Research progress of process and structures optimization for 3D printed continuous fiber-reinforced polymers

-

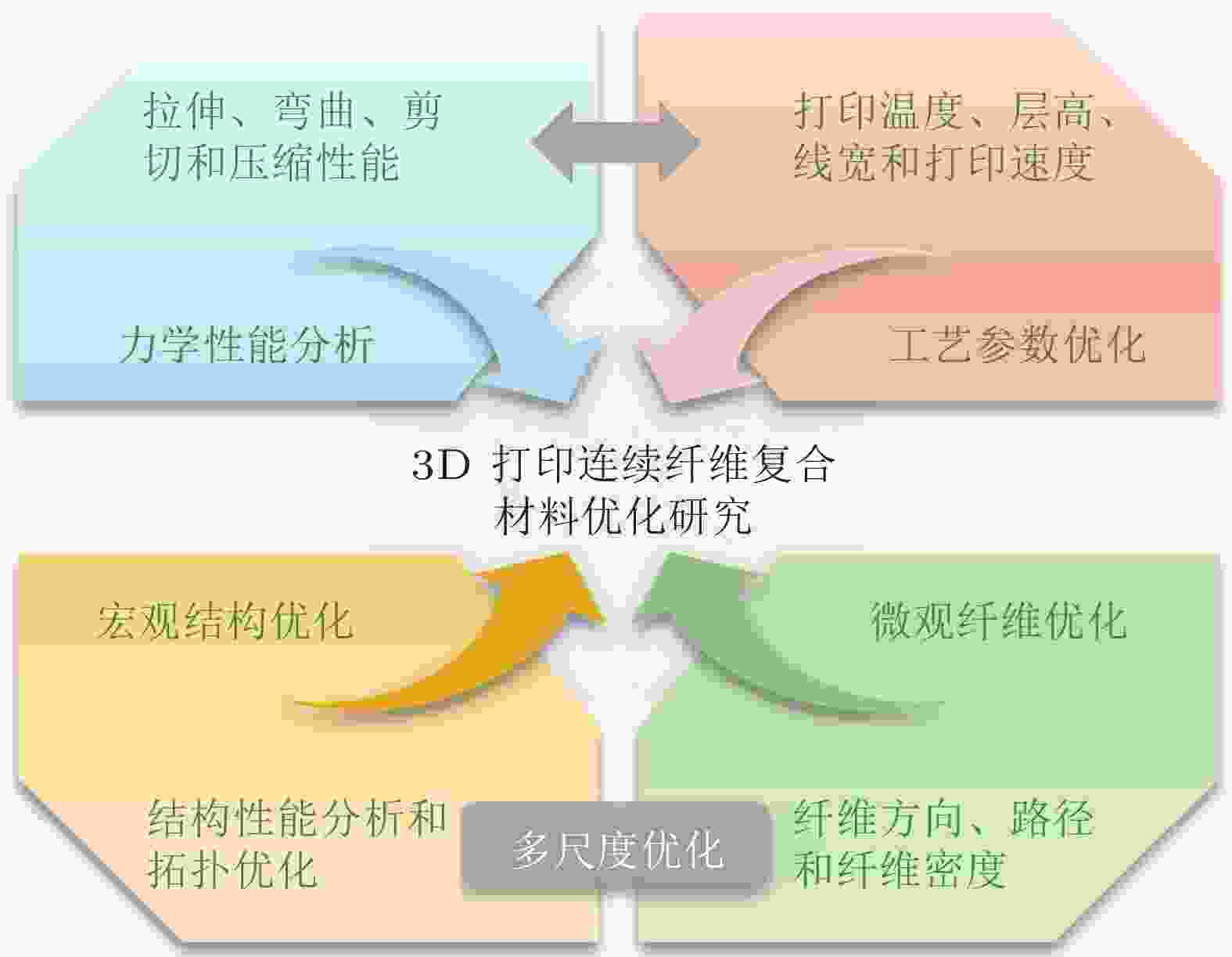

摘要: 连续纤维增强复合材料由于优异的比强度、比刚度、可设计性和轻量化特质, 日益受到航空航天等高端装备制造领域的青睐. 3D打印技术的发展改变了连续纤维复合材料结构的生产制造流程, 使复杂结构的自由成型成为可能, 为先进结构材料提供了巨大的设计空间. 为充分发挥先进材料性能优势和3D打印成型灵活性, 研究人员分别从材料性能和结构设计出发, 探索与3D打印连续纤维复合材料相适应的设计制造一体化解决方案, 实现产品创新设计和性能提升. 本文系统性地回顾了面向连续纤维复合材料性能分析、工艺改进和结构优化的研究工作, 结合研究实践对连续纤维复合材料的结构多尺度优化方法进行总结分析, 并对未来先进材料结构设计实时化、功能化、智能化的发展趋势进行探讨和展望.Abstract: Continuous fiber-reinforced polymers (CFRP) has been broadly applied in the aerospace engineering due to its excellent specific strength, specific stiffness, designability and lightweight feature. The development of 3D printing has changed the manufacturing process of CFRP structures, which makes the free form of complex structures possible and provides more design space for advanced structural materials. In order to give full play to the performance advantages of CFRP and the flexibility of 3D printing process, and achieve innovative structural design and performance improvement, researchers explored the solutions of design and manufacturing integration for 3D printing CFRP from the aspects of material performance and structural design, respectively. In this paper, the development of properties analysis, process improvement and structure optimization of CFRP is reviewed systematically. Various multi-scale optimization methods of CFRP are summarized and illustrated, the development trend of real-time, functional and intelligent structural design method of advanced materials in the future is discussed and prospected.

-

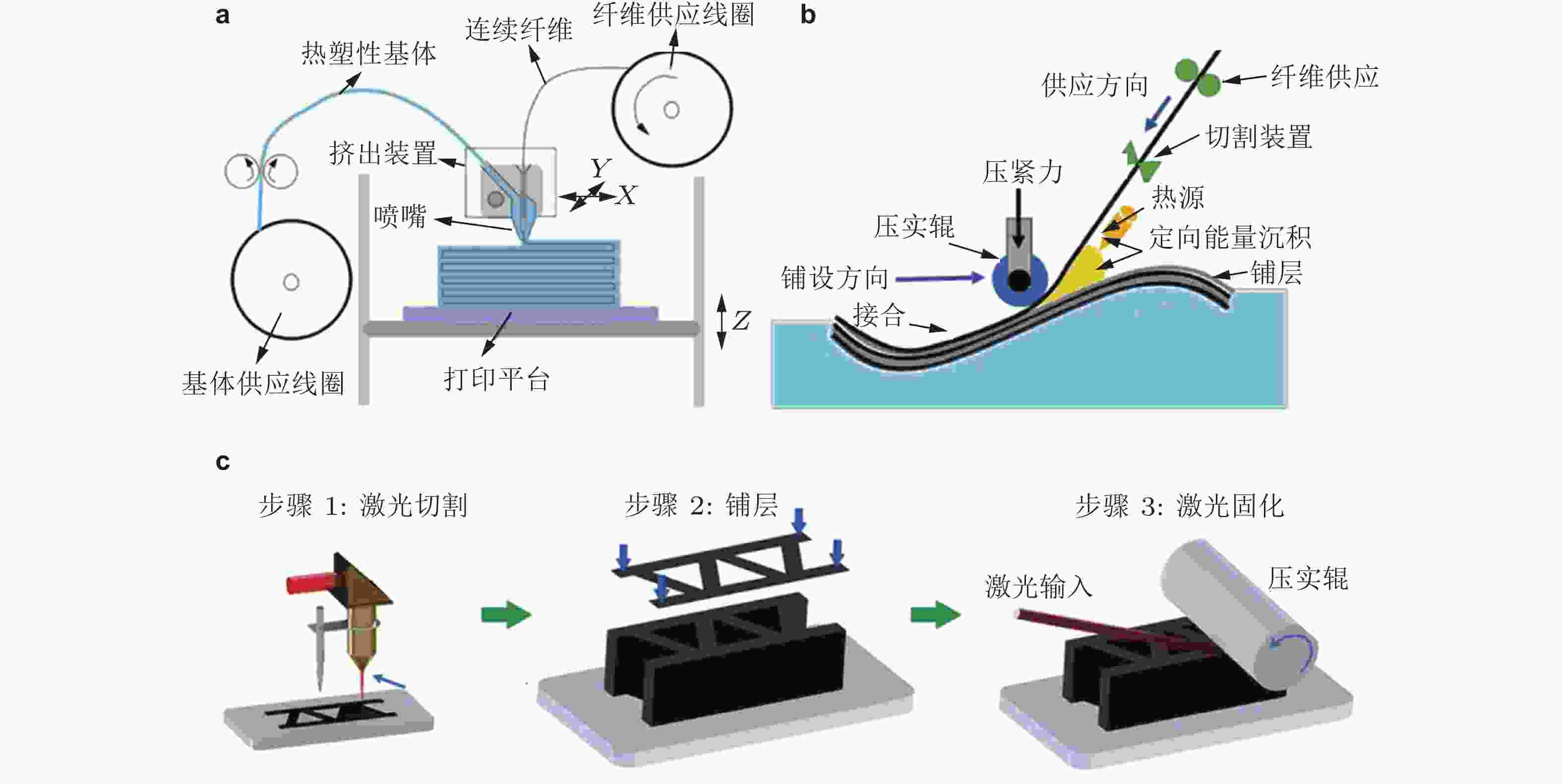

图 2 连续纤维复合材料增材制造工艺. (a)材料挤出成型(Zhuo et al. 2021), (b)自动纤维铺放(Liu G et al. 2021), (c)分层实体制造(Chang et al. 2020)

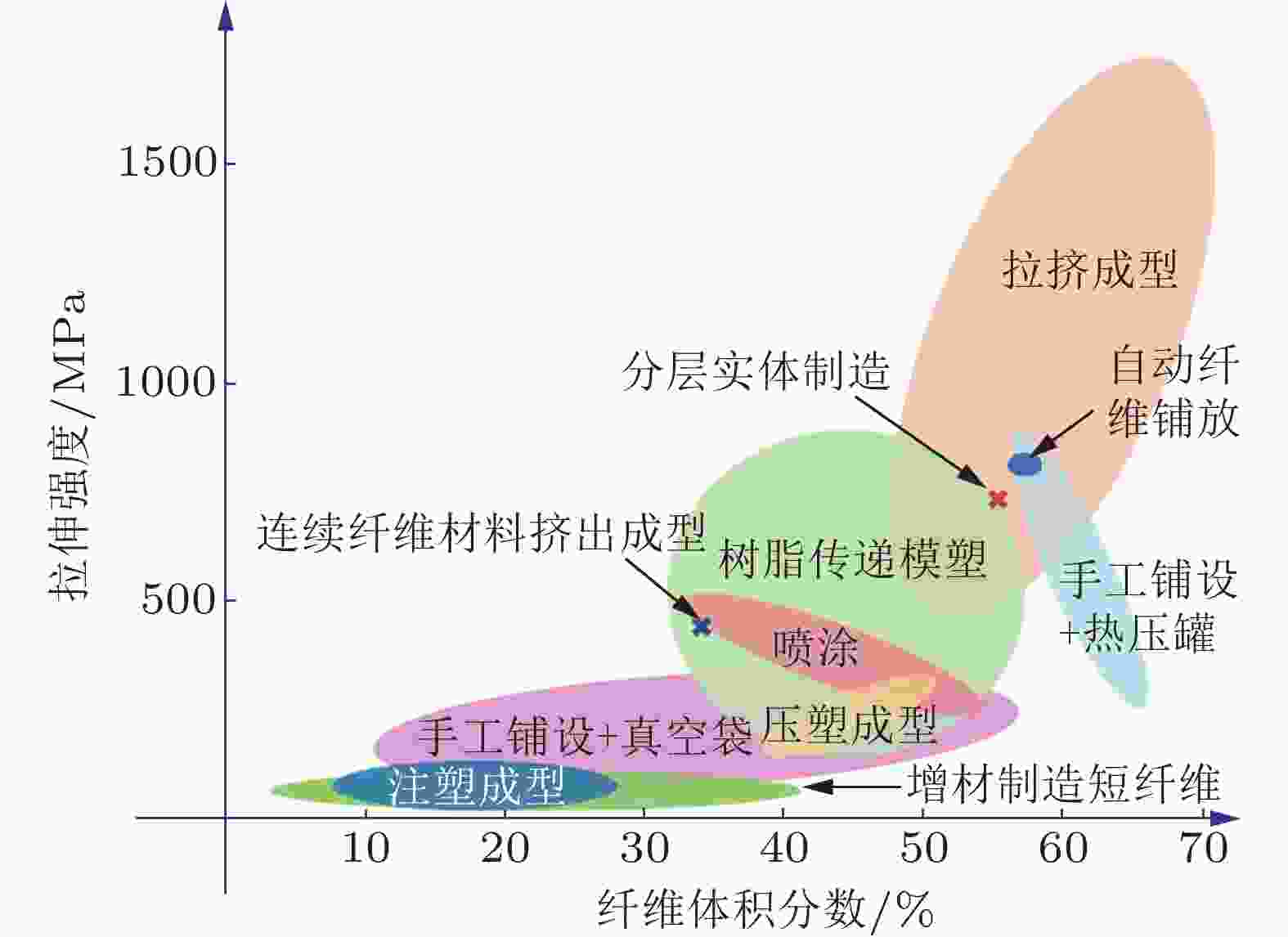

图 3 不同纤维体积分数对复合材料强度的影响(Goh et al. 2019)

图 4 连续纤维复合材料单胞结构形状. (a)传统单胞形状(Sugiyama et al. 2018), (b)波纹夹层结构(Hou et al. 2018), (c)箭头型单胞(Gao Y et al. 2021), (d)金字塔型单胞(Liu S et al. 2018)

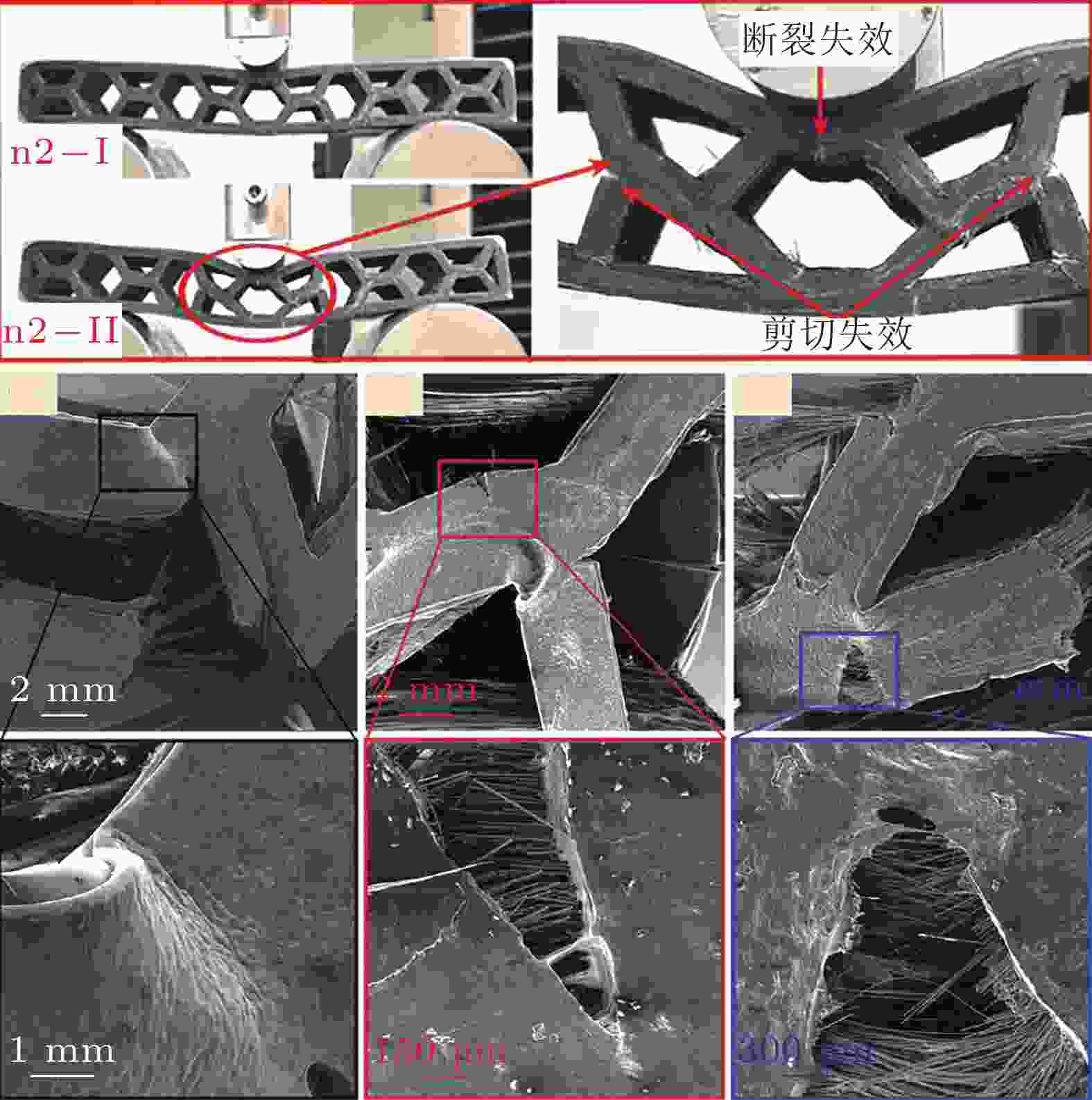

图 5 连续纤维复合材料蜂窝夹层结构失效模式(Zeng et al. 2021b)

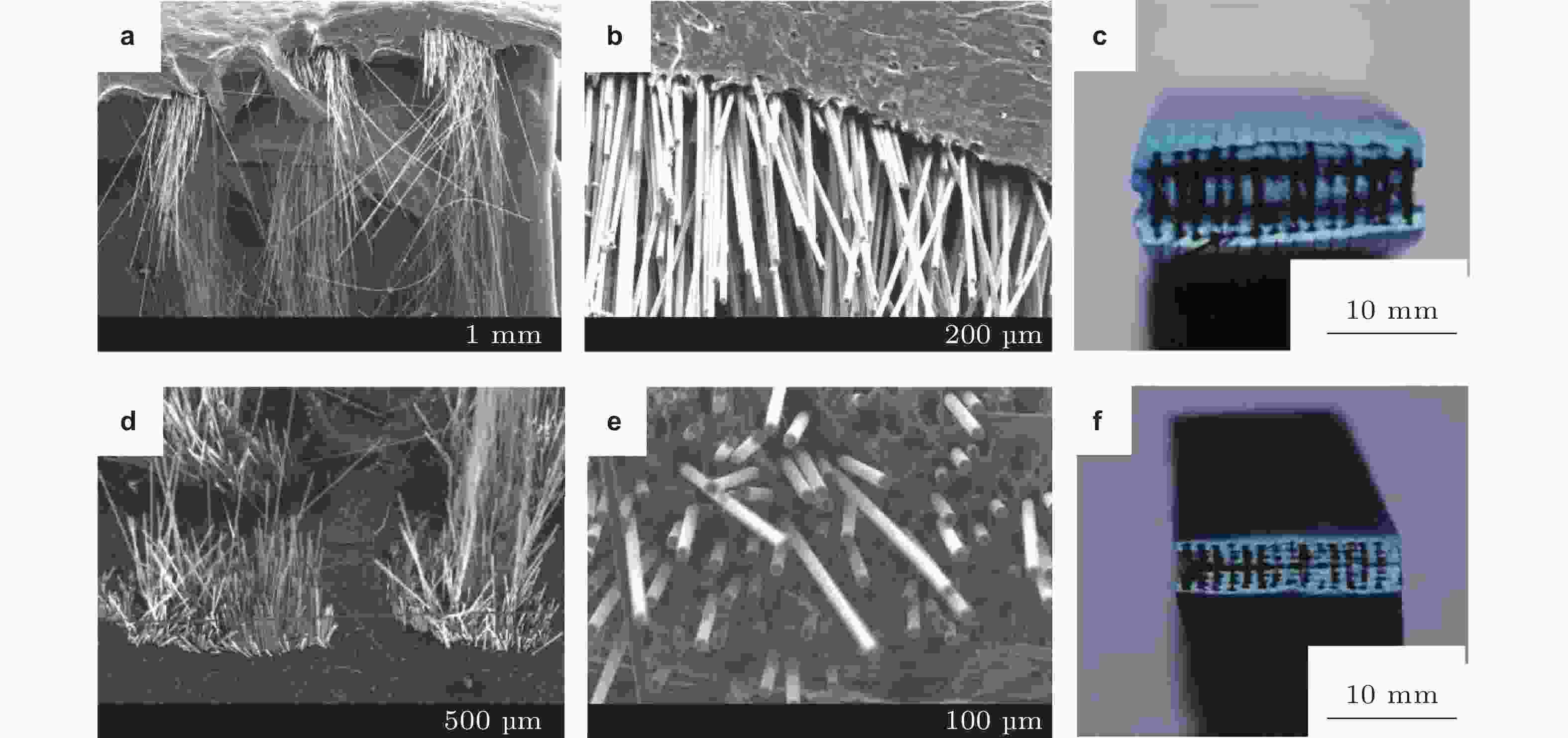

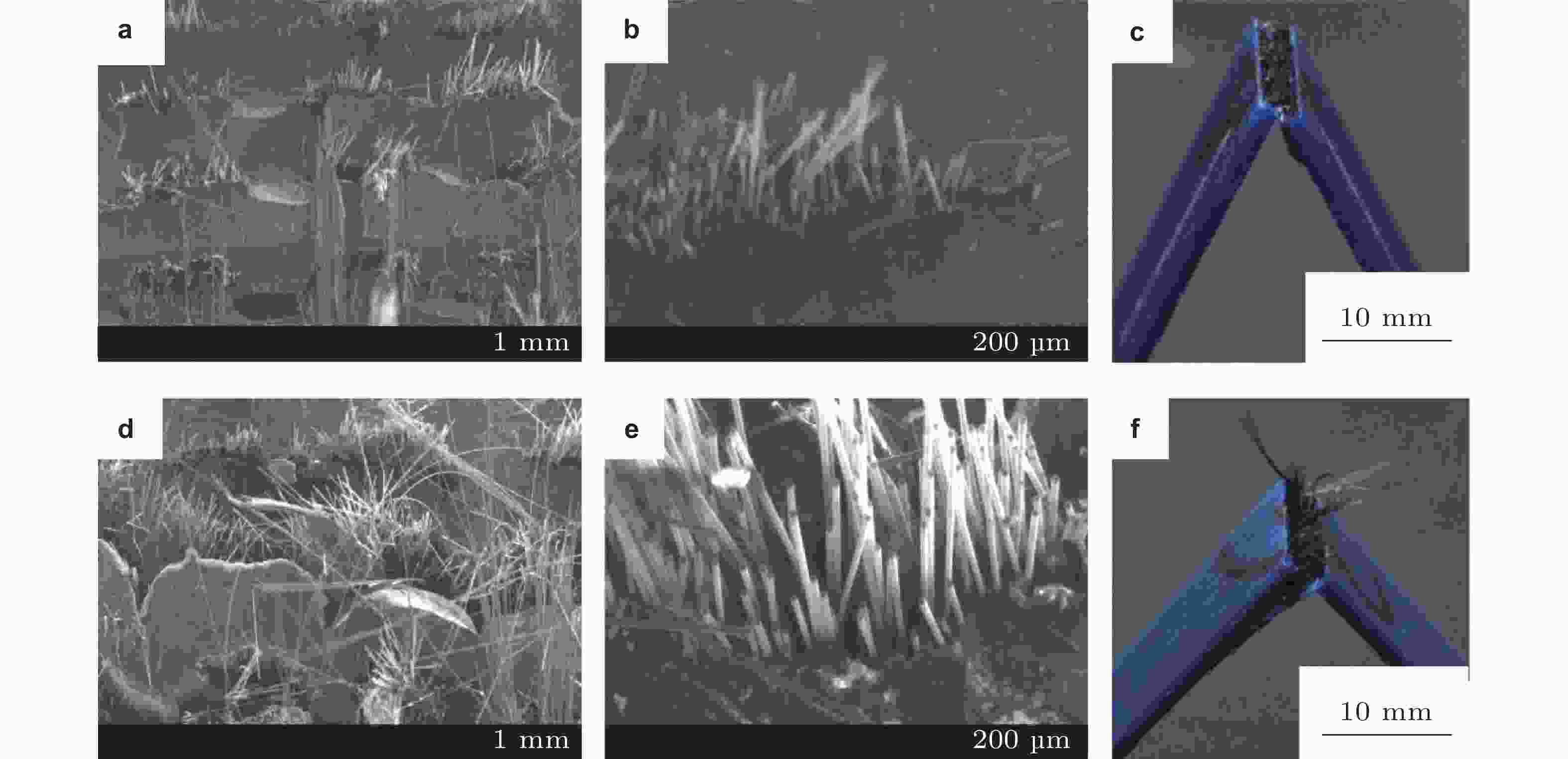

图 6 不同打印温度的连续纤维复合材料界面和断裂模式. (a-c)180°C, (d-f)240°C (Tian et al. 2016)

图 7 不同层高连续纤维复合材料界面和断裂模式. (a-c)层高0.5mm, (d-f)层高0.7mm (Tian et al. 2016)

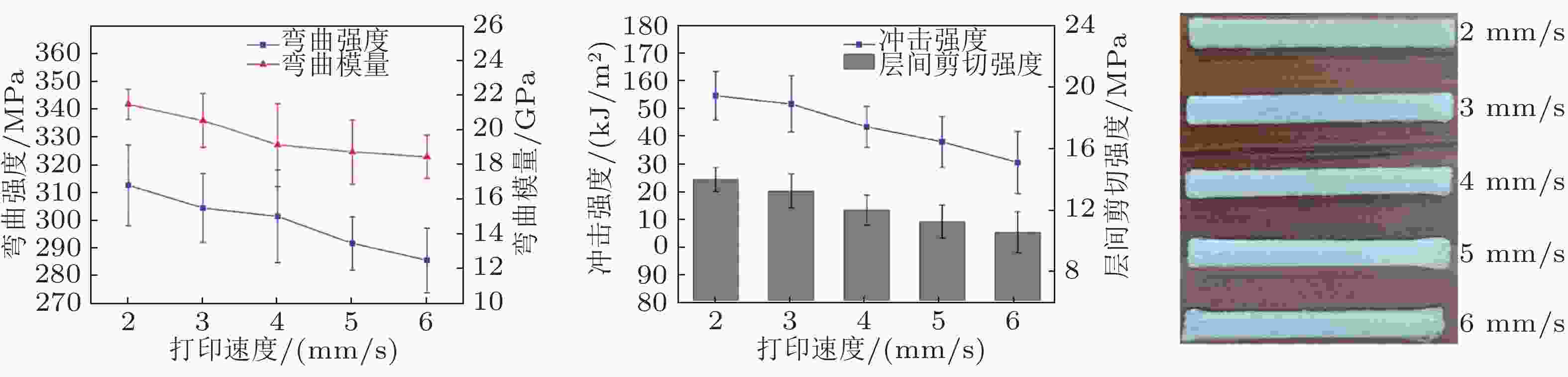

图 8 打印速度对弯曲强度和冲击强度的影响(Chen et al. 2021)

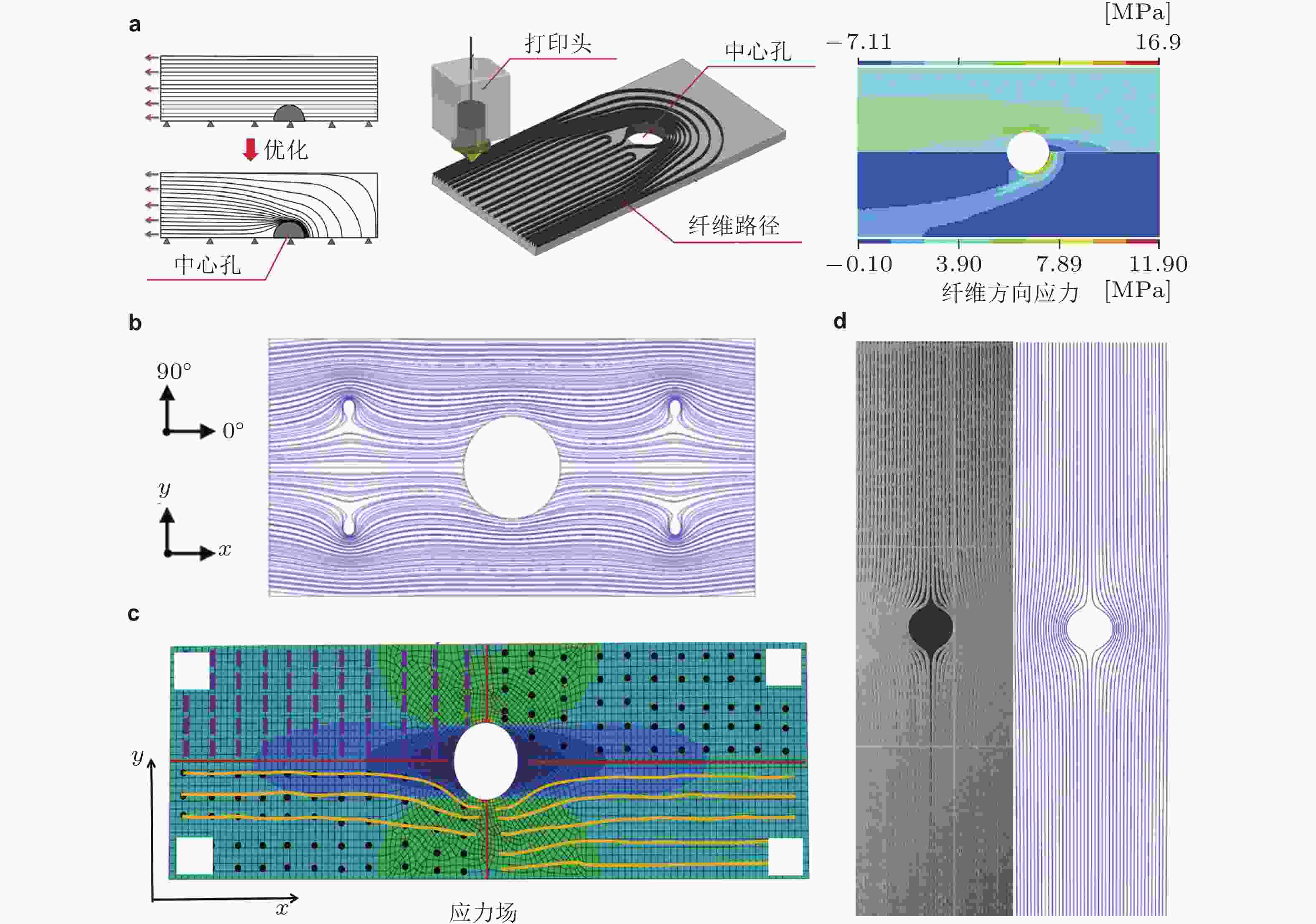

图 9 纤维路径优化方法. (a)主应力方向(Sugiyama et al. 2020), (b)流线(Yamanaka et al. 2016), (c)应力梯度(Hou et al. 2021), (d)势流场(Khan et al. 2020)

图 10 连续纤维路径规划研究 (Li N et al. 2020)

图 11 纤维路径优化方法的应用研究(Suzuki et al. 2020, Zhao et al. 2021)

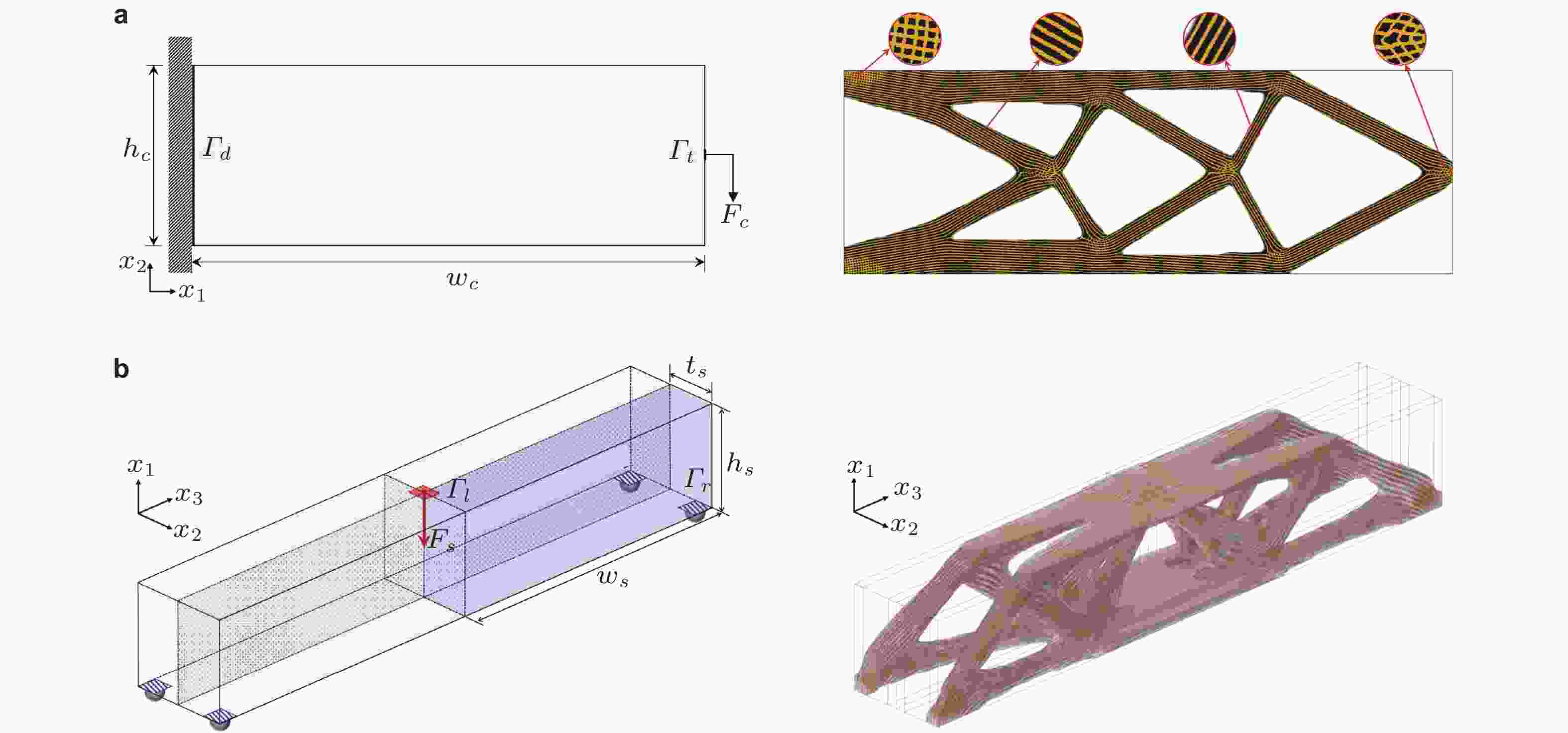

图 12 基于均匀化理论的连续纤维复合材料多尺度优化结果(Jung et al. 2022; Kim et al. 2020)

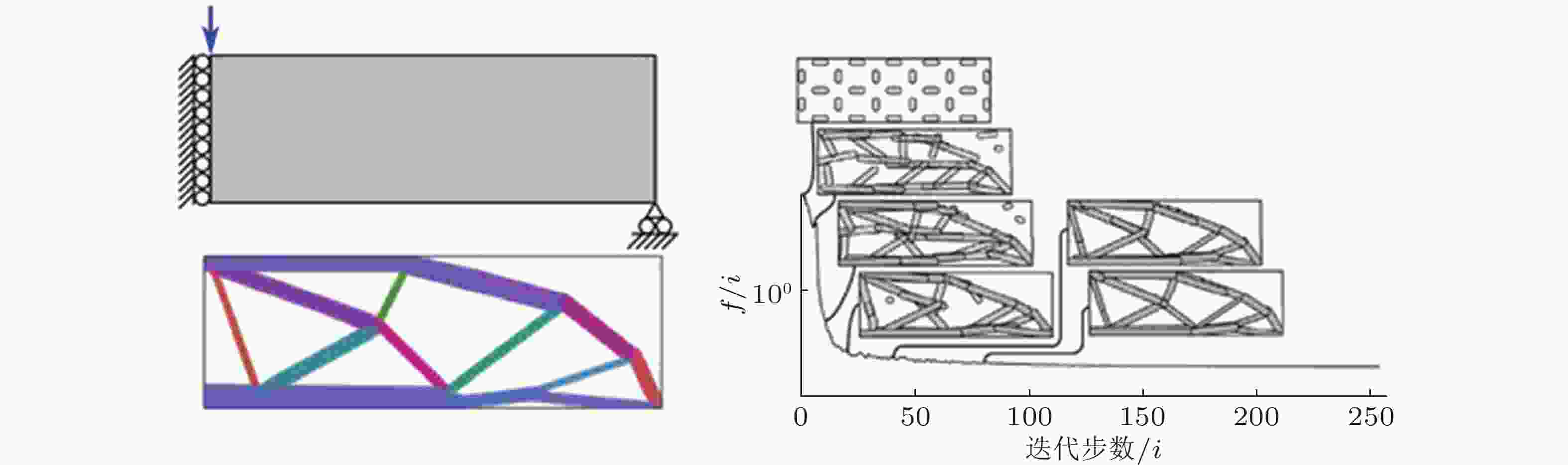

图 13 基于离散纤维取向参数化的分步顺序多尺度拓扑优化策略(Lee et al. 2018)

图 14 基于几何投影的纤维增强复合材料拓扑优化设计(Smith & Norato 2021)

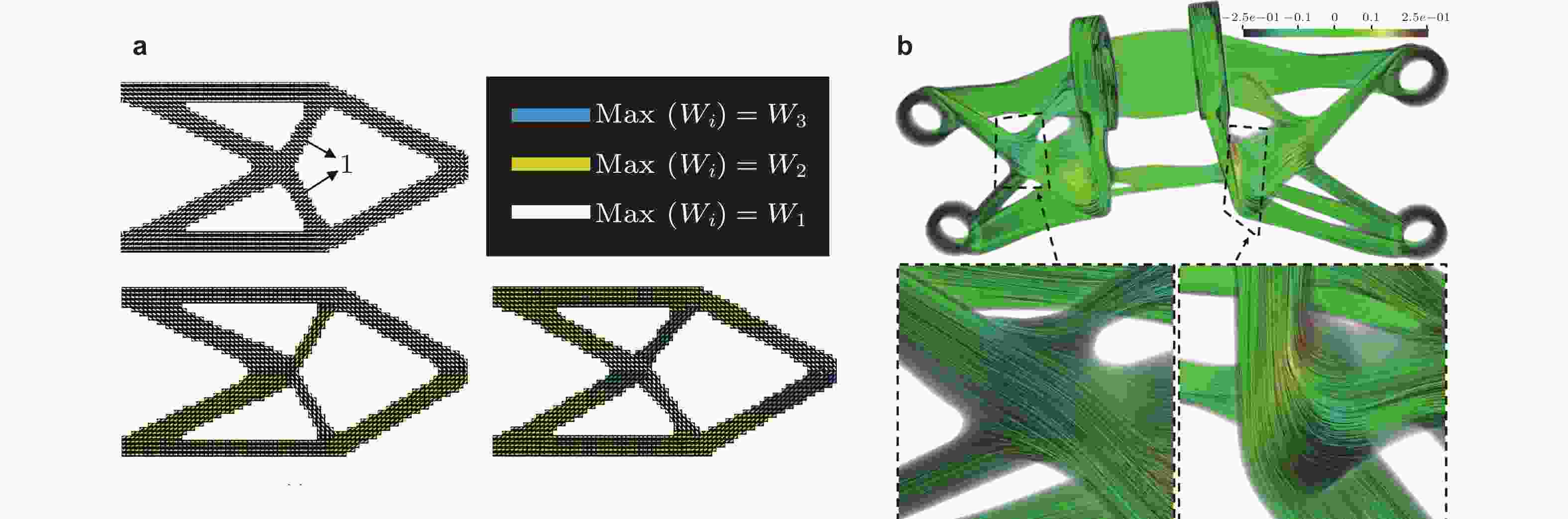

图 15 基于离散纤维取向参数化的多材料多尺度拓扑优化方法(Duan et al. 2023)

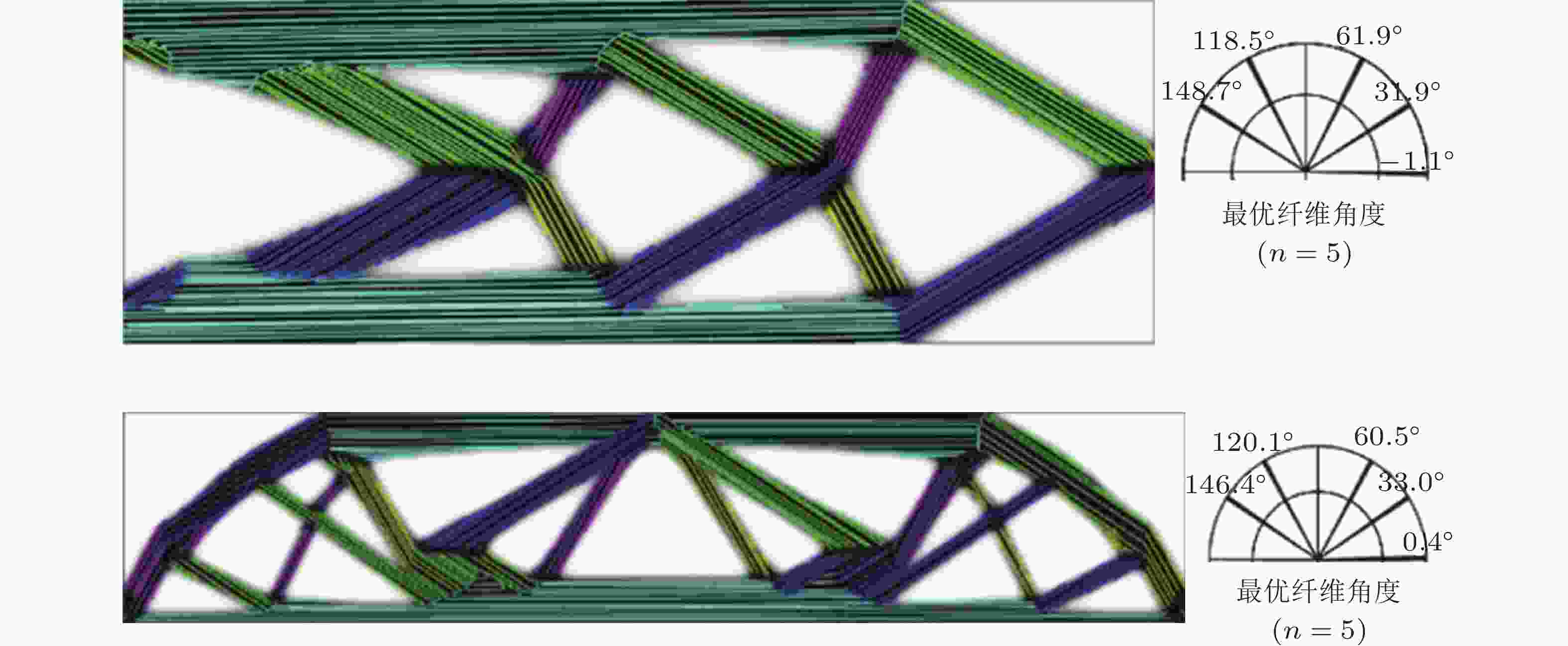

图 16 连续纤维角度优化方法的二维(Luo et al. 2020)和三维应用(Schmidt et al. 2020)

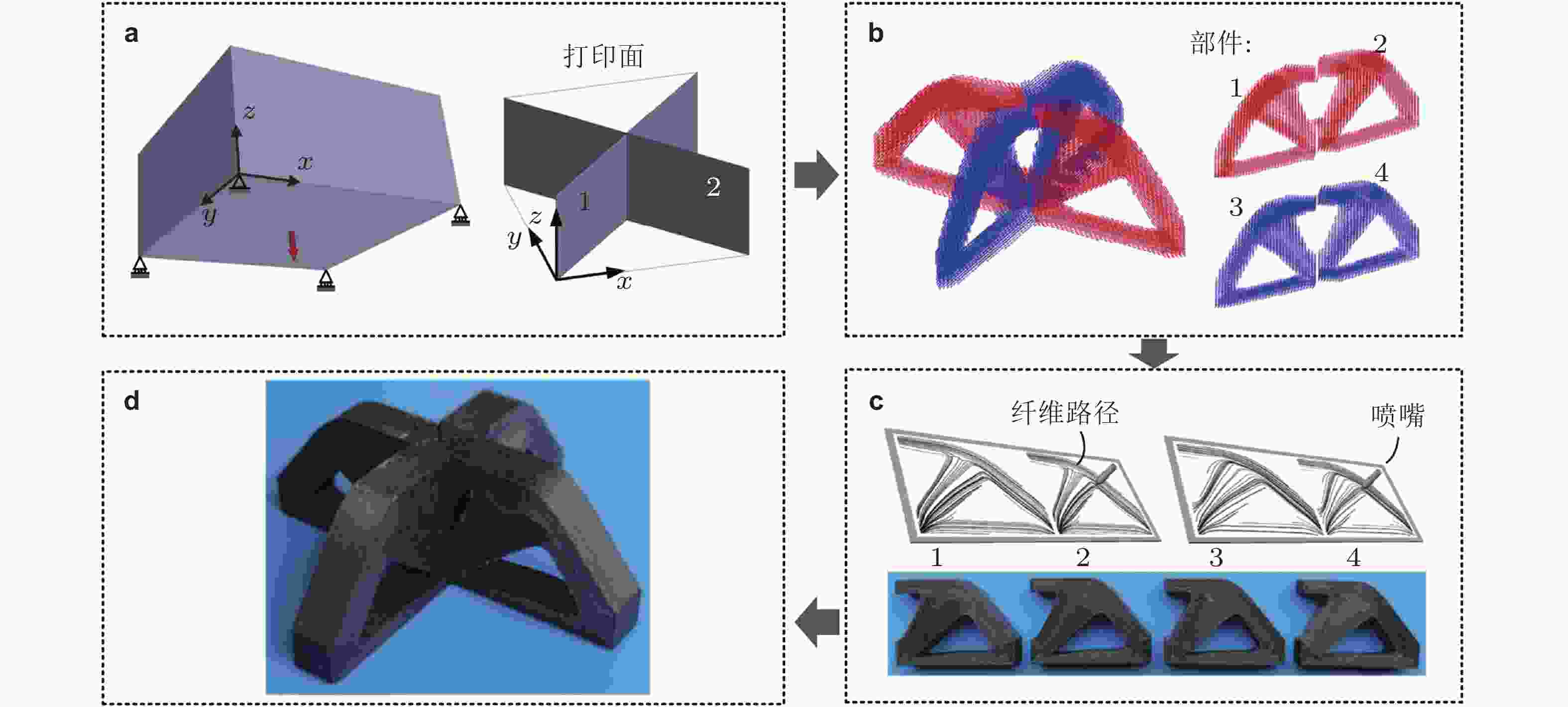

图 17 基于DCP的多打印平面纤维取向优化设计和制造流程(Qiu et al. 2022)

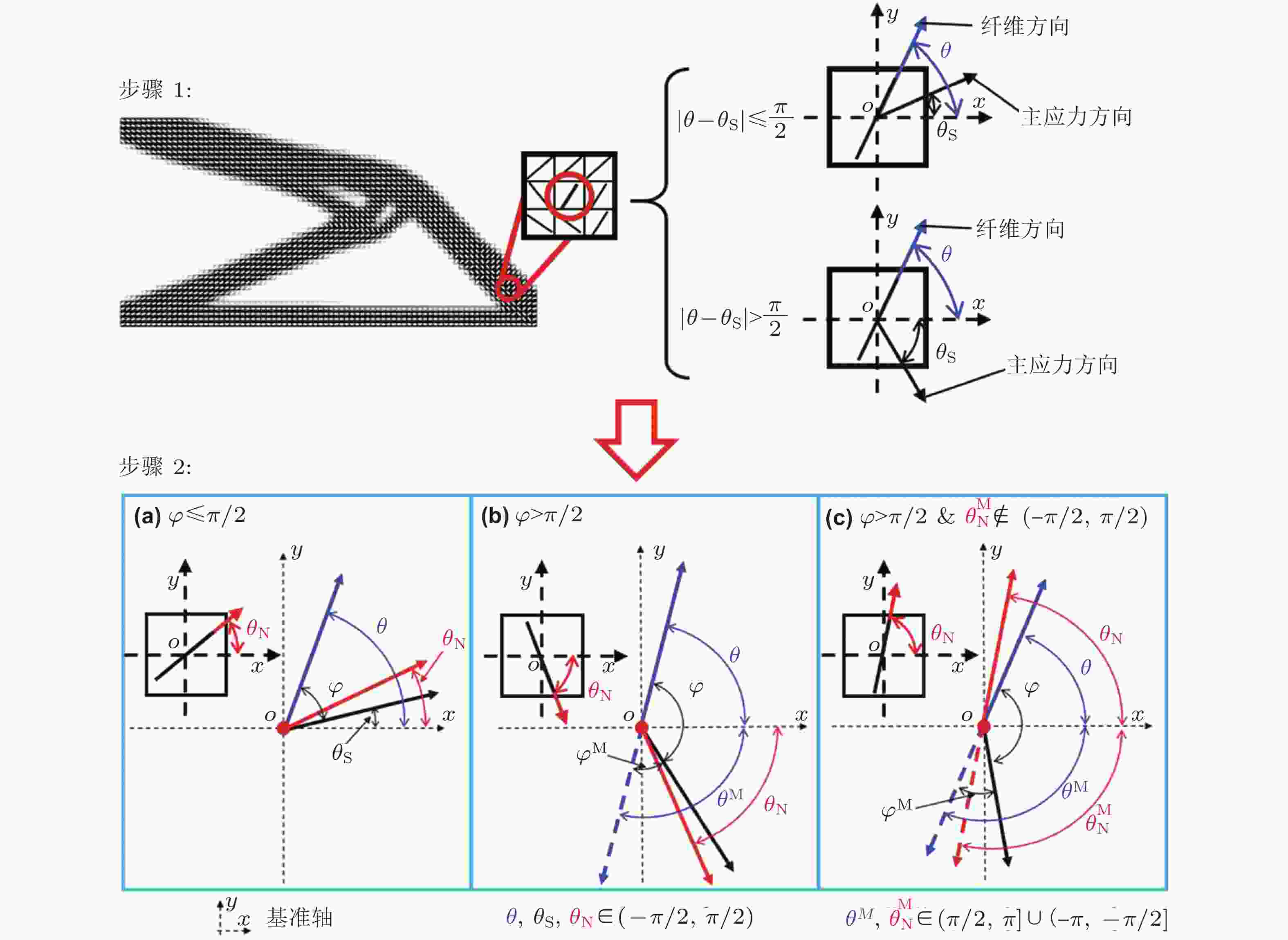

图 18 基于主应力方向的连续纤维取向优化策略(Ye et al. 2023)

图 19 基于PSO-CFAO法在不同初始纤维角度下的L型梁设计(Ye et al. 2023)

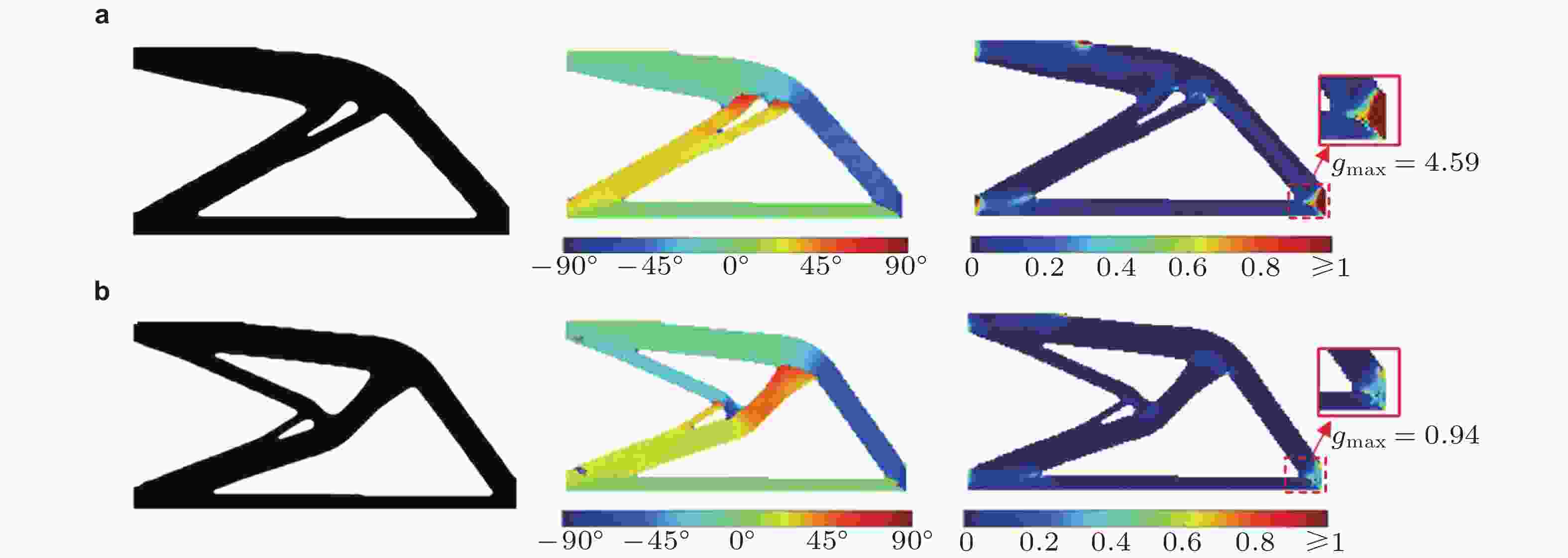

图 20 连续纤维复合材料悬臂梁结构优化拓扑、纤维角度和最大Tsai-Wu值分布. (a)无约束设计, (b)残余应力约束设计(Dong et al. 2023)

表 1 增材制造连续纤维复合材料力学性能汇总

工艺 纤维 基体 纤维方向 纤维体积分数 (%) 拉伸强度 (MPa) 弯曲强度 (MPa) 文献 ME CF Nylon 0° 14.1 250 —— (Oztan et al. 2019) CF Nylon 0° 27 719 —— (Pyl et al. 2019) CF Nylon 0°/90° 27 217 —— (Pyl et al. 2019) CF Nylon ± 45° 27 48 —— (Pyl et al. 2019) CF Nylon 0°/45°/90° 9.01 79 —— (Mei et al. 2019a) CF Nylon 30°/45°/60° 9.28 69 —— (Mei et al. 2019a) CF Nylon Isotropic(0°) 30 534 —— (Chabaud et al. 2019) CF Nylon Isotropic(0°) 41 600 430 (Goh et al. 2018) CF Nylon Concentric 11 216 250.23 (Dickson et al. 2017) CF Nylon Concentric 40.97 300 —— (Al Abadi et al. 2018) CF Nylon Concentric 17.18 —— 83.5 (Araya et al. 2018) CF Nylon Concentric 32.19 —— 143.3 (Araya et al. 2018) CF Nylon Concentric 48.93 —— 231.1 (Araya et al. 2018) CF Epoxy 0° —— 792.8 202 (Hao et al. 2018) CF PLA —— 20 26.57 60.14 (Yao et al. 2017) CF PLA Isotropic(0°) 34 91 156 (Li N et al. 2016) GF Nylon 0°/90° 40.08 165 —— (Al Abadi et al. 2018) GF Nylon Isotropic(0°) 10 206 196.75 (Dickson et al. 2017) GF Nylon Isotropic(0°) 33.1 382 —— (Chabaud et al. 2019) GF Nylon Isotropic(0°) 35 450 149 (Goh et al. 2018) GF Nylon Concentric 8 194 165.79 (Dickson et al. 2017) GF Epoxy 0° 43 272.51 299.36 (Ming et al. 2020a) Kevlar Nylon 0° 16.5 150 —— (Oztan et al. 2019) Kevlar Nylon 0°/90° 40.08 155 —— (Al Abadi et al. 2018) Kevlar Nylon Isotropic(0°) 10 164 125.8 (Dickson et al. 2017) Kevlar Nylon Concentric 8 150 106.6 (Dickson et al. 2017) LOM CF Nylon 0° 49 1760.2 1025.9 (Chang et al. 2020a) CF Nylon 0°/45° 49 1009.5 565.2 (Chang et al. 2020a) CF Nylon 0°/90° 49 855.4 430.1 (Chang et al. 2020a) CF PEEK 0° 59 1513.8 1901.1 (Chang et al. 2020b) CF PEEK 0°/45° 59 782.8 1041.9 (Chang et al. 2020b) CF PEEK 0°/90° 59 806.8 888.8 (Chang et al. 2020b) 表 2 典型3D打印热塑性树脂和连续纤维增强复合材料的物理和力学性能

材料 材料特性 参考文献 密度/

g/cm3线材直径/μm

(单丝数, 直径)拉伸模量 /

GPa弯曲模量 /

GPa基体 Nylon 1.1 1750 0.94 0.84 (Naranjo et al. 2019) PLA 1.25 1750 2.02 2.392 (Chacón et al. 2017) ABS 1.04 1750 0.998 1.9 (Kabir et al. 2020) PEEK 1.3 1750 3.7 3.6 (Li W et al. 2020) Epoxy 1.25 1750 3.6 3.5 (Kabir et al. 2020) 连续纤维 Carbon Fiber 1.4 400(1000, 10) 54 51 (Dickson & Dowling 2019) Kevlar Fiber 1.2 300(1000,12) 27 26 (Sugiyama et al. 2018) Glass Fiber 1.5 300(1000,10) 21 22 (Dickson et al. 2017) -

[1] 崔永辉, 虞立果, 贾明印. 2020. 连续纤维增强PLA复合材料3D打印制备技术研究. 纤维复合材料, 37(3): 95-99 (Cui Y H, Yu L G, Jia M Y. 2020. Study on 3D printing technology of continuous fiber reinforced PLA composite. Fiber Composites, 37(3): 95-99). doi: 10.3969/j.issn.1003-6423.2020.03.020Cui Y H, Yu L G, Jia M Y. 2020. Study on 3D printing technology of continuous fiber reinforced PLA composite. Fiber Composites, 37(3): 95-99. doi: 10.3969/j.issn.1003-6423.2020.03.020 [2] 陈向明, 姚辽军, 果立成, 孙毅. 2021. 3D打印连续纤维增强复合材料研究现状综述. 航空学报, 42: 174-198 (Chen X M, Yao L J, Guo L C, Sun Y. 2021. 3D printed continuous fiber-reinforced composites: State of the art and perspectives. Acta Aeronautica et Astronautica Sinica, 42: 174-198).Chen X M, Yao L J, Guo L C, Sun Y. 2021. 3D printed continuous fiber-reinforced composites: State of the art and perspectives. Acta Aeronautica et Astronautica Sinica, 42: 174-198 [3] 程长征, 卞光耀, 王选, 龙凯, 李景传, 吴桥国. 2020. 连续纤维增强复合材料结构基频最大化设计. 力学学报, 52: 1422-1430 (Cheng C Z, Bian G Y, Wang X, Long K, Li J C, Wu Q G. 2020. Fundamental frequency maximization design for continuous fiber-reinforced composite structures. Chinese Journal of Theoretical and Applied Mechanics, 52: 1422-1430).Cheng C Z, Bian G Y, Wang X, Long K, Li J C, Wu Q G. 2020. Fundamental frequency maximization design for continuous fiber-reinforced composite structures. Chinese Journal of Theoretical and Applied Mechanics, 52: 1422-1430 [4] 杜晨, 彭雄奇. 2022. 变厚度连续纤维增强复合材料铺层设计优化方法. 应用数学和力学, 43: 1313-1323 (Du C, Peng X Q. 2022. Lamination design optimization for continuous fiber reinforced composites of variable thicknesses. Applied Mathematics and Mechanics, 43: 1313-1323).Du C, Peng X Q. 2022. Lamination design optimization for continuous fiber reinforced composites of variable thicknesses. Applied Mathematics and Mechanics, 43: 1313-1323 [5] 李婷, 肖鸿, 明越科, 段玉岗, 郭文辉. 2022. 基于3D打印的混杂连续纤维增强复合材料结构设计及性能. 工程塑料应用, 50: 74-81 (Li T, Xiao H, Ming Y K, Duan Y G, Guo W H. 2022. Structural design and properties of hybrid continuous fiber reinforced composites based on 3D printing. Engineering Plastics Application, 50: 74-81).Li T, Xiao H, Ming Y K, Duan Y G, Guo W H. 2022. Structural design and properties of hybrid continuous fiber reinforced composites based on 3D printing. Engineering Plastics Application, 50: 74-81 [6] 李想, 严子铭, 柳占立, 庄茁. 2021. 基于仿真和数据驱动的先进结构材料设计. 力学进展, 51: 82-105 (Li X, Yan Z M, Liu Z L, Zhuang Z. 2021. Advanced structural material design based on simulation and data-driven method. Advances in Mechanics, 51: 82-105). doi: 10.6052/1000-0992-20-012Li X, Yan Z M, Liu Z L, Zhuang Z. 2021. Advanced structural material design based on simulation and data-driven method. Advances in Mechanics, 51: 82-105 doi: 10.6052/1000-0992-20-012 [7] 李岩, 龙昱, 郝潞岑, 张航华, 肖建庄. 2022. 3D打印纤维增强复合材料力学性能研究进展. 力学季刊, 43: 731-750 (Li Y, Long Y, Hao L C, Zhang H H, Xiao J Z. 2022. Recent advances in the mechanical properties of 3D printed fiber-reinforced composites. Chinese Quarterly of Mechanics, 43: 731-750).Li Y, Long Y, Hao L C, Zhang H H, Xiao J Z. 2022. Recent advances in the mechanical properties of 3D printed fiber-reinforced composites. Chinese Quarterly of Mechanics, 43: 731-750 [8] 孟云聪, 周光明, 蔡登安, 张楠. 2023. 连续芳纶纤维增强PLA复合材料3D打印技术成型缺陷及工艺优化方法研究. 复合材料科学与工程, 1-8 ((Meng Y C, Zhou G M, Cai D A, Zhang N. 2023. Forming defects and optimization methods of 3D printing for continuous aramid fiber reinforced PLA composites. Composites Science and Engineering, 1-8).(Meng Y C, Zhou G M, Cai D A, Zhang N. 2023. Forming defects and optimization methods of 3D printing for continuous aramid fiber reinforced PLA composites. Composites Science and Engineering, 1-8 [9] 牟宇松, 姜沅政, 李红宾, 杨化林. 2021. 基于FDM技术的连续纤维增强复合材料研究进展. 工程塑料应用, 49: 153-156 (Mu Y S, Jiang Y Z, Li H B, Yang H L. 2021. Research progress of continuous fiber reinforced composites based on FDM technology. Engineering Plastics Application, 49: 153-156).Mu Y S, Jiang Y Z, Li H B, Yang H L. 2021. Research progress of continuous fiber reinforced composites based on FDM technology. Engineering Plastics Application, 49: 153-156 [10] 单忠德, 范聪泽, 孙启利, 战丽. 2020. 纤维增强树脂基复合材料增材制造技术与装备研究. 中国机械工程, 31: 221-226 (Shan Z D, Fan C Z, Sun Q L, Zhan L. 2020. Research on additive manufacturing technology and equipment for fiber reinforced resin composites. China Mechanical Engineering, 31: 221-226). doi: 10.3969/j.issn.1004-132X.2020.02.007Shan Z D, Fan C Z, Sun Q L, Zhan L. 2020. Research on additive manufacturing technology and equipment for fiber reinforced resin composites. China Mechanical Engineering, 31: 221-226 doi: 10.3969/j.issn.1004-132X.2020.02.007 [11] 田小永, 张亚园, 刘腾飞, 李涤尘. 2021. 连续碳纤维增强尼龙复合材料预浸丝制备与3D打印性能研究. 航空制造技术, 64(15): 24-33 (Tian X Y, Zhang Y Y, Liu T F, et al. 2021. Prepreg preparation and 3D printing of continuous carbon fiber reinforced nylon composite. Aeronautical Manufacturing Technology, 64(15): 24-33).Tian X Y, Zhang Y Y, Liu T F, et al. 2021. Prepreg preparation and 3D printing of continuous carbon fiber reinforced nylon composite. Aeronautical Manufacturing Technology, 64(15): 24-33 [12] 阎军, 许琦, 张起, 范志瑞, 杜洪泽, 耿东岭, 阎琨, 牛斌. 2021. 人工智能在结构拓扑优化领域的现状与未来趋势. 计算力学学报, 38: 412-422 (Yan J, Xu Q, Zhang Q et al. 2021. Current and future trends of artificial intelligence in the field of structural topology optimization. Chinese Journal of Computational Mechanics, 38: 412-422). doi: 10.7511/jslx20210517401Yan J, Xu Q, Zhang Q et al. 2021. Current and future trends of artificial intelligence in the field of structural topology optimization. Chinese Journal of Computational Mechanics, 38: 412-422 doi: 10.7511/jslx20210517401 [13] 张荣耀, 钱波, 刘钢. 2023. 基于连续碳纤维3D打印的结构拓扑优化及工艺研究. 材料科学与工艺: 1-14 (Zhang R Y, Qian B, Liu G. 2023. Structural topology optimization and process research based on continuous carbon fiber 3D printing. Materials Science and Technology: 1-14).Zhang R Y, Qian B, Liu G. 2023. Structural topology optimization and process research based on continuous carbon fiber 3D printing. Materials Science and Technology: 1-14 [14] Akhoundi B, Behravesh AH, Bagheri Saed A. 2019. Improving mechanical properties of continuous fiber-reinforced thermoplastic composites produced by FDM 3D printer. J. Reinf. Plast. Comp., 38: 99-116 doi: 10.1177/0731684418807300 [15] Al Abadi H, Thai H, Paton-Cole V, Patel VI. 2018. Elastic properties of 3D printed fibre-reinforced structures. Composite Structures, 193: 8-18 doi: 10.1016/j.compstruct.2018.03.051 [16] Allaire G, Jouve F, Toader A. 2004. Structural optimization using sensitivity analysis and a level-set method. J. Comput. Phys., 194: 363-393 doi: 10.1016/j.jcp.2003.09.032 [17] Araya-Calvo M, López-Gómez I, Chamberlain-Simon N, León-Salazar J L, Guillén-Girón T, Corrales-Cordero J S, Sánchez-Brenes O. 2018. Evaluation of compressive and flexural properties of continuous fiber fabrication additive manufacturing technology. Additive Manufacturing, 22: 157-164 doi: 10.1016/j.addma.2018.05.007 [18] Bourdin B, Chambolle A. 2003. Design-dependent loads in topology optimization. ESAIM: Control, Optimisation and Calculus of Variations, 9 : 19-48 [19] Brampton C J, Wu K C, Kim H A. 2015. New optimization method for steered fiber composites using the level set method. Struct. Multidiscip. O., 52: 493-505 doi: 10.1007/s00158-015-1256-6 [20] Bruyneel M. 2011. SFP—A new parameterization based on shape functions for optimal material selection: application to conventional composite plies. Struct. Multidiscip. O., 43: 17-27 doi: 10.1007/s00158-010-0548-0 [21] Bruyneel M, Fleury C. 2002. Composite structures optimization using sequential convex programming. Advances in Engineering Software, 33: 697-711 doi: 10.1016/S0965-9978(02)00053-4 [22] Caminero MA, Chacón JM, García-Moreno I, Reverte JM. 2018a. Interlaminar bonding performance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling. Polym. Test., 68: 415-423 doi: 10.1016/j.polymertesting.2018.04.038 [23] Caminero, MA, et al. 2018b. Impact damage resistance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling. Composites Part B:Engineering, 148: 93-103. doi: 10.1016/j.compositesb.2018.04.054 [24] Chabaud G, Castro M, Denoual C, Le Duigou A. 2019. Hygromechanical properties of 3D printed continuous carbon and glass fibre reinforced polyamide composite for outdoor structural applications. Additive Manufacturing, 26: 94-105 doi: 10.1016/j.addma.2019.01.005 [25] Chacón JM, Caminero MA, García-Plaza E, Núñez PJ. 2017. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Materials & Design, 124: 143-157 [26] Chacón JM, Caminero MA, Núñez PJ, García-Plaza E, García-Moreno I, Reverte JM. 2019. Additive manufacturing of continuous fibre reinforced thermoplastic composites using fused deposition modelling: Effect of process parameters on mechanical properties. Compos. Sci. Technol., 181: 107688 doi: 10.1016/j.compscitech.2019.107688 [27] Chandrasekhar A, Mirzendehdel A, Behandish M, Suresh K. 2023. FRC-TOuNN: Topology optimization of continuous fiber reinforced composites using neural network. Computer-Aided Design, 156: 103449 doi: 10.1016/j.cad.2022.103449 [28] Chang B, Parandoush P, Li X, Ruan S, Shen C, Behnagh RA, Liu Y, Lin D. 2020a. Ultrafast printing of continuous fiber-reinforced thermoplastic composites with ultrahigh mechanical performance by ultrasonic-assisted laminated object manufacturing. Polymer Composites, 41: 4706-4715 doi: 10.1002/pc.25744 [29] Chang B, Li X, Parandoush P, Ruan S, Shen C, Lin D. 2020b. Additive manufacturing of continuous carbon fiber reinforced poly-ether-ether-ketone with ultrahigh mechanical properties. Polym. Test., 88: 106563 doi: 10.1016/j.polymertesting.2020.106563 [30] Chen K, Yu L, Cui Y, Jia M, Pan K. 2021. Optimization of printing parameters of 3D-printed continuous glass fiber reinforced polylactic acid composites. Thin-Walled Structures, 164: 107717 doi: 10.1016/j.tws.2021.107717 [31] Cheng G, Pedersen P. 1997. On sufficiency conditions for optimal design based on extremum principles of mechanics. J. Mech. Phys. Solids., 45: 135-150 doi: 10.1016/S0022-5096(96)00070-1 [32] Cheng H C, Kikuchi N, Ma ZD. 1994. An improved approach for determining the optimal orientation of orthotropic material. Structural Optimization, 8: 101-112 doi: 10.1007/BF01743305 [33] Chu Q, Li Y, Xiao J, Huan D, Zhang X, Chen X. 2018. Processing and characterization of the thermoplastic composites manufactured by ultrasonic vibration–assisted automated fiber placement. J Thermoplast Compos, 31: 339-358 [34] Desai A, Mogra M, Sridhara S, Kumar K, Sesha G, Ananthasuresh GK. 2021. Topological-derivative-based design of stiff fiber-reinforced structures with optimally oriented continuous fibers. Struct. Multidiscip. O., 63: 703-720 doi: 10.1007/s00158-020-02721-1 [35] Diaz A R, Bendsoe M P. 1992. Shape optimization of structures for multiple loading conditions using a homogenization method. Structural Optimization, 4: 17-22 doi: 10.1007/BF01894077 [36] Dickson A N, Barry J N, McDonnell K A, Dowling D P. 2017. Fabrication of continuous carbon, glass and Kevlar fibre reinforced polymer composites using additive manufacturing. Additive Manufacturing, 16: 146-152 doi: 10.1016/j.addma.2017.06.004 [37] Dickson A N, Dowling D P. 2019. Enhancing the bearing strength of woven carbon fibre thermoplastic composites through additive manufacturing. Composite Structures, 212: 381-388 doi: 10.1016/j.compstruct.2019.01.050 [38] Ding H, Xu B, Huang C, Duan Z. 2021a. A multi-scale discrete material optimization model for optimization of structural topology and material orientations to minimize dynamic compliance. Struct. Multidiscip. O., 64: 1343-1365 doi: 10.1007/s00158-021-02922-2 [39] Ding H, Xu B. 2021b. A novel discrete–continuous material orientation optimization model for stiffness-based concurrent design of fiber composite. Composite Structures, 273: 114288 doi: 10.1016/j.compstruct.2021.114288 [40] Dong K, Ke H, Panahi-Sarmad M, Yang T, Huang X, Xiao X. 2021. Mechanical properties and shape memory effect of 4D printed cellular structure composite with a novel continuous fiber-reinforced printing path. Materials & Design, 198: 109303 [41] Dong K, Liu L, Huang X, Xiao X. 2020. 3D printing of continuous fiber reinforced diamond cellular structural composites and tensile properties. Composite Structures, 250: 112610 doi: 10.1016/j.compstruct.2020.112610 [42] Dong Y J, Ye H L, Yang J X, Li J C, Wang W. 2023. Topology optimization of continuous fiber-reinforced composite (CFRC) structures considering the residual stress in additive manufacturing. Mech. Adv. Mater. Struc., 1-14 [43] Duan Z, Liu Y, Fan J, Long K, Xu B, Zhu J, Yan J. 2023. Concurrent multi-material and multi-scale design optimization of fiber-reinforced composite material and structures for minimum structural compliance. Composite Structures, 311: 116796 doi: 10.1016/j.compstruct.2023.116796 [44] Duan Z, Yan J, Zhao G. 2015. Integrated optimization of the material and structure of composites based on the heaviside penalization of discrete material model. Struct. Multidiscip. O., 51: 721-732 doi: 10.1007/s00158-014-1168-x [45] Dutra, T. , Ferreira, R. , Resende, H. , & Guimarães, A. 2019. Mechanical characterization and asymptotic homogenization of 3D-printed continuous carbon fiber-reinforced thermoplastic. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 41 (3): 1-15 [46] Fedulov B, Fedorenko A, Khaziev A, Antonov F. 2021. Optimization of parts manufactured using continuous fiber three-dimensional printing technology. Composites Part B:Engineering, 227: 109406 doi: 10.1016/j.compositesb.2021.109406 [47] Gandhi Y, Minak G. 2022. A Review on topology optimization strategies for additively manufactured continuous fiber-reinforced composite structures. Applied sciences, 12: 11211 doi: 10.3390/app122111211 [48] Gao T, Zhang W, Duysinx P. 2012. A bi-value coding parameterization scheme for the discrete optimal orientation design of the composite laminate. Int. J. Numer. Meth. Eng., 91: 98-114 doi: 10.1002/nme.4270 [49] Gao Y, Zhou Z, Hu H, Xiong J. 2021. New concept of carbon fiber reinforced composite 3D auxetic lattice structures based on stretching-dominated cells. Mech. Mater., 152: 103661 doi: 10.1016/j.mechmat.2020.103661 [50] Gea H C, Luo J H. 2004. On the stress-based and strain-based methods for predicting optimal orientation of orthotropic materials. Struct. Multidiscip. O., 26: 229-234 doi: 10.1007/s00158-003-0348-x [51] Goh G D, Dikshit V, Nagalingam AP, Goh GL, Agarwala S, Sing SL, Wei J, Yeong WY. 2018. Characterization of mechanical properties and fracture mode of additively manufactured carbon fiber and glass fiber reinforced thermoplastics. Materials & Design, 137: 79-89 [52] Goh G D, Yap Y L, Agarwala S, Yeong W Y. 2019. Recent progress in additive manufacturing of fiber reinforced polymer composite. Adv. Mater. Technol., 4: 1800271 doi: 10.1002/admt.201800271 [53] Groen J P, Sigmund O. 2018. Homogenization‐based topology optimization for high-resolution manufacturable microstructures. Int. J. Numer. Meth. Eng., 113: 1148-1163 doi: 10.1002/nme.5575 [54] Gu X, He S, Dong Y, Song T. 2022. An improved ordered SIMP approach for multiscale concurrent topology optimization with multiple microstructures. Composite Structures, 287: 115363 doi: 10.1016/j.compstruct.2022.115363 [55] Guo X, Zhang WS, Zhong WL. 2014. Doing topology optimization explicitly and geometrically — A new moving morphable components based framework. Journal of Applied Mechanics, 8: 81009 [56] Hao W, Liu Y, Zhou H, Chen H, Fang D. 2018. Preparation and characterization of 3D printed continuous carbon fiber reinforced thermosetting composites. Polym. Test., 65: 29-34 doi: 10.1016/j.polymertesting.2017.11.004 [57] He Q, Wang H, Fu K, Ye L. 2020. 3D printed continuous CF/PA6 composites: Effect of microscopic voids on mechanical performance. Compos. Sci. Technol., 191: 108077 doi: 10.1016/j.compscitech.2020.108077 [58] Heidari-Rarani, M. , Rafiee-Afarani, M. , & Zahedi, A. 2019. Mechanical characterization of FDM 3D printing of continuous carbon fiber reinforced PLA composites. Composites. Part B, Engineering, 175 : 107147 [59] Hou Z, Tian X, Zhang J, Li D. 2018. 3D printed continuous fibre reinforced composite corrugated structure. Composite Structures, 184: 1005-1010 doi: 10.1016/j.compstruct.2017.10.080 [60] Hou Z, Tian X, Zhang J, Zheng Z, Zhe L, Li D, Malakhov AV, Polilov AN. 2021. Optimization design and 3D printing of curvilinear fiber reinforced variable stiffness composites. Compos. Sci. Technol., 201: 108502 doi: 10.1016/j.compscitech.2020.108502 [61] Hozić D, Thore C, Cameron C, Loukil M. 2021. A new method for simultaneous material and topology optimization of composite laminate structures using hyperbolic function parametrization. Composite Structures, 276: 114374 doi: 10.1016/j.compstruct.2021.114374 [62] Hu Q, Duan Y, Zhang H, Liu D, Yan B, Peng F. 2018. Manufacturing and 3D printing of continuous carbon fiber prepreg filament. J. Mater. Sci., 53: 1887-1898 doi: 10.1007/s10853-017-1624-2 [63] Huang Y, Tian X, Wu L, Zia AA, Liu T, Li D. 2023. Progressive concurrent topological optimization with variable fiber orientation and content for 3D printed continuous fiber reinforced polymer composites. Composites Part B:Engineering, 255: 110602 doi: 10.1016/j.compositesb.2023.110602 [64] Hvejsel CF, Lund E. 2011. Material interpolation schemes for unified topology and multi-material optimization. Struct. Multidiscip. O., 43: 811-825 doi: 10.1007/s00158-011-0625-z [65] Ichihara N, Ueda M. 2022. 3D-print infill generation using the biological phase field of an optimized discrete material orientation vector field. Composites Part B:Engineering, 232: 109626 doi: 10.1016/j.compositesb.2022.109626 [66] Iragi M, Pascual-González C, Esnaola A, Lopes CS, Aretxabaleta L. 2019. Ply and interlaminar behaviours of 3D printed continuous carbon fibre-reinforced thermoplastic laminates; effects of processing conditions and microstructure. Additive Manufacturing, 30: 100884 doi: 10.1016/j.addma.2019.100884 [67] Jung T, Lee J, Nomura T, Dede EM. 2022. Inverse design of three-dimensional fiber reinforced composites with spatially-varying fiber size and orientation using multiscale topology optimization. Composite Structures, 279: 114768 doi: 10.1016/j.compstruct.2021.114768 [68] Justo J, Távara L, García-Guzmán L, París F. 2018. Characterization of 3D printed long fibre reinforced composites. Composite Structures, 185: 537-548 doi: 10.1016/j.compstruct.2017.11.052 [69] Kabir SMF, Mathur K, Seyam AM. 2020. A critical review on 3D printed continuous fiber-reinforced composites: History, mechanism, materials and properties. Composite Structures, 232: 111476 doi: 10.1016/j.compstruct.2019.111476 [70] Keller D. 2010 Optimization of ply angles in laminated composite structures by a hybrid, asynchronous, parallel evolutionary algorithm. Composite Structures, 92 : 2781-2790 [71] Khan S, Fayazbakhsh K, Fawaz Z, Arian Nik M. 2018. Curvilinear variable stiffness 3D printing technology for improved open-hole tensile strength. Additive Manufacturing, 24: 378-385 doi: 10.1016/j.addma.2018.10.013 [72] Kim D, Lee J, Nomura T, Dede EM, Yoo J, Min S. 2020. Topology optimization of functionally graded anisotropic composite structures using homogenization design method. Comput. Method. Appl. M., 369: 113220 doi: 10.1016/j.cma.2020.113220 [73] Kiyono CY, Silva ECN, Reddy JN. 2017. A novel fiber optimization method based on normal distribution function with continuously varying fiber path. Composite Structures, 160: 503-515 doi: 10.1016/j.compstruct.2016.10.064 [74] Lee J, Kim D, Nomura T, Dede EM, Yoo J. 2018. Topology optimization for continuous and discrete orientation design of functionally graded fiber-reinforced composite structures. Composite Structures, 201: 217-233 doi: 10.1016/j.compstruct.2018.06.020 [75] Lemaire E, Zein S, Bruyneel M. 2015. Optimization of composite structures with curved fiber trajectories. Composite Structures, 131: 895-904 doi: 10.1016/j.compstruct.2015.06.040 [76] Li H, Gao L, Li H, Li X, Tong H. 2021. Full-scale topology optimization for fiber-reinforced structures with continuous fiber paths. Comput. Method. Appl. M., 377: 113668 doi: 10.1016/j.cma.2021.113668 [77] Li H M, Liu B, Ge L, Chen Y, Zheng H, Fang D. 2021. Mechanical performances of continuous carbon fiber reinforced PLA composites printed in vacuum. Composites Part B:Engineering, 225: 109277 doi: 10.1016/j.compositesb.2021.109277 [78] Li J, Ye H, Yuan B, Wei N. 2022a. Cross-resolution topology optimization for geometrical non-linearity by using deep learning. Struct. Multidiscip. O, 65: 133 doi: 10.1007/s00158-022-03231-y [79] Li J, Ye H, Zhang X, Wei N. 2022b. Adjustable mechanical properties design of microstructure by using generative and adversarial network with gradient penalty. Mech. Adv. Mater. Struc., ahead-of-print: 1-12 [80] Li L, Liu W, Sun L. 2022. Mechanical characterization of 3D printed continuous carbon fiber reinforced thermoplastic composites. Compos. Sci. Technol., 227: 109618 doi: 10.1016/j.compscitech.2022.109618 [81] Li N, Li Y, Liu S. 2016. Rapid prototyping of continuous carbon fiber reinforced polylactic acid composites by 3D printing. J. Mater. Process. Tech., 238: 218-225 doi: 10.1016/j.jmatprotec.2016.07.025 [82] Li N, Link G, Wang T, Ramopoulos V, Neumaier D, Hofele J, Walter M, Jelonnek J. 2020. Path-designed 3D printing for topological optimized continuous carbon fibre reinforced composite structures. Composites Part B:Engineering, 182: 107612 doi: 10.1016/j.compositesb.2019.107612 [83] Li W, Sang L, Jian X, Wang J. 2020. Influence of sanding and plasma treatment on shear bond strength of 3D-printed PEI, PEEK and PEEK/CF. International Journal of Adhesion and Adhesives, 100: 102614 doi: 10.1016/j.ijadhadh.2020.102614 [84] Lindgaard E, Lund E. 2011. Optimization formulations for the maximum nonlinear buckling load of composite structures. Struct. Multidiscip. O., 43: 631-646 doi: 10.1007/s00158-010-0593-8 [85] Liu G, Xiong Y, Zhou L. 2021. Additive manufacturing of continuous fiber reinforced polymer composites: Design opportunities and novel applications. Composites Communications, 27: 100907 doi: 10.1016/j.coco.2021.100907 [86] Liu S, Li Y, Li N. 2018. A novel free-hanging 3D printing method for continuous carbon fiber reinforced thermoplastic lattice truss core structures. Materials & Design, 137: 235-244 [87] Liu T, Tian X, Zhang M, Abliz D, Li D, Ziegmann G. 2018. Interfacial performance and fracture patterns of 3D printed continuous carbon fiber with sizing reinforced PA6 composites. Composites Part A:Applied Science and Manufacturing, 114: 368-376 doi: 10.1016/j.compositesa.2018.09.001 [88] Long Y, Zhang Z, Fu K, Li Y. 2021. Efficient plant fibre yarn pre-treatment for 3D printed continuous flax fibre/poly(lactic) acid composites. Composites Part B:Engineering, 227: 109389 doi: 10.1016/j.compositesb.2021.109389 [89] Luo J H, Gea H C. 1998. Optimal orientation of orthotropic materials using an energy based method. Structural Optimization, 15: 230-236 doi: 10.1007/BF01203536 [90] Luo M, Tian X, Shang J, Zhu W, Li D, Qin Y. 2019. Impregnation and interlayer bonding behaviours of 3D-printed continuous carbon-fiber-reinforced poly-ether-ether-ketone composites. Composites Part A:Applied Science and Manufacturing, 121: 130-138 doi: 10.1016/j.compositesa.2019.03.020 [91] Luo Y, Chen W, Liu S, Li Q, Ma Y. 2020. A discrete-continuous parameterization (DCP) for concurrent optimization of structural topologies and continuous material orientations. Composite Structures, 236: 111900 doi: 10.1016/j.compstruct.2020.111900 [92] Ma G, Yang W, Wang L. 2022. Strength-constrained simultaneous optimization of topology and fiber orientation of fiber-reinforced composite structures for additive manufacturing. Adv. Struct. Eng., 25: 1636-1651 doi: 10.1177/13694332221088946 [93] Malakhov A V, Polilov A N, Zhang J, Hou Z, Tian X. 2020. A modeling method of continuous fiber paths for additive manufacturing (3D Printing) of variable stiffness composite structures. Appl. Compos. Mater., 27: 185-208 doi: 10.1007/s10443-020-09804-8 [94] Mei H, Ali Z, Yan Y, Ali I, Cheng L. 2019a. Influence of mixed isotropic fiber angles and hot press on the mechanical properties of 3D printed composites. Additive Manufacturing, 27: 150-158 doi: 10.1016/j.addma.2019.03.008 [95] Mei H, Ali Z, Ali I, Cheng L. 2019b. Tailoring strength and modulus by 3D printing different continuous fibers and filled structures into composites. Advanced Composites and Hybrid Materials, 2: 312-319 doi: 10.1007/s42114-019-00087-7 [96] Ming Y, Xin Z, Zhang J, Duan Y, Wang B. 2020a. Fabrication of continuous glass fiber-reinforced dual-cure epoxy composites via UV-assisted fused deposition modeling. Composites Communications, 21: 100401 doi: 10.1016/j.coco.2020.100401 [97] Ming Y, Zhang S, Han W, Wang B, Duan Y, Xiao H. 2020b. Investigation on process parameters of 3D printed continuous carbon fiber-reinforced thermosetting epoxy composites. Additive Manufacturing, 33: 101184 doi: 10.1016/j.addma.2020.101184 [98] Naranjo-Lozada J, Ahuett-Garza H, Orta-Castañón P, Verbeeten WMH, Sáiz-González D. 2019. Tensile properties and failure behavior of chopped and continuous carbon fiber composites produced by additive manufacturing. Additive Manufacturing, 26: 227-241 doi: 10.1016/j.addma.2018.12.020 [99] Niu B, Feng N, Lund E, Leng Y. 2022. Discrete material optimization of composite structures subjected to initial excitation for minimum residual vibration. Thin-Walled Structures, 173: 108901 doi: 10.1016/j.tws.2022.108901 [100] Nomura T, Dede EM, Lee J, Yamasaki S, Matsumori T, Kawamoto A, Kikuchi N. 2015. General topology optimization method with continuous and discrete orientation design using isoparametric projection. Int. J. Numer. Meth. Eng., 101: 571-605 doi: 10.1002/nme.4799 [101] Nomura T, Kawamoto A, Kondoh T, Dede EM, Lee J, Song Y, Kikuchi N. 2019. Inverse design of structure and fiber orientation by means of topology optimization with tensor field variables. Composites Part B:Engineering, 176: 107187 doi: 10.1016/j.compositesb.2019.107187 [102] O'Connor H J, Dowling DP. 2019. Low-pressure additive manufacturing of continuous fiber-reinforced polymer composites. Polymer Composites, 40: 4329-4339 doi: 10.1002/pc.25294 [103] Oztan C, Karkkainen R, Fittipaldi M, Nygren G, Roberson L, Lane M, Celik E. 2019. Microstructure and mechanical properties of three dimensional-printed continuous fiber composites. J. Compos. Mater., 53: 271-280 doi: 10.1177/0021998318781938 [104] Papapetrou V S, Patel C, Tamijani AY. 2020. Stiffness-based optimization framework for the topology and fiber paths of continuous fiber composites. Composites Part B:Engineering, 183: 107681 doi: 10.1016/j.compositesb.2019.107681 [105] Pyl L, Kalteremidou K, Van Hemelrijck D. 2019. Exploration of the design freedom of 3D printed continuous fibre-reinforced polymers in open-hole tensile strength tests. Compos. Sci. Technol., 171: 135-151 doi: 10.1016/j.compscitech.2018.12.021 [106] Qiu Z, Li Q, Luo Y, Liu S. 2022. Concurrent topology and fiber orientation optimization method for fiber-reinforced composites based on composite additive manufacturing. Comput. Method. Appl. M., 395: 114962 doi: 10.1016/j.cma.2022.114962 [107] Quan C, Han B, Hou Z, Zhang Q, Tian X, Lu T J. 2020. 3d printed continuous fiber reinforced composite auxetic honeycomb structures. Composites Part B:Engineering, 187: 107858 doi: 10.1016/j.compositesb.2020.107858 [108] Safonov A A. 2019. 3D topology optimization of continuous fiber-reinforced structures via natural evolution method. Composite Structures, 215: 289-297 [109] Schmidt M, Couret L, Gout C, Pedersen CBW. 2020. Structural topology optimization with smoothly varying fiber orientations. Struct. Multidiscip. O., 62: 3105-3126 doi: 10.1007/s00158-020-02657-6 [110] Sigmund O. 2001. A 99 line topology optimization code written in Matlab. Struct. Multidiscip. O., 21: 120-127 doi: 10.1007/s001580050176 [111] Smith H, Norato J A. 2021. Topology optimization with discrete geometric components made of composite materials. Comput. Method. Appl. M., 376: 113582 doi: 10.1016/j.cma.2020.113582 [112] Sørensen R, Lund E. 2015. Thickness filters for gradient based multi-material and thickness optimization of laminated composite structures. Struct. Multidiscip. O., 52: 227-250 doi: 10.1007/s00158-015-1230-3 [113] Sørensen S N, Sørensen R, Lund E. 2014. DMTO-a method for discrete material and thickness optimization of laminated composite structures. Struct. Multidiscip. O., 50: 25-47 doi: 10.1007/s00158-014-1047-5 [114] Stegmann J, Lund E. 2005. Discrete material optimization of general composite shell structures. Int. J. Numer. Meth. Eng., 62: 2009-2027 doi: 10.1002/nme.1259 [115] Sugiyama K, Matsuzaki R, Malakhov AV, Polilov AN, Ueda M, Todoroki A, Hirano Y. 2020. 3D printing of optimized composites with variable fiber volume fraction and stiffness using continuous fiber. Compos. Sci. Technol., 186: 107905 doi: 10.1016/j.compscitech.2019.107905 [116] Sugiyama K, Matsuzaki R, Ueda M, Todoroki A, Hirano Y. 2018. 3D printing of composite sandwich structures using continuous carbon fiber and fiber tension. Composites Part A:Applied Science and Manufacturing, 113: 114-121 doi: 10.1016/j.compositesa.2018.07.029 [117] Sui Yunkang, Yang Deqing. 1998. A new method for structural topological optimization based on the concept of independent continuous variables and smooth model. Acta Mech Sinica, 2: 179-185 [118] Suzuki T, Fukushige S, Tsunori M. 2020. Load path visualization and fiber trajectory optimization for additive manufacturing of composites. Additive Manufacturing, 31: 100942 doi: 10.1016/j.addma.2019.100942 [119] Tian X, Liu T, Wang Q, Dilmurat A, Li D, Ziegmann G. 2017. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J. Clean. Prod., 142: 1609-1618 doi: 10.1016/j.jclepro.2016.11.139 [120] Tian X, Liu T, Yang C, Wang Q, Li D. 2016. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites. Composites Part A:Applied Science and Manufacturing, 88: 198-205 doi: 10.1016/j.compositesa.2016.05.032 [121] Walker M, Smith RE. 2003. A technique for the multiobjective optimisation of laminated composite structures using genetic algorithms and finite element analysis. Composite Structures, 62: 123-128 doi: 10.1016/S0263-8223(03)00098-9 [122] Wang P, Zou B, Ding S, Li L, Huang C. 2021. Effects of FDM-3D printing parameters on mechanical properties and microstructure of CF/PEEK and GF/PEEK. Chinese J. Aeronaut, 34: 236-246 doi: 10.1016/j.cja.2020.05.040 [123] Wang T, Li N, Link G, et al. 2021. Load-dependent path planning method for 3D printing of continuous fiber reinforced plastics. Composites Part A:Applied Science and Manufacturing, 140: 106181. doi: 10.1016/j.compositesa.2020.106181 [124] Wang X, Meng Z, Yang B, Cheng C, Long K, Li J. 2022. Reliability-based design optimization of material orientation and structural topology of fiber-reinforced composite structures under load uncertainty. Composite Structures, 291: 115537 doi: 10.1016/j.compstruct.2022.115537 [125] Woldseth RV, Aage N, Bærentzen JA, Sigmund O. 2022. On the use of artificial neural networks in topology optimisation. Struct. Multidiscip. O., 65(10): 294 doi: 10.1007/s00158-022-03347-1 [126] Xia Q, Shi T. 2017. Optimization of composite structures with continuous spatial variation of fiber angle through Shepard interpolation. Composite Structures, 182: 273-282 doi: 10.1016/j.compstruct.2017.09.052 [127] Yamanaka Y, Todoroki A, Ueda M, Hirano Y, Matsuzaki R. 2016. Fiber line optimization in single ply for 3D printed composites. Open Journal of Composite Materials, 06: 121-131 doi: 10.4236/ojcm.2016.64012 [128] Yan M, Tian X, Peng G, Li D, Zhang X. 2018. High temperature rheological behavior and sintering kinetics of CF/PEEK composites during selective laser sintering. Compos. Sci. Technol., 165: 140-147 doi: 10.1016/j.compscitech.2018.06.023 [129] Yan X, Huang X, Zha Y, Xie YM. 2014. Concurrent topology optimization of structures and their composite microstructures. Comput. Struct., 133: 103-110 doi: 10.1016/j.compstruc.2013.12.001 [130] Yan X, Xu Q, Hua H, Huang D, Huang X. 2020. Concurrent topology optimization of structures and orientation of anisotropic materials. Eng. Optimiz., 52: 1598-1611 doi: 10.1080/0305215X.2019.1663186 [131] Yang C, Tian X, Liu T, Cao Y, Li D. 2017. 3D printing for continuous fiber reinforced thermoplastic composites: mechanism and performance. Rapid Prototyping J., 23: 209-215 doi: 10.1108/RPJ-08-2015-0098 [132] Yang Y, Yang B, Chang Z, et al. 2023. Research status of and prospects for 3D printing for continuous fiber-reinforced thermoplastic composites. Polymers, 15(17): 3653 doi: 10.3390/polym15173653 [133] Yang Z, Fu K, Zhang Z, Zhang J, Li Y. 2022. Topology optimization of 3D-printed continuous fiber-reinforced composites considering manufacturability. Compos. Sci. Technol., 230: 109727 doi: 10.1016/j.compscitech.2022.109727 [134] Yao X, Luan C, Zhang D, Lan L, Fu J. 2017. Evaluation of carbon fiber-embedded 3D printed structures for strengthening and structural-health monitoring. Materials & Design, 114: 424-432 [135] Ye H, Dong Y, Yang J, Wang W, Cheng M. 2023. Concurrent optimization method of principal stress orientation interpolated continuous fiber angle (PSO-CFAO) and structural topology. Composite Structures, 325: 117572 doi: 10.1016/j.compstruct.2023.117572 [136] Young D, Wetmore N, Czabaj M. 2018. Interlayer fracture toughness of additively manufactured unreinforced and carbon-fiber-reinforced acrylonitrile butadiene styrene. Additive Manufacturing, 22: 883-890 doi: 10.1016/j.addma.2018.02.010 [137] Yu L, Chen K, Xue P, et al. 2021. Impregnation modeling and preparation optimization of continuous glass fiber reinforced polylactic acid filament for 3D printing. Polymer Composites, 42(11): 5731-5742. doi: 10.1002/pc.26255 [138] Zeng C, Liu L, Bian W, Leng J, Liu Y. 2021a. Compression behavior and energy absorption of 3D printed continuous fiber reinforced composite honeycomb structures with shape memory effects. Additive Manufacturing, 38: 101842 doi: 10.1016/j.addma.2021.101842 [139] Zeng C, Liu L, Bian W, Leng J, Liu Y. 2021b. Bending performance and failure behavior of 3D printed continuous fiber reinforced composite corrugated sandwich structures with shape memory capability. Composite Structures, 262: 113626 doi: 10.1016/j.compstruct.2021.113626 [140] Zhang H, Yang D, Sheng Y. 2018. Performance-driven 3D printing of continuous curved carbon fibre reinforced polymer composites: A preliminary numerical study. Composites Part B:Engineering, 151: 256-264 doi: 10.1016/j.compositesb.2018.06.017 [141] Zhang Z, Cai S, Li Y, Wang Z, Long Y, Yu T, Shen Y. 2020. High performances of plant fiber reinforced composites—A new insight from hierarchical microstructures. Compos. Sci. Technol., 194: 108151 doi: 10.1016/j.compscitech.2020.108151 [142] Zhang Z, Long Y, Yang Z, Fu K, Li Y. 2022. An investigation into printing pressure of 3D printed continuous carbon fiber reinforced composites. Composites Part A:Applied Science and Manufacturing, 162: 107162 doi: 10.1016/j.compositesa.2022.107162 [143] Zhao S, Wu N, Wang Q. 2021. Load path-guided fiber trajectory in composite panels: A comparative study and a novel combined method. Composite Structures, 263: 113689 doi: 10.1016/j.compstruct.2021.113689 [144] Zhuo P, Li S, Ashcroft IA, Jones AI. 2021. Material extrusion additive manufacturing of continuous fibre reinforced polymer matrix composites: A review and outlook. Composites. Part B, Engineering, 224: 109143 doi: 10.1016/j.compositesb.2021.109143 -

下载:

下载: