Development and application of electromagnetic loading expansion ring test technology

-

摘要: 电磁加载膨胀环试验技术是实现高应变率拉伸加载的重要手段, 可实现应变率104 s−1量级的一维拉伸加载. 洛伦兹力作为一种体力均匀施加于膨胀环试样, 避免了面力加载的波传播效应, 且环形试样结构的特点避免了传统狗骨形试样末端夹持效应的影响, 因此, 电磁加载膨胀环试验技术被广泛应用于材料在高应变率下的拉伸力学行为研究. 本文首先介绍了膨胀环试验技术的基本原理, 回顾了膨胀环试验加载技术的发展历史以及应用于膨胀环试验的测试技术发展情况. 然后对电磁加载膨胀环试验技术的应用进行了综述, 梳理了该试验技术在材料动态力学性能、动态断 (碎) 裂行为、动态延性行为、高温绝热特性等方面的前沿研究进展. 最后讨论了电磁加载膨胀环试验技术在固体力学领域的发展前景与方向. 为从事材料动态力学行为试验技术领域的科研工作者提供较为系统的信息参考, 同时为那些对电磁加载膨胀环试验技术感兴趣的青年科研人员提供本领域系统全面的知识.Abstract: Electromagnetic loading expansion ring test technology is an important means to achieve high strain rate tensile loading, capable of achieving strain rates on the order of 104 s−1 for one-dimensional tensile loading. Electromagnetic Lorentz forces are uniformly applied to the expansion ring specimens as a body force, and the dynamic loading process does not involve stress wave propagation effects. Moreover, the characteristic structure of the ring specimens avoids the end grip effects seen with traditional dog-bone-shaped specimens. Therefore, electromagnetic loading expansion ring test technology is widely used in the study of the tensile mechanical behavior of materials at high strain rates. This paper first introduces the basic principles of dynamic loading expansion ring test technology, then discusses the disadvantages of explosion-driven expansion ring test technology and the advantages of electromagnetic-driven expansion ring test technology, and reviews the development history of electromagnetic loading expansion ring test technology. It then summarizes the cutting-edge research progress of electromagnetic loading expansion ring test technology in the dynamic mechanical properties of materials, dynamic fracture behavior, dynamic ductile behavior, and high-temperature adiabatic properties. Finally, it discusses the development prospects and directions of electromagnetic loading expansion ring test technology in the field of solid mechanics. This provides a relatively systematic reference for researchers engaged in the experimental technology field of dynamic mechanical behavior of materials and offers a comprehensive and systematic knowledge of the field for young researchers interested in electromagnetic loading expansion ring test technology.

-

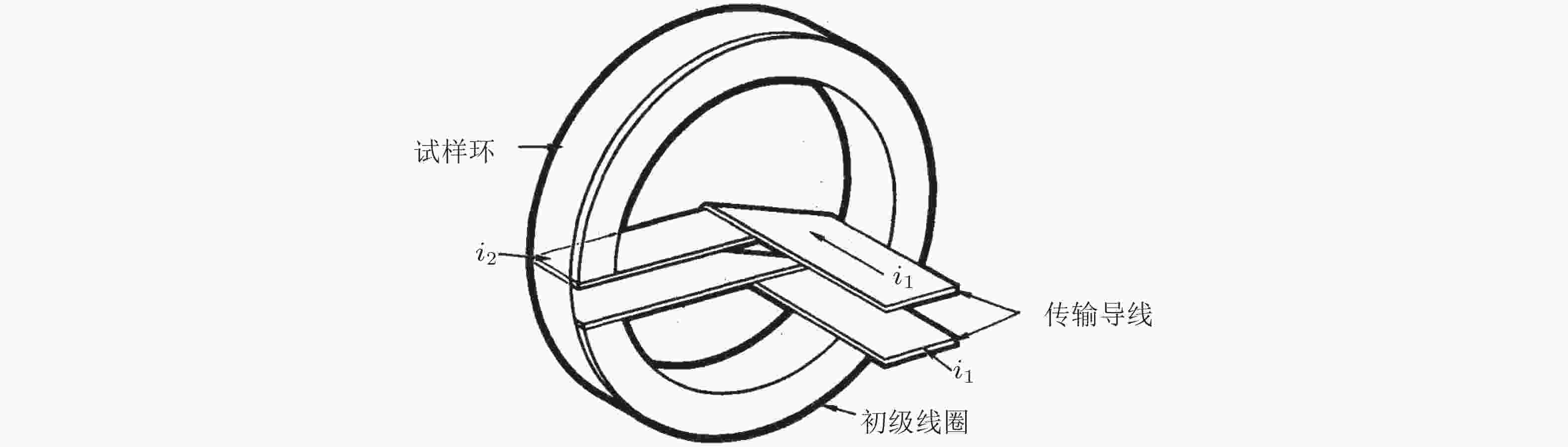

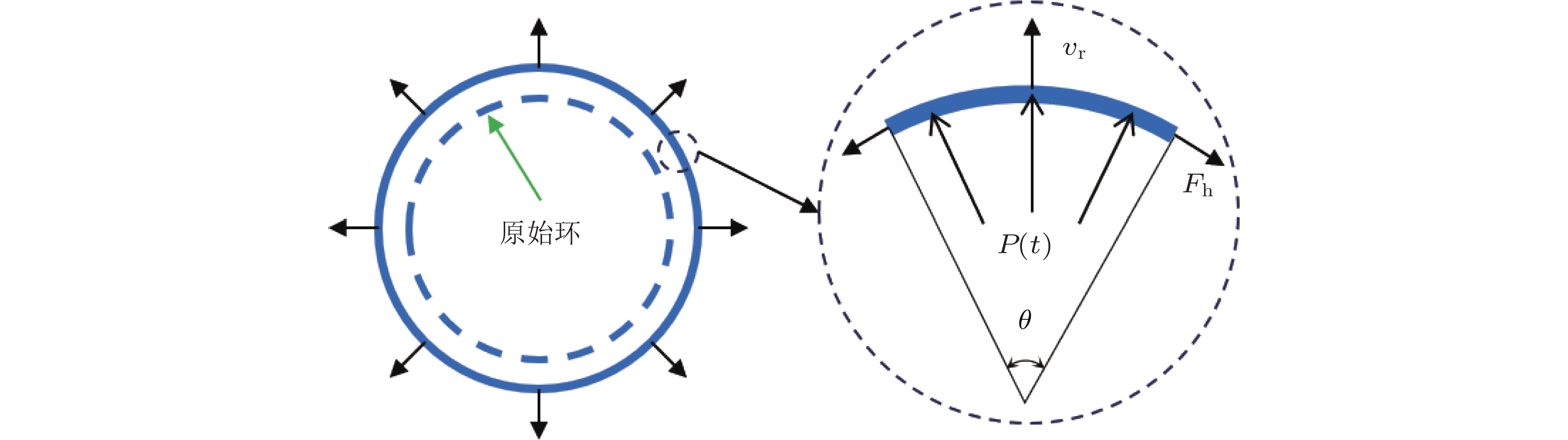

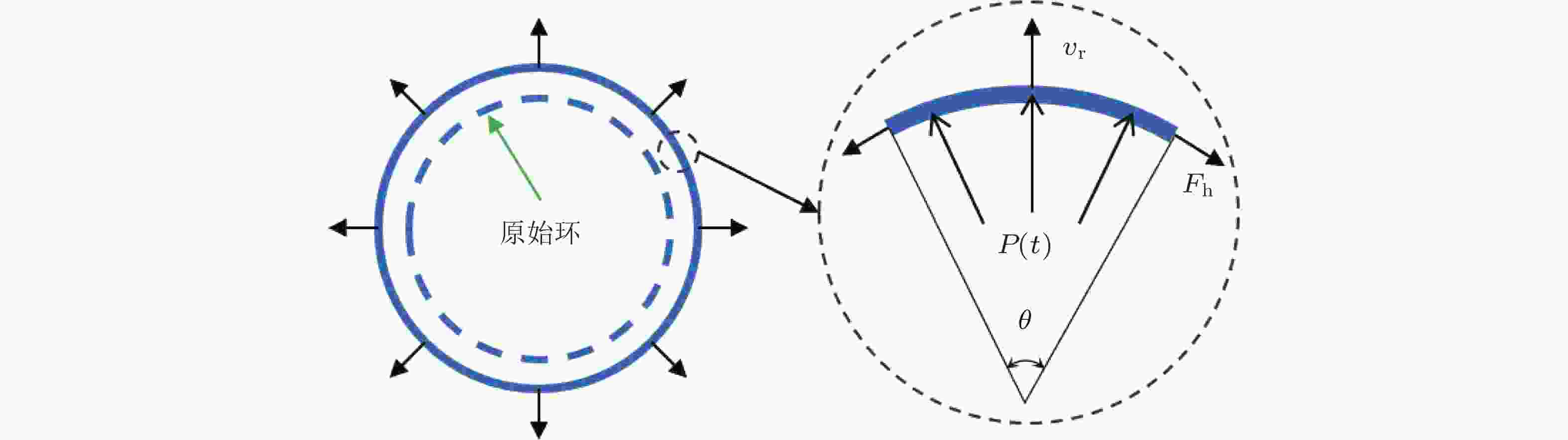

图 1 膨胀环原理示意图(Johnson et al. 1963)

图 2 Walling的电磁加载系统(Forrestal & Walling 1972)

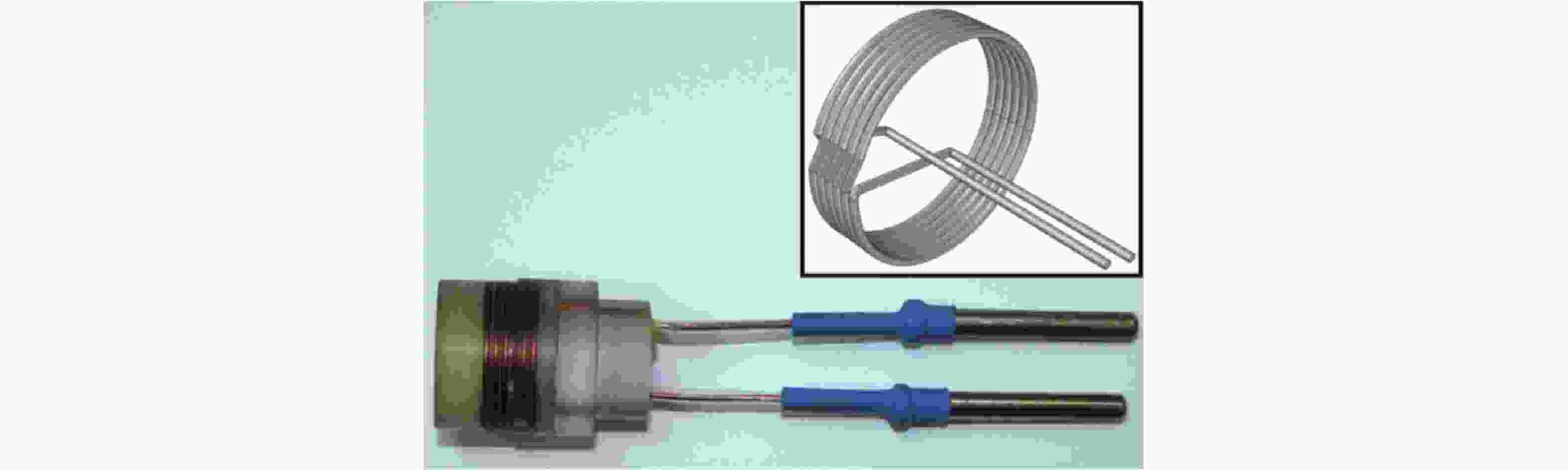

图 3 Grady设计的电磁膨胀环线圈及试样系统(Grady & Benson 1983)

图 4 Gourdin所设计的电磁驱动原理示意图(Gourdin 1989c)

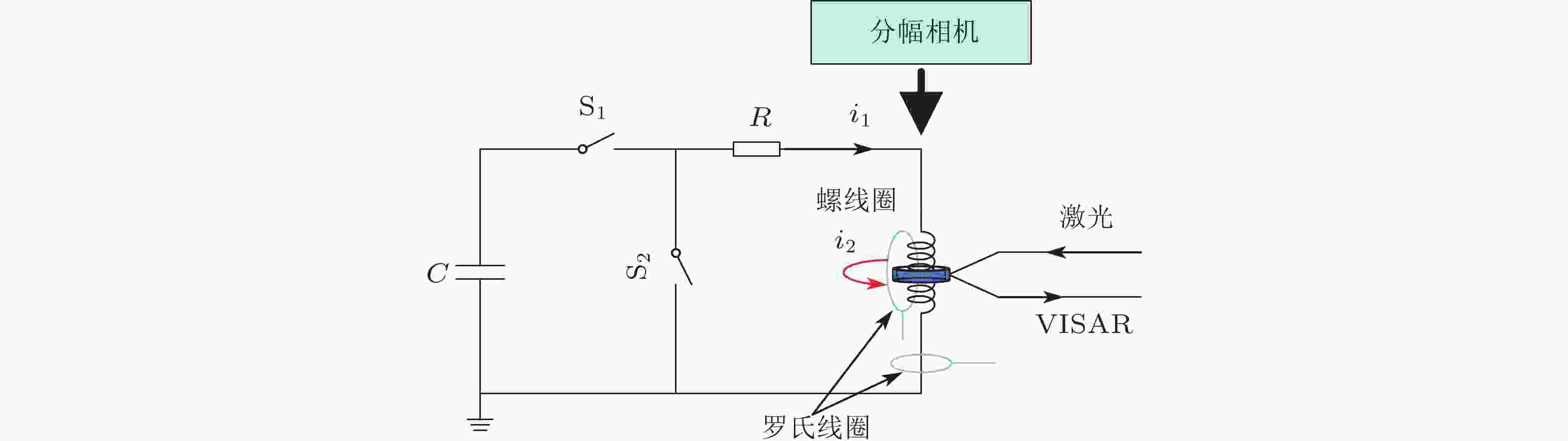

图 5 截流方式影响. (a)短路截流方式, (b)断路截流方式(俞鑫炉 等 2017)

