-

摘要: 连接结构作为工业装备的核心部件之一, 是装备制造领域着重攻关优化的关键基础部件. 当前, 因连接界面的非线性、复杂性、不确定性等引起的跨尺度和多物理场复杂力学行为机理不明, 导致精准预测连接结构动力学特性和监测其动态服役性能存在困难, 成为制约精密结构动力学分析、高保真仿真、设计、优化和控制等问题突破的瓶颈. 然而连接结构应用广泛, 工程和技术人员对连接结构的机理及其多功能化有进一步的需求. 本文主要综述连接结构界面摩擦力学的解析建模、有限元建模以及实验系统, 并提出新型连接结构设计的发展趋势. 首先, 根据连接使役环境需求、工程存在问题及缺乏有效强度刚度预测理论, 综述了螺栓连接结构载荷类型及精准构建连接等效模型应用. 其次, 重点概述了连接结构界面摩擦的几类主流理论模型, 包括描述微/纳尺度分析连接界面多尺度物理行为和规律的本构模型、采用系统辨识理论和方法得到宏观界面力学响应的唯象模型、结合本构微观接触机理和系统辨识宏观角度的唯象学本构摩擦模型. 然后, 综述了以有限元方法为基础的连接结构仿真以及实验方法, 具体包括直接有限元建模、间接等效有限元建模、实验基准系统以及各向激励连接结构实验平台. 最后, 基于装备领域连接结构多功能需求, 提出“传静抑动”连接件以及轻量化仿生连接件的新型连接件设计思想.Abstract: Joints, as fundamental components of industrial machinery, are pivotal for extensive research and optimization in the realm of equipment manufacturing. Currently, due to the nonlinearity, complexity, and uncertainty of joint interfaces, the behavior mechanism of cross-scale and multi-physical field complex mechanics is unclear, making it difficult to accurately predict the dynamic characteristics of joint structures and monitor their dynamic service performance. This has become a bottleneck that restricts the breakthrough in precision structural dynamics analysis, high-fidelity simulation, design, optimization, and control. However, joint structures are widely used, and engineering and technical personnel have further demand for the mechanism and multifunctionality of joint structures. This article mainly reviews the analytical modeling, finite element modeling, and experimental systems of joint structure interface friction mechanics, and proposes the development trend of new joint structure design. Firstly, based on the requirements of the joint's working environment, engineering problems, and the lack of effective strength and stiffness prediction theory, this paper reviews the load types of bolted connection structures and the application of precise joint equivalent models. Secondly, several mainstream theoretical models of friction joint structures were summarized, including a constitutive model that analyzes the multi-scale physical behavior and laws of the joint interface at the micro/nano scale, a phenomenological model that derives macroscopic dynamic responses using system identification theory and methods, and a phenomenological constitutive friction model that integrates the microscopic contact mechanism of the constitutive model with the macroscopic perspective of system identification. Then, reviewing the simulation method based on the finite element and experimental methods of joint structures, which include direct finite element modeling, indirect equivalent finite element modeling, experimental benchmark systems, and anisotropic excitation joint structure experimental platforms. Finally, a new joint design concept addressing the multifunctional requirements of joint structures in the equipment field is proposed. This concept involves “transmitting static and suppressing dynamic” joint components as well as lightweight biomimetic joint components.

-

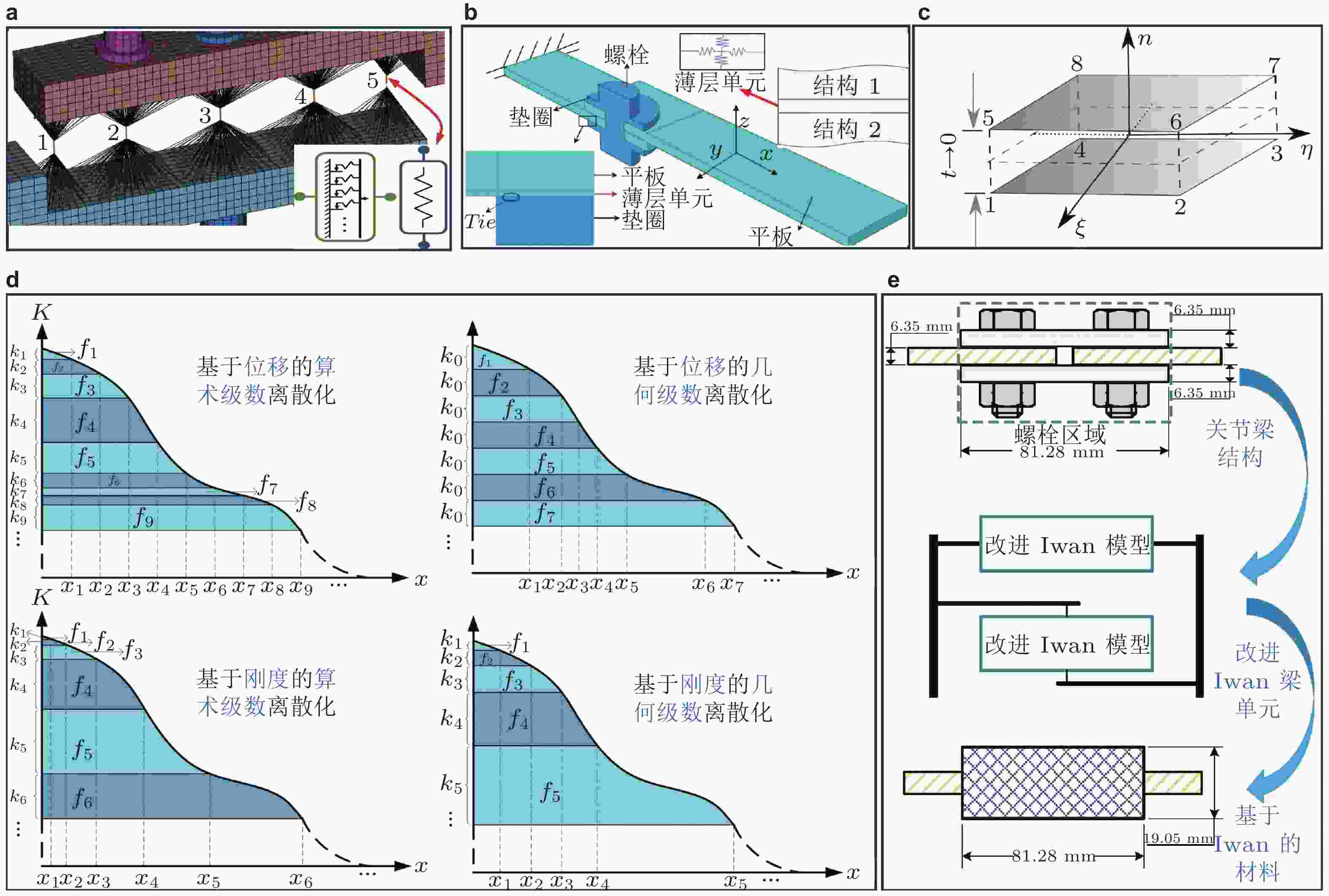

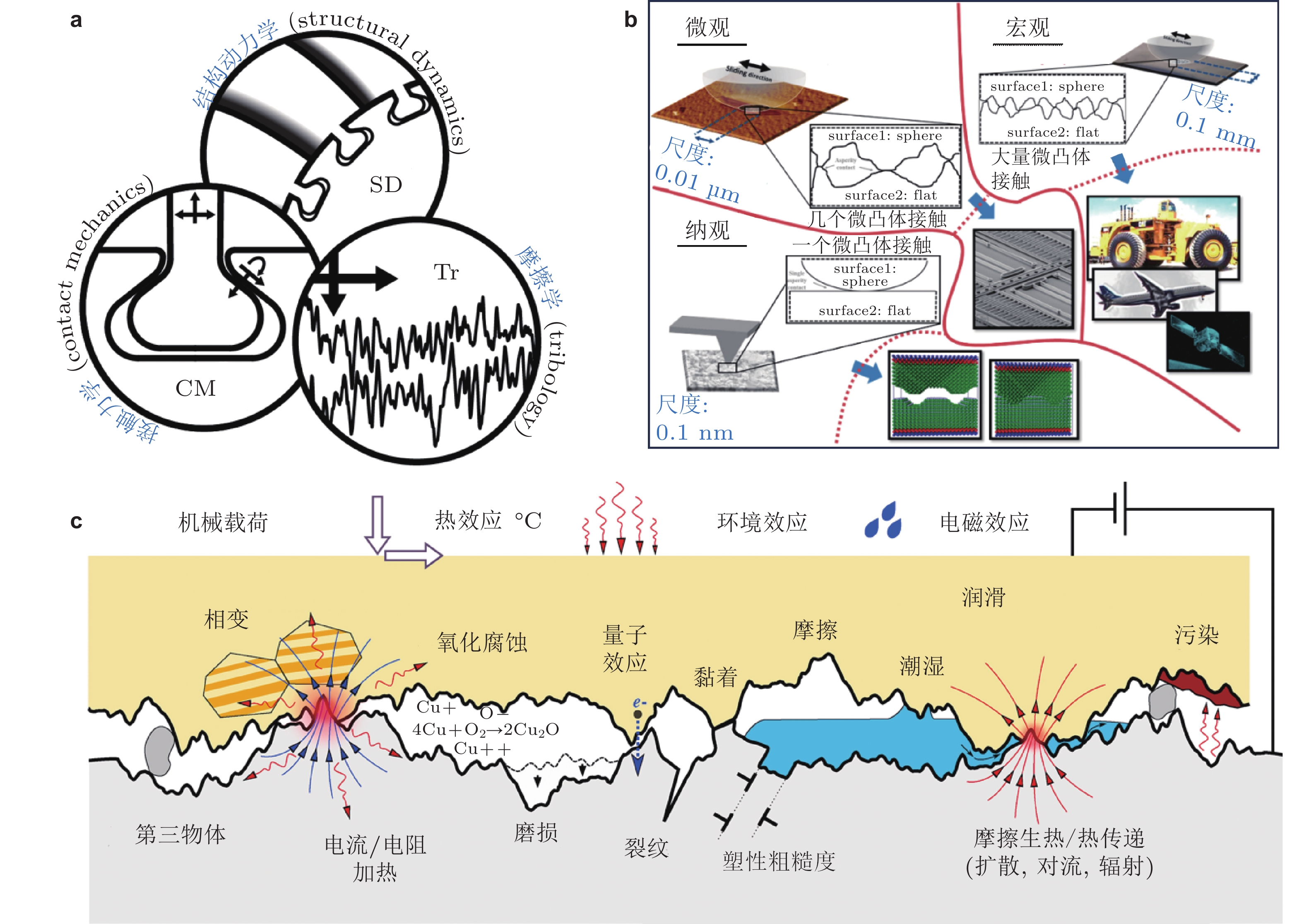

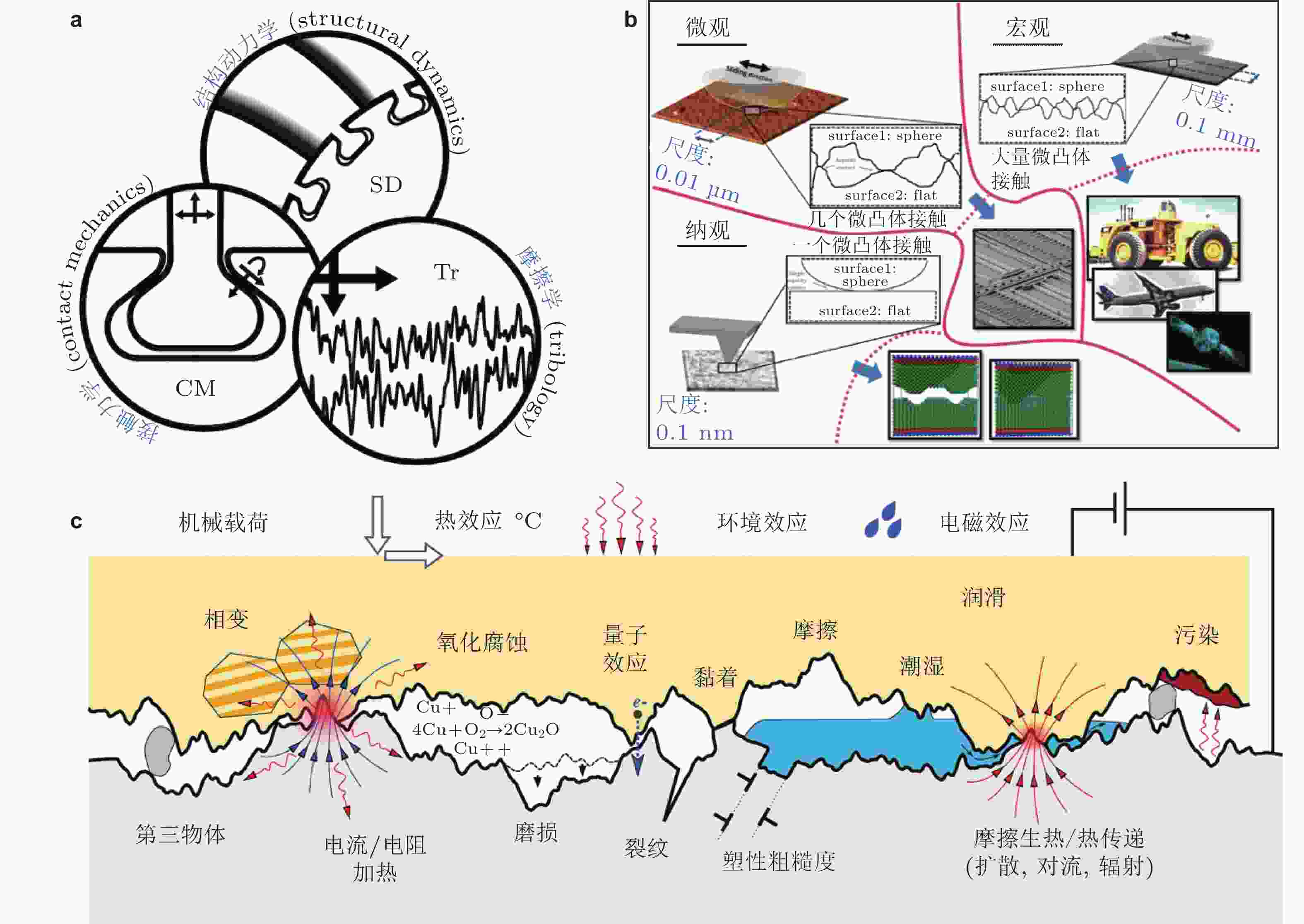

图 1 连接结构所涉及的学科、尺度以及物理场. (a)连接结构研究涉及方向, (b)连接结构的多尺度(Stoyanov & Chromik 2017), (c)连接结构的多物理场(Vakis et al. 2018)

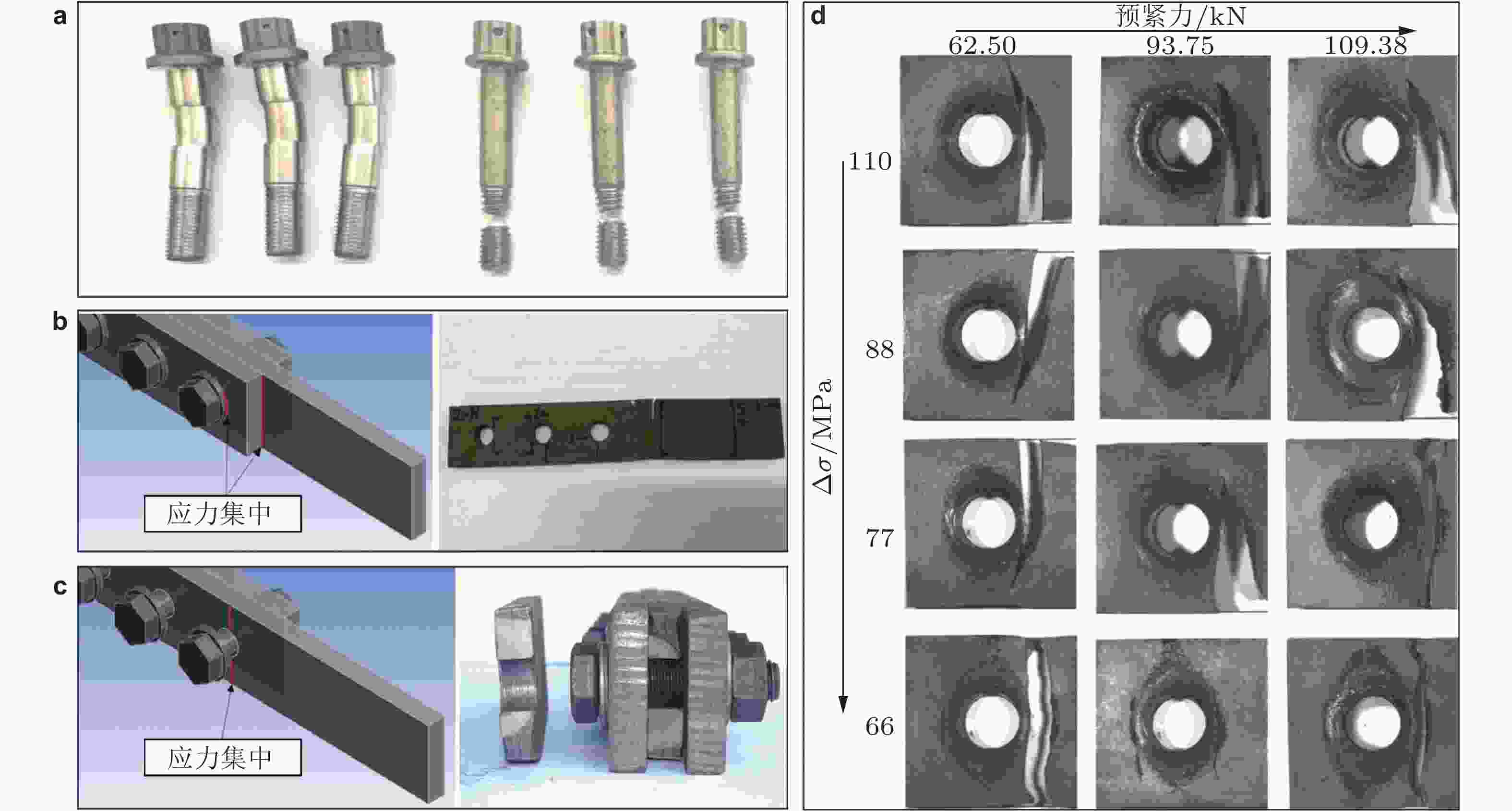

图 2 螺栓连接载荷分类. (a)剪切载荷, (b)拉伸载荷(Yang X et al. 2012), (c)扭转载荷, (d)撬动载荷(Fonfría et al. 2023)

图 3 连接结构强度破坏. (a)螺栓拉伸强度与剪切强度破坏(王帅 等 2022), (b)连接件应力集中, (c)螺栓孔应力集中(Zampieri et al. 2019), (d)不同应力及预紧力下连接件疲劳破坏(Jiménez-Peña et al. 2017)

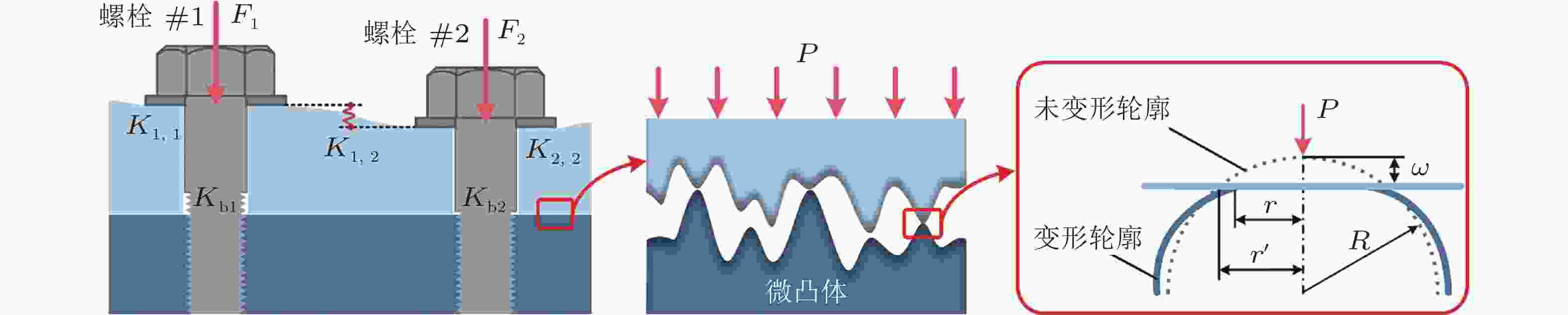

图 4 螺栓连接界面微观力学(Chang Y et al. 2023)

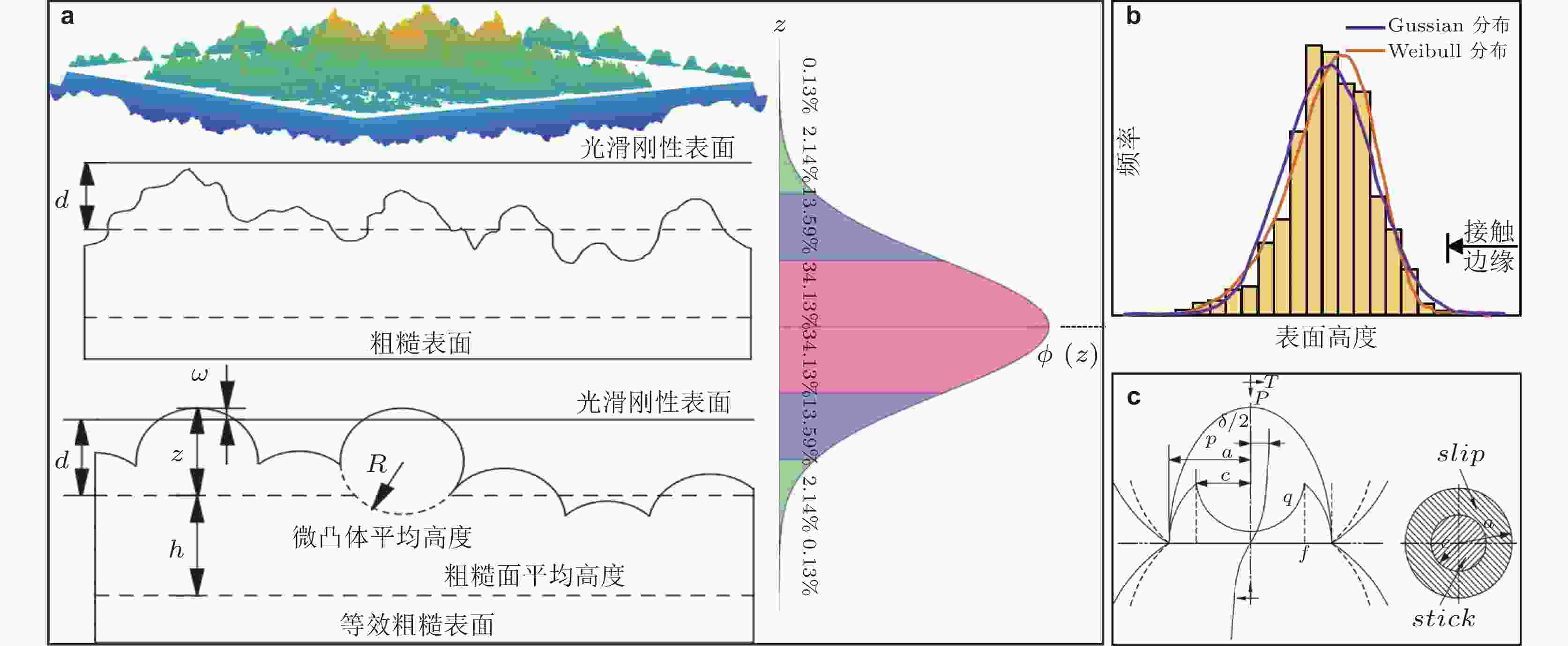

图 5 统计分析方法建模. (a)粗糙表面接触示意图(王东 等 2018), (b)表面粗糙度Gussian分布和Weibull分布拟合直方图(Yu & Polycarpou 2002), (c)单个微凸体黏滑状态示意图(王东 等 2018)

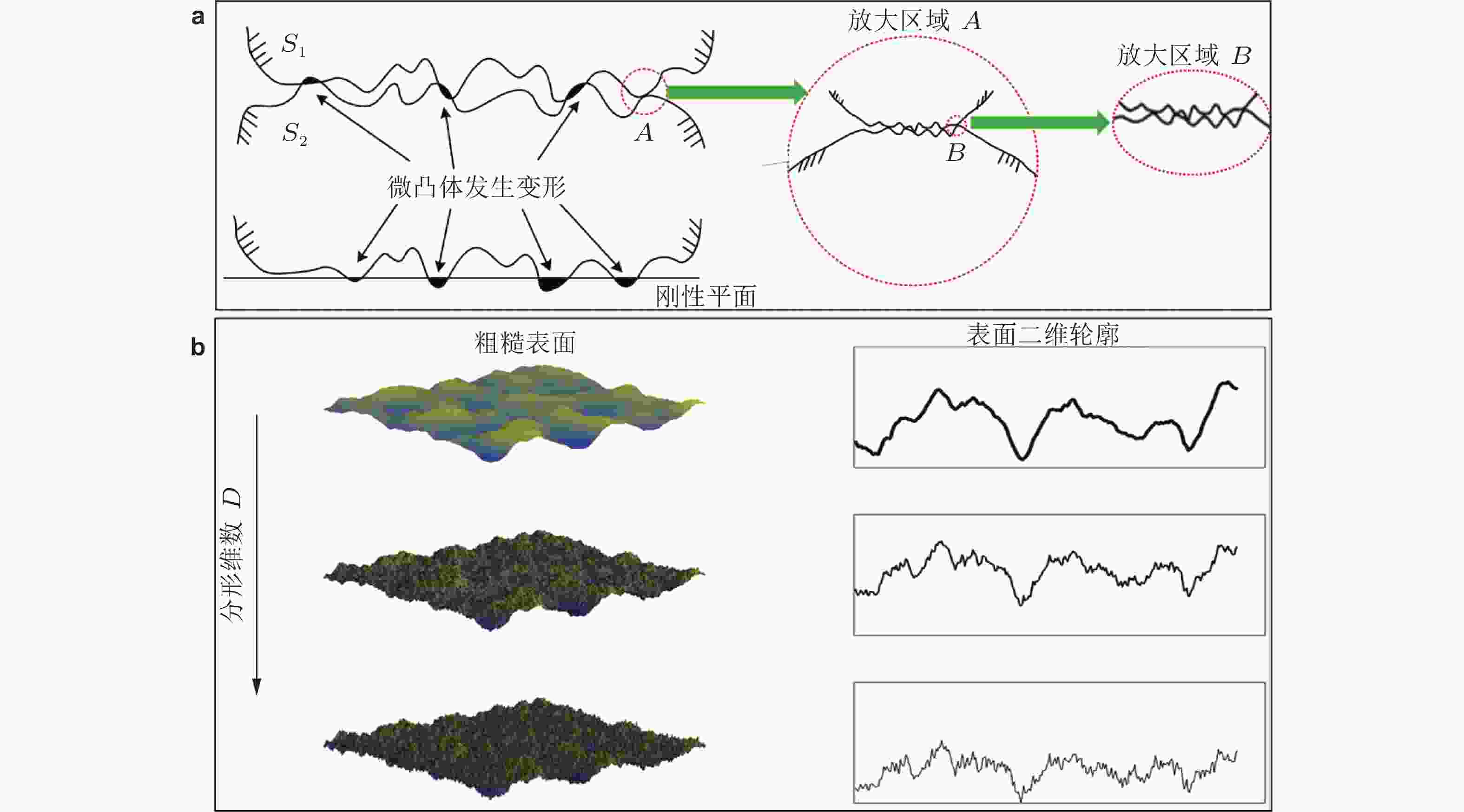

图 6 分形几何方法建模. (a)粗糙表面分形特征(张凯 2019), (b)不同分形维数下粗糙表面(Teengad 2023)

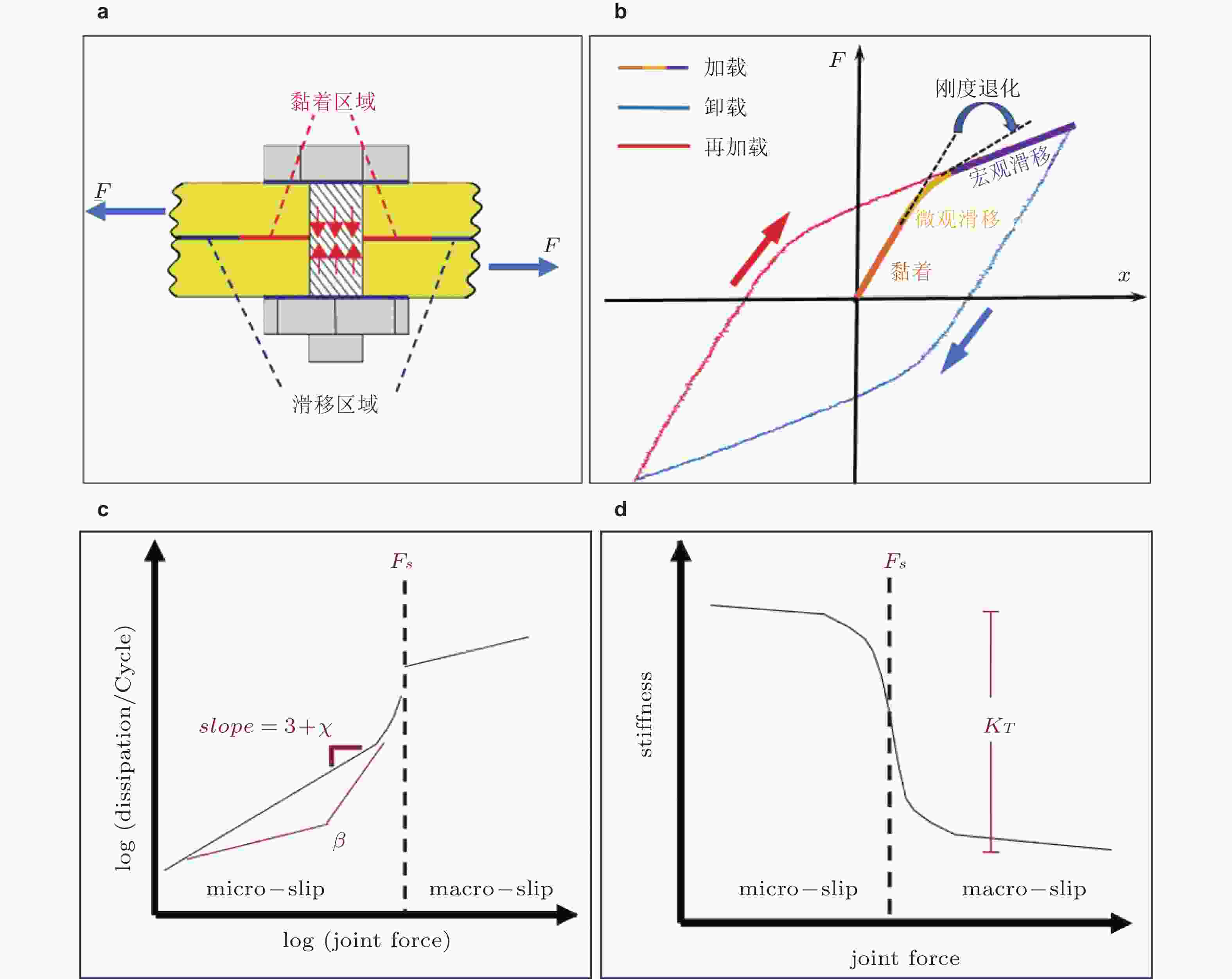

图 7 连接结构的实验特性. (a)螺栓连接结构示意图, (b)加卸载时力与位移关系, (c)力与能量耗散的幂律关系, (d)刚度软化(Brake et al. 2014)

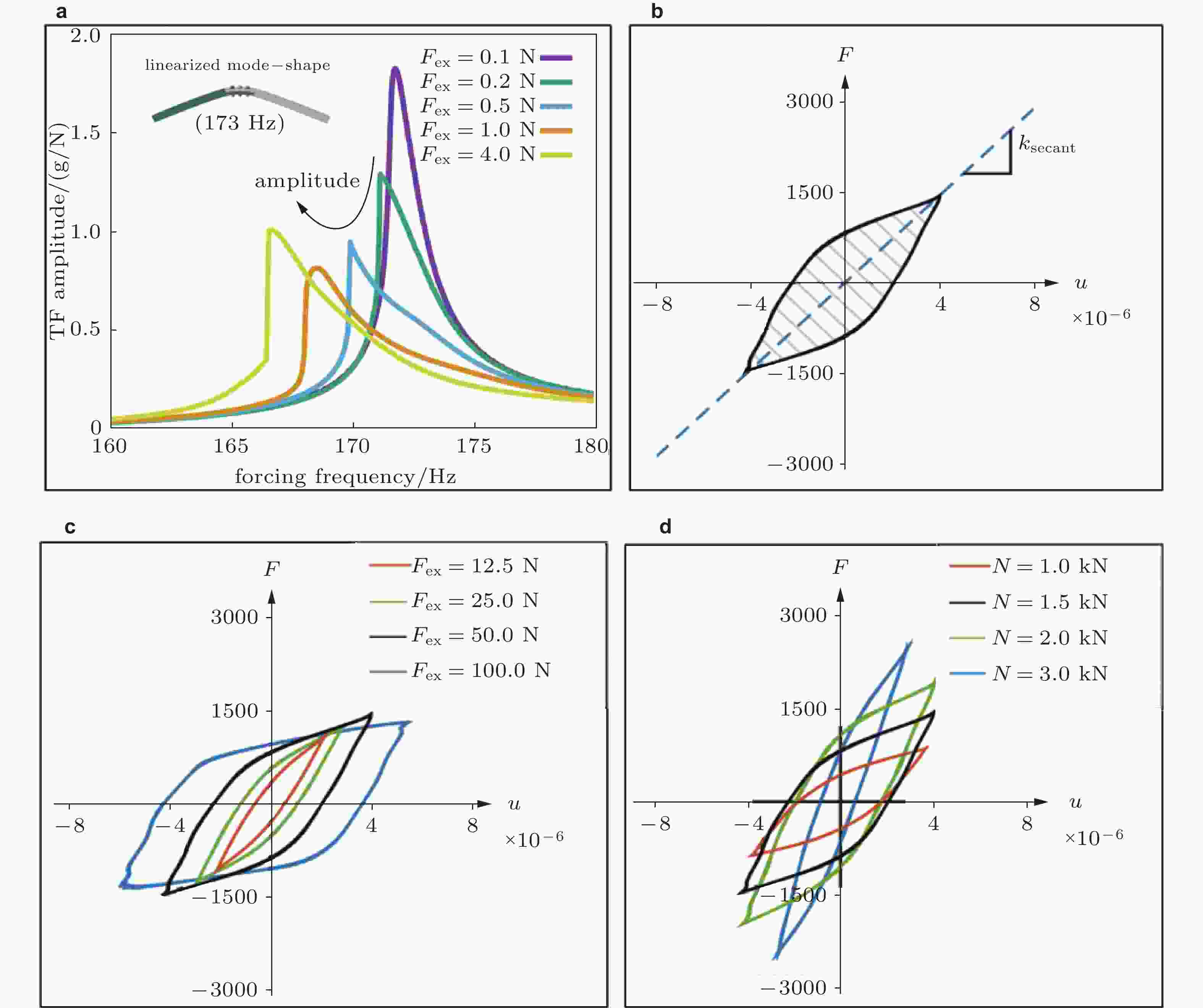

图 8 连接结构的实验趋势(Mathis et al. 2020). (a)不同激励振幅下的频率响应, (b)滞回曲线割线斜率, (c)不同激励振幅下滞回曲线, (d)不同预紧力下滞回曲线

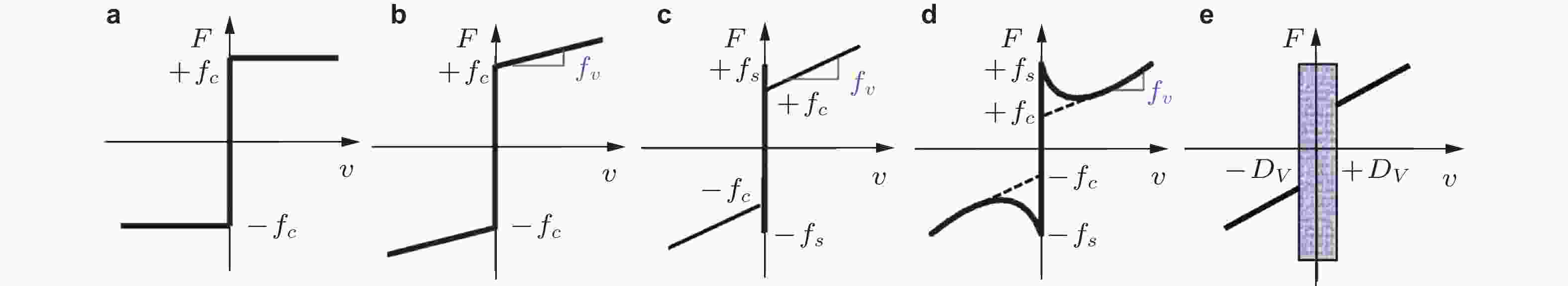

图 9 静态摩擦模型(Gaul & Nitsche 2001). (a)库伦模型, (b)库伦 + 黏性模型, (c)静摩擦 + 库伦 + 黏性摩擦模型, (d) Stribeck摩擦模型, (e) Karnopp摩擦模型

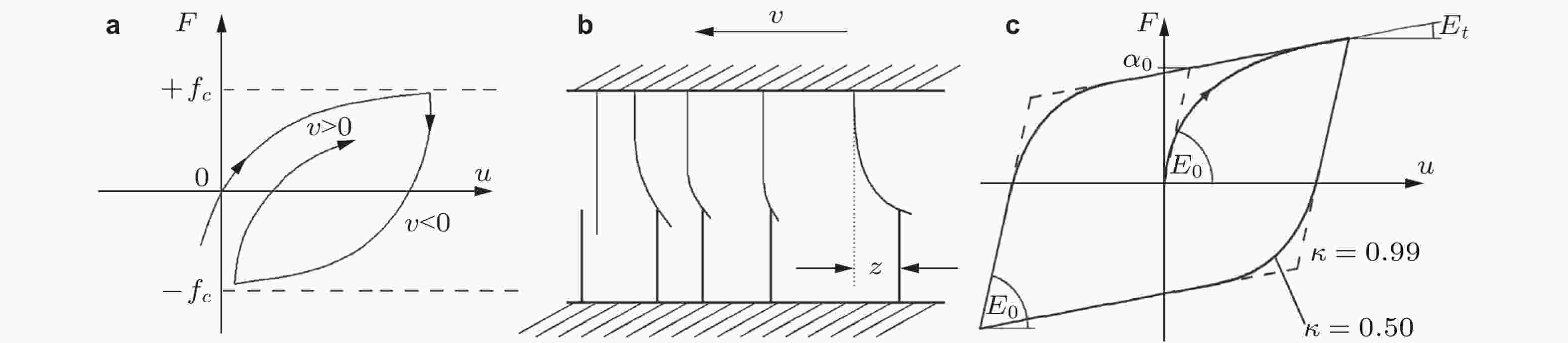

图 10 动态摩擦模型. (a) Dahl模型(Dahl 1976), (b) LuGre模型(De Wit et al. 1995), (c) Valanis模型(Valanis 1971, Gaul et al.1998)

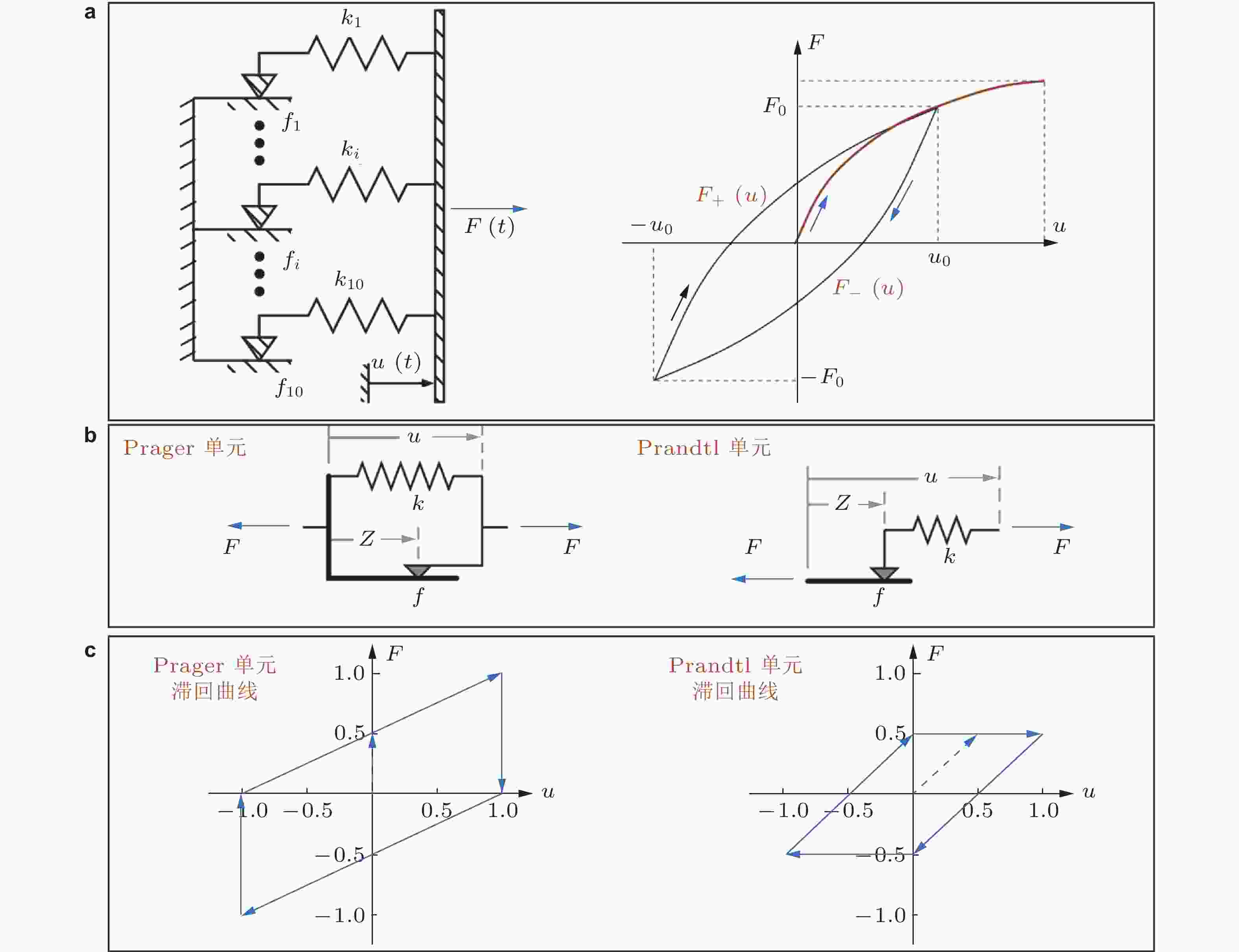

图 11 Iwan模型的发展(Mathis et al. 2020). (a)Masing模型, (b)Prandtl-Ishlinskiĭ单元, (c) Prandtl-Ishlinskiĭ模型滞回曲线

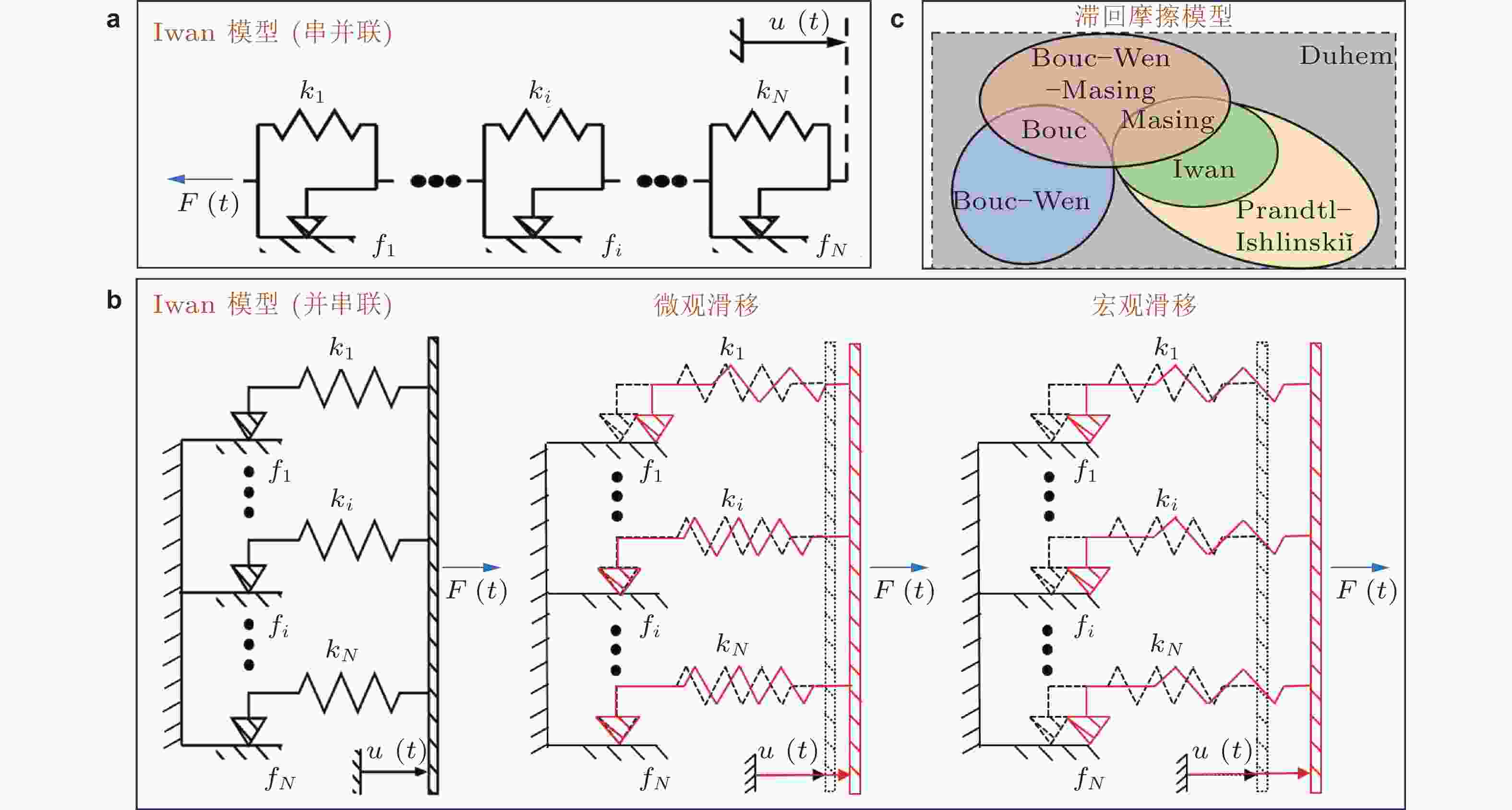

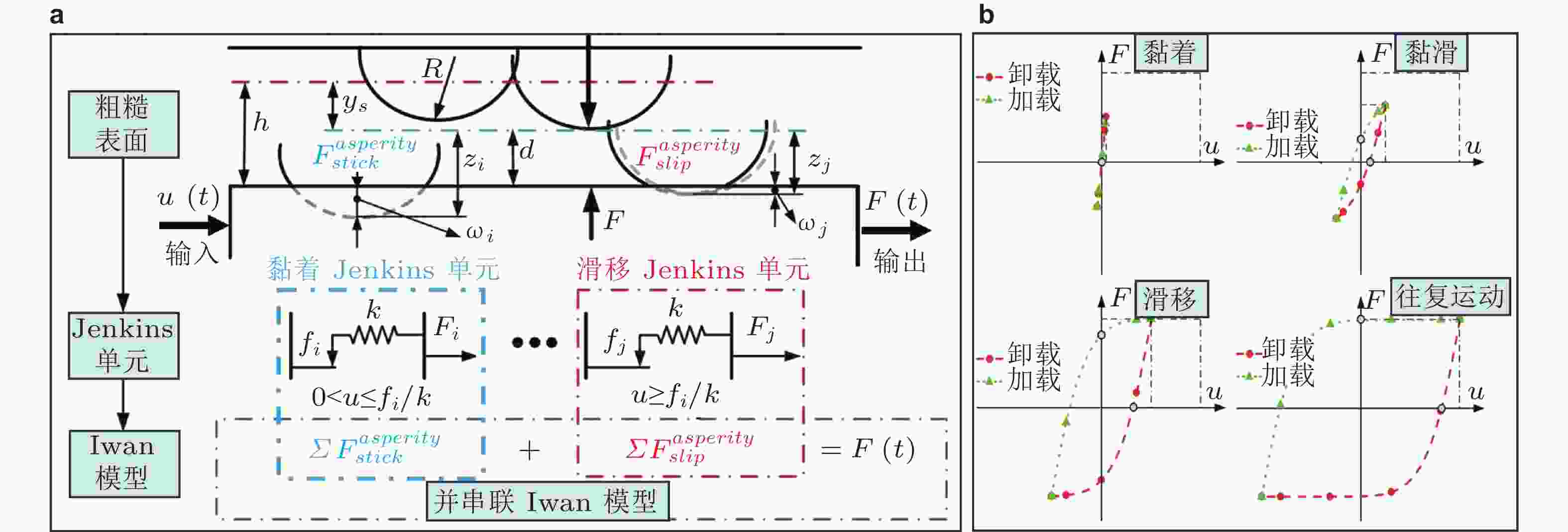

图 12 Iwan模型. (a)串并联Iwan模型(Prager单元串联)(Mathis et al. 2020), (b)并串联Iwan模型(Prandtl单元并联), (c)滞回摩擦模型逻辑关系

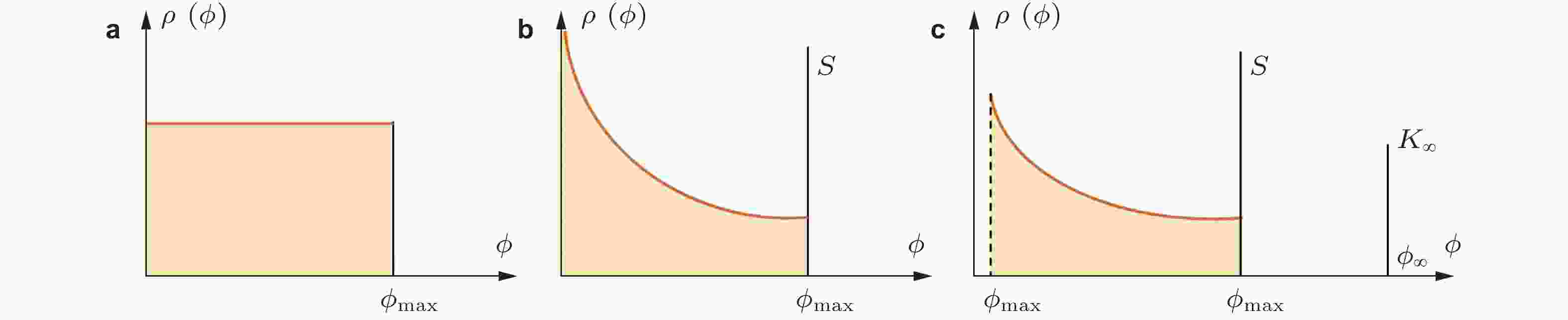

图 13 屈服力分布密度函数. (a)均匀分布密度函数(Iwan 1966, Iwan 1967), (b)含截断幂律分布密度函数(Segaleman 2005), (c)含截断幂律分布和双脉冲的密度函数(Li Y & Hao 2016)

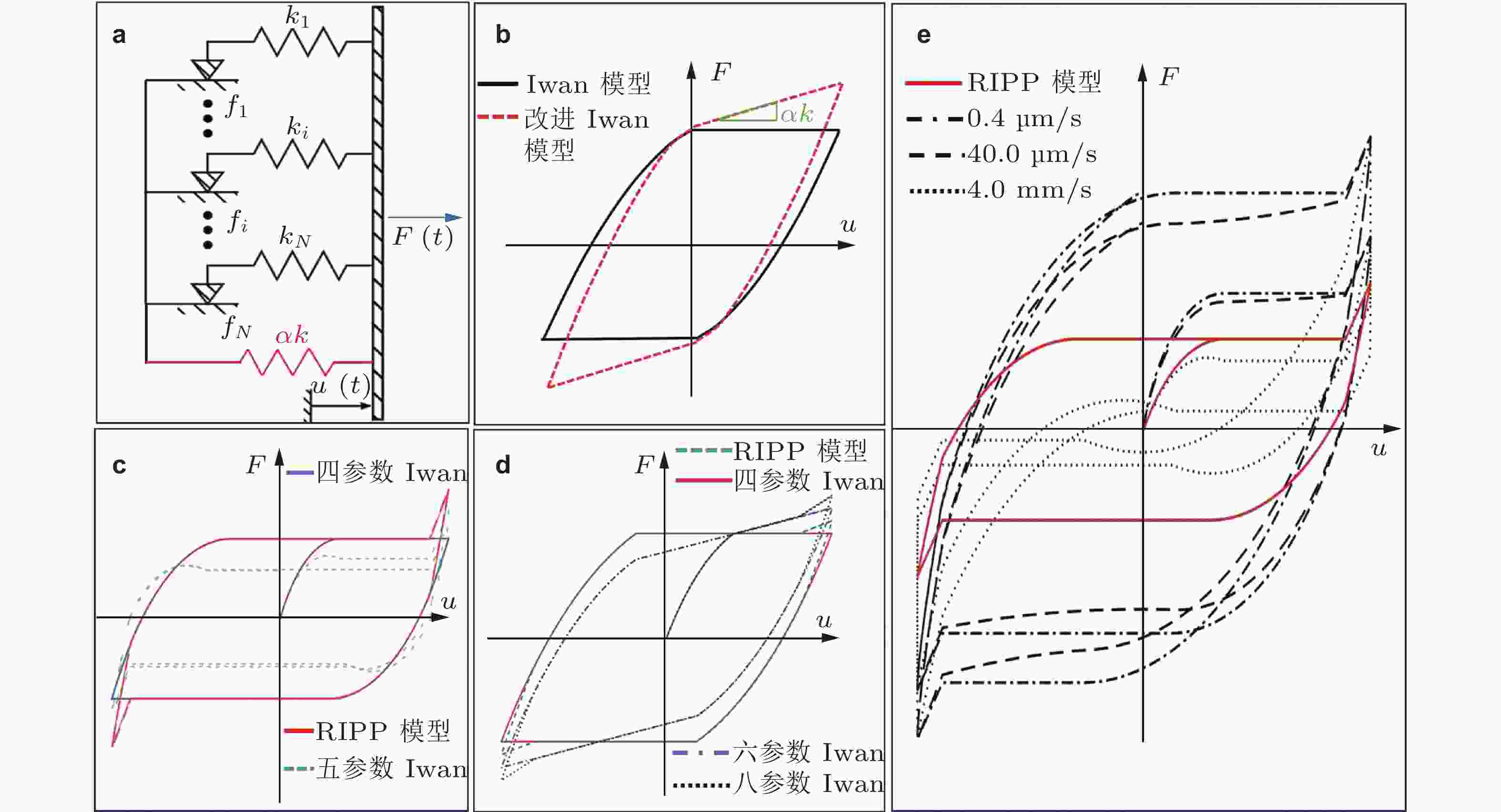

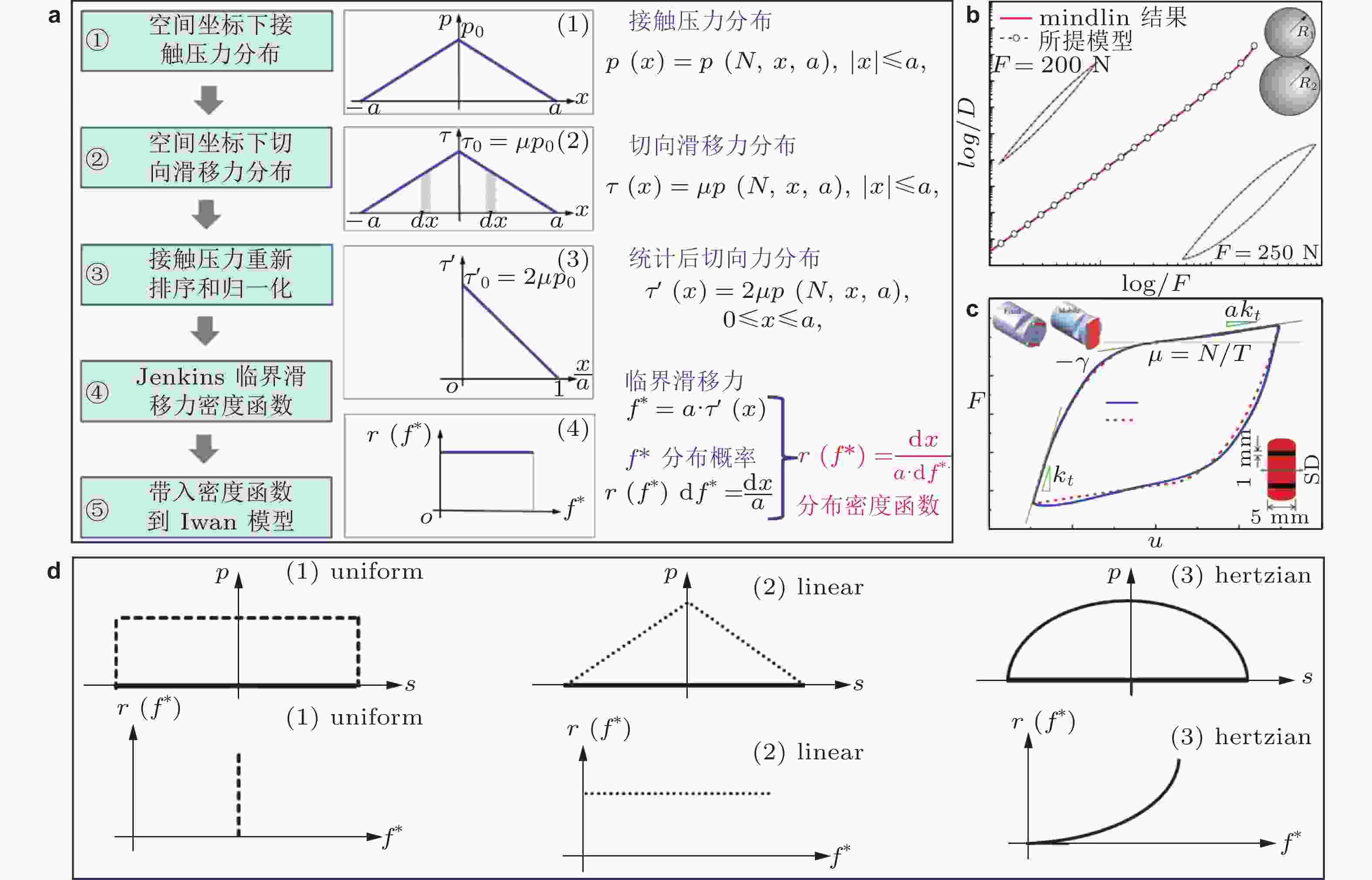

图 14 不同Iwan模型对比. (a)改进Iwan模型示意图, (b)改进Iwan模型滞回曲线(Song Y et al. 2004), (c)四参数Iwan模型、RIPP模型以及五参数Iwan模型对比(Brake 2017), (d)六参数Iwan模型和八参数Iwan模型对比(Ranjan & Pandey 2022), (e)基于高阶摩擦的Iwan模型(Brake 2017)

图 15 考虑表面形貌的微观接触建模(Chen J et al. 2019). (a)建模流程及Jenkins单元接触受力示意图, (b)连接结构4类接触状态

图 16 考虑连接界面的接触压力分布建模(Li D et al. 2020a). (a)建模方法流程图, (b)球-球接触结果, (c)平面-平面接触结果, (d) 3类接触压力分布及相应密度函数(Li D et al. 2020b)

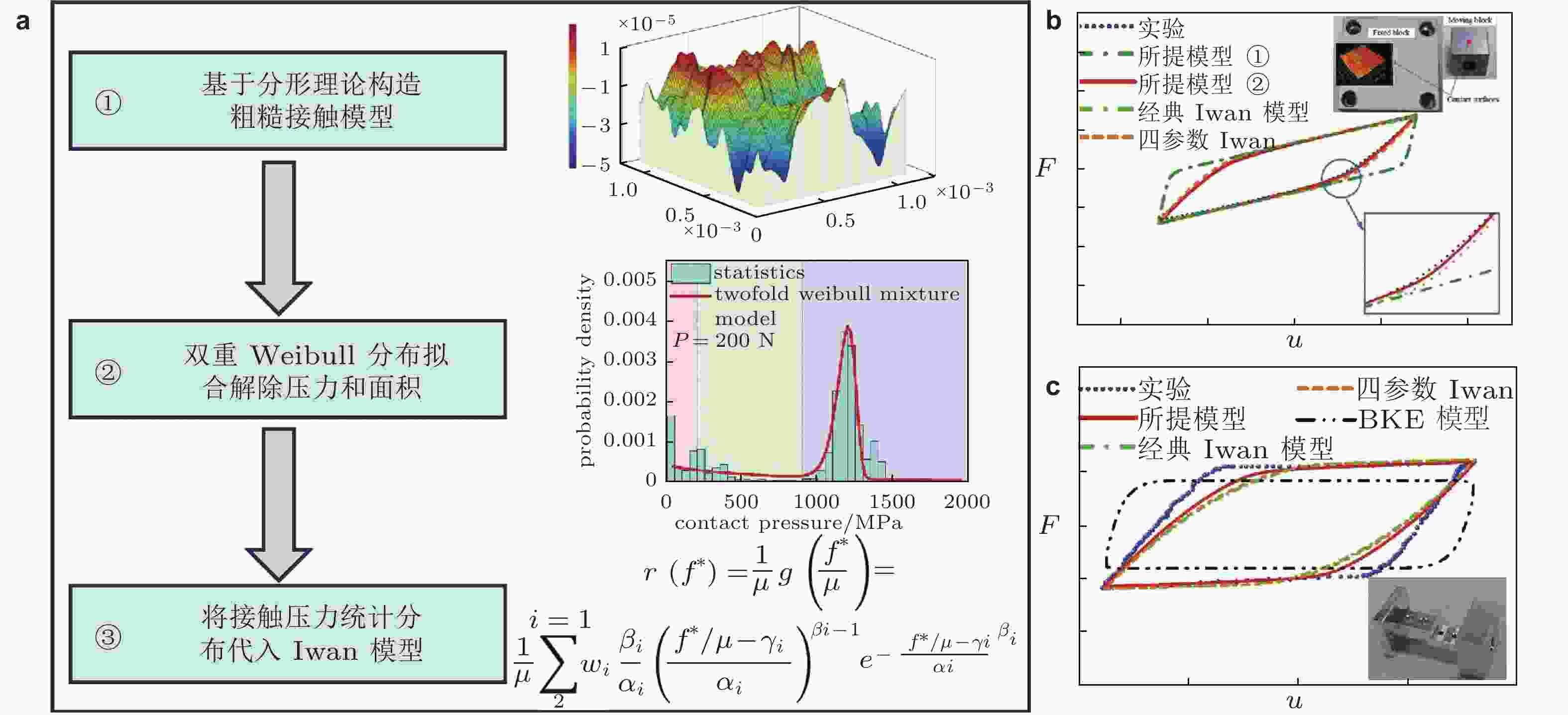

图 17 考虑粗糙表面接触压力分布的统计建模(Yang H et al. 2023). (a)建模方法流程图, (b)平面-平面接触, (c)螺栓连接接触

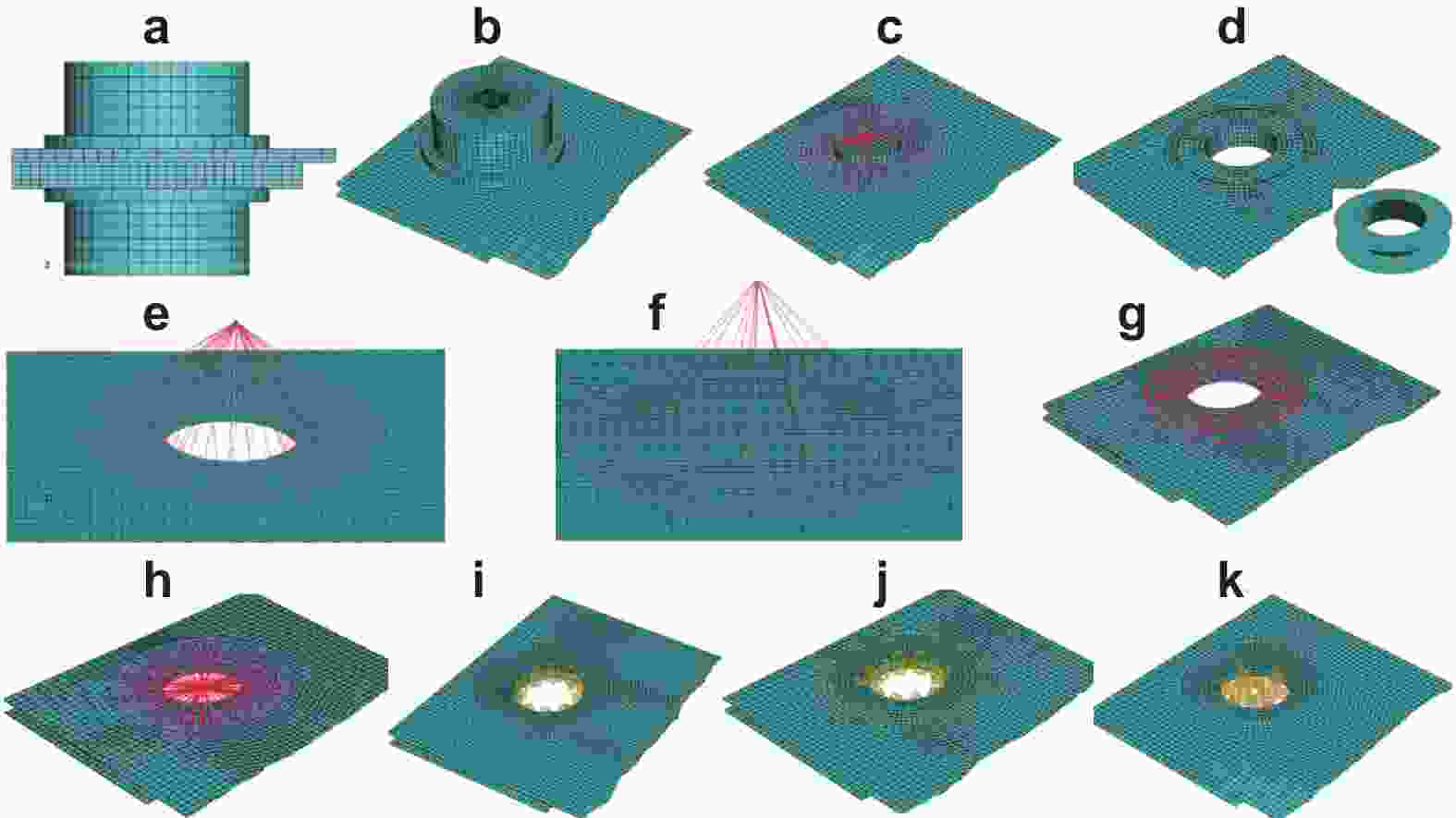

图 18 有限元直接建模方法(Tanlak et al. 2011). (a)实体连接螺栓模型, (b)壳连接实体螺栓模型, (c)耦合螺栓模型, (d)壳连接螺栓模型, (e) Timoshenko梁耦合螺栓模型, (f) Timoshenko梁无孔耦合螺栓模型, (g)孔绑定模型, (h)交叉耦合约束模型, (i)孔周围梁连接模型, (j)垫片周围梁连接模型, (k)交叉梁连接模型

图 19 有限元间接等效建模. (a)节点到节点接触(Lacayo et al. 2019), (b)薄层单元(Zhang Z et al. 2019), (c)零厚度单元(Balaji et al. 2020), (d)Jenkins单元离散(Li Y & Hao 2016, Li Y et al. 2017), (e) 基于Iwan材料(Jiang et al. 2023)

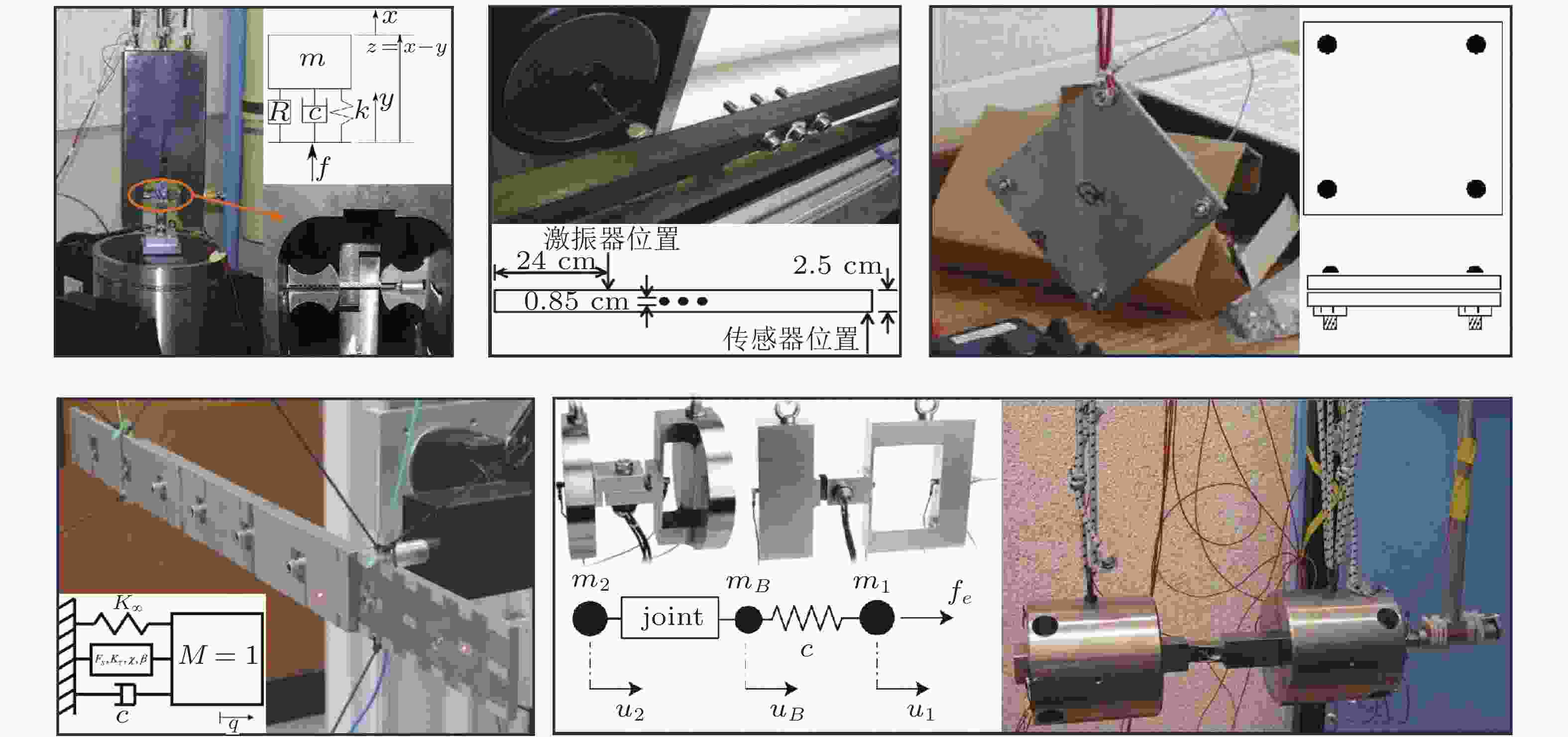

图 20 典型摩擦连接实验基准系统. (a) BMD (Segalman et al. 2009b), (b) Brake-Reuβ梁(Brake et al. 2014), (c)四螺栓连接方形板(Segalman et al. 2015), (d)双Sumali梁连接(Deaner et al. 2015), (e) Gaul谐振器和双质量哑铃装置(Gaul et al. 1994, Gaul & Lenz 1997, Segalman et al. 2009b)

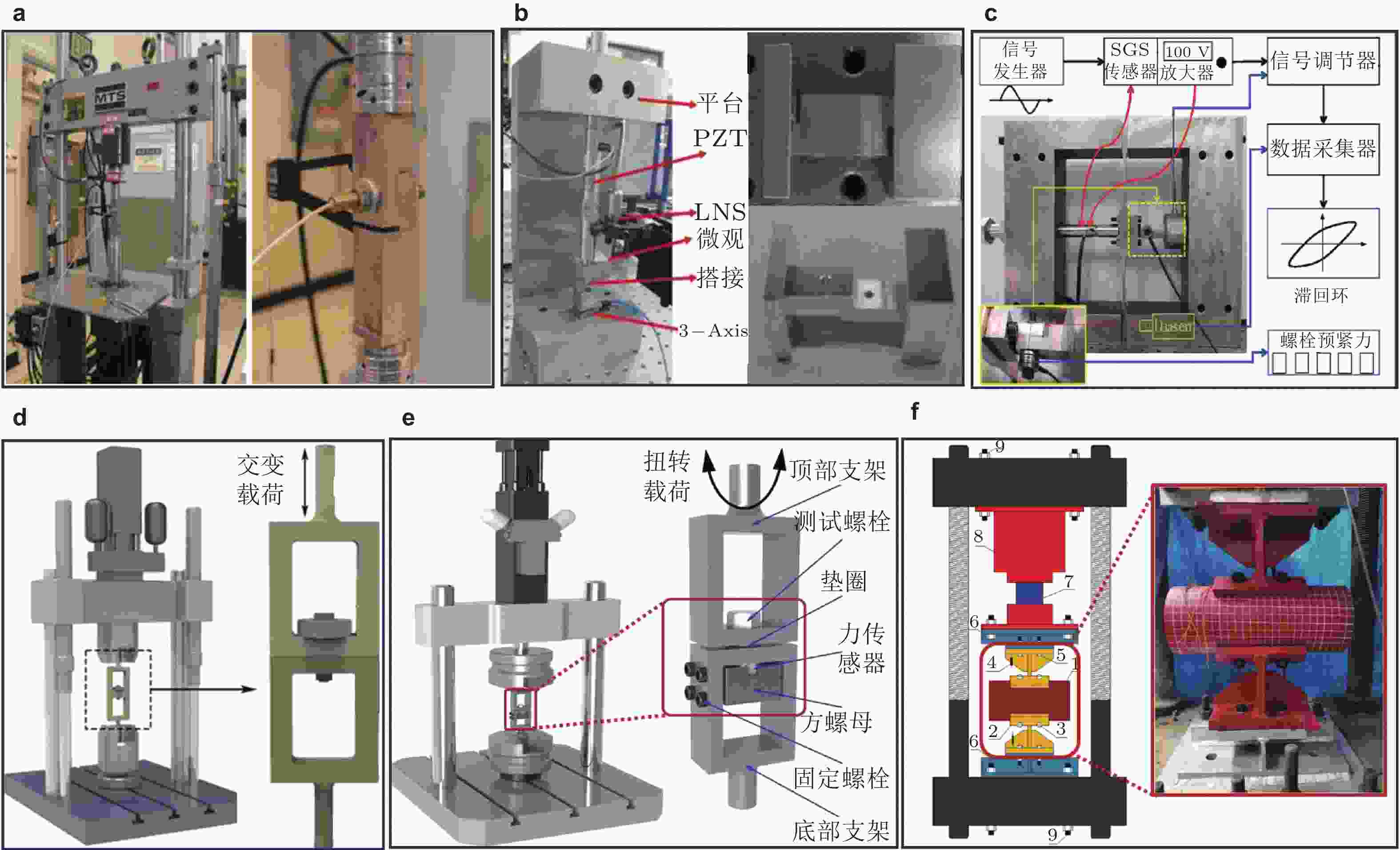

图 21 连接结构各向激励实验台 (a)横向剪切激励1(Segalman et al. 2009b), (b)横向剪切激励2 (Eriten et al. 2011c, Eriten et al. 2011d, Eriten et al. 2012), (c)横向剪切激励3 (Li D et al. 2020c), (d)轴向拉伸激励(Li H et al. 2022), (e)扭转激励(Liu J et al. 2019)(f)撬动激励(Liu L et al. 2023b, Chen H et al. 2023).

-

[1] 艾延廷, 解松霖, 刘玉, 田晶, 赵丹, 刘俊男. 2022. 粗糙表面接触刚度模型的研究进展. 航空发动机, 48: 82-91 (Ai Y T, Xie S L, Liu Y, Tian J, Zhao D, Liu J N. 2022. Research progress of contact stiffness models for rough surfaces. Aeroengine, 48: 82-91).Ai Y T, Xie S L, Liu Y, Tian J, Zhao D, Liu J N. 2022. Research progress of contact stiffness models for rough surfaces. Aeroengine, 48: 82-91. [2] 蔡力钢, 王锋, 李玲, 郭铁能, 赵永胜, 刘志峰. 2013. 栓接结合部动态特性研究进展. 机械工程学报, 09: 158-168 (Cai L G, Wang F, Li L, Guo T N, Zhao Y S, Liu Z F. 2013. Review on dynamic properties of bolted joints. Journal of Mechanical Engineering, 09: 158-168).Cai L G, Wang F, Li L, Guo T N, Zhao Y S, Liu Z F. 2013. Review on dynamic properties of bolted joints. Journal of Mechanical Engineering, 09: 158-168. [3] 曹军义, 刘清华, 洪军. 2021. 螺栓连接微观摩擦到宏观动力学研究综述. 中国机械工程, 32: 1261-1273 (Cao J Y, Liu Q H, Hong J. 2021. Overview of micro friction to macro dynamics for bolted connections. China Mechanical Engineering, 32: 1261-1273).Cao J Y, Liu Q H, Hong J. 2021. Overview of micro friction to macro dynamics for bolted connections. China Mechanical Engineering, 32: 1261-1273. [4] 陈海平, 曾攀, 方刚, 雷丽萍. 2010. 螺纹副承载的分布规律. 机械工程学报, 46: 171-178 (Chen H P, Zeng P, Fang G, Lei L P. 2010. Load distribution of bolted joint. Journal of Mechanical Engineering, 46: 171-178).Chen H P, Zeng P, Fang G, Lei L P. 2010. Load distribution of bolted joint. Journal of Mechanical Engineering, 46: 171-178. [5] 陈建江, 原园, 徐颖强. 2018a. 粗糙表面的加卸载分形接触解析模型. 西安交通大学学报, 52: 98-110 (Chen J J, Yuan Y, Xu Y Q. 2018a. An analytical model of loading-unloading contact between rough surfaces based on fractal theory. Journal of Xi'an Jiaotong University, 52: 98-110).Chen J J, Yuan Y, Xu Y Q. 2018a. An analytical model of loading-unloading contact between rough surfaces based on fractal theory. Journal of Xi'an Jiaotong University, 52: 98-110. [6] 陈建江, 原园, 成雨, 何亚飞. 2018b. 尺度相关的分形结合面法向接触刚度模型. 机械工程学报, 21: 127-137 (Chen J J, Yuan Y, Cheng Y, He Y F. 2018b. Scale dependent normal contact stiffness fractal model of joint interfaces. Journal of Mechanical Engineering, 21: 127-137).Chen J J, Yuan Y, Cheng Y, He Y F. 2018b. Scale dependent normal contact stiffness fractal model of joint interfaces. Journal of Mechanical Engineering, 21: 127-137. [7] 陈奇, 黄守武, 张振, 马运波. 2016. 考虑静摩擦的两圆柱体分形接触强度模型研究. 合肥工业大学学报: 自然科学版, 39: 577-581 (Chen Q, Huang S W, Zhan Z, Ma Y B. 2016. Research on contact strength calculation of two cylinders based on by static friction by fractal theory. Journal of Hefei University of Technology (Natural Science), 39: 577-581).Chen Q, Huang S W, Zhan Z, Ma Y B. 2016. Research on contact strength calculation of two cylinders based on by static friction by fractal theory. Journal of Hefei University of Technology (Natural Science), 39: 577-581. [8] 丁千, 翟红梅. 2013. 机械系统摩擦动力学研究进展. 力学进展, 43: 112-131 (Ding Q, Zhai H M. 2013. The advance in researches of friction dynamics in mechanics system. Advances in Mechanics, 43: 112-131).Ding Q, Zhai H M. 2013. The advance in researches of friction dynamics in mechanics system. Advances in Mechanics, 43: 112-131. [9] 贺李平, 任雪梅. 2020. 螺栓联接的有限元建模方法研究. 北京理工大学学报, 40: 1275-1281 (He L P, Ren X M. 2020. Study on finite element modeling method of bolted joints. Transactions of Beijing Institute of Technology, 40: 1275-1281).He L P, Ren X M. 2020. Study on finite element modeling method of bolted joints. Transactions of Beijing Institute of Technology, 40: 1275-1281. [10] 李九一, 周丰峻, 刘建华, 孙云厚, 朱精忠, 邱明坤. 2023. 扭转荷载下螺旋形螺纹连接件的IWAN改进模型. 吉林大学学报(工学版), 53: 1305-1314 (Li J Y, Zhou F J, Liu J H, Sun Y H, Zhu J Z, Qiu M K. 2023. Modified IWAN model of helical threaded connector imposed to torsional load. Journal of Jilin University(Engineering and Technology Edition), 53: 1305-1314).Li J Y, Zhou F J, Liu J H, Sun Y H, Zhu J Z, Qiu M K. 2023. Modified IWAN model of helical threaded connector imposed to torsional load. Journal of Jilin University(Engineering and Technology Edition), 53: 1305-1314. [11] 李玲, 赵凯, 林红, 王晶晶, 蔡安江. 2023. 螺栓结合面法向接触刚度不确定性量化. 吉林大学学报(工学版), 53: 1911-1919 (Li L, Zhao K, Lin H, Wang J J, Cai A J. 2023. Uncertainty quantification of normal contact stiffness of bolt joint surface. Journal of Jilin University(Engineering and Technology Edition), 53: 1911-1919).Li L, Zhao K, Lin H, Wang J J, Cai A J. 2023. Uncertainty quantification of normal contact stiffness of bolt joint surface. Journal of Jilin University(Engineering and Technology Edition), 53: 1911-1919. [12] 李小彭, 刘洋, 王雪, 户丹丹, 毛昕, 王冰冰. 2018. 三维分形接触热导的建模与多参数影响分析. 振动与冲击, 37: 1-6 (Li X P, Liu Y, Wang X, Hu D D, Mao X, Wang B B. 2018. Modeling of 3-D fractal thermal contact conductance and multi-parameter effect analyses. Journal of Vibration and Shock, 37: 1-6).Li X P, Liu Y, Wang X, Hu D D, Mao X, Wang B B. 2018. Modeling of 3-D fractal thermal contact conductance and multi-parameter effect analyses. Journal of Vibration and Shock, 37: 1-6. [13] 李一堃, 郝志明, 章定国. 2015. 基于六参数非均匀密度函数的伊万模型研究. 力学学报, 47: 513-520 (Li Y K, Hao Z M, Zhang D G, 2015. Investigation into Iwan model based on the six-parameter non-uniform density function. Chinese Journal of Theoretical and Applied Mechanics, 47: 513-520).Li Y K, Hao Z M, Zhang D G, 2015. Investigation into Iwan model based on the six-parameter non-uniform density function. Chinese Journal of Theoretical and Applied Mechanics, 47: 513-520. [14] 李一堃, 郝志明. 2018. 连接结构宏观滑移能量耗散特性研究. 机械工程学报, 54: 125-131 (Li Y K, Hao Z M. 2018. Investigation on the energy dissipation properties of jointed structure during macro-slip stage. Journal of Mechanical Engineering, 54: 125-131).Li Y K, Hao Z M. 2018. Investigation on the energy dissipation properties of jointed structure during macro-slip stage. Journal of Mechanical Engineering, 54: 125-131. [15] 李玉奇, 罗忠, 栗江, 侯小捷. 2019. 考虑螺栓联接结构的轴承-转子系统振动特性分析. 机械工程学报, 55: 60-67 (Li Y Q, Luo Z, Li J, Hou X J. 2019. Vibration characteristics of rotor bearing system with bolted joint structure. Journal of Mechanical Engineering, 55: 60-67).Li Y Q, Luo Z, Li J, Hou X J. 2019. Vibration characteristics of rotor bearing system with bolted joint structure. Journal of Mechanical Engineering, 55: 60-67. [16] 刘嘉鸣, 全东, 赵国群. 2023. 航空复合材料连接成形技术研究进展. 机械工程学报, 59: 119-142 (Liu J M, Quan D, Zhao G Q. 2023. Progress in joint forming technology of aviation composites. Journal of Mechanical Engineering, 59: 119-142). doi: 10.3901/JME.2023.20.119Liu J M, Quan D, Zhao G Q. 2023. Progress in joint forming technology of aviation composites. Journal of Mechanical Engineering, 59: 119-142. doi: 10.3901/JME.2023.20.119 [17] 刘丽兰, 刘宏昭, 吴子英, 王忠民. 2008. 机械系统中摩擦模型的研究进展. 力学进展, 38: 201-213 (Liu L L, Liu H Z, Wu Z Y, Wang Z M. 2008. An overview of friction models in mechanical systems. Advances in Mechanics, 38: 201-213).Liu L L, Liu H Z, Wu Z Y, Wang Z M. 2008. An overview of friction models in mechanical systems. Advances in Mechanics, 38: 201-213. [18] 山美娟, 赵丽滨. 2023. 复合材料螺栓连接的增强设计与分析研究进展. 复合材料学报, 40: 3771-3784 (Shan M J, Zhao L B. 2023. Research progress in reinforcement design and analysis of composite bolted joints. Acta Materiae Compositae Sinica, 40: 3771-3784).Shan M J, Zhao L B. 2023. Research progress in reinforcement design and analysis of composite bolted joints. Acta Materiae Compositae Sinica, 40: 3771-3784. [19] 田红亮, 钟先友, 秦红玲, 赵春华, 方子帆, 朱大林, 张发军. 2013. 依据各向异性分形几何理论的固定结合部法向接触力学模型. 机械工程学报, 49: 108-122 (Tian H L, Zhong X Y, Qin H L, Zhao C H, Fang Z F, Zhu D L, Zhang F J. 2013. Normal contact mechanics model of fixed joint interface adopting anisotropic fractal geometrical theory. Journal of Mechanical Engineering, 49: 108-122).Tian H L, Zhong X Y, Qin H L, Zhao C H, Fang Z F, Zhu D L, Zhang F J. 2013. Normal contact mechanics model of fixed joint interface adopting anisotropic fractal geometrical theory. Journal of Mechanical Engineering, 49: 108-122. [20] 田红亮, 严峥嵘, 郑金华, 张屹. 2016. 一个新的干摩擦结合部法向接触阻尼方程. 哈尔滨工业大学学报, 48: 133-140 (Tian H L, Yan Z R, Zheng J H, Zhang Y. 2016. A novel expression of normal contact damping for dry tribology joint interface. Journal of Harbin Institute of Technology, 48: 133-140).Tian H L, Yan Z R, Zheng J H, Zhang Y. 2016. A novel expression of normal contact damping for dry tribology joint interface. Journal of Harbin Institute of Technology, 48: 133-140. [21] 王东, 徐超, 胡杰, 万强, 陈红永. 2018. 连接结构接触界面非线性力学建模研究. 力学学报, 50: 44-57 (Wang D, Xu C, Hu J, Wan Q, Chen H Y. 2018. Nonlinear mechanics modeling for joint interface of assembled structure. Chinese Journal of Theoretical and Applied Mechanics, 50: 44-57).Wang D, Xu C, Hu J, Wan Q, Chen H Y. 2018. Nonlinear mechanics modeling for joint interface of assembled structure. Chinese Journal of Theoretical and Applied Mechanics, 50: 44-57. [22] 王帅, 卢红立, 石玉红, 郝鹏, 马勇. 2022. MJ螺纹沉淀硬化不锈钢螺栓破坏研究. 强度与环境, 49: 82-87 (Wang S, Lu H L, Shi Y H, Hao P, Ma Y. 2022. Research on failure of MJ thread bolt made with precipitation-hardening stainless steel. Structure & Environment Engineering, 49: 82-87).Wang S, Lu H L, Shi Y H, Hao P, Ma Y. 2022. Research on failure of MJ thread bolt made with precipitation-hardening stainless steel. Structure & Environment Engineering, 49: 82-87. [23] 王余松, 张学良, 温淑花, 范世荣. 2018. 分形粗糙表面特征长度尺度参数小波识别法. 机械工程学报, 54: 185-192 (Wang Y S, Zhang X L, Wen S H, Fan S R. 2018. Wavelet method identifying the characteristic length scale parameter of fractal rough surface. Journal of Mechanical Engineering, 54: 185-192).Wang Y S, Zhang X L, Wen S H, Fan S R. 2018. Wavelet method identifying the characteristic length scale parameter of fractal rough surface. Journal of Mechanical Engineering, 54: 185-192. [24] 文双玲, 田珊, 侯兆欣. 2014. 《钢结构高强度螺栓连接技术规程》修订内容简述. 建筑结构, 44: 89-92 (Wen S L, Tian S, Hou Z X. 2014. Brief introduction of revised contents of technical specification for high strength bolt connections of steel structures. Building Structure, 44: 89-92).Wen S L, Tian S, Hou Z X. 2014. Brief introduction of revised contents of technical specification for high strength bolt connections of steel structures. Building Structure, 44: 89-92. [25] 徐超, 王东. 2014. 考虑粗糙表面接触的连接面黏滑摩擦建模. 西安交通大学学报, 48: 131-140 (Xu C, Wang D. 2014. Stick-slip friction modeling of structural joint interface considering rough contact. Journal of Xi'an Jiaotong University, 48: 131-140). doi: 10.7652/xjtuxb201407022Xu C, Wang D. 2014. Stick-slip friction modeling of structural joint interface considering rough contact. Journal of Xi'an Jiaotong University, 48: 131-140. doi: 10.7652/xjtuxb201407022 [26] 杨毅, 朱涛, 张江田, 黄明惠, 肖守讷, 丁浩谞. 2022. 剪切螺栓设计及在电力机车结构耐撞性上的运用. 中南大学学报(自然科学版), 53: 1877-1888 (Yang Y, Zhu T, Zhang H T, Huang M H, Xiao S N, Ding H X. 2022. Shear bolt design and its application in crashworthiness of electric locomotive structure. Journal of Central South University(Science and Technology), 53: 1877-1888).Yang Y, Zhu T, Zhang H T, Huang M H, Xiao S N, Ding H X. 2022. Shear bolt design and its application in crashworthiness of electric locomotive structure. Journal of Central South University(Science and Technology), 53: 1877-1888. [27] 姚星宇, 王建军. 2017. 航空发动机螺栓连接载荷与结构参数对连接刚度影响规律. 推进技术, 38: 424-433 (Yao X Y, Wang J J. 2017. Effects of load and structure parameters of aero-engine bolted joints on joint stiffness. Journal of Propulsion Technology, 38: 424-433).Yao X Y, Wang J J. 2017. Effects of load and structure parameters of aero-engine bolted joints on joint stiffness. Journal of Propulsion Technology, 38: 424-433. [28] 张根辈, 臧朝平, 王晓伟, 张璋. 2014. 螺栓连接框架结构的有限元模型修正. 工程力学, 31: 26-33 (Zhang G B, Zang C P, Wang X W, Zhang Z. 2014. Finite element model updating of a framed structure with bolted joints. Engineering Mechanics, 31: 26-33).Zhang G B, Zang C P, Wang X W, Zhang Z. 2014. Finite element model updating of a framed structure with bolted joints. Engineering Mechanics, 31: 26-33. [29] 张凯. 2019. 基于分形结合面的精密机械结构装配性能研究. 长沙: 国防科技大学(Zhang K. 2019. Research on assembly performance of precision mechanical structure based on fractal joint surface. Changsha: National University of Defense Technology. [30] 张文明, 孟光. 2005. 静电微电机微转子接触动力学特性分析. 力学学报, 37: 756-763 (Zhang W M, Meng G. Contact dynamics of the micro-rotor in electrostatic micromotor. Chinese Journal of Theoretical and Applied Mechanics, 37: 756-763).Zhang W M, Meng G. Contact dynamics of the micro-rotor in electrostatic micromotor. Chinese Journal of Theoretical and Applied Mechanics, 37: 756-763. [31] 张学良, 张伟, 温淑花, 姚世生. 2021. 结合面静摩擦因数尺度关联三维分形模型. 机械工程学报, 57: 127-138 (Zhang X L, Zhang W, Wen S H, Yao S S. 2021. Three-dimensional fractal model with scale correlation for static friction factor of joint interfaces. Journal of Mechanical Engineering, 57: 127-138). doi: 10.3901/JME.2021.09.127Zhang X L, Zhang W, Wen S H, Yao S S. 2021. Three-dimensional fractal model with scale correlation for static friction factor of joint interfaces. Journal of Mechanical Engineering, 57: 127-138. doi: 10.3901/JME.2021.09.127 [32] 赵宏达, 丁继锋, 郝志伟, 刘伟, 孙毅, 刘一志. 2020. 复杂航天器结构火工冲击环境预示方法研究. 宇航学报, 41: 35-43 (Zhao H D, Ding J F, Hao Z W, Liu W, Sun Y, Liu Y Z. 2020. Study on prediction methods of pyroshock environment for complex spacecraft structures. Journal of Astronautics, 41: 35-43). doi: 10.3873/j.issn.1000-1328.2020.01.005Zhao H D, Ding J F, Hao Z W, Liu W, Sun Y, Liu Y Z. 2020. Study on prediction methods of pyroshock environment for complex spacecraft structures. Journal of Astronautics, 41: 35-43. doi: 10.3873/j.issn.1000-1328.2020.01.005 [33] Abad J, Medel F J, Franco J M. 2014. Determination of valanis model parameters in a bolted lap joint: Experimental and numerical analyses of frictional dissipation. Int. J. Mech. Sci., 89: 289-298. doi: 10.1016/j.ijmecsci.2014.09.014 [34] Abar B M, Ghobadi M S. 2022. New generation of bolted bracket connections: Safe load-carrying capacity and structural damage assessment. Eng. Struct., 252: 113662. doi: 10.1016/j.engstruct.2021.113662 [35] Afzal M, Arteaga I L, Kari L. 2016. An analytical calculation of the Jacobian matrix for 3D friction contact model applied to turbine blade shroud contact. Comput. Struct., 177: 204-217. doi: 10.1016/j.compstruc.2016.08.014 [36] Armstrong-Hélouvry B. 1991. Control of machines with friction. Springer Science & Business Media. [37] Armstrong-Hélouvry B, Dupont P, De Wit C C. 1994. A survey of models, analysis tools and compensation methods for the control of machines with friction. Automatica, 30: 1083-1138. doi: 10.1016/0005-1098(94)90209-7 [38] Ataş A, Soutis C. 2017. Damage and failure analysis of bolted joints in composite laminates. In: The structural integrity of carbon fiber composites. Volume 21. [39] Avellon, G. 2014. Fastener failures prove surprisingly common in the automotive industry. Available online:https://boltfailure.com/fastener-failures-prove-surprisingly-common-in-the-automotive-industry. [40] Awrejcewicz J, Dzyubak L, Lamarque C H. 2008. Modelling of hysteresis using Masing-Bouc-Wen’s framework and search of conditions for the chaotic responses. Commun. Nonlinear Sci. Numer. Simul., 13: 939-958. doi: 10.1016/j.cnsns.2006.09.003 [41] Balaji N N, Brake M R. 2019. The surrogate system hypothesis for joint mechanics. Mech. Syst. Signal Proc., 126: 42-64. doi: 10.1016/j.ymssp.2019.02.013 [42] Balaji N N, Chen W, Brake M R. 2020. Traction-based multi-scale nonlinear dynamic modeling of bolted joints: Formulation, application, and trends in micro-scale interface evolution. Mech. Syst. Signal Proc., 139: 106615. doi: 10.1016/j.ymssp.2020.106615 [43] Bauschinger J. 1886. Ueber die Veranderung der elasticitatsgrenge und der festigkeit des eisens und stahls durch strecken und quetschn, durch erwarmen und abkuhlen und durch oftmal wiederholte beanspruchung. Mitteilungen aus dem Mechanisch-Technischen Laboratorium der K. Technischen Hochschule in Munchen 13. [44] Beards C F, Williams J L. 1977. The damping of structural vibration by rotational slip in joints. J. Sound Vibr., 53: 333-340. doi: 10.1016/0022-460X(77)90418-7 [45] Beards C F, Woowat A. 1985. The control of frame vibration by friction damping in joints. J. Vib. Acoust., 107: 1-7. doi: 10.1115/1.3274710 [46] Becker J. 2009. Semi-active control of friction dampers and feedforward tracking control design for structural vibration reduction. University of Stuttgart. [47] Bograd S, Reuss P, Schmidt A, Gaul L, Mayer M. 2011. Modeling the dynamics of mechanical joints. Mech. Syst. Signal Proc., 25: 2801-2826. doi: 10.1016/j.ymssp.2011.01.010 [48] Bohlin T. 1994. A case study of grey box identification. Automatica, 30: 307-318. doi: 10.1016/0005-1098(94)90032-9 [49] Bonney M S, Robertson B A, Mignolet M, Schempp F, Brake M R. 2016. Experimental determination of frictional interface models. In: Dynamics of Coupled Structures. Volume 4. [50] Botto D, Gastadi C, Gola M M, Umer M. 2018. An experimental investigation of the dynamics of a blade with two under-platform dampers. J. Eng. Gas Turbines Power., 140: 032504. doi: 10.1115/1.4037865 [51] Bouc R. 1971. A mathematical model for hysteresis. Acta Acust. United Acust., 24: 16-25. [52] Brake M R, Reuss P, Schwingshackl C W, Salles L, Negus M E, Peebles D E, Tiedemann M. 2014. The 2014 Sandia nonlinear mechanics and dynamics summer research institute. Albuquerque: Sandia National Laboratories. [53] Brake M R, Ewins D J, Segalman D J, Bergman L A, Quinn D D. 2016. Proceedings of the fourth international workshop on jointed structures. Albuquerque: Sandia National Laboratories. [54] Brake M R. 2017. A reduced Iwan model that includes pinning for bolted joint mechanics. Nonlinear Dyn., 87: 1335-1349. doi: 10.1007/s11071-016-3117-2 [55] Brake M R. 2018. The mechanics of jointed structures. Springer. International Publishing, Berlin. [56] Brake M R, Schwingshackl C W, Reuß P. 2019. Observations of variability and repeatability in jointed structures. Mech. Syst. Signal Proc., 129: 282-307. doi: 10.1016/j.ymssp.2019.04.020 [57] Britannica. 1985. Japan Airlines flight 123.https://www.britannica.com/facts/Mount-Osutaka-airline-disaster. [58] Brizmer V, Zait Y, Kligerman Y, Etsion I. 2006a. The effect of contact conditions and material properties on elastic-plastic spherical contact. J. Mech. Mater. Struct., 01: 865-879. doi: 10.2140/jomms.2006.1.865 [59] Brizmer V, Kligerman Y, Etsion I. 2006b. The effect of contact conditions and material properties on the elasticity terminus of a spherical contact. Int. J. Solids Struct., 43: 5736-5749. doi: 10.1016/j.ijsolstr.2005.07.034 [60] Brizmer V, Kligerman Y, Etsion I. 2007. Elastic–plastic spherical contact under combined normal and tangential loading in full stick. Tribol. Lett., 25: 61-70. [61] Chang W R, Etsion I, Bogy D B. 1987. An elastic-plastic model for the contact of rough surfaces. J. Tribol., 109: 257-263 doi: 10.1115/1.3261348 [62] Chang W R. 1997. An elastic-plastic contact model for a rough surface with an ion-plated soft metallic coating. Wear, 212: 229-237. doi: 10.1016/S0043-1648(97)00148-8 [63] Chang Y, Ding J, Fan H. 2023. Interfacial micromechanics study on contact modeling for bolted joints. Acta Mech., 234: 3377-3396. doi: 10.1007/s00707-023-03562-x [64] Chen H, Liu L, Cai M, Sun L, Wang P, Liu M. 2023. Mechanical behavior of TOBs bolted T-stubs with thick arc-shaped flange to steel tube under tension: A numerical and theoretical investigation. Structures, 56: 104880. doi: 10.1016/j.istruc.2023.104880 [65] Chen J, Zhang J, Hong J, Zhu L. 2019. Modeling tangential contact of lap joints considering surface topography based on Iwan model. Tribol. Int., 137: 66-75. doi: 10.1016/j.triboint.2019.04.031 [66] Chen Q, Xu F, Liu P, Fan H. 2016. Research on fractal model of normal contact stiffness between two spheroidal joint surfaces considering friction factor. Tribol. Int., 97: 253-264. doi: 10.1016/j.triboint.2016.01.023 [67] Choi J I, Hasheminia S M, Chun H J, Park J C., Chang H S. 2018. Failure load prediction of composite bolted joint with clamping force. Compos. Struct., 189: 247-255. doi: 10.1016/j.compstruct.2018.01.037 [68] Chu Y, Wen H, Chen T. 2016. Nonlinear modeling and identification of an aluminum honeycomb panel with multiple bolts. Shock Vib., 2016: 1276753. [69] Cohen D, Kligerman Y, Etsion I. 2008. A model for contact and static friction of nominally flat rough surfaces under full stick contact condition. J. Tribol., 130: 031401. doi: 10.1115/1.2908925 [70] Cohen D, Kligerman Y, Etsion I. 2009. The effect of surface roughness on static friction and junction growth of an elastic-plastic spherical contact. J. Tribol., 131: 021404. doi: 10.1115/1.3075866 [71] Cooper S B, Rosatello M, Mathis A T, Johnson K, Brake M R, Allen M S, Mayes R L. 2017. Effect of far-field structure on joint properties. In: Dynamics of Coupled Structures, Volume 4. [72] Crawley E F. 1989. Nonlinear characteristics of joints as elements of multi-body dynamic systems. NASA, Langley Research Center, Computational Methods for Structural Mechanics and Dynamics. [73] Dahl P R. 1975. Solid friction damping of spacecraft vibrations. In: Proceedings of AIAA Guidance and Control Conf, Boston. [74] Dahl P R. 1976. Solid friction damping of mechanical vibrations. AIAA J., 14: 1675-1682. doi: 10.2514/3.61511 [75] De Wit C C, Olsson H, Astrom K J, Lischinsky P. 1995. A new model for control of systems with friction. IEEE Trans. Autom. Control, 40: 419-425. doi: 10.1109/9.376053 [76] De Wit C C, Lischinsky P. 1997. Adaptive friction compensation with partially known dynamic friction model. Int. J. Adapt. Control Signal Process., 11: 65-80. doi: 10.1002/(SICI)1099-1115(199702)11:1<65::AID-ACS395>3.0.CO;2-3 [77] Deaner B J, Allen M S, Starr M J, Segalman D J, Sumali H. 2015. Application of viscous and Iwan modal damping models to experimental measurements from bolted structures. J. Vib. Acoust., 137: 021012. doi: 10.1115/1.4029074 [78] Dossogne T, Jerome T W, Lancereau D P, Smith S A, Brake M R, Pacini B R, Schwingshackl C W. 2017a. Experimental assessment of the influence of interface geometries on structural dynamic response. In: Dynamics of Coupled Structures, Volume 4. [79] Dossogne T, Jerome T W, Lancereau D P, Smith S A, Brake M R, Pacini B R, Reuss P, Schwingshackl C W. 2017b. Experimental assessment of jointed configuration. In: A Conference and Exposition on Structural Dynamics, Garden Grove. [80] Duhem P. 1897. Die dauernden aenderungen und die thermodynamik. Z. Phys. Chem., 24: 666. [81] Epower Metals. 2020. Failure analysis of bolt corrosion. Available online: https://www.epowermetals.com/failure-analysis-of-bolt-corrosion.html. [82] Eriten M, Polycarpou A A, Bergman L A. 2011a. Surface roughness effects on energy dissipation in fretting contact of nominally flat surfaces. J. Appl. Mech., 78: 021011. doi: 10.1115/1.4002433 [83] Eriten M, Polycarpou A A, Bergman L. 2011b. Physics-based modeling for fretting behavior of nominally flat rough surfaces. Int. J. Solids Struct., 48: 1436-1450. doi: 10.1016/j.ijsolstr.2011.01.028 [84] Eriten M, Polycarpou A A, Bergman L A. 2011c. Development of a lap joint fretting apparatus. Exp. Mech., 51: 1405-1419. doi: 10.1007/s11340-010-9458-8 [85] Eriten M, Polycarpou A A, Bergman L A. 2011d. Effects of surface roughness and lubrication on the early stages of fretting of mechanical lap joints. Wear, 271: 2928-2939. doi: 10.1016/j.wear.2011.06.011 [86] Eriten M, Lee C H, Polycarpou A A. 2012. Measurements of tangential stiffness and damping of mechanical joints: Direct versus indirect contact resonance methods. Tribol. Int., 50: 35-44. doi: 10.1016/j.triboint.2012.01.002 [87] Esmaeili F, Chakherlou T N, Zehsaz M. 2014. Investigation of bolt clamping force on the fatigue life of double lap simple bolted and hybrid (bolted/bonded) joints via experimental and numerical analysis. Eng. Fail. Anal., 45: 406-420. doi: 10.1016/j.engfailanal.2014.07.014 [88] Etsion I, Kligerman Y, Kadin Y. 2005. Unloading of an elastic–plastic loaded spherical contact. Int. J. Solids Struct., 42: 3716-3729. doi: 10.1016/j.ijsolstr.2004.12.006 [89] Evseev D G, Medvedev B M, Grigoriyan G G. 1991. Modification of the elastic-plastic model for the contact of rough surfaces. Wear, 150: 79-88. doi: 10.1016/0043-1648(91)90307-G [90] Federal Aviation Administration. 1979. Lessons learned from transport airplane accidents: N110AA. https://www.faa.gov/lessons_learned/transport_airplane/accidents/N110AA. [91] Fidalgo A, Packer J A. 2022. Evaluation of bolted CHS flange-plate connections under axial tension. J. Constr. Steel. Res., 196: 107399. doi: 10.1016/j.jcsr.2022.107399 [92] Flicek R C, Moore K J, Castelluccio G M, Brake M R, Truster T, Hammetter C I. 2016. Stress waves propagating through bolted joints. In: Dynamics of Coupled Structures, Volume 4. [93] Fonfría J J, Amador A M, González A Q, Fernández L P. 2023. Investigating the T-stub connection with different web-to-flange joint configurations. Eng. Struct., 294: 116715. doi: 10.1016/j.engstruct.2023.116715 [94] Galińska A. 2020. Mechanical joining of fibre reinforced polymer composites to metals—A review. Part I: Bolted joining. Polymers, 12: 2252. doi: 10.3390/polym12102252 [95] Gaul L, Nackenhorst U, Willner K, Lenz J. 1994. Nonlinear vibration damping of structures with bolted joints. In: Proceedings-Spie the International Society for Optical Engineering. [96] Gaul L, Lenz J. 1997. Nonlinear Dyn. of structures assembled by bolted joints. Acta Mech., 125: 169-181. doi: 10.1007/BF01177306 [97] Gaul L, Lenz J, Sachau D. 1998. Active damping of space structures by contact pressure control in joints. Mech. Struct. Mach., 26: 81-100. doi: 10.1080/08905459808945421 [98] Gaul L, Nitsche R. 2001. The role of friction in mechanical joints. Appl. Mech. Rev., 54: 93-106. doi: 10.1115/1.3097294 [99] Gaul L, Becker J. 2010. Damping prediction of structures with bolted joints. Shock Vib., 17: 359-371. doi: 10.1155/2010/314354 [100] Ge T, Xu Z D, Guo Y Q, Huang X. H, He Z F. 2022. Experimental investigation and multiscale modeling of VE damper considering chain network and ambient temperature influence. J. Eng. Mech., 148: 04021124. [101] Gong H, Liu J, Feng H. 2022. Review on anti-loosening methods for threaded fasteners. Chin. J. Aeronaut., 35: 47-61. [102] Gray P J, McCarthy C T. 2010. A global bolted joint model for finite element analysis of load distributions in multi-bolt composite joints. Compos. B Eng., 41: 317-325. doi: 10.1016/j.compositesb.2010.03.001 [103] Greenwood J A, Williamson J P. 1966. Contact of nominally flat surfaces. Proc. R. Soc. Lond. A, 295: 300-319. doi: 10.1098/rspa.1966.0242 [104] Greenwood J A, Tripp J H. 1967. The elastic contact of rough spheres. J. Appl. Mech., 34: 153-159. doi: 10.1115/1.3607616 [105] Greenwood J A, Tripp J H. 1970. The contact of two nominally flat rough surfaces. Proc. Inst. Mech. Eng., 185: 625-633. doi: 10.1243/PIME_PROC_1970_185_069_02 [106] Gregory D L, Resor B R, Coleman R G, Smallwood D O. 2003. Experimental investigations of an inclined lap-type bolted joint. Albuquerque: Sandia National Laboratories. [107] Gross J, Armand J, Lacayo R M, Reuß P, Salles L, Schwingshackl C W, Kuether R J. 2016. A numerical round robin for the prediction of the dynamics of jointed structures. In: Dynamics of Coupled Structures, Volume 4. [108] Hammami C, Balmes E, Guskov M. 2016. Numerical design and test on an assembled structure of a bolted joint with viscoelastic damping. Mech. Syst. Signal Proc., 70: 714-724. [109] Hausmann J M, Helfrich B, Motsch N. 2017. Aspects of preloaded bolted joints of fiber reinforced polymers and metals. Key Eng. Mater., 742: 401-407. doi: 10.4028/www.scientific.net/KEM.742.401 [110] Ho-Nguyen-Tan T, Kim H G. 2020. A novel scheme for modelling and analysis of spot-welded shell structures using interface shell elements. Comput. Struct., 239: 106340. doi: 10.1016/j.compstruc.2020.106340 [111] Huang J, Liu J, Gong H, Deng X. 2022. A comprehensive review of loosening detection methods for threaded fasteners. Mech. Syst. Signal Proc., 168: 108652. doi: 10.1016/j.ymssp.2021.108652 [112] Interbartolo M. 2009. Apollo spacecraft and saturn v launch vehicle pyrotechnics/explosive devices. Nasa Technical Reports Server. [113] Ishlinskii A Y. 1944. Some applications of statistical methods to describing deformations of bodies. Izv. Akad. Nauk SSSR, 09: 583-590. [114] Iurian C, Ikhouane F, Rodellar Benedé J, Griñó Cubero R. 2005. Identification of a system with dry friction. Technical Report, Universitat Politècnica de Catalunya, Spain. [115] Iwan W D. 1966. A distributed-element model for hysteresis and its steady-state dynamic response. J. Appl. Mech., 33: 893-900. doi: 10.1115/1.3625199 [116] Iwan W D. 1967. On a class of models for the yielding behavior of continuous and composite systems. J. Appl. Mech., 34: 612-617. doi: 10.1115/1.3607751 [117] Jalali H, Ahmadian H, Pourahmadian F. 2011. Identification of micro-vibro-impacts at boundary condition of a nonlinear beam. Mech. Syst. Signal Proc., 25: 1073-1085. doi: 10.1016/j.ymssp.2010.09.007 [118] Jiang D, Wang M, Sun Y, Hang X. 2023. Equivalent modeling of bolted connections under transverse load using iwan-based material properties. Metals, 13: 91. doi: 10.3390/met13010091 [119] Jiménez-Peña C, Talemi R H, Rossi B, Debruyne D. 2017. Investigations on the fretting fatigue failure mechanism of bolted joints in high strength steel subjected to different levels of pre-tension. Tribol. Int., 108: 128-140. doi: 10.1016/j.triboint.2016.11.014 [120] Johnson K L. 1987. Contact mechanics. Cambridge, Cambridge University Press. [121] Junker G H. 1969. New criteria for self-loosening of fasteners under vibration. Sae Trans., 78: 314-335. [122] Junker G H. 1972. Criteria for self loosening of fasteners under vibration. Aircr. Eng. Aerosp. Technol., 44: 14-16. [123] Juoksukangas J, Lehtovaara A, Mäntylä A. 2016. Experimental and numerical investigation of fretting fatigue behavior in bolted joints. Tribol. Int., 103: 440-448. doi: 10.1016/j.triboint.2016.07.021 [124] Kadin Y, Kligerman Y, Etsion I. 2006. Unloading an elastic–plastic contact of rough surfaces. J. Mech. Phys. Solids, 54: 2652-2674. doi: 10.1016/j.jmps.2006.04.013 [125] Kapti S, Sayman O, Ozen M, Benli S. 2010. Experimental and numerical failure analysis of carbon/epoxy laminated composite joints under different conditions. Mater. Des., 31: 4933-4942. doi: 10.1016/j.matdes.2010.05.018 [126] Karakuzu R, Taylak N, İçten B M, Aktaş M. 2008. Effects of geometric parameters on failure behavior in laminated composite plates with two parallel pin-loaded holes. Compos. Struct., 85: 1-9. doi: 10.1016/j.compstruct.2007.10.003 [127] Karnopp D. 1985. Computer simulation of stick-slip friction in mechanical dynamic systems. J Dyn Syst Meas Control, 107: 100-103 doi: 10.1115/1.3140698 [128] Kelly G, Hallström S. 2004. Bearing strength of carbon fibre/epoxy laminates: effects of bolt-hole clearance. Compos. B Eng., 35: 331-343. doi: 10.1016/j.compositesb.2003.11.001 [129] Khani R, Hosseinzadeh Y, Asl M H. 2023. Investigating the prying force magnitude and location in the T-stub connection based on the energy method. Eng. Struct., 280: 115655. doi: 10.1016/j.engstruct.2023.115655 [130] Khashaba U A, Sallam H E, Al-Shorbagy A E, Seif M A. 2006. Effect of washer size and tightening torque on the performance of bolted joints in composite structures. Compos. Struct., 73: 310-317. doi: 10.1016/j.compstruct.2005.02.004 [131] Kim J, Yoon J C, Kang B S. 2007. Finite element analysis and modeling of structure with bolted joints. Appl. Math. Model., 31: 895-911. doi: 10.1016/j.apm.2006.03.020 [132] Kim J S, Huh H, Kwon T S. 2008. Crashworthiness design of the shear bolts for light collision safety devices. Int. J. Mod. Phys. B, 22: 5603-5608. doi: 10.1142/S0217979208050887 [133] Kogut L, Etsion I. 2002. Elastic-plastic contact analysis of a sphere and a rigid flat. J. Appl. Mech., 69: 657-662. doi: 10.1115/1.1490373 [134] Kombate T J, Taşkın K. 2022) State-of-the-art review on the behaviour of T-stubs and prying action. J. Constr. Steel. Res., 191: 107203. [135] Lacayo R M, Deaner B J, Allen M S. 2017. A numerical study on the limitations of modal Iwan models for impulsive excitations. J. Sound Vibr., 390: 118-140. doi: 10.1016/j.jsv.2016.11.038 [136] Lacayo R, Pesaresi L, Groß J, Fochler D, Armand J, Salles L, Brake M. 2019. Nonlinear modeling of structures with bolted joints: a comparison of two approaches based on a time-domain and frequency-domain solver. Mech. Syst. Signal Proc., 114: 413-438. doi: 10.1016/j.ymssp.2018.05.033 [137] Li C, Miao X, Qiao R, Tang Q. 2021a. Modeling method of bolted joints with micro-slip features and its application in flanged cylindrical shell. Thin-Walled Struct., 164: 107854. doi: 10.1016/j.tws.2021.107854 [138] Li C, Jiang Y, Qiao R, Miao X. 2021b. Modeling and parameters identification of the connection interface of bolted joints based on an improved micro-slip model. Mech. Syst. Signal Proc., 153: 107514. doi: 10.1016/j.ymssp.2020.107514 [139] Li D, Botto D, Xu C, Liu T, Gola M. 2019a. A micro-slip friction modeling approach and its application in underplatform damper kinematics. Int. J. Mech. Sci., 161: 105029. [140] Li D, Xu C, Liu T, Gola M M, Wen L. 2019b. A modified Iwan model for micro-slip in the context of dampers for turbine blade dynamics. Mech. Syst. Signal Proc., 121: 14-30. doi: 10.1016/j.ymssp.2018.11.002 [141] Li D, Botto D, Xu C, Gola M. 2020a. A new approach for the determination of the Iwan density function in modeling friction contact. Int. J. Mech. Sci., 180: 105671. doi: 10.1016/j.ijmecsci.2020.105671 [142] Li D, Xu C, Kang J, Zhang Z. 2020b. Modeling tangential friction based on contact pressure distribution for predicting dynamic responses of bolted joint structures. Nonlinear Dyn., 101: 255-269. doi: 10.1007/s11071-020-05765-6 [143] Li D, Xu C, Botto D, Zhang Z, Gola M. 2020c. A fretting test apparatus for measuring friction hysteresis of bolted joints. Tribol. Int., 151: 106431. doi: 10.1016/j.triboint.2020.106431 [144] Li D, Botto D, Li R, Xu C, Zhang W. 2022. Experimental and theoretical studies on friction contact of bolted joint interfaces. Int. J. Mech. Sci., 236: 107773. doi: 10.1016/j.ijmecsci.2022.107773 [145] Li H, Zhao Y, Jiang J, Wang H, He J, Liu J, Zhu M. 2022. Effect of frequency on the fatigue performance of bolted joints under axial excitation. Tribol. Int., 176: 107933. doi: 10.1016/j.triboint.2022.107933 [146] Li Y, Hao Z. 2016. A six-parameter Iwan model and its application. Mech. Syst. Signal Proc., 68: 354-365. [147] Li Y, Hao Z, Feng J, Zhang D. 2017. Investigation into discretization methods of the six-parameter Iwan model. Mech. Syst. Signal Proc., 85: 98-110. doi: 10.1016/j.ymssp.2016.07.032 [148] Li Y, Hao Z, Du Q, Xing M, Dou L, Li Y. 2021. An experimental approach on energy dissipation of bolted joints using a modified oscillator device. J. Vib. Control, 28: 2268-2278. [149] Lin J, Wang X, Liu C. 2023. Modeling and experimental study on dynamics of a gas-driven split nut device. Multibody Syst. Dyn., 58: 365-395. doi: 10.1007/s11044-022-09873-6 [150] Liu L, Chen H, Jin X, Li S, Sun L, Wang P, Chen L. 2023a. Prediction of yield strength and prying action of TOBs bolted arc-shaped endplate. J. Constr. Steel. Res., 208: 108039. doi: 10.1016/j.jcsr.2023.108039 [151] Liu L, Chen H, Cai M, Jin X, Wang P, Liu M, Sun L. 2023b. Behavior of TOBs bolted curved T-stubs to steel tube with internal stiffener. J. Constr. Steel. Res., 210: 108107. doi: 10.1016/j.jcsr.2023.108107 [152] Liu J, Ouyang H, Feng Z, Cai, Mo J, Peng J, Zhu M. 2019. Dynamic behaviour of a bolted joint subjected to torsional excitation. Tribol. Int., 140: 105877. doi: 10.1016/j.triboint.2019.105877 [153] Liu P, Zhao H, Huang K, Chen Q. 2015. Research on normal contact stiffness of rough surface considering friction based on fractal theory. Appl. Surf. Sci., 349: 43-48. doi: 10.1016/j.apsusc.2015.04.174 [154] Liu X, Fan J, Wang H, Jiang J, Liu J, Gong X, Peng J, Zhu M. 2022. Effect of wear between contact surfaces on self-loosening behaviour of bolted joint under low frequency torsional excitation. Tribol. Int., 174: 107764. doi: 10.1016/j.triboint.2022.107764 [155] Liu Y, Wang Y, Chen X, Yu H. 2018. A spherical conformal contact model considering frictional and microscopic factors based on fractal theory. Chaos Solitons Fractals, 111: 96-107. doi: 10.1016/j.chaos.2018.04.017 [156] Lu F, Cai D A, Tang J, Li W, Deng J, Zhou G. 2018. Bearing failure of single-/double-shear composite bolted joints: An explicit finite element modeling. J. Reinf. Plast. Compos., 37: 933-944. doi: 10.1177/0731684418772355 [157] Majumdar A, Bhushan B. 1991. Fractal model of elastic-plastic contact between rough surfaces. J. Tribol., 113: 1-11 doi: 10.1115/1.2920588 [158] Mandelbrot B. 1967. How long is the coast of Britain? Statistical self-similarity and fractional dimension. Science, 156: 636-638. doi: 10.1126/science.156.3775.636 [159] Masing G, 1926. Eigenspannungen und vertfestigung beim messing. In: Proceedings of the Second International Congress of Applied Mechanics, Zurich, Switzerland. [160] Mathis A T, Balaji N N, Kuether R J, Brink A R, Brake M R, Quinn D D. 2020. A review of damping models for structures with mechanical joints. Appl. Mech. Rev., 72: 040802. doi: 10.1115/1.4047707 [161] Mayer M H, Gaul L. 2007. Segment-to-segment contact elements for modelling joint interfaces in finite element analysis. Mech. Syst. Signal Proc., 21: 724-734. doi: 10.1016/j.ymssp.2005.10.006 [162] McCarthy M, Stanley W, Lawlor V. 2001. Bolted joints in composite aircraft structures. Air Space Eur., 3: 139-142. doi: 10.1016/S1290-0958(01)90077-2 [163] McCarthy M, McCarthy C T, Lawlor V P, Stanley W F. 2005. Three-dimensional finite element analysis of single-bolt, single-lap composite bolted joints: part I—model development and validation. Compos. Struct., 71: 140-158. doi: 10.1016/j.compstruct.2004.09.024 [164] Miao X, Huang X. 2014. A complete contact model of a fractal rough surface. Wear, 309: 146-151. doi: 10.1016/j.wear.2013.10.014 [165] Milan M T, Spinelli D, Bose Filho W W, Montezuma M F, Tita V. 2004. Failure analysis of a SAE 4340 steel locking bolt. Eng. Fail. Anal., 11: 915-924. doi: 10.1016/j.engfailanal.2003.12.003 [166] Moore K J, Kurt M, Eriten M, Dodson J C, Foley J R, Wolfson J C, Vakakis A F. 2017. Nonlinear parameter identification of a mechanical interface based on primary wave scattering. Exp. Mech., 57: 1495-1508. doi: 10.1007/s11340-017-0320-0 [167] Moore K J. 2019. A reduced-order model for loosening of bolted joints subjected to axial shock excitation. J. Appl. Mech., 86: 121007. doi: 10.1115/1.4044813 [168] Morag Y, Etsion I. 2007. Resolving the contradiction of asperities plastic to elastic mode transition in current contact models of fractal rough surfaces. Wear, 262: 624-629. doi: 10.1016/j.wear.2006.07.007 [169] Morin A J. 1833. New friction experiments carried out at Metz. Proc. French R. Acad. Sci., 04: 1-128. [170] Na J, Chen Q, Ren X. 2018. Adaptive identification and control of uncertain systems with non-smooth dynamics. Emerging Methodologies and Applications in Modelling, Identification and Control. USA. Academic Press. [171] Nassar S A, Virupaksha V L, Ganeshmurthy S. 2007. Effect of bolt tightness on the behavior of composite joints. J. Pressure Vessel Technol., 129: 43-51. doi: 10.1115/1.2389000 [172] Nassar S A, Yang X, Gandham S V, Wu Z. 2011. Nonlinear deformation behavior of clamped bolted joints under a separating service load. J. Pressure Vessel Technol., 133: 021001. doi: 10.1115/1.4002674 [173] Olsson H, Åström K J, De Wit C C, Gäfvert M, Lischinsky P. 1998. Friction models and friction compensation. Eur. J. Control, 04: 176-195. doi: 10.1016/S0947-3580(98)70113-X [174] Omar R, Rani M N, Yunus M A, Mirza W I, Zin M S. 2018. Efficient finite element modelling for the investigation of the dynamic behaviour of a structure with bolted joints. In: International Conference on Electrical, Electronics, Materials and Applied Science. [175] Ouyang H, Oldfield M J, Mottershead J E. 2006. Experimental and theoretical studies of a bolted joint excited by a torsional dynamic load. Int. J. Mech. Sci., 48: 1447-1455. doi: 10.1016/j.ijmecsci.2006.07.015 [176] Ozen M, Sayman O. 2011. Failure loads of mechanical fastened pinned and bolted composite joints with two serial holes. Compos. B Eng., 42: 264-274. doi: 10.1016/j.compositesb.2010.10.003 [177] Pan W, Li X, Wang L, Guo N, Mu J. 2017. A normal contact stiffness fractal prediction model of dry-friction rough surface and experimental verification. Eur. J. Mech. A-Solids, 66: 94-102. doi: 10.1016/j.euromechsol.2017.06.010 [178] Park H J. 2001. Effects of stacking sequence and clamping force on the bearing strengths of mechanically fastened joints in composite laminates. Compos. Struct., 53: 213-221. doi: 10.1016/S0263-8223(01)00005-8 [179] Polycarpou A A, Soom A. 1995. Measured transitions between sticking and slipping at lubricated line contacts. J. Vib. Acoust., 117: 294-299. doi: 10.1115/1.2874450 [180] Prandtl L. 1928. Ein Gedankenmodell zur kinetischen theorie der festen Körper. J. Appl. Math. Mech. /Z. Angew. Math. Mech., 08: 85-106. [181] Qu C, Wu L, Ma J, Xia Q, Ma S. 2013. A fractal model of normal dynamic parameters for fixed oily porous media joint interface in machine tools. Int J Adv Manuf Technol., 68: 2159-2167. doi: 10.1007/s00170-013-4825-0 [182] Quinn D D, Segalman D J. 2005. Using series-series Iwan-type models for understanding joint dynamics. J. Appl. Mech., 72: 666-673. doi: 10.1115/1.1978918 [183] Quinn D D. 2012. Modal analysis of jointed structures. J. Sound Vibr., 331: 81-93. doi: 10.1016/j.jsv.2011.08.017 [184] Rakotondrabe M. 2012. Classical Prandtl-Ishlinskii modeling and inverse multiplicative structure to compensate hysteresis in piezoactuators. In: 2012 American control conference. [185] Ranjan P, Pandey A K. 2021. Modeling of pinning phenomenon in Iwan model for bolted joint. Tribol. Int., 161: 107071. doi: 10.1016/j.triboint.2021.107071 [186] Ranjan P, Pandey A K. 2022. Iwan model for bolted joint with residual macroslip stiffness and pinning. In: Machines, Mechanism and Robotics. [187] Resor B R, Starr M J. 2007. Influence of misfit mechanisms on jointed structure response. Albuquerque: Sandia National Laboratories. [188] Rose Joel. 2024. 2 major airlines find loose bolts, other problems on grounded Boeing jets.https://www.npr.org/2024/01/08/1223517098/door-plug-boeing-737-max-portland-ntsb-faa. [189] Sawata K. 2015. Strength of bolted timber joints subjected to lateral force. J. Wood Sci., 61: 221-229. doi: 10.1007/s10086-015-1469-8 [190] Segalman D J. 2001. An initial overview of Iwan modeling for mechanical joints. Albuquerque: Sandia National Laboratories. [191] Segalman D J. 2005. A four-parameter Iwan model for lap-type joints. J. Appl. Mech., 72: 752-760. doi: 10.1115/1.1989354 [192] Segalman D J. Bergman L A, Ewins D J. 2006a. Report on the SNL/NSF international workshop on joint mechanics, Arlington, Virginia. Albuquerque: Sandia National Laboratories. [193] Segalman D J. 2006b. Modelling joint friction in structural dynamics. Struct. Control Health Monitor, 13: 430-453 doi: 10.1002/stc.119 [194] Segalman D J, Starr M J. 2008. Inversion of Masing models via continuous Iwan systems. Int. J. Non-Linear Mech., 43: 74-80. doi: 10.1016/j.ijnonlinmec.2007.10.005 [195] Segalman D J. Bergman L A, Ewins D J. 2009a. Report on the SNL/AWE/NSF international workshop on joint mechanics, Dartington, United Kingdom. Albuquerque: Sandia National Laboratories. [196] Segalman D J, Gregory D L, Starr M J, Resor B R, Jew M D, Lauffer J P, Ames N M. 2009b. Handbook on dynamics of jointed structures. Albuquerque: Sandia National Laboratories. [197] Segalman D J, Starr M J. 2012. Iwan models and their provenance. In: International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. [198] Segalman D J, Allen M S, Eriten M, Hoppman K. 2015. Experimental assessment of joint-like modal models for structures. In: International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. [199] Semke W H, Bibel G D, Jerath S, Gurav S B, Webster A L. 2006. Efficient dynamic structural response modelling of bolted flange piping systems. Int. J. Pressure Vessels Pip., 83: 767-776. doi: 10.1016/j.ijpvp.2006.06.003 [200] Shi J, Cao X, Hu Y, Zhu H. 2015. Statistical analysis of tangential contact stiffness of joint surfaces. Arch. Appl. Mech., 85: 1997-2008. doi: 10.1007/s00419-015-1033-4 [201] Shi T, Liu Y, Liu Z, Liu C S. 2024. Distributions of tension and torsion in a threaded connection. Int. J. Mech. Sci., 261: 108684. doi: 10.1016/j.ijmecsci.2023.108684 [202] Shi X, Polycarpou A A. 2006. Adhesive effects on dynamic friction for unlubricated rough planar surfaces. J. Tribol., 128: 841-850. doi: 10.1115/1.2345392 [203] Shiryayev O V, Page S M, Pettit C L, Slater J C. 2007. Parameter estimation and investigation of a bolted joint model. J. Sound Vibr., 307: 680-697. doi: 10.1016/j.jsv.2007.06.033 [204] Skelton R P, Maier H J, Christ H J. 1997. The Bauschinger effect, Masing model and the Ramberg–Osgood relation for cyclic deformation in metals. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process., 238: 377-390. doi: 10.1016/S0921-5093(97)00465-6 [205] Song H, Vakis A I, Liu X, Van der Giessen E. 2017. Statistical model of rough surface contact accounting for size-dependent plasticity and asperity interaction. J. Mech. Phys. Solids, 106: 1-14. [206] Song Y, Hartwigsen C J, McFarland D M, Vakakis A F, Bergman L A. 2004. Simulation of dynamics of beam structures with bolted joints using adjusted Iwan beam elements. J. Sound Vibr., 273: 249-276. doi: 10.1016/S0022-460X(03)00499-1 [207] Sopwith D G. 1948. The distribution of load in screw threads. Proc Inst Mech Eng, 159: 373-383. doi: 10.1243/PIME_PROC_1948_159_030_02 [208] Soykok I F, Sayman O, Pasinli A. 2013. Effects of hot water aging on failure behavior of mechanically fastened glass fiber/epoxy composite joints. Compos. B Eng., 54: 59-70. doi: 10.1016/j.compositesb.2013.04.073 [209] Starr M J, Brake M R, Segalman D J, Bergman L A, Ewins D J. 2013. Proceedings of the third international workshop on jointed structures. Albuquerque: Sandia National Laboratories. [210] Stoyanov P, Chromik R R. 2017. Scaling effects on materials tribology: from macro to micro scale. Materials, 10: 550. doi: 10.3390/ma10050550 [211] Stribeck R. 1902. Die wesentlichen eigenschaften der gleit-und rollenlager. Z. Ver. Dtsch. Zucker-Ind, 46: 1342-1348,1432-1437. [212] Süß D, Willner K. 2015. Investigation of a jointed friction oscillator using the multiharmonic balance method. Mech. Syst. Signal Proc., 52: 73-87. [213] Tanlak N, Sonmez F O, Talay E. 2011. Detailed and simplified models of bolted joints under impact loading. J. Strain Analysis, 46: 213-225. doi: 10.1177/0309324710396997 [214] Teengad. 2023.https://blog.csdn.net/qq_32515081/article/details/129380459. [215] Thoppul S D, Finegan J, Gibson R F. 2009. Mechanics of mechanically fastened joints in polymer–matrix composite structures–a review. Compos. Sci. Technol., 69: 301-329. doi: 10.1016/j.compscitech.2008.09.037 [216] Vakis A I, Yastrebov V A, Scheibert J, Nicola L, Dini D, Minfray C, Ciavarella M. 2018. Modeling and simulation in tribology across scales: An overview. Tribol. Int., 125: 169-199. doi: 10.1016/j.triboint.2018.02.005 [217] Valanis K C. 1971. A theory of viscoplasticity without a yield surface, Part I: General theory. Arch. Mech., 23: 517-533. [218] Visintin A. 2013. Differential models of hysteresis. Springer Science & Business Media. [219] Wang D, Xu C, Fan X, Wan Q. 2018. Reduced-order modeling approach for frictional stick-slip behaviors of joint interface. Mech. Syst. Signal Proc., 103: 131-138. doi: 10.1016/j.ymssp.2017.10.001 [220] Wang H, Jia P, Wang L, Yun F, Wang G, Wang X, Liu M. 2020. Research on the loading–unloading fractal contact model between two three-dimensional spherical rough surfaces with regard to friction. Acta Mech., 231: 4397-4413. doi: 10.1007/s00707-020-02787-4 [221] Wang K, & Tian Q. 2023. A nonsmooth method for spatial frictional contact dynamics of flexible multibody systems with large deformation. Int. J. Numer. Methods Eng., 124: 752-779. doi: 10.1002/nme.7141 [222] Wang R, Crocombe A, Richardson G, Underwood C. 2005. Modelling of damping in small satellite structures incorporating bolted joints. In: Proceedings of the 19th annual AIAA/USU, small satellite conference. [223] Wang S A, Zhu M, Xie X, Li B, Liang T X, Shao Z Q, Liu Y L. 2022. Finite element analysis of elastoplastic elements in the Iwan model of bolted joints. Materials, 15: 5817. doi: 10.3390/ma15175817 [224] Wang X Q, Mignolet M P. 2014. Stochastic Iwan-type model of a bolted joint: formulation and identification. In: Dynamics of coupled structures, Volume 1. [225] Wemming H, Lindström S B, Johansson L, Kapidžić Z. 2023. Modelling and experimental parameter identification for fasteners in composite–aluminium bolted structures. Compos. Struct., 323: 117464. doi: 10.1016/j.compstruct.2023.117464 [226] Wen Y K. 1976. Method for random vibration of hysteretic systems. J. Eng. Mech. Div., 102: 249-263. doi: 10.1061/JMCEA3.0002106 [227] Wriggers P, Schröder J, Schwarz A. 2013. A finite element method for contact using a third medium. Comput. Mech., 52: 837-847. doi: 10.1007/s00466-013-0848-5 [228] Xu Y, Jackson R L, Marghitu D B. 2014. Statistical model of nearly complete elastic rough surface contact. Int. J. Solids Struct., 51: 1075-1088. doi: 10.1016/j.ijsolstr.2013.12.005 [229] Yamamoto A. 1980. The theory and computation of threads connection. Youkendo, Tokyo, 39-54. [230] Yan W, Komvopoulos K. 1998. Contact analysis of elastic-plastic fractal surfaces. J. Appl. Phys., 84: 3617-3624. doi: 10.1063/1.368536 [231] Yang G W, Yang L, Xiao S N, Jiang S L, Ma W. 2021. Competitive failure of loosening and fatigue of bolts under composite excitation. Shock Vib., 2021: 1441122. [232] Yang H, Xu C, Guo N. 2023. Modelling tangential friction considering contact pressure distribution of rough surfaces. Mech. Syst. Signal Proc., 198: 110406. doi: 10.1016/j.ymssp.2023.110406 [233] Yang J G, Kim H K, Park J H, Back M C. 2013. Analytical models for the initial axial tensile stiffness and ultimate tensile load of a T-stub, including the effects of prying action. Int. J. Steel Struct., 13: 341-352. doi: 10.1007/s13296-013-2012-7 [234] Yang L, Yang B, Yang G, Xiao S, Jiang S. 2022. Research on factors affecting competitive failure between loosening and fatigue of bolt under combined excitation. J. Constr. Steel. Res., 189: 107110. doi: 10.1016/j.jcsr.2021.107110 [235] Yang X, Nassar S A, Wu Z, Meng A. 2012. Nonlinear behavior of preloaded bolted joints under a cyclic separating load. J. Pressure Vessel Technol., 134: 011206. doi: 10.1115/1.4004614 [236] Yu N, Polycarpou A A. 2002. Contact of rough surfaces with asymmetric distribution of asperity heights. J. Trib., 124: 367-376. doi: 10.1115/1.1403458 [237] Yuan Y, Cheng Y, Liu K, Gan L. 2017. A revised Majumdar and Bushan model of elastoplastic contact between rough surfaces. Appl. Surf. Sci., 425: 1138-1157. doi: 10.1016/j.apsusc.2017.06.294 [238] Yuan Y, Chen J, Zhang L. 2018. Loading-unloading contact model between three-dimensional fractal rough surfaces. AIP Adv., 08: 075017. doi: 10.1063/1.5027437 [239] Zampieri P, Curtarello A, Maiorana E, Pellegrino C. 2019. A review of the fatigue strength of shear bolted connections. Int. J. Steel Struct., 19: 1084-1098. doi: 10.1007/s13296-018-0189-5 [240] Zhai Y, Li D, Li X, Wang L, Yin Y. 2015. An experimental study on the effect of bolt-hole clearance and bolt torque on single-lap, countersunk composite joints. Compos. Struct., 127: 411-419. doi: 10.1016/j.compstruct.2015.03.028 [241] Zhang P, Li J, Zhao Y, Li J. 2023. Crack propagation analysis and fatigue life assessment of high-strength bolts based on fracture mechanics. Sci. Rep., 13: 14567. doi: 10.1038/s41598-023-41804-z [242] Zhang Z, Xiao Y, Xie Y, Su Z. 2019. Effects of contact between rough surfaces on the dynamic responses of bolted composite joints: multiscale modeling and numerical simulation. Compos. Struct., 211: 13-23. doi: 10.1016/j.compstruct.2018.12.019 [243] Zhao B, Wu F, Sun K, Mu X, Zhang Y, Sun Q. 2021. Study on tangential stiffness nonlinear softening of bolted joint in friction-sliding process. Tribol. Int., 156: 106856. doi: 10.1016/j.triboint.2021.106856 [244] Zhao Y, Maietta D M, Chang L. 2000. An asperity microcontact model incorporating the transition from elastic deformation to fully plastic flow. J. Trib., 122: 86-93. doi: 10.1115/1.555332 -

下载:

下载: