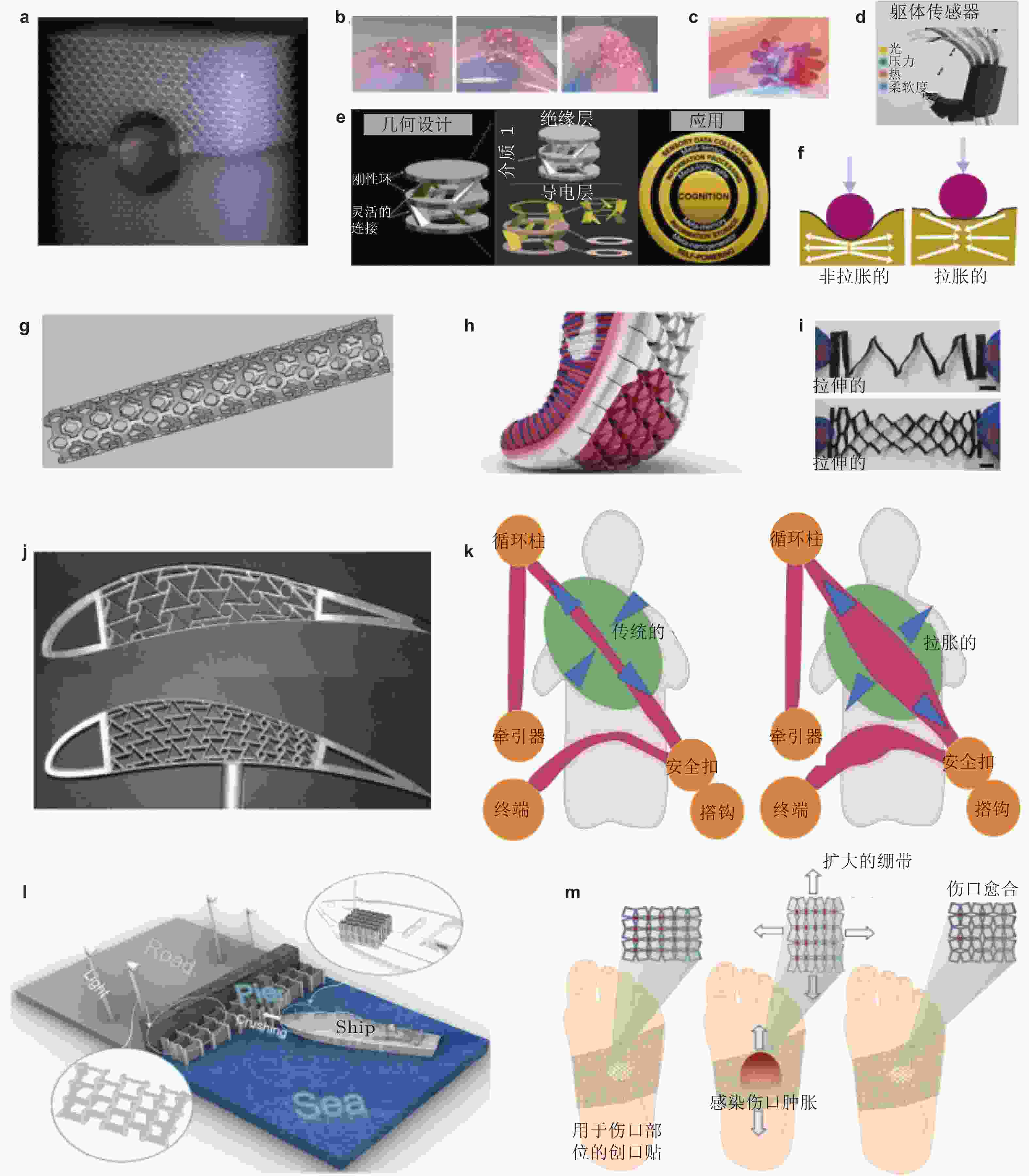

图 4 力学超材料的实际应用 (a)隐身斗篷(Bückmann et al. 2014). (b)电子皮肤(Li K et al. 2019). (c)软体机器人(Cheng et al. 2020). (d)仿生夹具(Wang X Q et al. 2020). (e)通过超材料进行力学计算(Zhang et al. 2023). (f)抗冲击结构(Evans & Alderson 2000). (g)血管支架(Jia et al. 2018). (h)跑鞋(Gleeson 2020). (i)柔性电池(Bao et al. 2020). (j)桁架芯翼型(Spadoni & Ruzzene 2007). (k)拉胀安全带(Balan P et al. 2023). (l)海洋防护结构应用中的组装蜂窝结构(Lang et al. 2023). (m)拉胀绷带(Balan P et al. 2023). 值得注意的是, 我们在这里只提到了几个有代表性的应用, 实际上这个列表是无穷无尽的

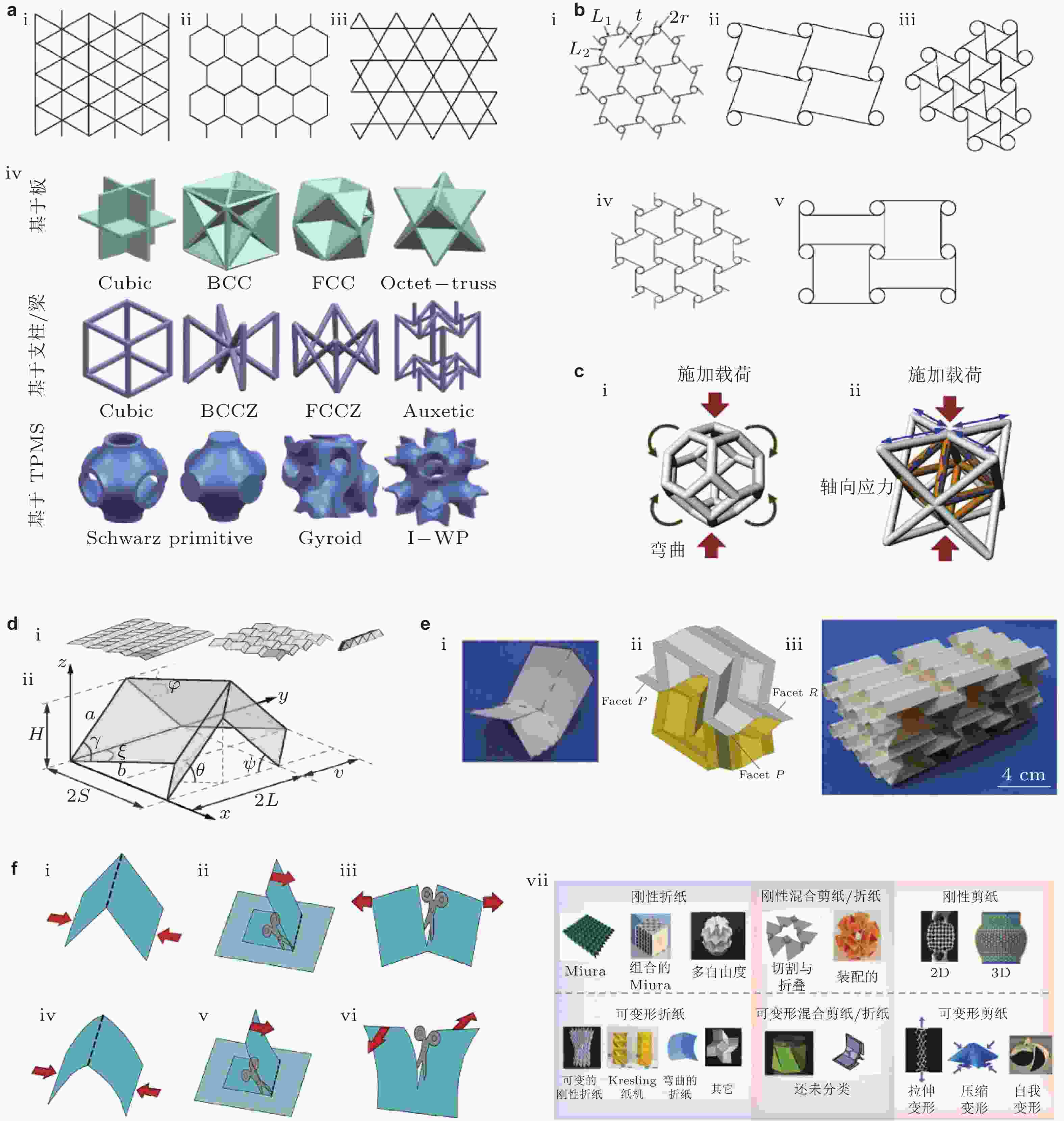

图 5 超材料的微结构构型 (a)不同形状的晶格: (i)规则的三角形网格; (ii)正六边形晶格; (iii)被称为Kagome的半正三角形-六边形晶格(Ongaro 2018); (iv)具有不同类型组成元素的晶格超材料, 例如基于板、基于支柱/梁和基于TPMS的构件(Zhong et al. 2023). (b)手性和反手性蜂窝(Ongaro 2018): (i)三手性蜂窝(Alderson et al. 2010); (ii)四手性蜂窝; (iii)六手性蜂窝; (iv)反三手性蜂窝(Alderson et al. 2010); (v)反四手性蜂巢. (c)基本变形模式: (i)弯曲占优势的晶格晶胞; (ii)受拉伸支配的晶格单胞(Zheng et al. 2014). (d)基于折纸的力学超材料: (i) Miura-ori层的运动行为; (ii) Miura-ori折纸结构的单胞几何形状(Schenk & Guest 2013). (e)混合折纸超材料: (i)标准Miura-ori图案化的晶胞, 可表现出面内拉胀性; (ii)混合折纸单元的3D视图, 由常规凹六边形蜂窝单元和常规Miura-ori图案组合而成; (iii)通过周期性重复单胞获得的超材料微结构(Wang H et al. 2020). (f)基于折纸和剪纸不同类别的超材料: (i)刚性折纸; (ii)刚性混合折纸/剪纸; (iii)刚性剪纸; (iv)可变形折纸; (v)可变形的混合折纸/剪纸; (vi)可变形的剪纸; (vii)基于折纸和剪纸的超材料的子类(Zhai et al. 2021)

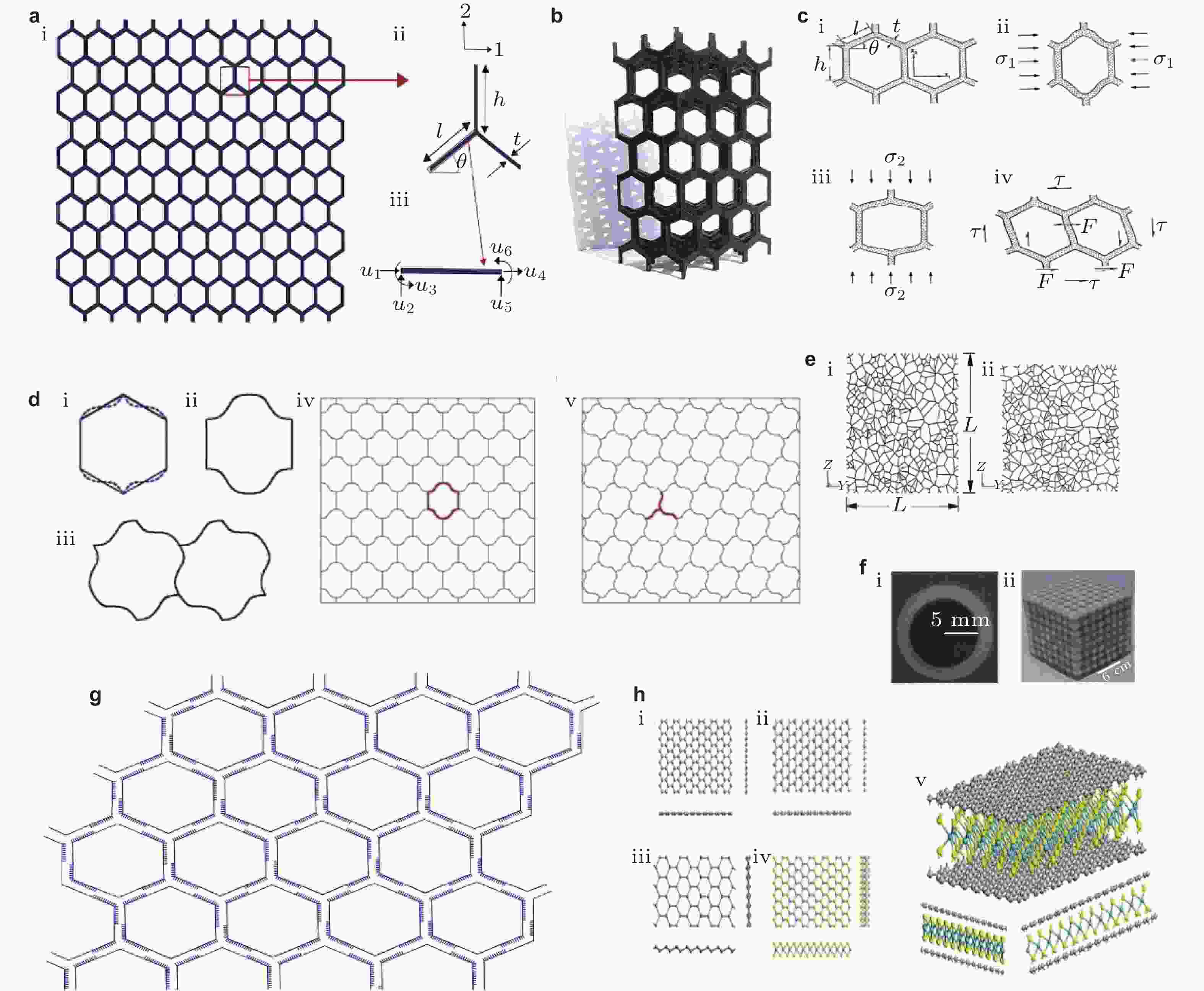

图 6 力学超材料的被动特性调制 (a)基于单胞自下而上的方法对蜂窝结构分析: (i)规则的2D蜂窝状晶格; (ii)堆叠时形成整个晶格的蜂窝的单胞; (iii)蜂窝的单元壁, 将其视为具有自由度的梁单元(P Sinha & Mukhopadhyay 2022). (b)规则的3D蜂窝晶格(Sinha et al. 2023a). (c) 2D六边形蜂窝结构的力学特性: (i)未变形的蜂窝; (ii)沿X1方向承受面内载荷的单胞; (iii)沿X2方向承受面内载荷的单胞; (iv)承受面内剪切载荷的单胞(Andrews et al. 1999). 对于其他2D和3D晶格, 需要适当分析单胞的力学特性. (d)不同应力条件下晶格中的抗弯曲效应: (i)正六边形晶格的单胞; (ii)在经受沿X1方向的拉伸载荷的压应力时, 具有弯曲胞壁的单胞; (iii)当受到剪切应力时获得的具有弯曲细胞壁的单胞; (iv)针对X1方向上的拉伸正应力, 蜂窝网格单元壁中具有的反曲率; (v)蜂窝晶格单元壁在抗逆时针剪应力具有的反曲率(Ghuku & Mukhopadhyay 2023). (e) 2D Voronoi蜂窝的单元不规则性: (i)未变形构型中的随机Voronoi蜂窝; (ii)具有周期性边界条件的变形Voronoi蜂窝结构(Zhu et al. 2001). (f)波在力学超材料中的传播: (i)共振球形原子的横截面; (ii)声波晶体中具有单胞的声学超材料(Lu et al. 2009). (g)具有区域不连续性的典型非不变蜂窝晶格(Sinha et al. 2023b). (h)基于纳米异质结构的纳米级超材料概念: (i)典型纳米结构的侧视图和俯视图, 其中单一类型的原子在单一平面中形成整个结构; (ii)典型纳米结构的侧视图和俯视图, 其中不同类型的原子在单个平面中形成整个结构; (iii)典型纳米结构的侧视图和俯视图, 其中原子在多个平面中形成整个结构; (iv)典型纳米结构的侧视图和俯视图, 其中不同类型的原子在多个平面中形成整个结构; (v)由不同2D材料组成的多层异质结构(Mukhopadhyay et al. 2020b)

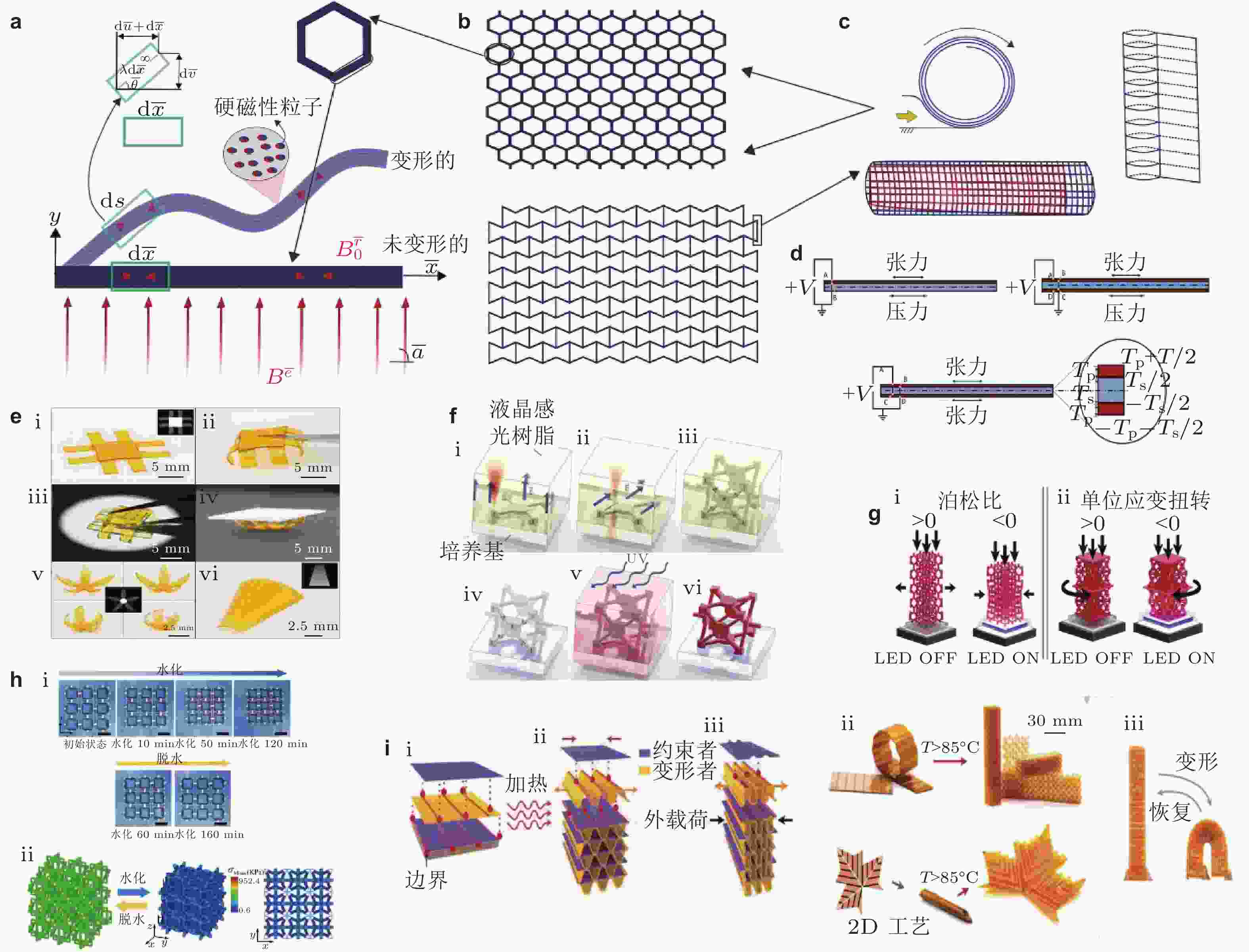

图 7 力学超材料的主动特性调制 (a) ~ (d)双能级主动晶格超材料: (b)中所示的晶格(拉胀型和非拉胀型)由(a)、(c)和(d)中所示的不同主动梁组件制成; 基于(a)中所示的硬磁软(HMS)梁形成磁驱动主动力学超材料, 图中显示了外磁驱动下未变形和变形配置的HMS梁(Sinha & Mukhopadhyay 2023); 压力驱动的主动力学超材料是基于(c)所示的可充气梁形成的, 在这种可膨胀的晶格中可以进行卷绕和密实堆叠(P Sinha et al. 2023); 电驱动主动力学超材料基于压电复合梁形成, 如(d)所示, 其中通过单晶形和双晶形构型可以实现纯弯曲、纯拉伸和弯曲/拉伸组合模式(Singh et al. 2022b). (e)光驱动主动力学超材料: (i)光聚合后的聚合物片; (ii)空间的、 不同固化板的自由弯曲; (iii)用后固化法在均匀光线下对弯曲结构进行定形; (iv)后固化后的硬样品; (v)花结构的不同开放程度; (vi)聚合物板材曲率的连续变化(Zhao et al. 2017). (f) 3D光学力学超材料: (i)使用外部准静态电场

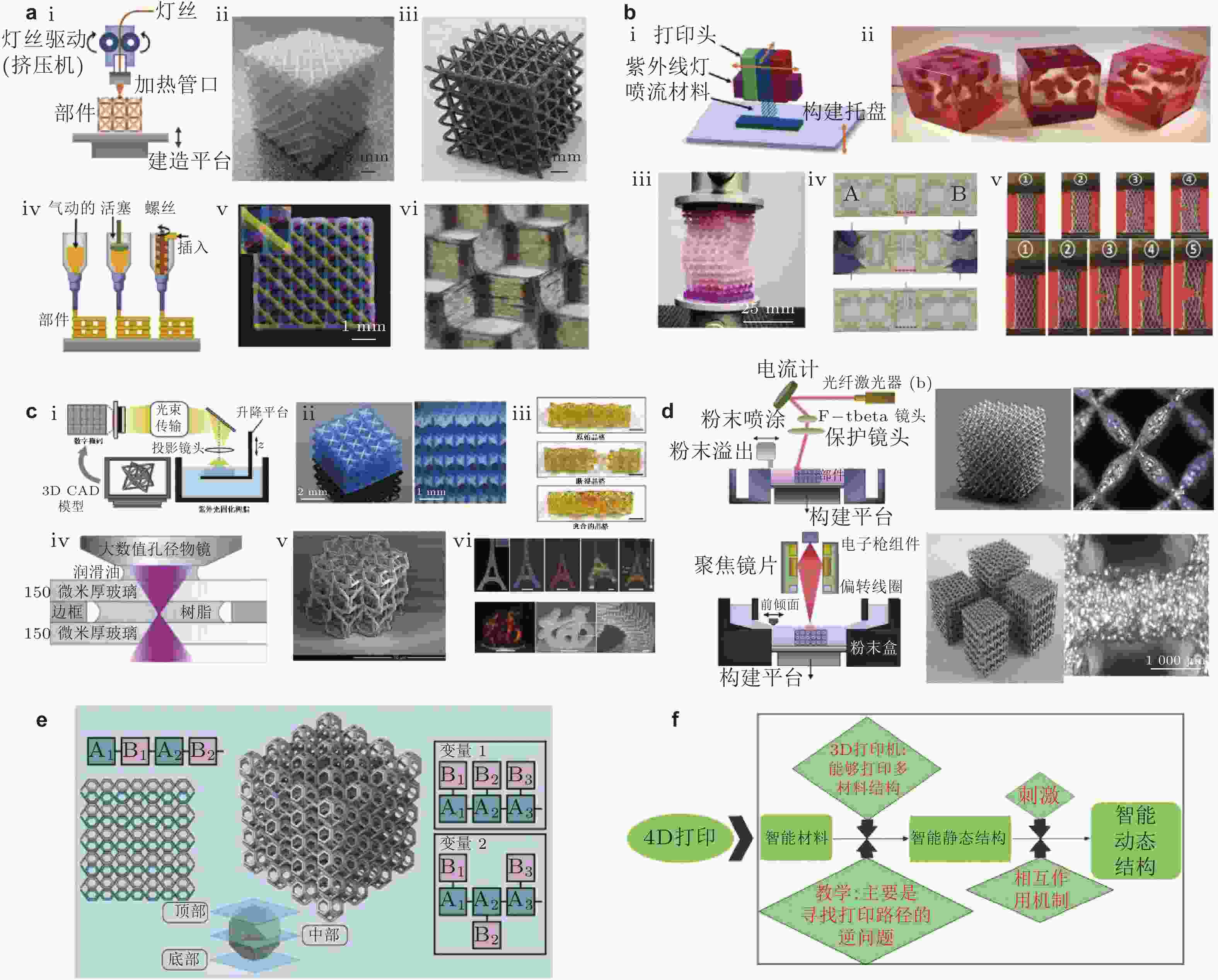

$ \overrightarrow{E} $ 来定向光敏树脂的液晶方向, 然后通过双光子聚合(TPP)打印的体素进行局部固定; (ii)结构的另一部分具有不同的方向排列, 导致电场的排列发生变化; (iii)结构的聚合和未聚合区域; (iv)包含定向3D液晶导向场的光学透明聚合结构; (v)样品浸泡在染料溶液中, 染料溶液扩散到样品中, 并作为吸收剂与刺激光耦合; (vi)最终超材料(Münchinger et al. 2022). (g)受光刺激的力学超材料: 基于晶格的结构, 当外部LED关闭和打开时, 分别显示正的和负的(i)泊松比和(ii)扭转应变(Münchinger et al. 2022). (h)化学驱动的主动力学超材料: (i) 2D超材料在水合和脱水时的变形模式; (ii) 3D超材料的负水化膨胀变形(Wei et al. 2020). (i)热驱动主动力学超材料: (i)热致动超弹性超材料的变形; (ii)弹性薄层压板向体积材料的转变; (iii)超材料的大变形, 卸载后可恢复其形状(Wu et al. 2021)图 8 力学超材料的物理实现 (a)材料挤压工艺: (i)熔融沉积建模 (FDM) 的设置和工作方法演示 (Surjadi et al. 2019); (ii)基于FDM的聚合物八重桁架晶格(Kaur et al. 2017); (iii)通过化学镀和FDM制造的具有Ni外壳和聚合物芯的复合晶格(Song et al. 2018); (iv)直接墨水书写(DIW)的基本工作方法说明 (Surjadi et al. 2019); (v)一种基于3D微点阵的DIW (Rozvany 2009); (vi)使用DIW (Compton & Lewis 2014)制造的纤维填充环氧蜂窝复合材料. (b)喷墨打印: (i)喷墨打印设置示意图(IJP) (Ding et al. 2017); (ii)使用Polyjet打印尺寸和形状可调的颗粒复合材料(Tee et al. 2020); (iii)由于使用Polyjet在周期性晶格中插入刚性缺陷, 导致周期性晶格屈曲(Janbaz et al. 2019); (iv)使用PolyJet印刷制造的物理与门, 允许逻辑可调属性(Waheed et al. 2020); (v)通过改变数字材料的比例来控制2D复合材料 (PolyJet打印) 的断裂特性(Lei et al. 2018). (c)光固化技术: (i)数字光处理(DLP)技术图示(Chen & Zheng 2018); (ii)使用多材料μDLP方法(Chen & Zheng 2018)创建具有可定制泊松比的超材料; (iii)由于光固化技术的灵活性, 晶格的愈合得以实现(Yu et al. 2020); (iv)双光子聚合 (TPP) 技术说明(Serbin et al. 2004); (v) TPP可以产生具有可调屈曲特性的微晶格(Vangelatos et al. 2019); (vi) TPP工艺可以导致更大的晶格间距, 因为它允许结构收缩, 从而使结构显示出光子性质(Liu Y et al. 2019). (d)粉末床熔融: (i)选择性激光熔化(SLM)装置演示(Surjadi et al. 2019); (ii)使用SLM印刷的五模超材料(Hedayati et al. 2017); (iii)电子束熔化(EBM)装置演示(Surjadi et al. 2019); (iv)使用EBM制造的晶格(Yang et al. 2015). (e)六边形晶格结构的运动动力学, 用于将其从平面配置折叠. 晶格结构的设计基于重复晶胞(Janbaz et al. 2017). (f)利用4D打印制造主动超材料, 并实现主动的时间依赖性和可编程响应(Boley et al. 2019, Kim et al. 2022, Zeng et al. 2022). 这本质上是通过耦合3D打印和主动材料来制造时间依赖性和外部刺激敏感的超材料来实现的

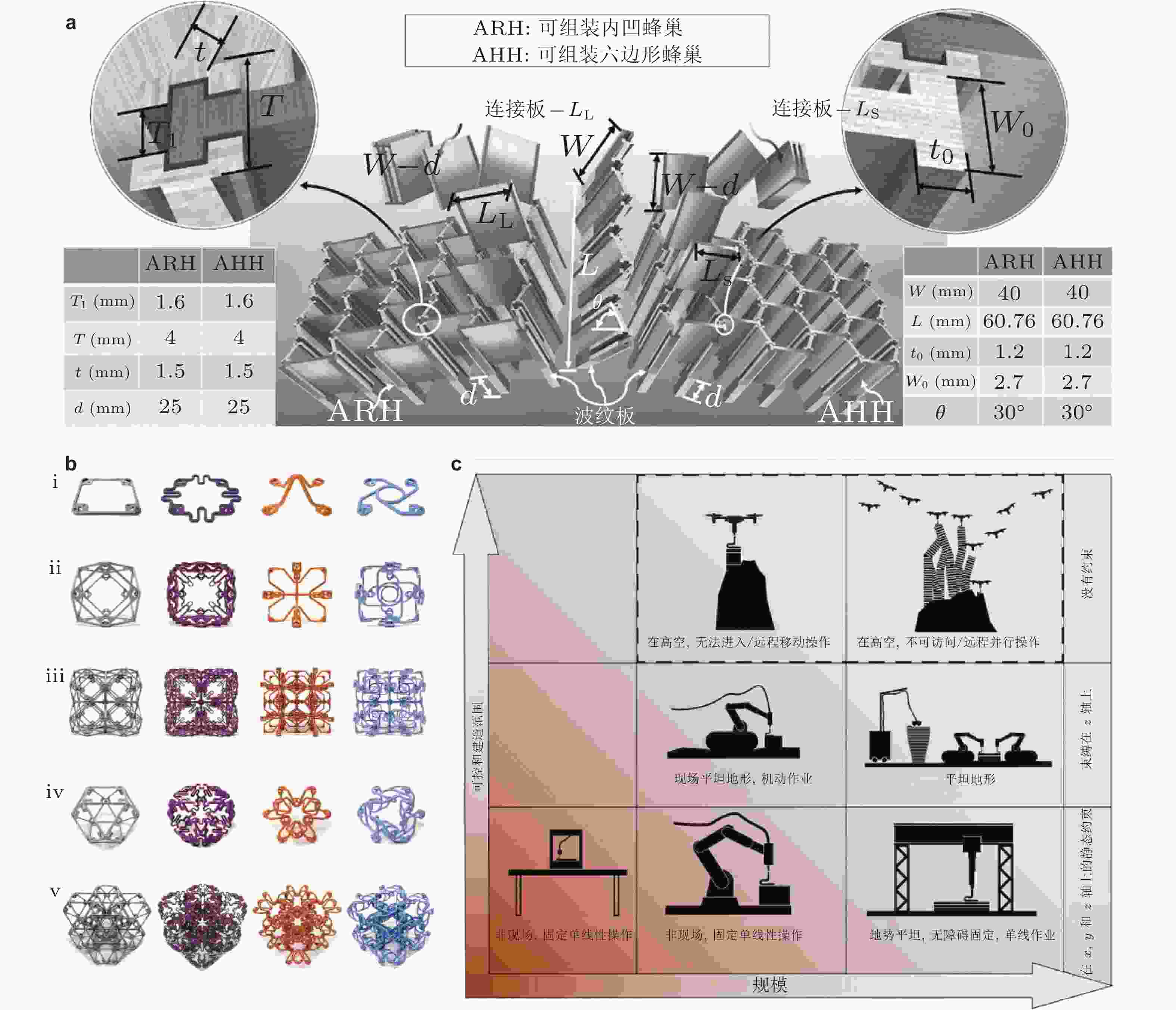

图 9 力学超材料的可扩展性和大型建造体积增材制造的途径. (a)通过组装过程制造超材料(Lang et al. 2023). 这里, 每个超材料晶胞(或一组几个晶胞)可以额外制造并随后组装以实现大的构建体积. (b)离散组装的力学超材料. 从左到右显示了四种不同类型的超材料, 即刚性、柔性、拉胀性和手性. (i)端面轮廓; (ii)单个体素的前视图; (iii) 2 × 2 × 2立方体的前视图; (iv)单个体素的斜视图; (v) 2 × 2 × 2斜视图(Jenett et al. 2020). (c)用于实现大构建体积和规模的常规、机器人和无人机辅助(空中)增材制造(Zhang et al. 2022)

-