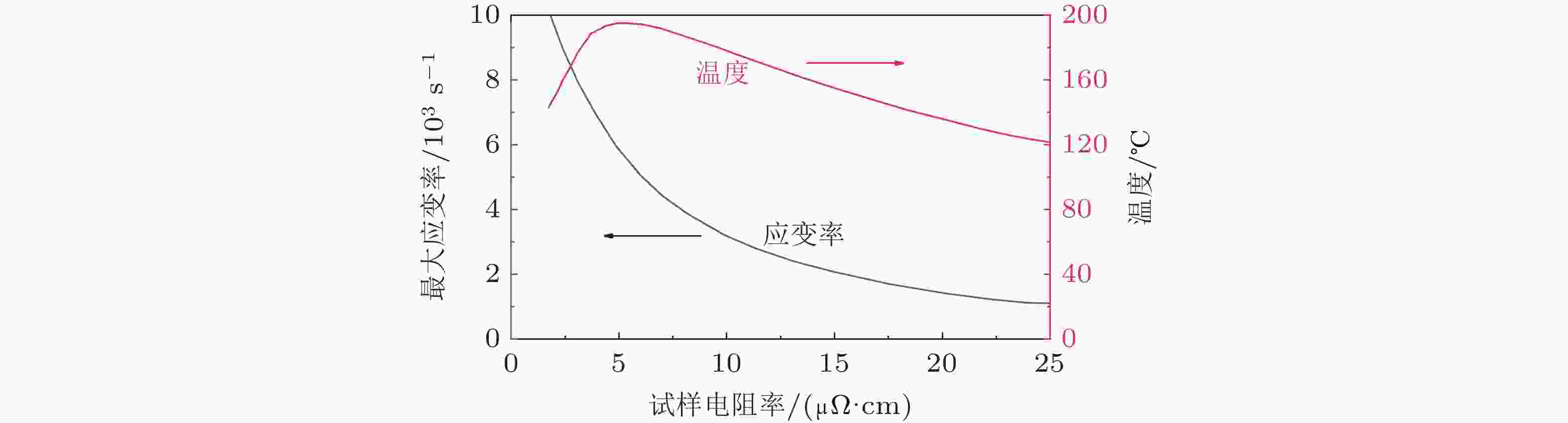

图 6 材料电阻率对电磁加载结果的影响(Gourdin et al. 1989b, Gourdin 1989c)

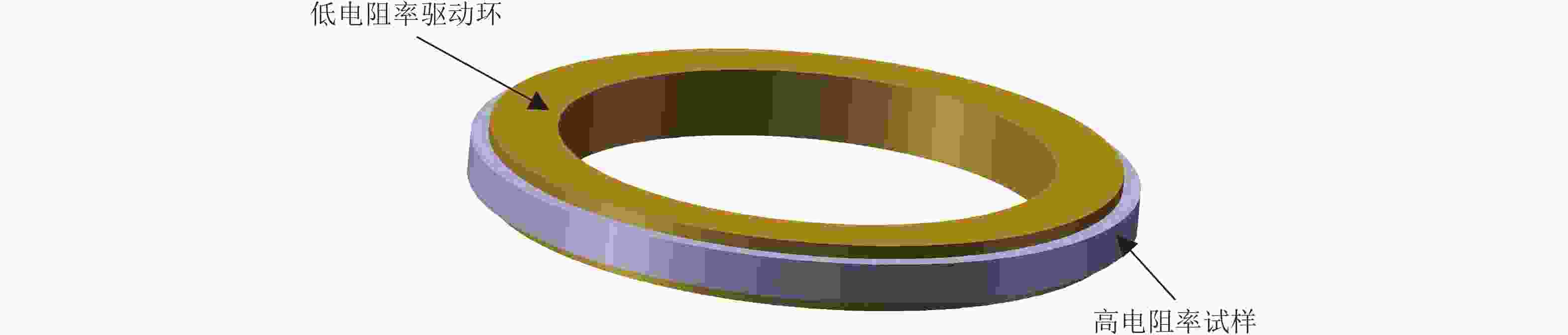

图 7 膨胀环复合加载方案(Gourdin 1989c)

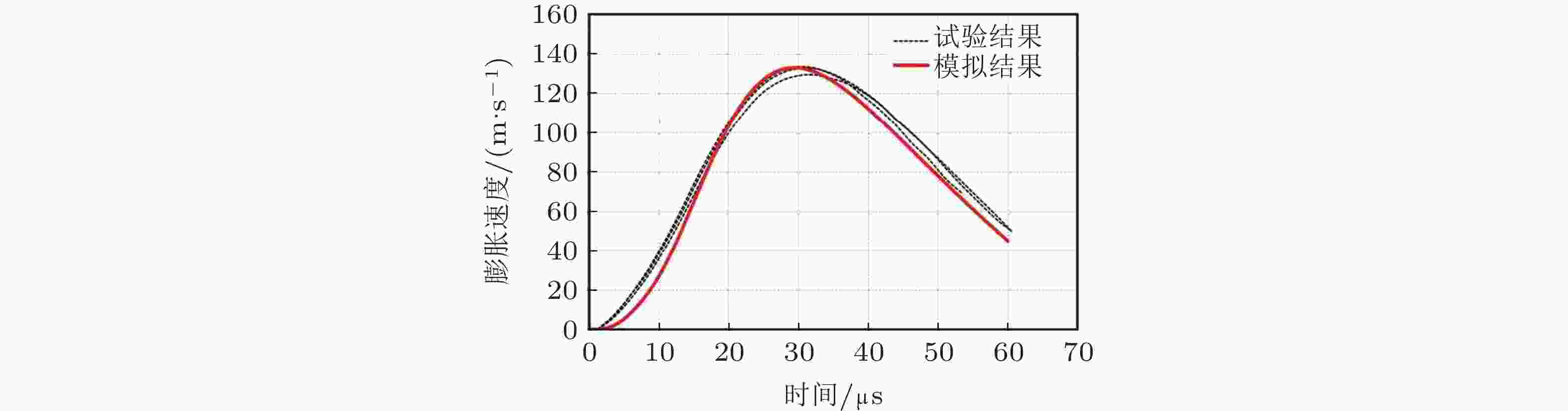

图 8 X37CrMoV51钢的膨胀速度曲线试验与模拟对比(Janiszewski & Panowicz 2013)

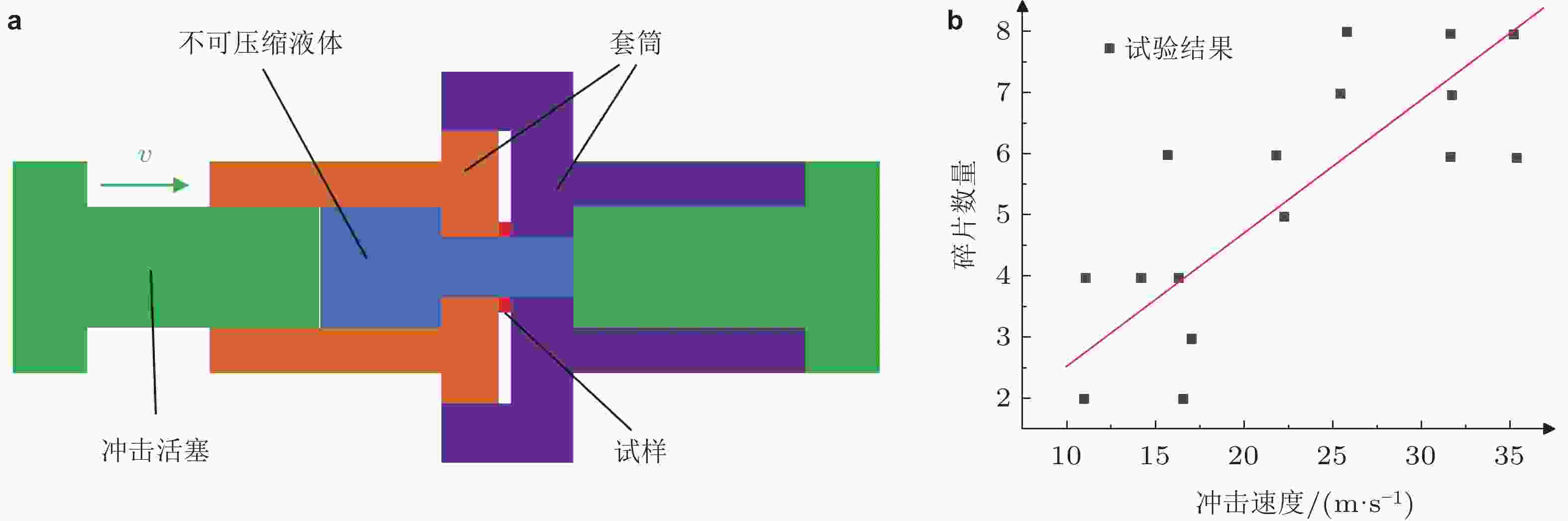

图 9 液压加载膨胀环. (a)试验原理, (b)铝环碎片数量与冲击速度关系 (郑宇轩 2013)

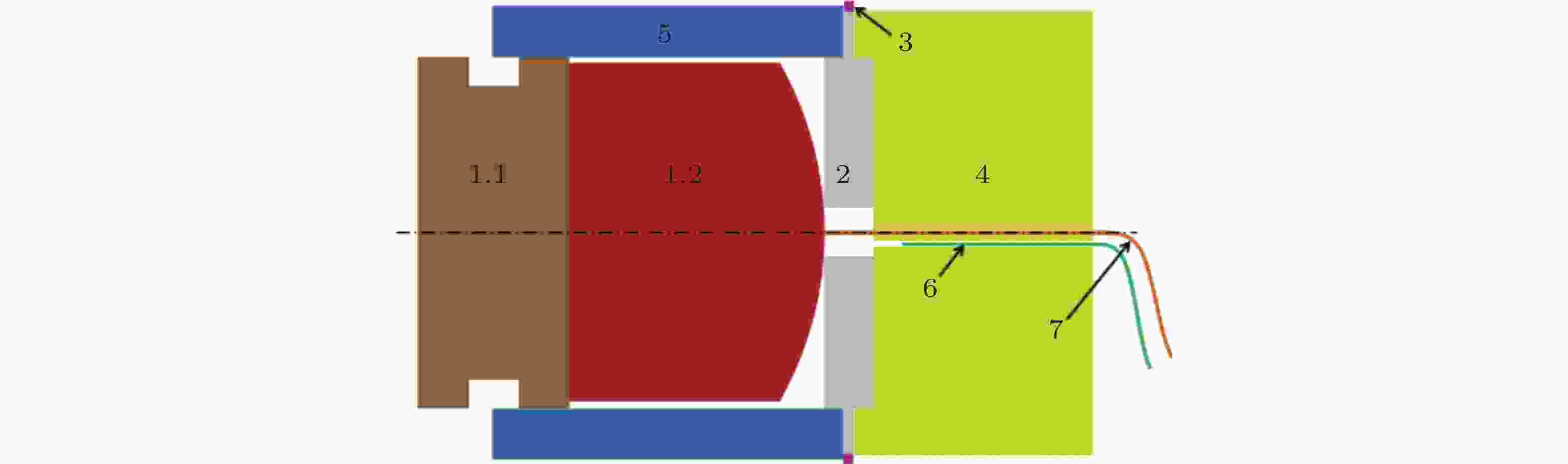

图 10 冲击驱动圆环膨胀装置原理. 1.1 弹丸引导结构, 1.2冲击弹丸, 2 HDPE圆盘, 3试样, 4 钢砧, 5 圆盘引导结构, 6 测试探头, 7 接触传感器 (Fanny et al. 2021)

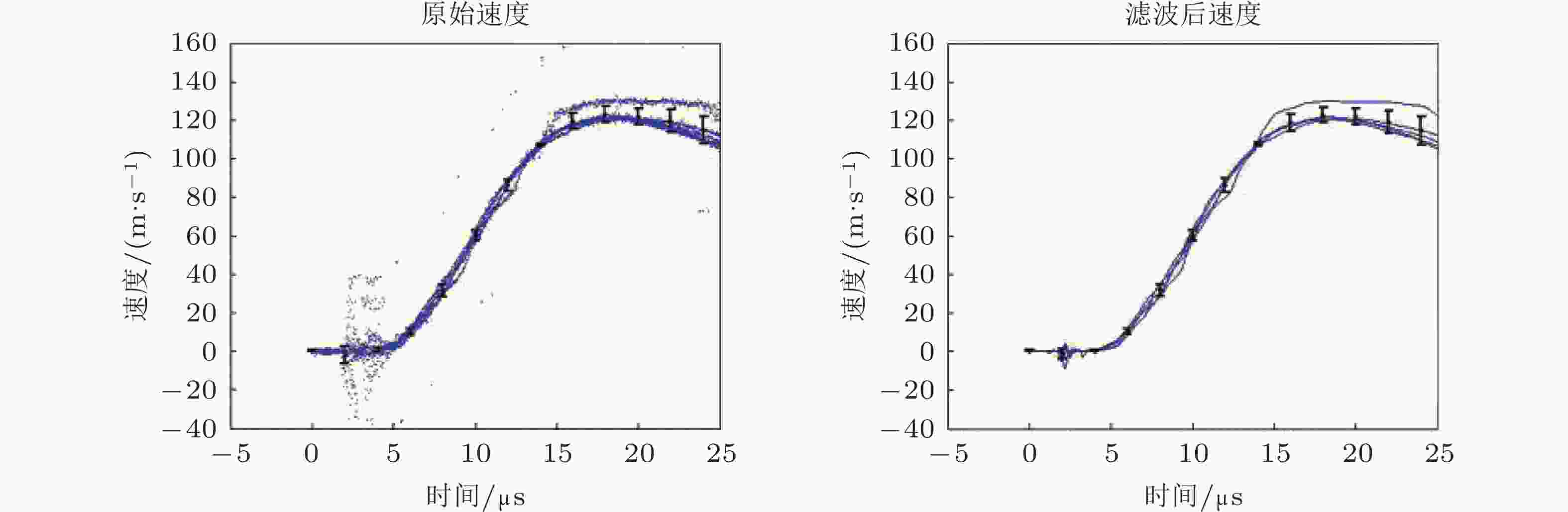

图 11 VISAR测试结果(Landen et al. 2005)

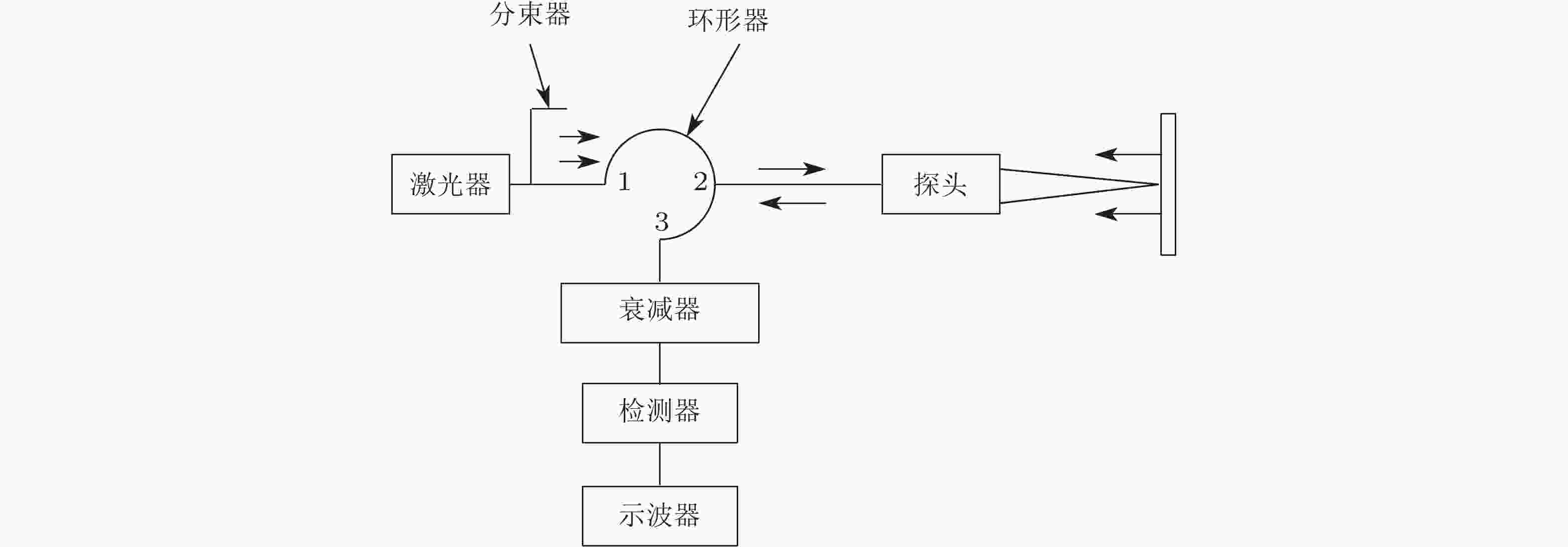

图 12 PDV系统示意图(Johnson et al. 2009)

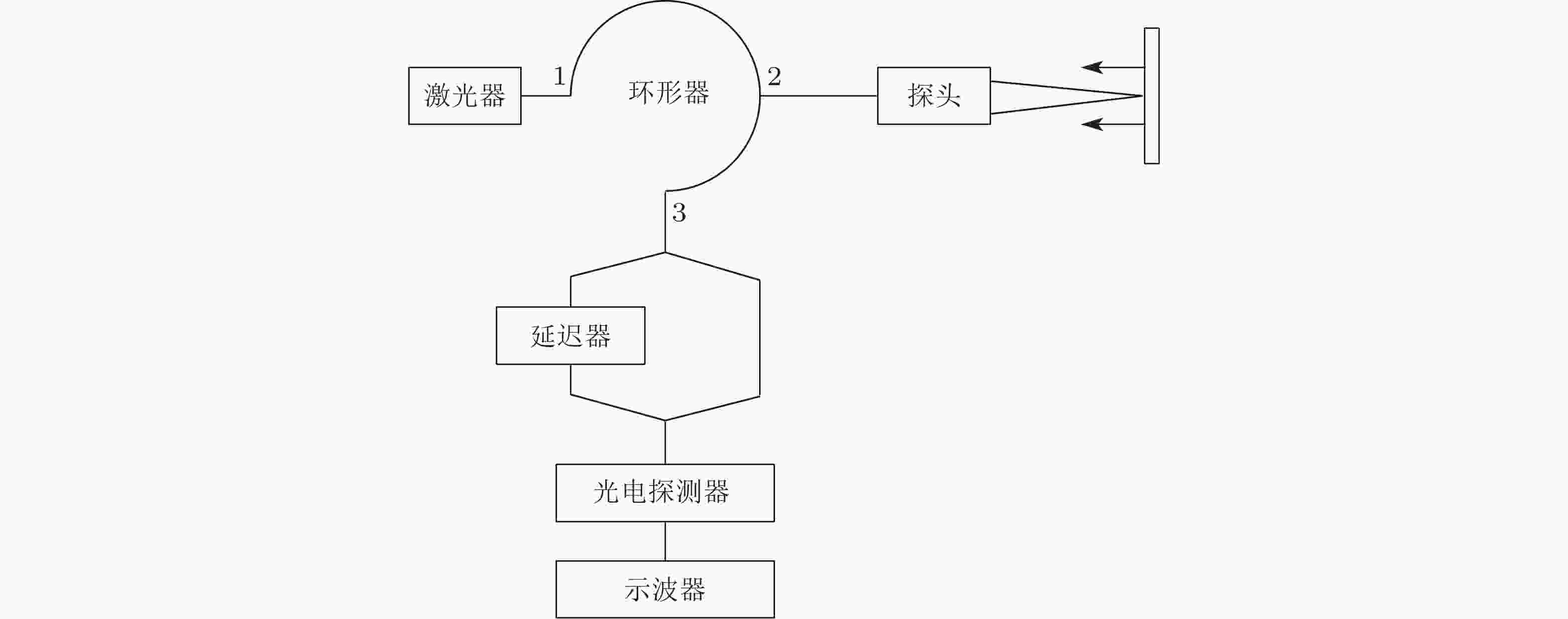

图 13 PDV系统示意图(Johnson et al. 2010)

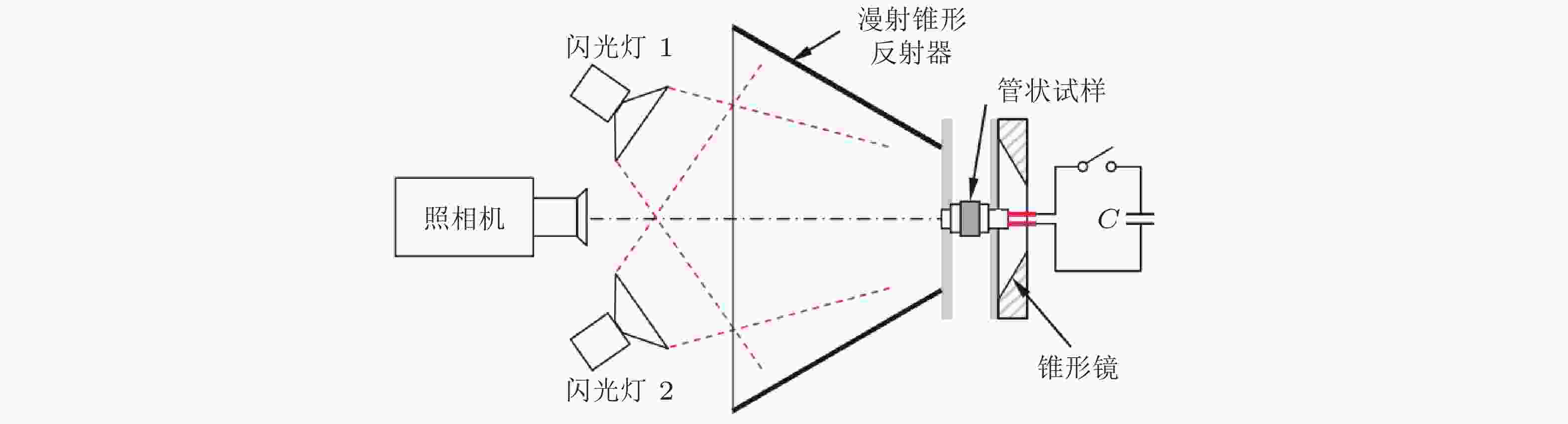

图 14 锥形反射镜检测系统示意图(Zhang & Ravi-Chandar 2010)

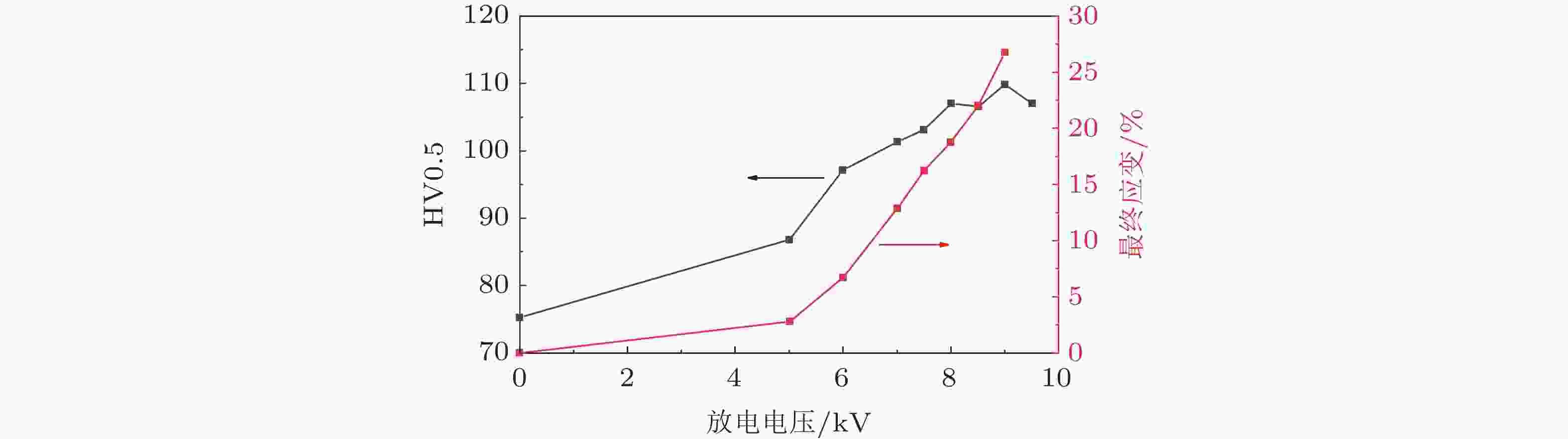

图 15 放电电压对最终应变和维氏硬度的影响(Huang et al. 2014)

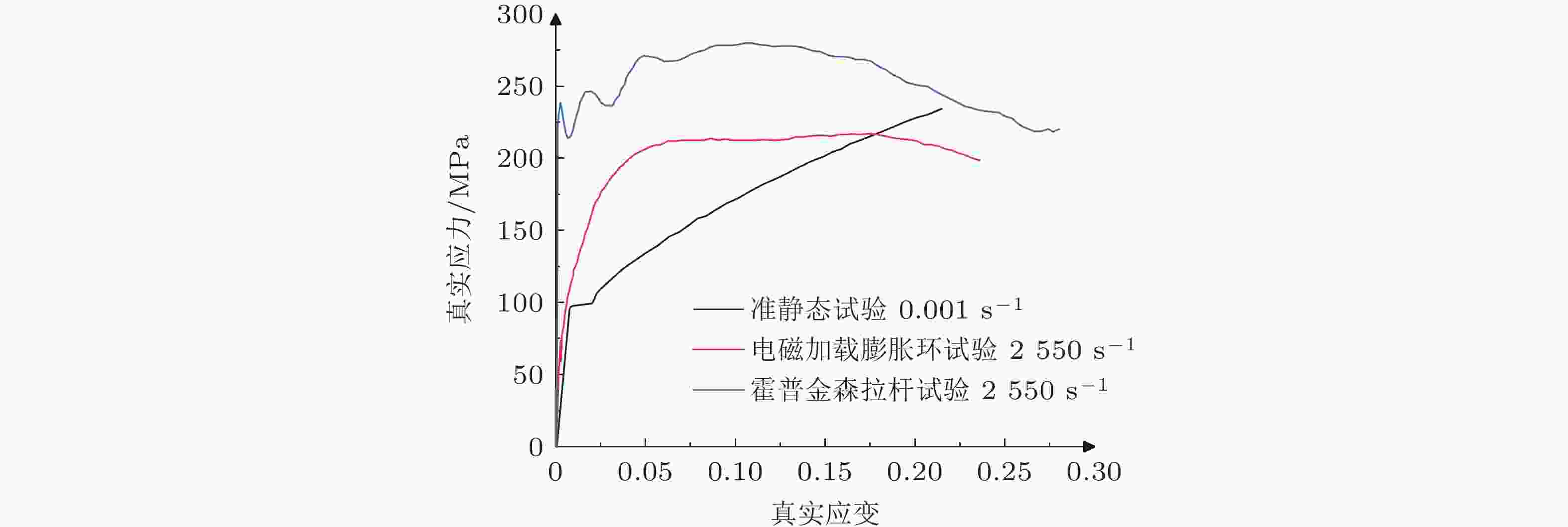

图 16 不同加载方式下的应力−应变曲线(Ma et al. 2021)

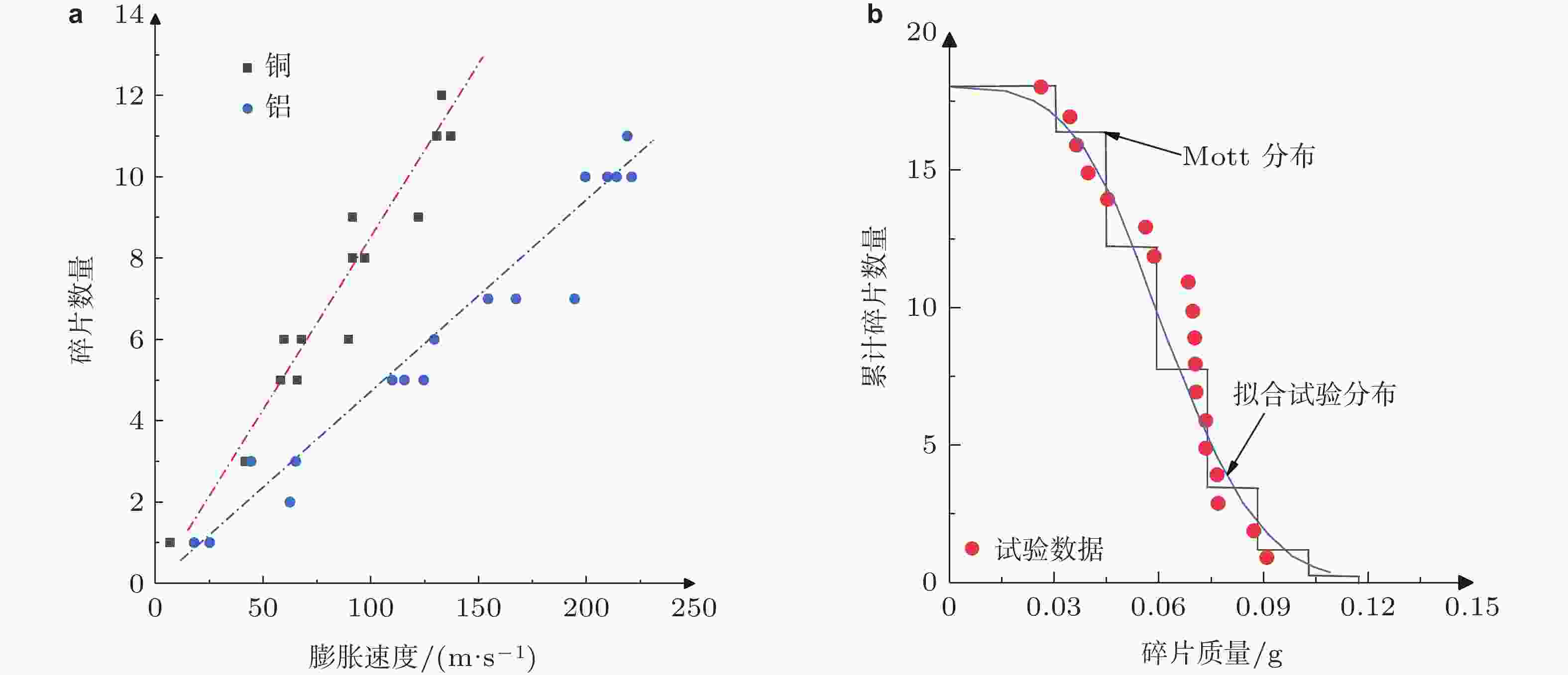

图 17 Grady的研究结果. (a)碎片数量与膨胀速度相关性(Grady & Benson 1983), (b)试验与mott理论预测对比(Grady & Olsen 2003)

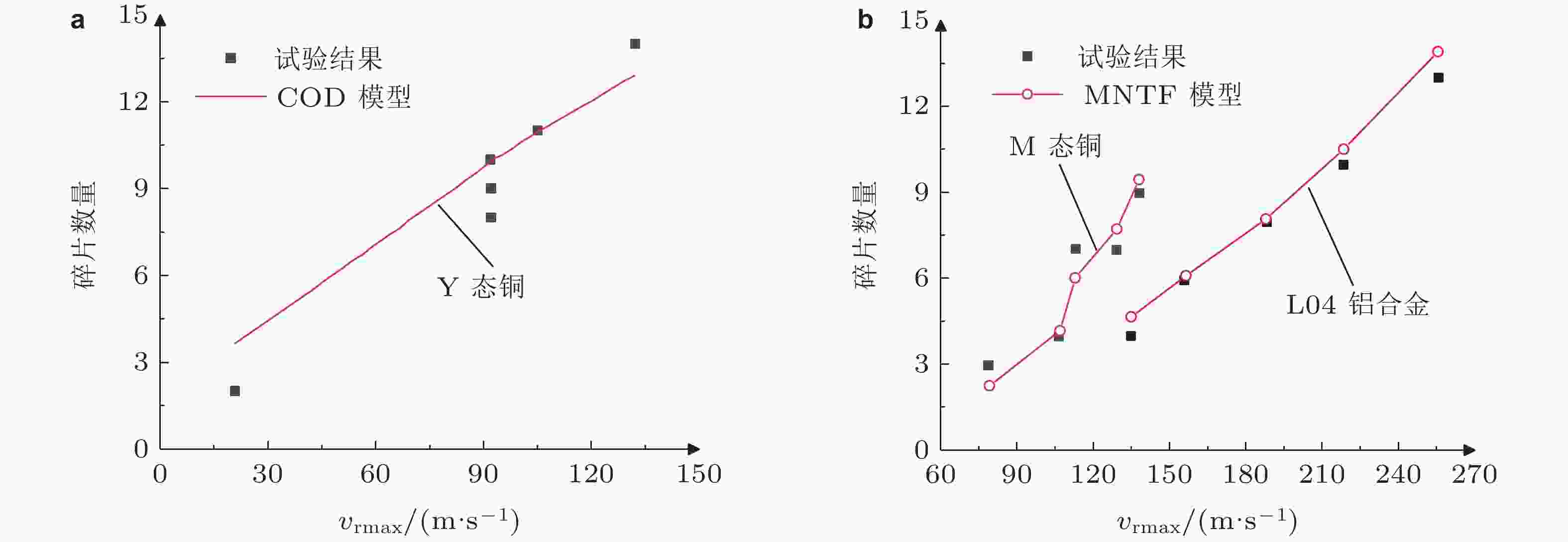

图 18 碎片数量与最大膨胀速度关系. (a) COD模型, (b) MNTF模型 (桂毓林 2007)

图 19 镁合金环的颈缩碎裂(Kahana et al. 2015)

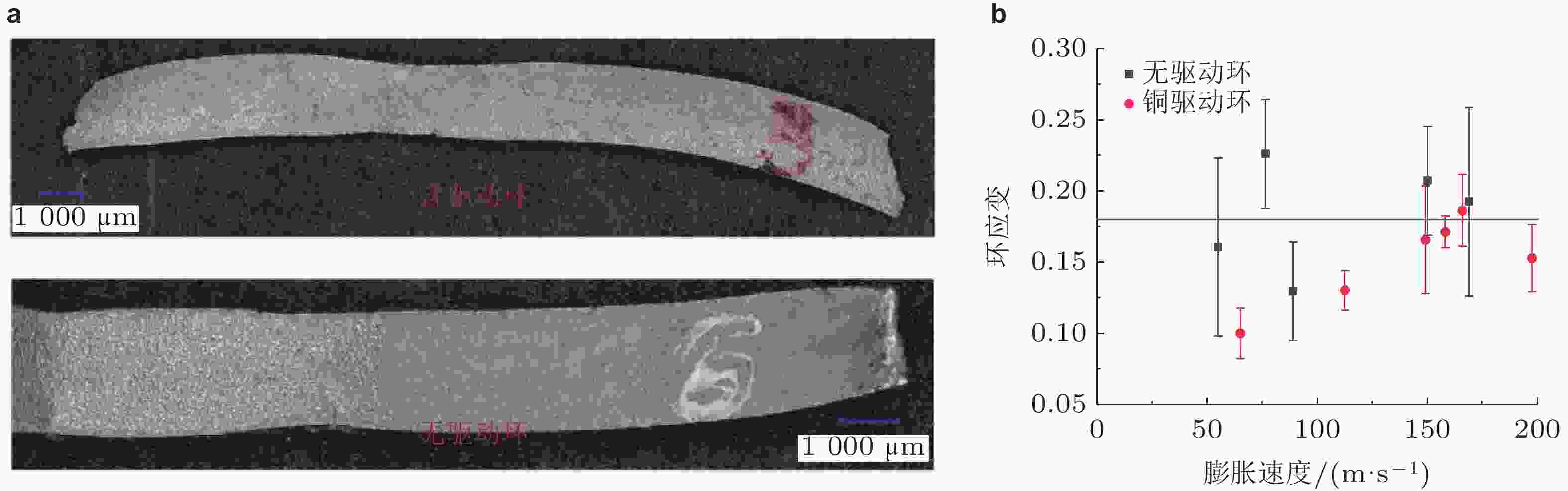

图 20 热效应对AZ31镁合金影响. (a)颈缩对比图, (b)平均应变与膨胀速度关系(Nicolas & Krishnaswamy 2018)

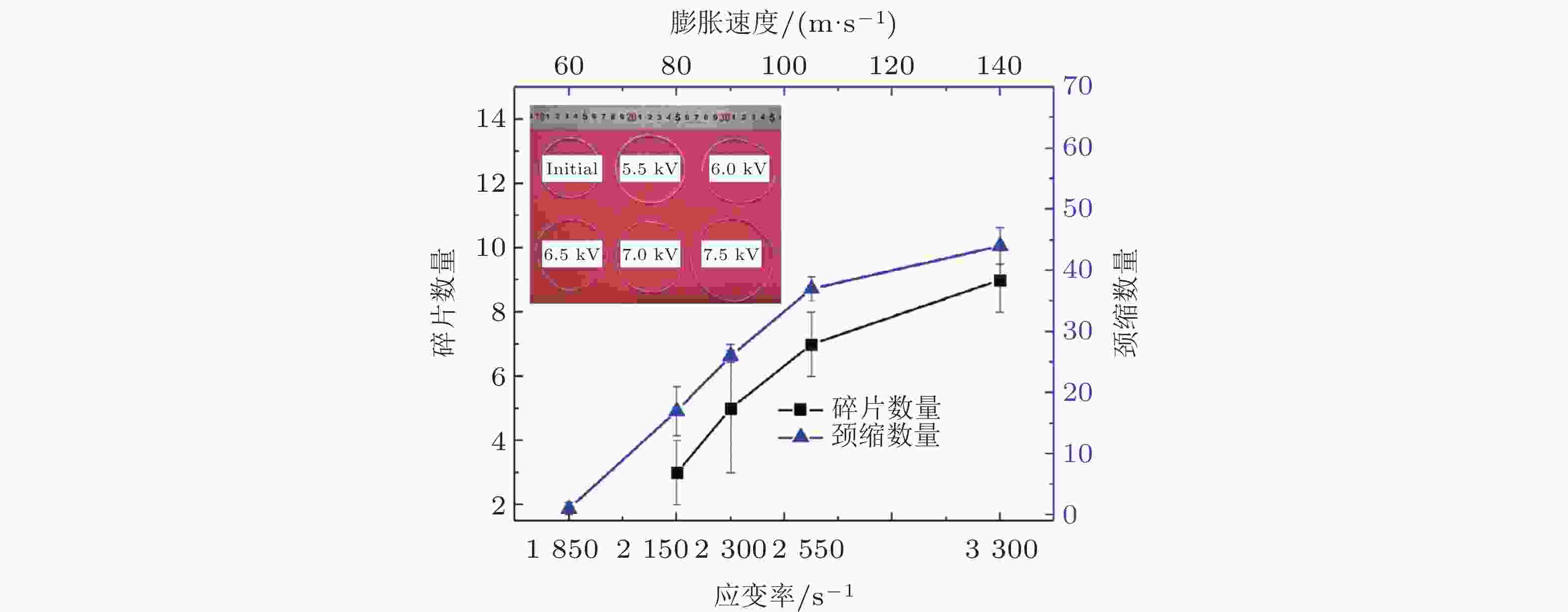

图 21 膨胀速度对颈缩和碎片数量影响(Ma et al. 2021)

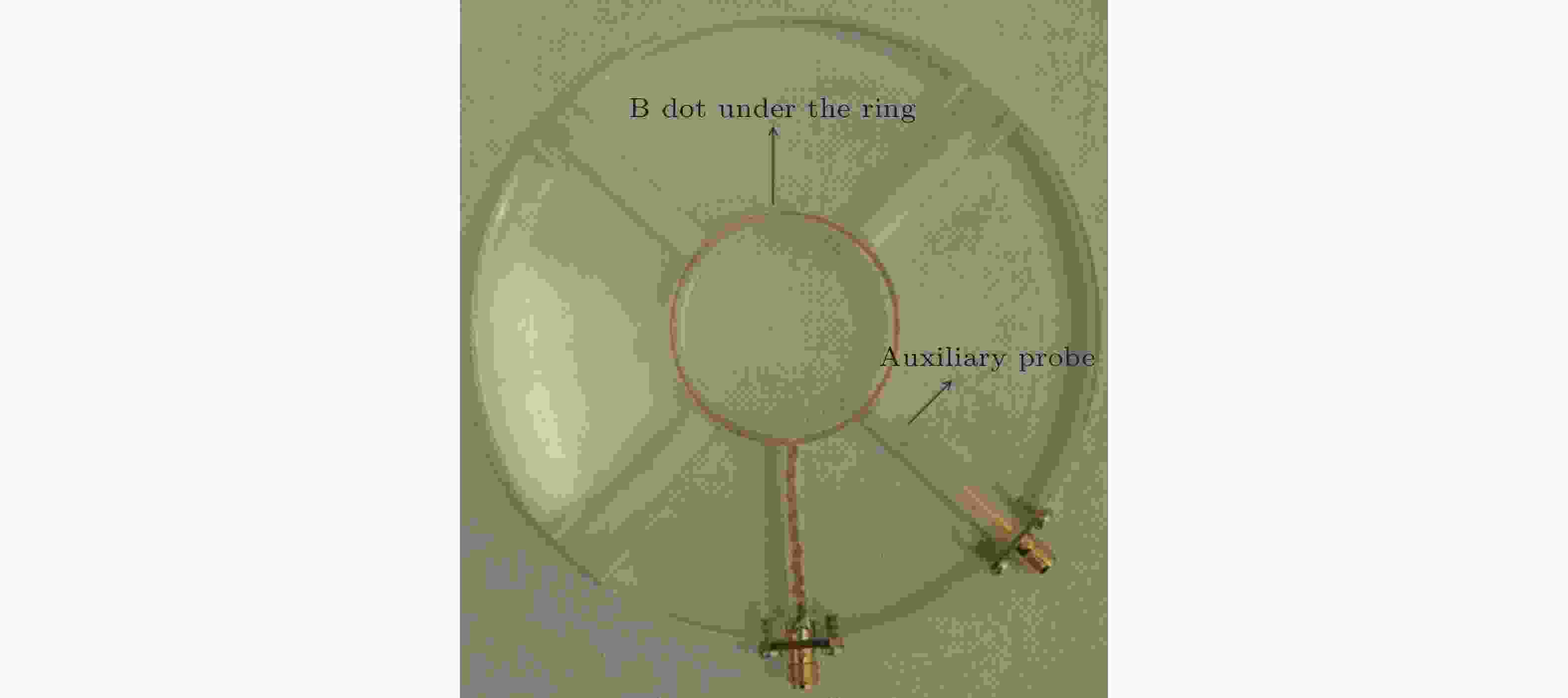

图 22 探针布置位置(Dan et al. 2020)

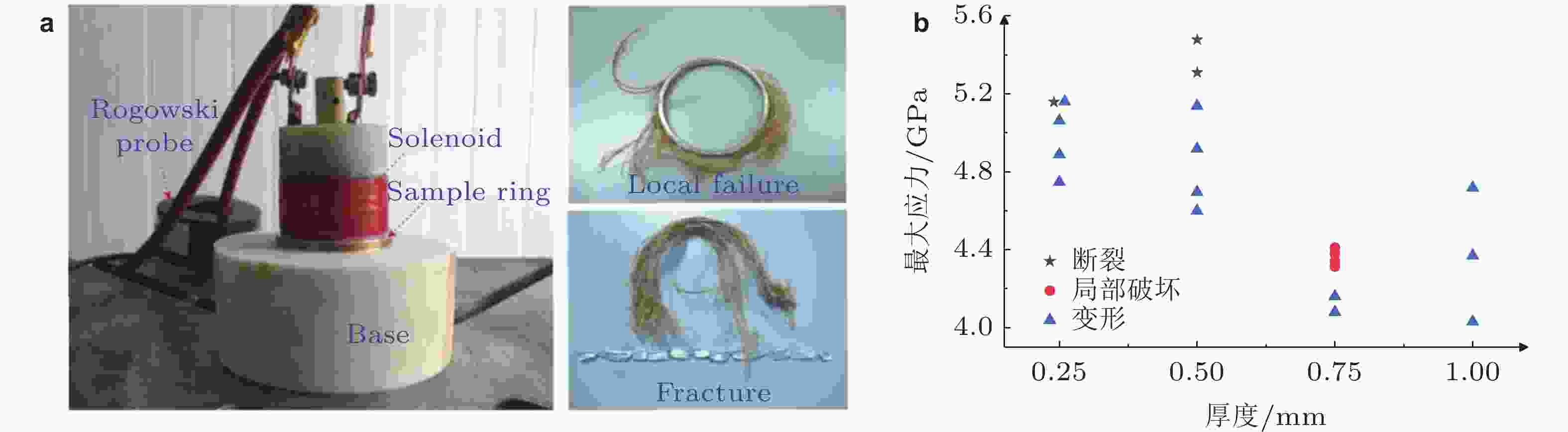

图 23 Zylon/epoxy复合材料电磁加载研究. (a)实验装置与结果, (b)破坏应力与试样厚度关系(Jiang et al. 2016)

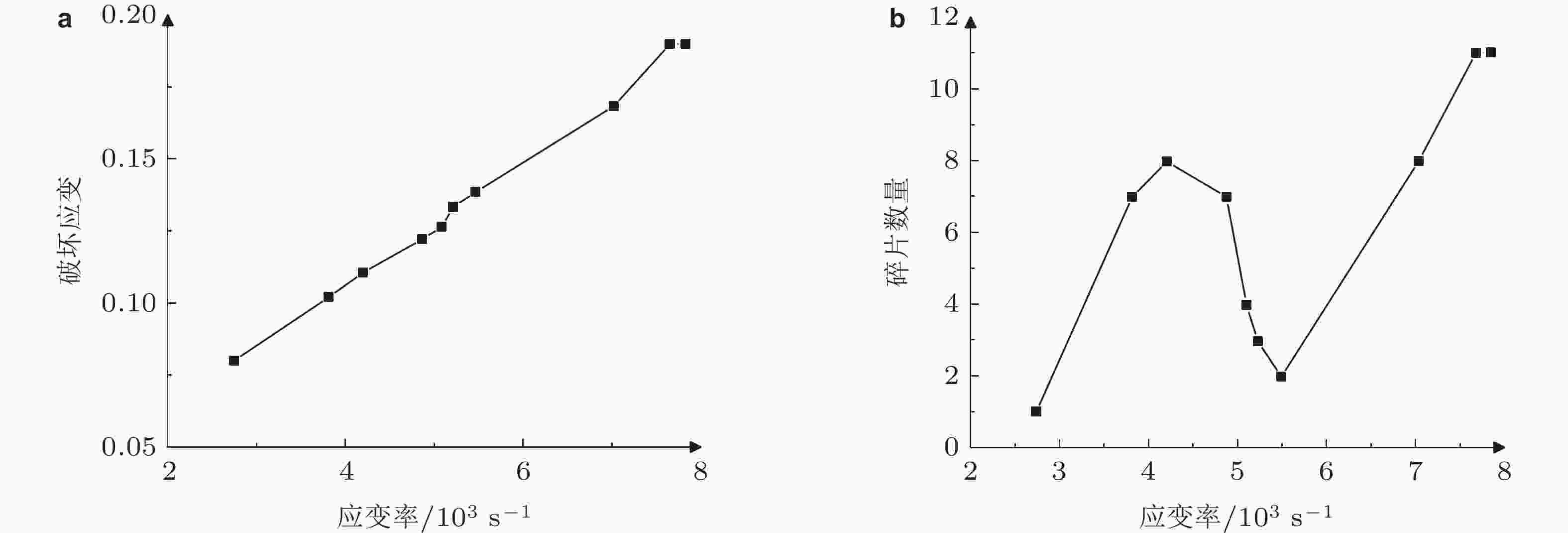

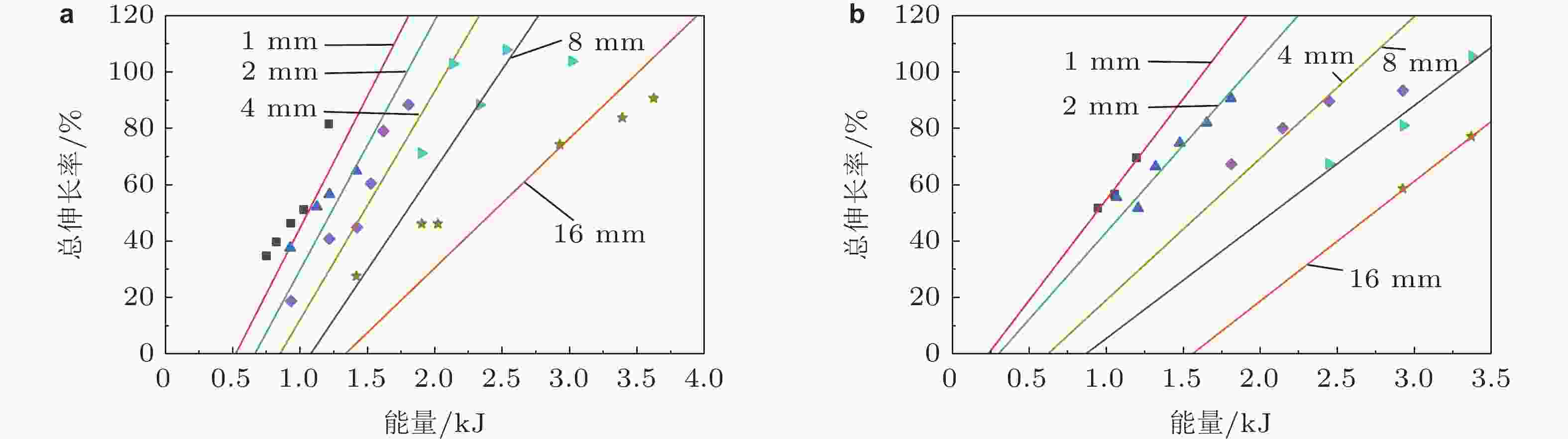

图 24 应变率对动态碎裂的影响. (a)失效应变, (b)碎片数量(Yang et al. 2016)

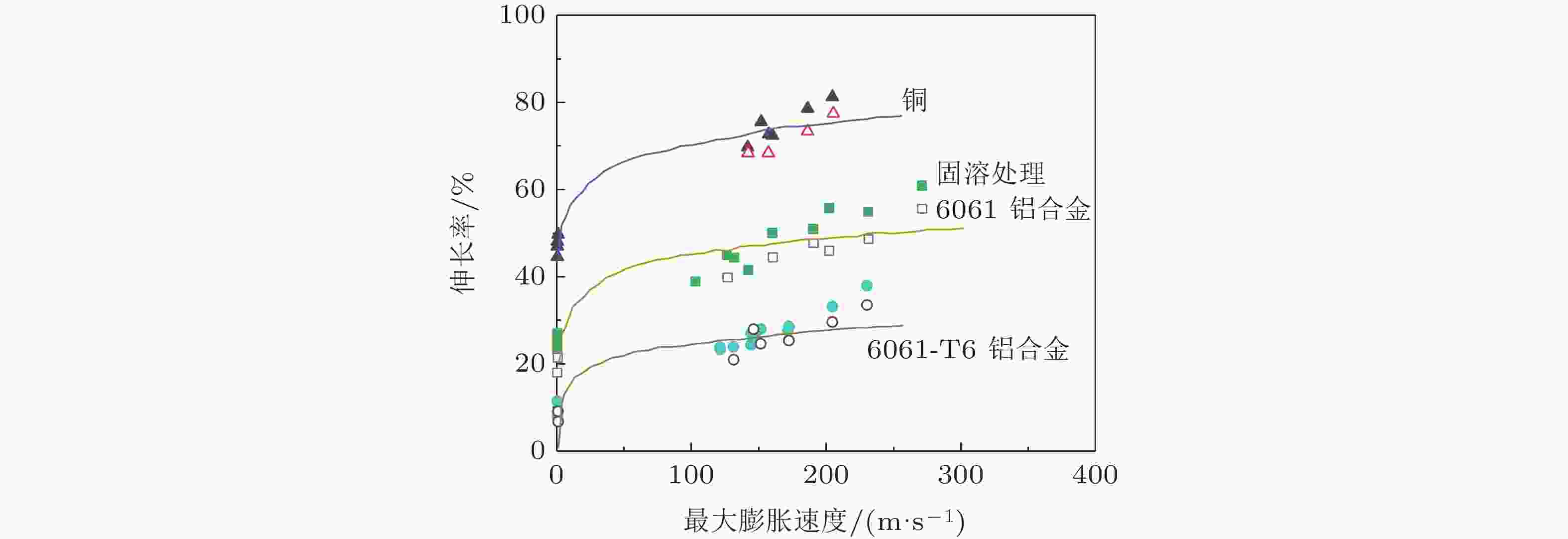

图 25 膨胀速度对铜、6061铝合金和6061-T6铝合金影响. 实心表示总伸长率, 空心表示均匀伸长率 (Altynova et al. 1996)

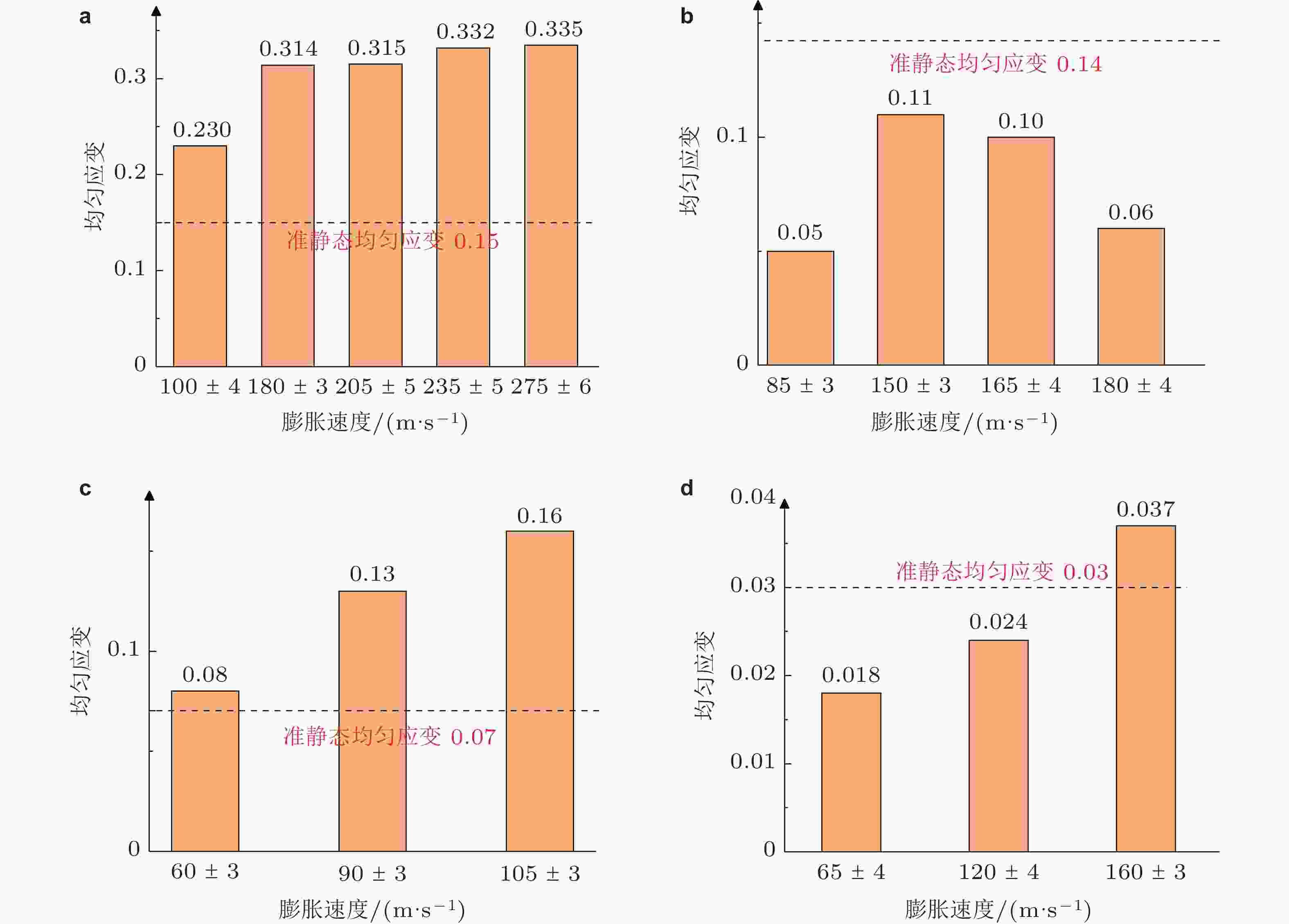

图 26 4种材料动态延性性能. (a) 冷轧铜Cu-ETP, (b) 7075铝合金, (c) 枪管钢, (d) 钨合金 (Janiszewski 2012b)

图 27 试样宽度对延性的影响. (a) 6061-T4铝合金, (b)铜 (Tamhane et al. 1996)

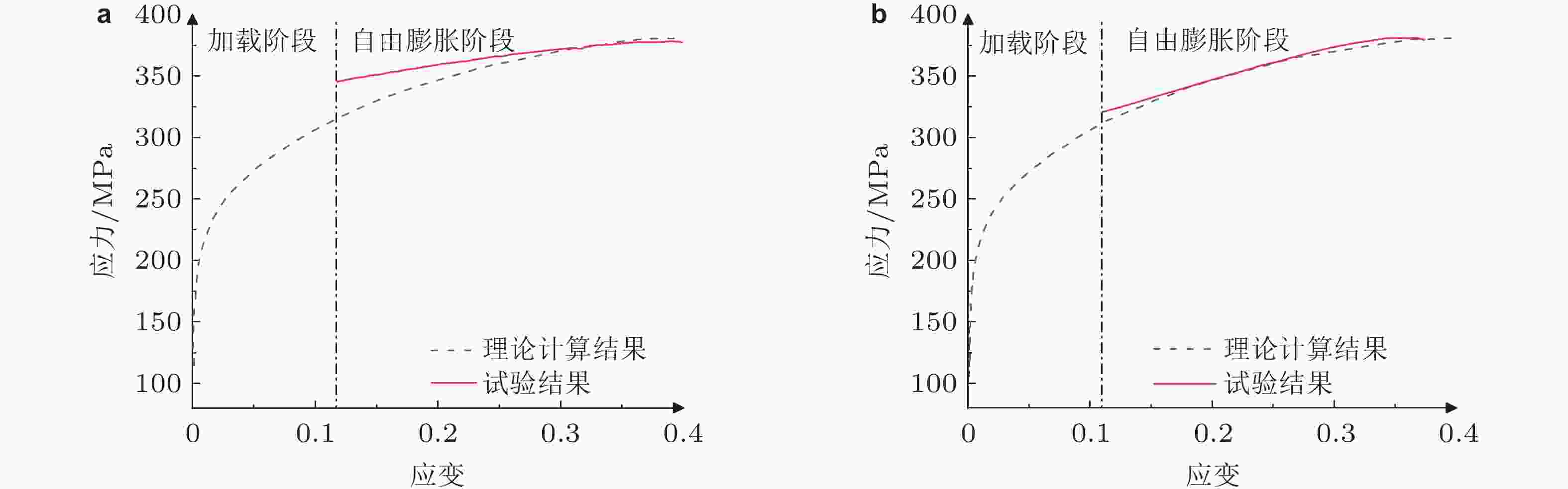

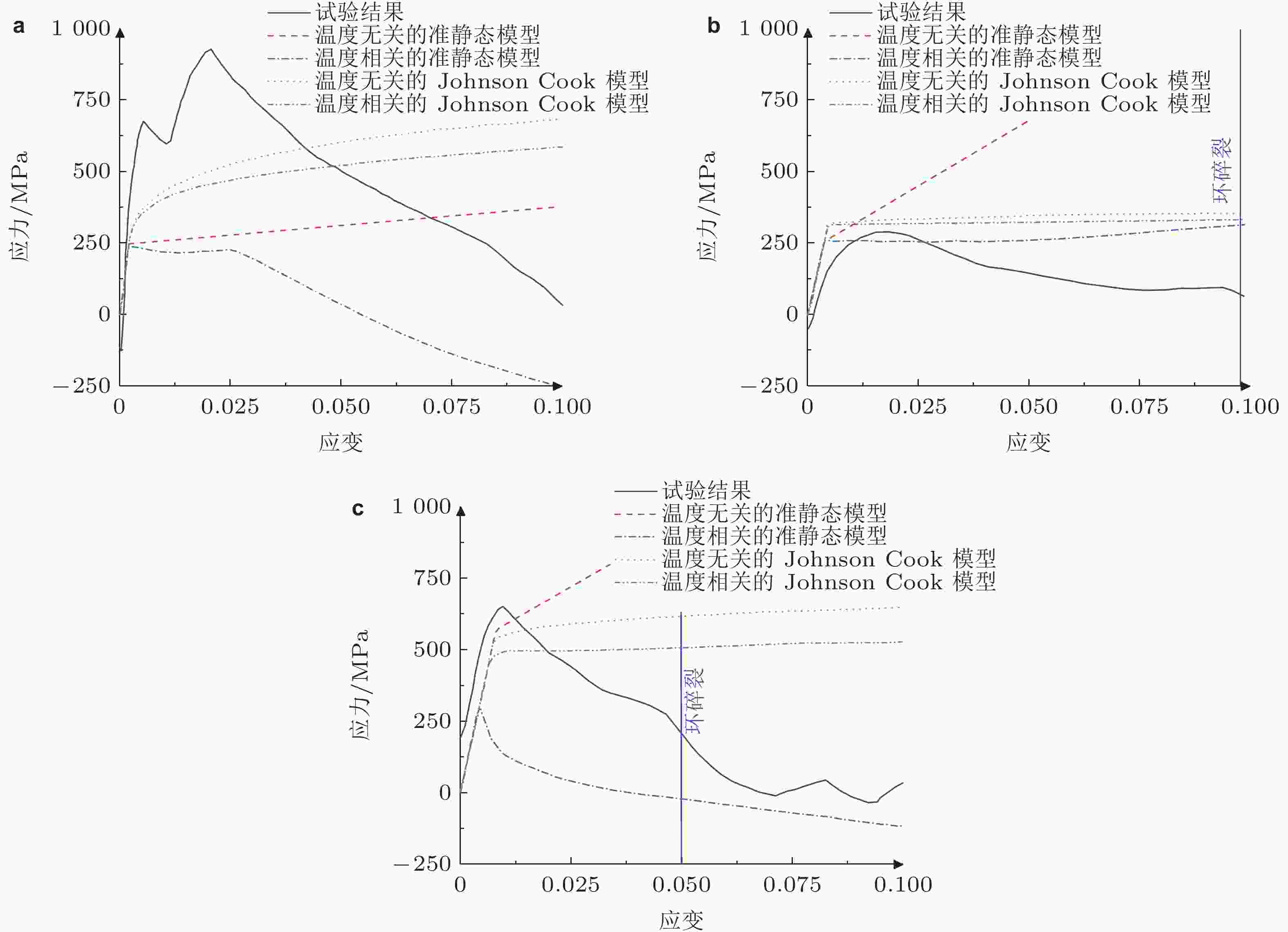

图 28 3种材料电磁膨胀环测试结果与数值计算结果对比. (a)

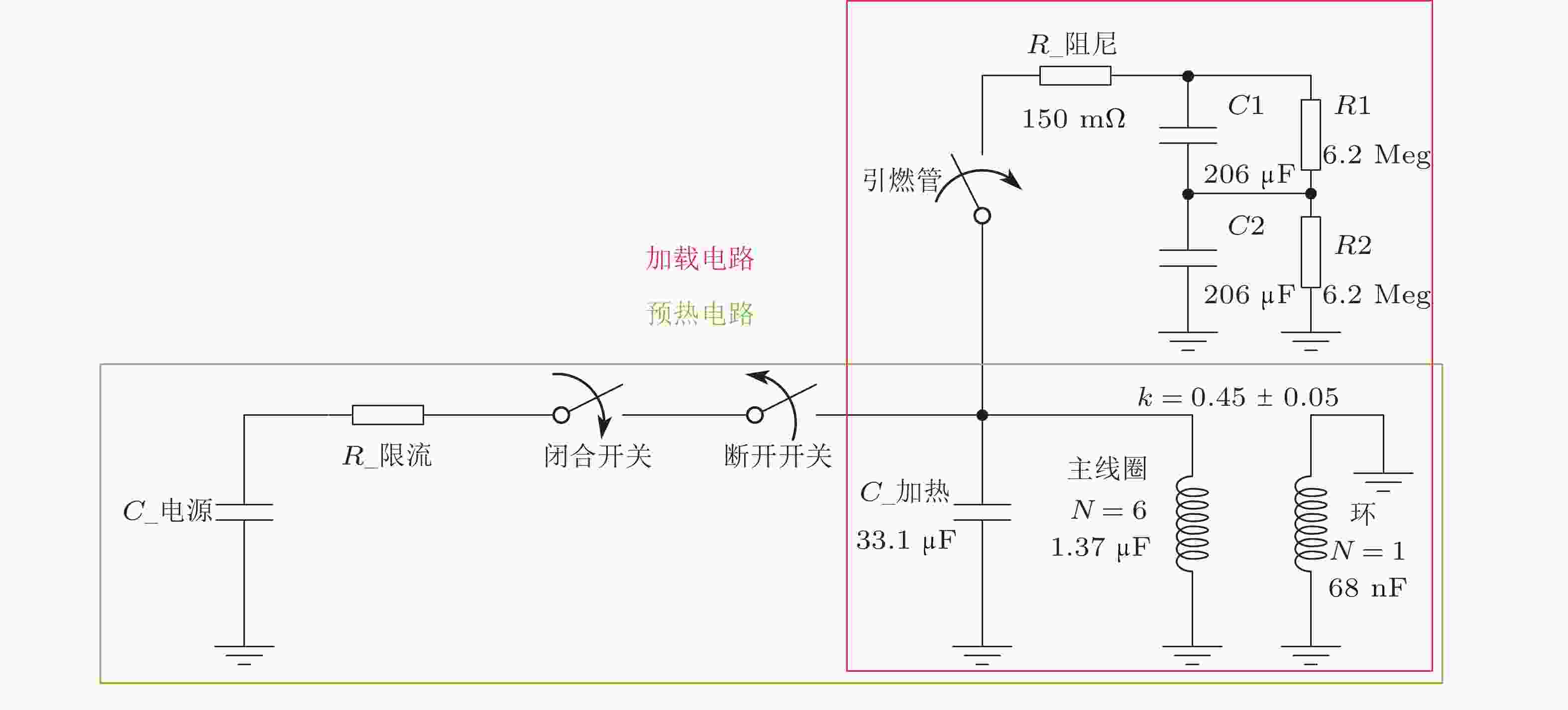

11000 铜, (b) 6061-T6铝合金, (c) 7075-T6铝合金(Satapathy & Landen 2006)图 29 预热电路和加载电路(Wetz et al. 2011)

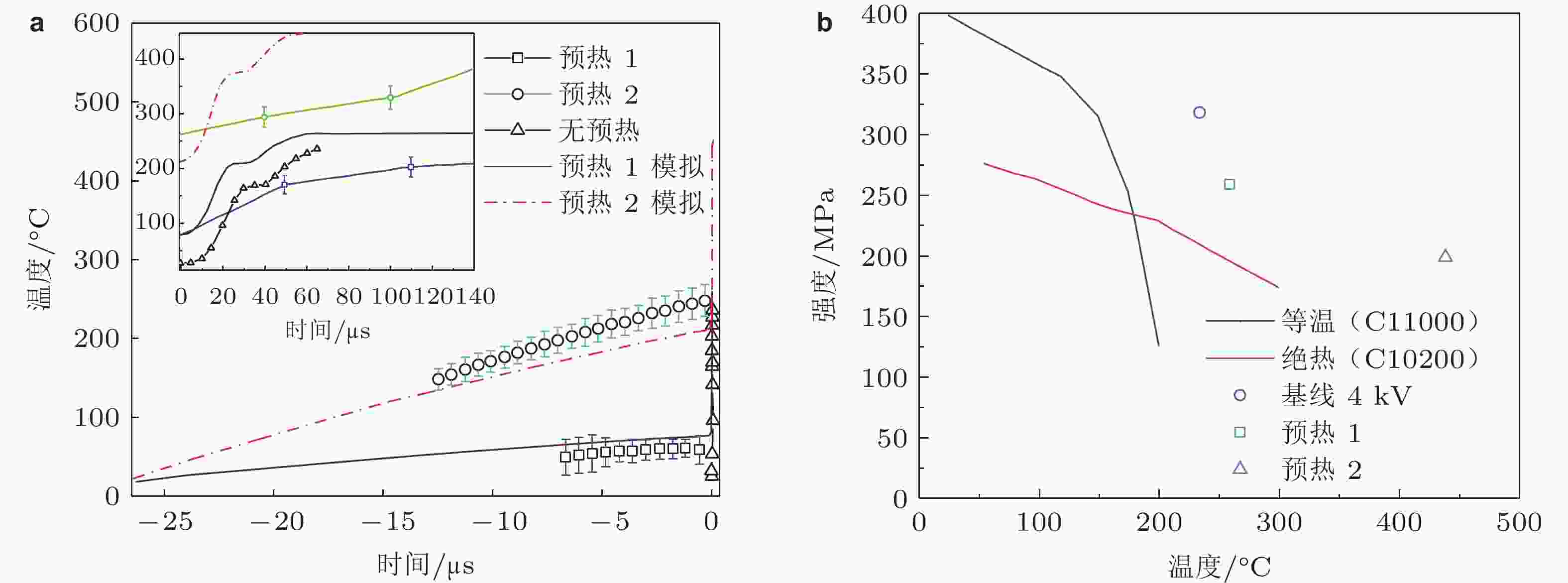

图 30 铜的高温特性研究. (a)预热温升, (b)强度对比(Landen et al. 2008, Weggel et al. 1994)

-

[1] 桂毓林. 2007. 电磁加载下金属膨胀环的动态断裂与碎裂研究. [博士论文]. 中国工程物理研究院 (Gui Y L. 2007. The study on the dynamic fracture and fragmentation of metal freely expanding ring driven by electromagnetically loading. [PhD Thesis] . Beijing: China Academy of Engineering Physics).Gui Y L. 2007. The study on the dynamic fracture and fragmentation of metal freely expanding ring driven by electromagnetically loading. [PhD Thesis] . Beijing: China Academy of Engineering Physics. [2] 郭昭亮, 范诚, 刘明涛等. 2016. 膨胀环受力历史对应力应变关系的影响. 爆炸与冲击, 36(6): 819-824 (Guo Z L, Fan C, Liu M T, et al. 2016. Effect of loading history on stress-strain relationship of expanding ring. Explosion and Shock Waves, 36(6): 819-824). doi: 10.11883/1001-1455(2016)06-0819-06Guo Z L, Fan C, Liu M T, et al. 2016. Effect of loading history on stress-strain relationship of expanding ring. Explosion and Shock Waves, 36(6): 819-824. doi: 10.11883/1001-1455(2016)06-0819-06 [3] 郭昭亮. 2019. 高应变率加载下金属环与柱壳膨胀变形失稳以断裂研究. [博士论文]. 中国工程物理研究院 (Guo Z L. 2019. Research on expansion deformation instability and fracture of metal rings and cylindrical shells under high strain rate loading. [PhD Thesis]. China Academy of Engineering Physics).Guo Z L. 2019. Research on expansion deformation instability and fracture of metal rings and cylindrical shells under high strain rate loading. [PhD Thesis]. China Academy of Engineering Physics. [4] 李嘉皓, 徐便, 郑宇轩等. 2023. 液压膨胀环恒应变率加载技术. 爆炸与冲击, 43 (2): 119-127 (Li J H, Xu B, Zheng Y X, et al. 2023. Constant strain-rate loading of liquid-driving expanding ring. Explosion and Shock Waves, 43 (2): 119-127).Li J H, Xu B, Zheng Y X, et al. 2023. Constant strain-rate loading of liquid-driving expanding ring. Explosion and Shock Waves, 43(2): 119-127. [5] 李天密. 2018. PMMA圆环动态拉伸碎裂特征研究. [硕士论文]. 宁波大学 (Li T M. 2018. Research on dynamic tensile fragmentation characteristics of PMMA ring. [Master Thesis]. Ningbo University).Li T M. 2018. Research on dynamic tensile fragmentation characteristics of PMMA ring. [Master Thesis]. Ningbo University. [6] 李天密, 张佳, 方继松等. 2018. PMMA膨胀环动态拉伸碎裂实验研究. 力学学报, 50 (4): 820-827 (Li T M, Zhang J, Fang J S, et al. 2018. Experimental study of the high velocity expansion and fragmentation of PMMA rings. Chinese Journal of Theoretical and Applied Mechanics, 50 (4): 820-827).Li T M, Zhang J, Fang J S, et al. 2018. Experimental study of the high velocity expansion and fragmentation of PMMA rings. Chinese Journal of Theoretical and Applied Mechanics, 50(4): 820-827. [7] 卢思凡, 张佳, 王珠等. 2019. 液压膨胀环动态拉伸碎裂的有限元模拟. 固体力学学报, 40 (4): 372-380 (Lu S F, Zhang J, Wang Z, et al. 2019. FEM simulation of dynamic fragmentation of liquid-driving expanding ring. Chinese Journal of Solid Mechanics, 40 (4): 372-380).Lu S F, Zhang J, Wang Z, et al. 2019. FEM simulation of dynamic fragmentation of liquid-driving expanding ring. Chinese Journal of Solid Mechanics, 40(4): 372-380. [8] 汤佳妮, 徐便, 郑宇轩等. 2021. 脆性膨胀环动态拉伸碎裂实验研究. 爆炸与冲击, 41 (1): 93-101 (Tang J N, Xu B, Zheng Y X, et al. 2021. Experimental study for dynamic fragmentation of brittle expansion rings. Explosion and Shock Waves, 41 (1): 93-101).Tang J N, Xu B, Zheng Y X, et al. 2021. Experimental study for dynamic fragmentation of brittle expansion rings. Explosion and Shock Waves, 41(1): 93-101. [9] 汤铁钢, 李庆忠, 陈永涛等. 2010a. 爆炸膨胀环一维应力假定的分析与讨论. 爆炸与冲击, 30(6): 577-582 (Tang T G, Li Q Z, Chen Y T, et al. 2010a. Discussion about one-dimensional stress presume for explosion expanding ring test. Explosion and Shock Waves, 30(6): 577-582).Tang T G, Li Q Z, Chen Y T, et al. 2010a. Discussion about one-dimensional stress presume for explosion expanding ring test. Explosion and Shock Waves, 30(6): 577-582. [10] 汤铁钢, 李庆忠, 刘仓理等. 2010b. 爆炸膨胀环的截面尺寸效应. 爆炸与冲击, 30(1): 39-44 (Tang T G, Li Q Z, Liu C L, et al. 2010b. Size effects of expanding ring by explosive loading. Explosion and Shock Waves, 30(1): 39-44).Tang T G, Li Q Z, Liu C L, et al. 2010b. Size effects of expanding ring by explosive loading. Explosion and Shock Waves, 30(1): 39-44. [11] 汤铁钢, 刘仓理. 2013a. 一种新型爆炸膨胀环实验装置. 实验力学, 28 (2): 247-254 (Tang T G, Liu C L. 2013a. A novel experimental setup for explosively loaded expanding ring test. Journal of Experimental Mechanics, 28 (2): 247-254).Tang T G, Liu C L. 2013a. A novel experimental setup for explosively loaded expanding ring test. Journal of Experimental Mechanics, 28(2): 247-254. [12] 杨晨, 刘明涛, 汤铁钢等. 2021. 电磁加载下7075铝环的膨胀断裂模式转变研究. 爆炸与冲击, 41 (3): 100-104 (Yang C, Liu M T, Tang T G, et al. 2021. Expansion fracture mode of 7075 aluminum ring under electromagnetic loading. Explosion and Shock Waves, 41 (3): 100-104).Yang C, Liu M T, Tang T G, et al. 2021. Expansion fracture mode of 7075 aluminum ring under electromagnetic loading. Explosion and Shock Waves, 41(3): 100-104. [13] 杨晨. 2018. 动态拉伸加载下7075Al环的断裂模式转变现象研究. [硕士论文]. 中国工程物理研究院 (Yang C. 2018. Research on the fracture mode transition phenomenon of 7075Al ring under dynamic tensile loading. [Master Thesis]. China Academy of Engineering Physics).Yang C. 2018. Research on the fracture mode transition phenomenon of 7075Al ring under dynamic tensile loading. [Master Thesis]. China Academy of Engineering Physics. [14] 俞鑫炉, 付应乾, 董新龙. 2017. 高加载率金属电磁膨胀环实验处理分析. 塑性工程学报, 24 (5): 13-18 (Yu X L, Fu Y Q, Dong X L. 2017. Data processing analysis of high strain-rate metal ring expanding test driven by electromagnetic method. Journal of Plasticity Engineering, 24 (5): 13-18).Yu X L, Fu Y Q, Dong X L. 2017. Data processing analysis of high strain-rate metal ring expanding test driven by electromagnetic method. Journal of Plasticity Engineering, 24(5): 13-18. [15] 张佳, 郑宇轩, 周风华. 2017. 立式液压膨胀环实验技术研究. 宁波大学学报(理工版), 30 (2): 35-38 (Zhang J, Zheng Y X, Zhou F H. 2017. Experimental technique for fragmentation of liquid-driven expanding ring. Journal of Ningbo University: Natural Science and Engineering Edition, 30 (2): 35-38).Zhang J, Zheng Y X, Zhou F H. 2017. Experimental technique for fragmentation of liquid-driven expanding ring. Journal of Ningbo University: Natural Science and Engineering Edition, 30(2): 35-38. [16] 郑宇轩. 2013. 韧性材料的动态碎裂特性研究. [博士论文]. 中国科学技术大学 (Zheng Y X. 2013. Research on dynamic fragmentation of ductile metals. [PhD Thesis]. University of Science and Technology of China).Zheng Y X. 2013. Research on dynamic fragmentation of ductile metals. [PhD Thesis]. University of Science and Technology of China [17] 郑宇轩, 周风华, 胡时胜. 2014. 一种基于SHPB的冲击膨胀环实验技术. 爆炸与冲击, 4 : 483-488 (Zheng Y X, Zhou F H, Hu S S. 2014. An SHPB-based experimental technique for dynamic fragmentations of expanding rings. Explosion and Shock Waves, 4 : 483-488).Zheng Y X, Zhou F H, Hu S S. 2014. An SHPB-based experimental technique for dynamic fragmentations of expanding rings. Explosion and Shock Waves, 4: 483-488. [18] Altynova M, Hu X, Daehn G S. 1996. Increased ductility in high velocity electromagnetic ring expansion. Metallurgical and Materials Transactions, 27: 1837-1844. doi: 10.1007/BF02651933 [19] Asay J R. 1997. The use of shock-structure methods for evaluating high-pressure material properties. International Journal of Impact Engineering, 20: 27-61. doi: 10.1016/S0734-743X(97)87478-7 [20] Challita A, Hanlin G A. 1995. Strength of aluminum under pulsed heating conditions. IEEE Transactions on Magnetics, 31(1): 684-688. doi: 10.1109/20.364611 [21] Chen Y, Guo H, Sun M Q, et al. 2022. Tensile mechanical properties and dynamic constitutive model of polyurea elastomer under different strain rates. Polymers, 14(17): 3579. doi: 10.3390/polym14173579 [22] Chen L, Yue C J, Zhou Y K, et al. 2021. Experimental and mesoscopic study of dynamic tensile properties of concrete using direct-tension technique. International Journal of Impact Engineering, 155: 103895. doi: 10.1016/j.ijimpeng.2021.103895 [23] Clark D S, Wood D S. 1950. The tensile impact properties of some metals and alloys. Transactions of the American Society for Metals, 42: 45-74. [24] Dan J K, Guo Z L, Chen Y, et al. 2020. Preliminary investigations on dynamic fracture of ductile metals by using electromagnetically driven expanding ring. AIP Advances, 10(10): 105001. doi: 10.1063/5.0016527 [25] Duffey T A, Karpp R R, Warnes R H, et al. 1981. Dynamic material property measurements using an improvement of the freely expanding ring technique. Society for Experimental Stress Analysis meeting, Dearborn, MI, USA. [26] Fanny G, Gabriel S, Patrice L, et al. 2021. Plate-impact-driven ring expansion test (PIDRET) for dynamic fragmentation. In: Proceedings of the 13th International Conference on Mechanical and Physical Behavior of Materials under Dynamic Loading (DYMAT) in Madrid. [27] Fanny G, Gabriel S, Patrice L, et al. 2024. High strain rate responses of some metals and alloys using a plate impact driven ring expansion test (PIDRET). International Journal of Impact Engineering, 184: 104829. doi: 10.1016/j.ijimpeng.2023.104829 [28] Forrestal M J, Walling H C. 1972. Axisymmetric plastic response of rings to short-duration pressure pulses. American Institute of Aeronautics and Astronautics, 10(10): 1382-1384. doi: 10.2514/3.6634 [29] Gourdin W H. 1989a. VISAR analysis in the presence of large intensity changes: Application to the expanding ring. Review of Scientific Instruments, 60(4): 754-759. doi: 10.1063/1.1141015 [30] Gourdin W H, Weinland S L, Boling R M. 1989b. Development of the electromagnetically launched expanding ring as a high-strain-rate test technique. Review of Scientific Instruments, 60(3): 427-432. doi: 10.1063/1.1140395 [31] Gourdin W H. 1989c. Analysis and assessment of electromagnetic ring expansion as a high-strain-rate test. Journal of Applied Physics, 65(2): 411-422. doi: 10.1063/1.343121 [32] Gourdin W H, Lassila D H. 1991. Flow-stress of OFE copper at strain rates from 10−3 to 104 s−1 grain-size effects and comparison to the mechanical threshold stress model. Acta Metallurgica et Materialia, 10(39): 2337-2348. [33] Grady D E, Benson D A. 1983. Fragmentation of metal rings by electromagnetic loading. Experimental Mechanics, 23(4): 393-400. doi: 10.1007/BF02330054 [34] Grady D E, Olsen M L. 2003. A statistics and energy based theory of dynamic fragmentation. International Journal of Impact Engineering, 29: 293-306. doi: 10.1016/j.ijimpeng.2003.09.026 [35] Han Z B, Qu W J, Zhu P. 2023. Tensile behavior of GFRP bar at quasi-static and high strain rate. Construction and Building Materials, 364: 129915. doi: 10.1016/j.conbuildmat.2022.129915 [36] Hoggatt C R, Recht R F. 1969. Stress-strain data obtained at high rates using an expanding ring. Experimental Mechanics, 9: 441-448. doi: 10.1007/BF02410405 [37] Huang L T, Han X T, Chen Q, et al. 2014. Effect of electromagnetic ring expansion on the mechanical property of A5083 aluminum alloy. IEEE Transactions on Applied Superconductivity, 24(3): 7100104. [38] Ivanov A G. 1976. Explosive deformation and destruction of tubes. Strength of Materials, 11(8): 1303-1306. [39] Ivanov A G, Kleshchevnikov O A, Tsypkin V I, et al. 1976. Experimental study of the explosive expansion of thin rings of annealed aluminum alloy. Combustion, Explosion and Shock Waves, 12(1): 105-109. doi: 10.1007/BF00740880 [40] Jia S G, Tan Q H, Ye J Y, et al. 2021. Experiments on dynamic mechanical properties of austenitic stainless steel S30408 and S31608. Journal of Constructional Steel Research, 179: 106556. doi: 10.1016/j.jcsr.2021.106556 [41] Janiszewski J. 2012a. Measurement procedure of ring motion with the use of high-speed camera during electromagnetic expansion. Metrology and Measurement Systems, 19(4): 797-804. doi: 10.2478/v10178-012-0071-2 [42] Janiszewski J. 2012b. Ductility of selected metals under electromagnetic ring test loading conditions. International Journal of Solids and Structures, 49: 1001-1008. doi: 10.1016/j.ijsolstr.2012.01.005 [43] Janiszewski J, Panowicz R. 2013. Development and validation of numerical model for predicting electromagnetic expansion of composite rings. Solid State Phenomena, 198: 627-632. doi: 10.4028/www.scientific.net/SSP.198.627 [44] Janiszewski J, Pichola W. 2009. Development of electromagnetic ring expansion apparatus for high-strain- rate test. Solid State Phenomena, 147-149: 645-650. doi: 10.4028/www.scientific.net/SSP.147-149.645 [45] Jiang F, Sun Q Q, Lai Z P, et al. 2016. Electromagnetically driven expanding ring test for the strength study of the Zylon/epoxy composite. IEEE Transactions on Applied Superconductivity, 26: 9000106. [46] Johnson J R, Taber G, Vivek A, et al. 2009. Coupling experiment and simulation in electromagnetic forming using photon Doppler velocimetry. Steel Research International, 80(5): 359-365. [47] Johnson J R, Taber G A, Daehn G S. 2010. Constitutive relation development through the FIRE test. Proceedings of 4th International Conference on High Speed Forming, Columbus. 295-306. [48] Johnson P C, Stein B A, Davis R S. 1963. Measurement of dynamic plastic flow properties under uniform stress. Symposium on the dynamic behavior of materials. ASTM Special Publication, 336: 195-198. [49] Kahana E, Ben-Artzy A, Sadot O, et al. 2015. Microstructural evolution of AZ31 magnesium alloy after high strain rate expanding rings tests. Materials Science and Engineering: A, 12(641): 274-280. [50] Landen D, Satapathy S, Suris D, et al. 2005. Electromagnetically driven expanding ring experiments for strength studies. 2005 IEEE Pulsed Power Conference. [51] Landen D, Satapathy S, Surls D. 2007. Measurement of high-strain-rate adiabatic strength of conductors. IEEE Transactions on Magnetics, 43(1): 349-354. doi: 10.1109/TMAG.2006.887677 [52] Landen D, Wetz D, Satapathy S, et al. 2008. Electromagnetically driven expanding ring with pre-heating. 14th Symposium on Electromagnetic Launch Technology. [53] Li M, Yu H, Zhang J Z, et al. 2023. Dynamic tensile mechanical properties of thermally damaged sandstone under impact loads and the influence mechanism of composition. Engineering Fracture Mechanics, 289: 109388. doi: 10.1016/j.engfracmech.2023.109388 [54] Li W, Chen H. 2023. Tensile performance of normal and high-strength structural steels at high strain rates. Thin-Walled Structures, 184: 110457. doi: 10.1016/j.tws.2022.110457 [55] Liang M Z, Li X Y, Qin J G, et al. 2013. Improved expanding ring technique for determining dynamic material properties. Review of Scientific Instruments, 84: 065114. doi: 10.1063/1.4811658 [56] Lipkin J, Swearengen J C, Karnes C H. 1973. Mechanical properties of 6061 Al-Mg-Si alloy after very rapid heating. Journal of the Mechanics and Physics of Solids, 21(2): 91-112. doi: 10.1016/0022-5096(73)90032-X [57] Ma H J, Mao W J, Su H L, et al. 2021. Rate-related study on mechanical properties and fracture characteristics in aluminium alloy via electromagnetic ring expansion test. International Journal of Mechanical Sciences, 209: 106712. doi: 10.1016/j.ijmecsci.2021.106712 [58] Mocko W, Brodecki A, Kruszka L. 2016. Mechanical response of dual phase steel at quasi-static and dynamic tensile loadings after initial fatigue loading. Mechanics of Materials, 92: 18-27. doi: 10.1016/j.mechmat.2015.07.015 [59] Mott N F. 1947. Fragmentation of shell cases. Proceedings of the Royal Society of London Series A-Mathematical and Physical Sciences, 189(1018): 300-308. [60] Nguyen K, Cheol K H, Hyunho S, et al. 2017. Numerical investigation into the stress wave transmitting characteristics of threads in the split Hopkinson tensile bar test. International Journal of Impact Engineering, 109: 253-263. doi: 10.1016/j.ijimpeng.2017.07.004 [61] Nicolas C, Krishnaswamy R C. 2018. Dynamic strain localization in magnesium alloy AZ31B-O. Mechanics of Materials, 116: 189-201. doi: 10.1016/j.mechmat.2017.09.008 [62] Niordson F I. 1965. A unit for testing materials at high strain rates. Experimental Mechanics, 5(1): 29-32. doi: 10.1007/BF02320901 [63] Perrone N. 1965. On a simplified method for solving impulsively loaded structures of rate-sensitive materials. Journal of Applied Mechanics, 32(3): 489-492. doi: 10.1115/1.3627249 [64] Perrone N. 1970. Impulsively loaded strain hardened rate-sensitive rings and tubes. International Journal of Solids and Structures, 6(8): 1119-1132. doi: 10.1016/0020-7683(70)90051-X [65] Peter J J, Lloyd P B, Dwight L, et al. 2011. Measurement of high-strain-rate strength of a metal-matrix composite conductor. Dynamic Behavior of Materials, Volume 1, Conference Proceedings of the Society for Experimental Mechanics Series, 269-276. [66] Pham T N, Choi H S, Kim J B. 2013. A numerical investigation into the tensile split Hopkinson pressure bars test for sheet metals. 4th International Conference on Information Technology for Manufacturing Systems, ITMS. [67] Rahmat M. 2019. Dynamic mechanical characterization of aluminum: Analysis of strain-rate-dependent behavior. Mechanics of Time-Dependent Materials, 2(23): 385-405. [68] Satapathy S, Landen D. 2006. Expanding ring experiments to measure high-temperature adiabatic properties. International Journal of Impact Engineering, 33: 735-744. doi: 10.1016/j.ijimpeng.2006.09.085 [69] Serikov S V. 1975. Stability of the flow of metallic rings under the action of an explosion. Combustion, Explosion and Shock Waves, 11(1): 98-104. [70] Strand O T, Goosman D R, Martinez C, et al. 2006. Compact system for high-speed velocimetry using heterodyne techniques. Review of Scientific Instruments, 77(8): 295-306. [71] Tamhane A A, Altynova M M, Daehn G S. 1996. Effect of sample size on ductility in electromagnetic ring expansion. Scripta Materialia, 34(8): 1345-1350. doi: 10.1016/1359-6462(95)00672-9 [72] Tang T G, Ren G W, Guo Z L, et al. 2013b. An improved technique of expanding metal ring experiment under high explosive loading. Review of Scientific Instruments, 84(4): 043908. doi: 10.1063/1.4802255 [73] Thomas D. 1972. An elastic-viscoplastic solution for impulsively loaded rings. International Journal of Solids and Structures, 8(7): 913-921. doi: 10.1016/0020-7683(72)90006-6 [74] von Karman T, Duwez P. 1950. The propagation of plastic deformation in solids. Journal of Applied Physics, 21: 987-994. doi: 10.1063/1.1699544 [75] Walling H C, Forrestal M J. 1973. Elastic-plastic expansion of 6061-T6 aluminum rings. American Institute of Aeronautics and Astronautics, 11(8): 1196-1197. doi: 10.2514/3.6894 [76] Warnes R H, Duffey T A, Karpp R R, et al. 1981. An improved technique for determining dynamic material properties using the expanding ring. Shock Waves and High-Strain-Rate Phenomena in Metals, 23-36. [77] Warnes R H, Duffey T A, Karpp R R, et al. 1982. Development of the freely expanding ring test for measuring dynamic material properties. Experimental mechanics, 22(5): 48. [78] Weggel R J, Ratka J O, Spiegelberg W D, et al. 1994. Strength of Hycon 3 HPTM Be-Cu and other copper alloys from 20 ℃ to 200 ℃. IEEE Transactions on Magnetics, 30(4): 2188-2191. doi: 10.1109/20.305706 [79] Wesenberg D L, Sagartz M J. 1977. Dynamic fracture of 6061-16 aluminum cylinders. Journal of Applied Mechanics, 44(4): 643-646. doi: 10.1115/1.3424150 [80] Wetz D, Landen D, Satapathy S, et al. 2011. Inductive heating of materials for the study of high temperature mechanical properties. IEEE Transactions on Dielectrics and Electrical Insulation, 18(4): 1452-1351. [81] Wood W W. 1967. Experimental mechanics at velocity extremes-very high strain rates: Study covers tensile and compression specimens, spherical bulging and cylindrical bulging for a wide variety of materials. Experimental Mechanics, 7(10): 441-446. doi: 10.1007/BF02326303 [82] Yang K, Taber G, Sapanathan T, et al. 2016. Suitability of the electromagnetic ring expansion test to characterize materials under high strain rate deformation. MATEC Web of Conferences, 80: 15002. doi: 10.1051/matecconf/20168015002 [83] Yu J C, Song B, Xia D B, et al. 2020. Dynamic tensile properties and microstructural evolution of extruded EW75 magnesium alloy at high strain rates. Journal of Magnesium and Alloys, 8(3): 849-859. doi: 10.1016/j.jma.2020.02.013 [84] Zhang H, Ravi-Chandar K. 2006. On the dynamics of necking and fragmentation I. Real-time and post-mortem observations in Al 6061-O. International Journal of Fracture, 142(3): 183-217. [85] Zhang H, Ravi-Chandar K. 2008. On the dynamics of necking and fragmentation II. Effect of material properties, geometrical constraints and absolute size. International Journal of Fracture, 150: 3-36. doi: 10.1007/s10704-008-9233-3 [86] Zhang H, Ravi-Chandar K. 2009. On the dynamics of necking and fragmentation III. Effect of cladding with a polymer. International Journal of Fracture, 155: 101-118. doi: 10.1007/s10704-009-9332-9 [87] Zhang H, Ravi-Chandar K. 2010. On the dynamics of localization and fragmentation-IV. Expansion of Al 6061-O tubes. International Journal of Fracture, 163(1-2): 41-65. doi: 10.1007/s10704-009-9441-5 [88] Zhang J, Zheng Y X, Zhou F H, et al. 2018. Experimental technique for dynamic fragmentation of liquid-driving expanding ring. EPJ Web of Conferences, 183: 1-5. doi: 10.1051/epjconf/201818300001 -

下载:

下载: