Research on impact response characteristics and damage evolution law of transparent ceramics

-

摘要: 透明陶瓷兼具有优秀的透光性能和抗冲击破坏性能, 是武器装备透明部分性能优异的防护材料之一, 在军事装备、航天等国防领域具有良好的应用前景. 冲击载荷下材料的加载响应特性对掌握材料破坏机制至关重要, 能为透明复合材料设计提供依据. 文章从透明陶瓷材料的抗冲击响应实验研究, 包括实验技术、应变率效应、裂纹扩展速度、材料破坏特征等方面, 对静、动态加载下透明陶瓷的冲击响应特性研究进行了较为系统地回顾; 同时结合陶瓷材料冲击破坏实验阐明了透明陶瓷材料的冲击破坏机制, 以此为基础阐述透明陶瓷冲击破坏的损伤模型、强度准则及冲击响应动态本构模型; 最后分析了透明陶瓷复合装甲抗冲击响应特性以及数值模拟技术的研究现状, 探讨了陶瓷材料抗冲击响应特性研究的发展趋势. 针对现今透明陶瓷冲击响应研究的不足, 提出了关于未来研究方向的建议.Abstract: Transparent ceramics excel in light transmission and impact damage resistance, and have good application prospects as superior protective materials in military equipment, aerospace and other national defense fields. It is important to explore the damage evolution process of transparent ceramics and clarify the loading response characteristics of materials under impact load in order to grasp the failure mechanism of materials and improve the elastic performance of transparent ceramic armor. This paper systematically reviews the impact response characteristics of transparent ceramics under static and dynamic loading from the experimental research, including experimental technology, strain rate effect, crack growth rate and material failure characteristics. At the same time, the impact failure mechanism of transparent ceramic materials is elucidated based on the impact failure test of ceramic materials, and thereby the damage model, strength criterion and dynamic constitutive model of impact response of transparent ceramic are elaborated. Finally, this paper analyzes the research status of impact response characteristics and numerical simulation technology of transparent ceramic composite packaging, discusses the development trend of impact response characteristics of ceramic materials, and provides the design of transparent composite targets. In view of the shortcomings of the current research on the impact response of transparent ceramics, this paper also proposes suggestions for future research directions.

-

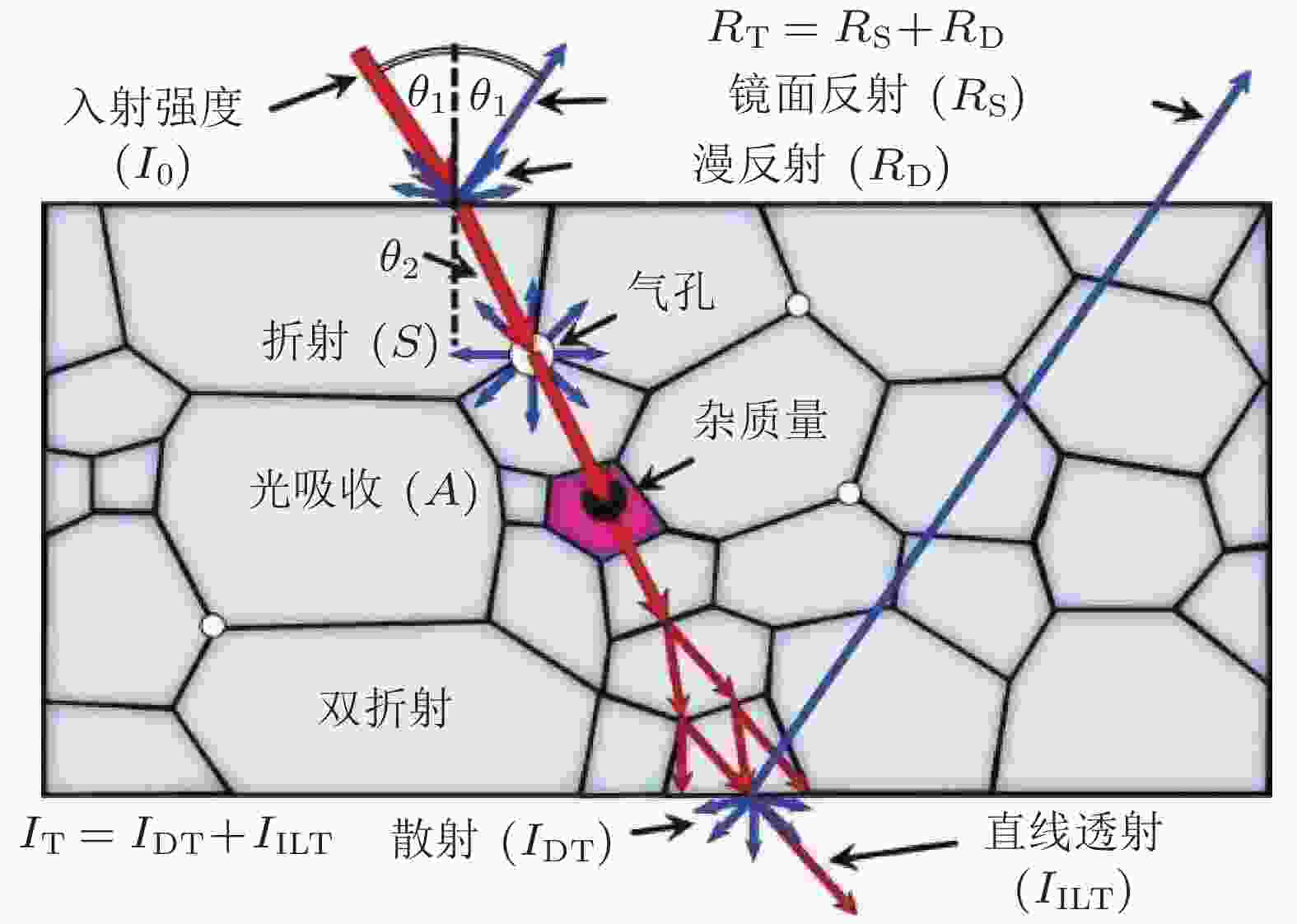

图 1 陶瓷中的主要散射效应(Dumerac et al. 2013)

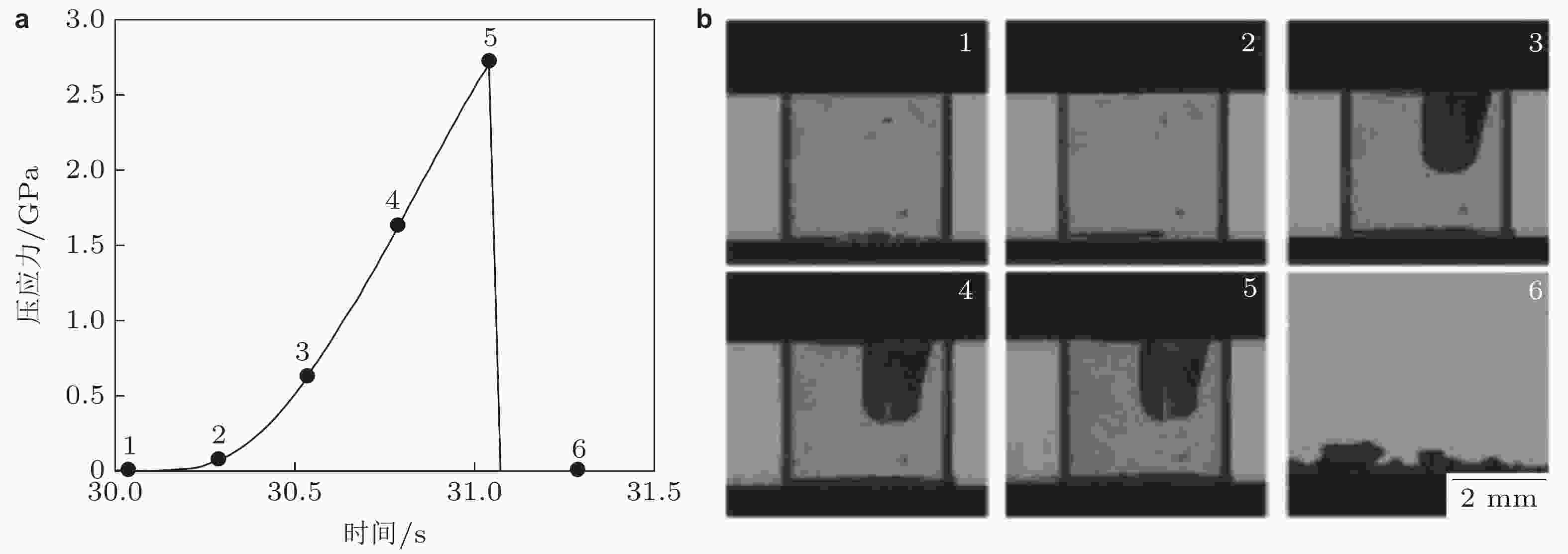

图 4 镁铝尖晶石透明陶瓷准静态压缩加载过程(Mccauley & Patel 2013). (a)应力−时间历程曲线, (b)对应的透明陶瓷准静态压缩破坏过程

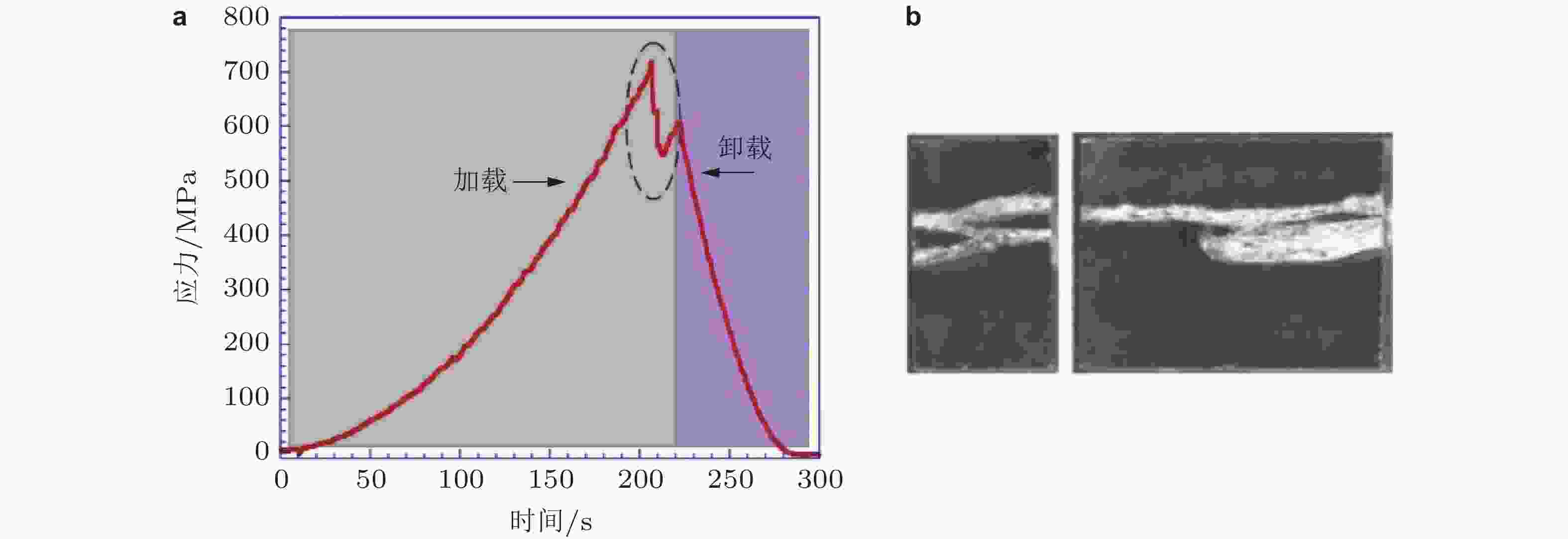

图 5 AlON透明陶瓷限制加载位移的准静态压缩实验(Paliwal et al. 2008). (a)试件的应力−时间曲线, (b)加载后试样正面和侧面的损伤形貌

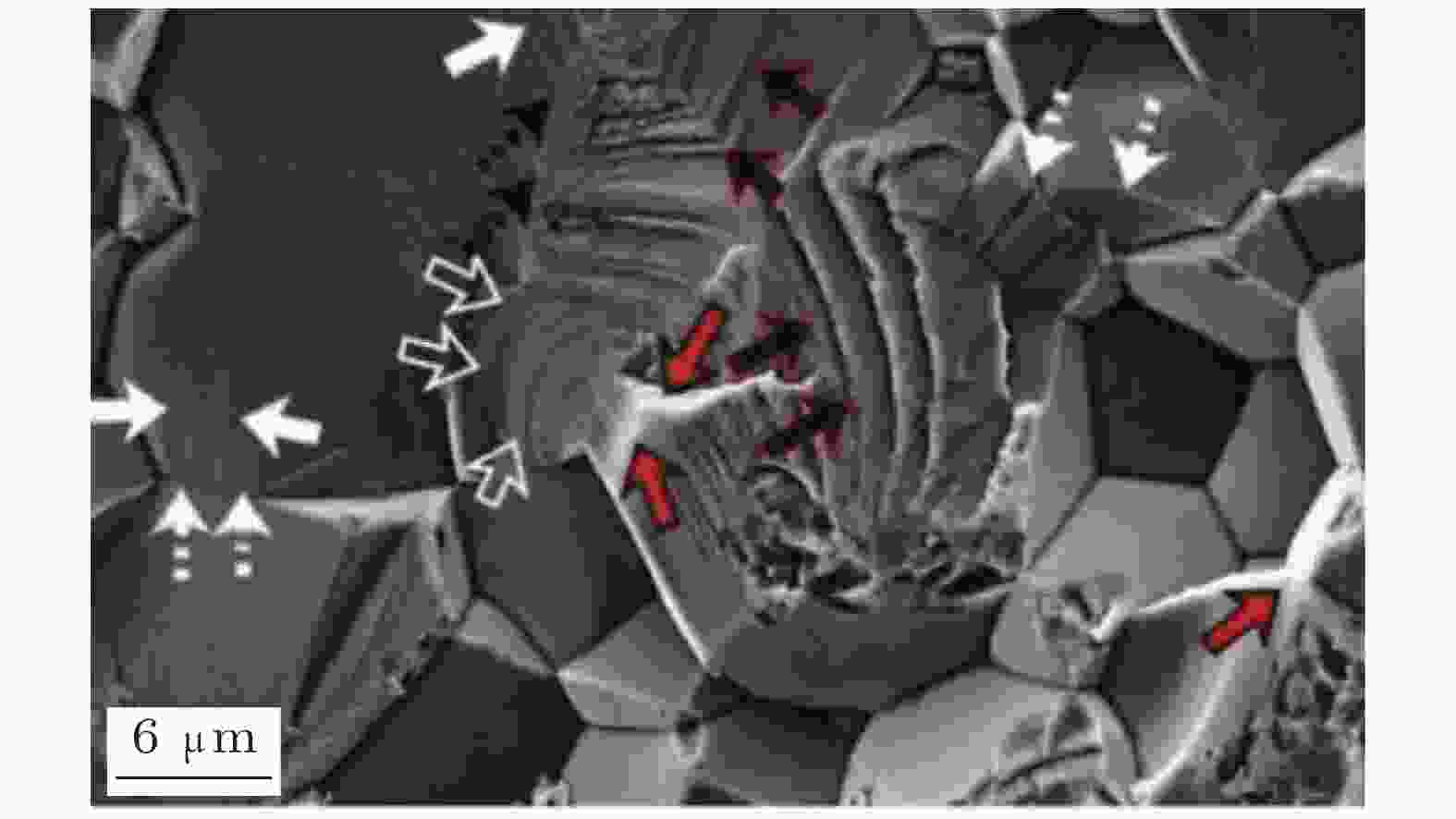

图 6 准静态加载下YAG透明陶瓷的细观破坏特征(Jiang et al. 2019b)

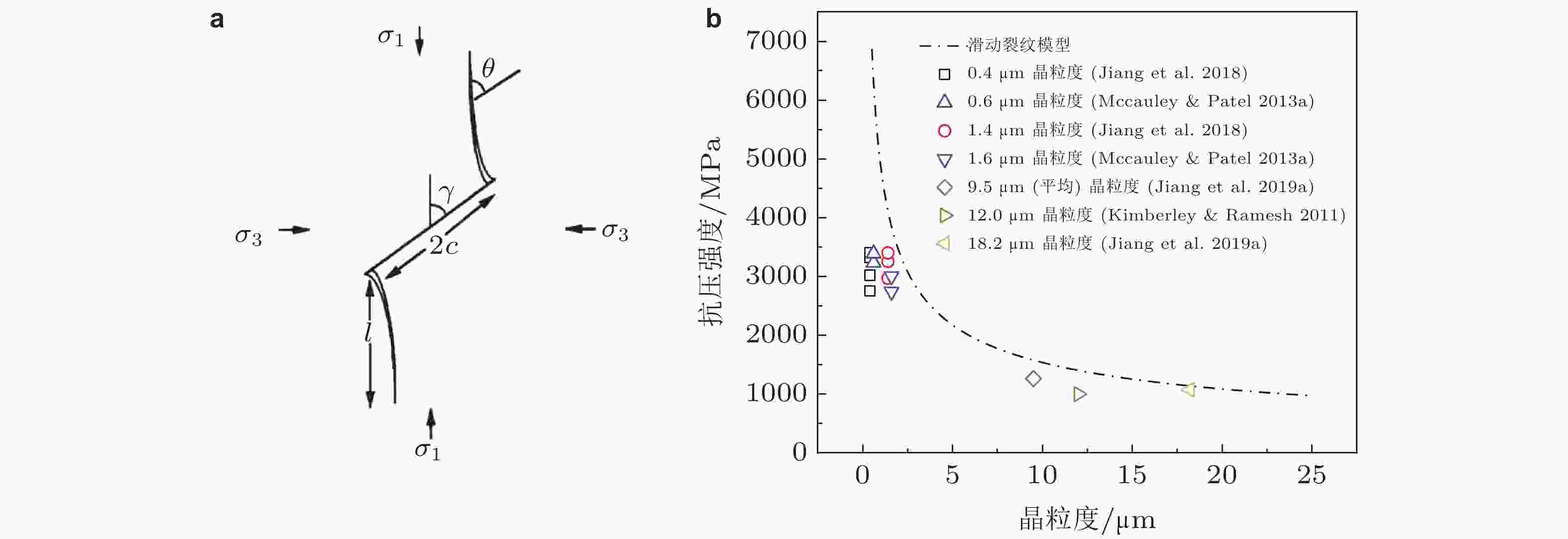

图 7 晶粒度大小对陶瓷强度的影响. (a) 用滑动裂纹模拟脆性断裂作用(Fredrich et al. 1990), (b)抗压强度随晶粒度变化的理论预测(Jiang et al. 2019a, Jiang et al. 2018, Mccauley & Patel 2013, Kimberley & Ramesh 2011)

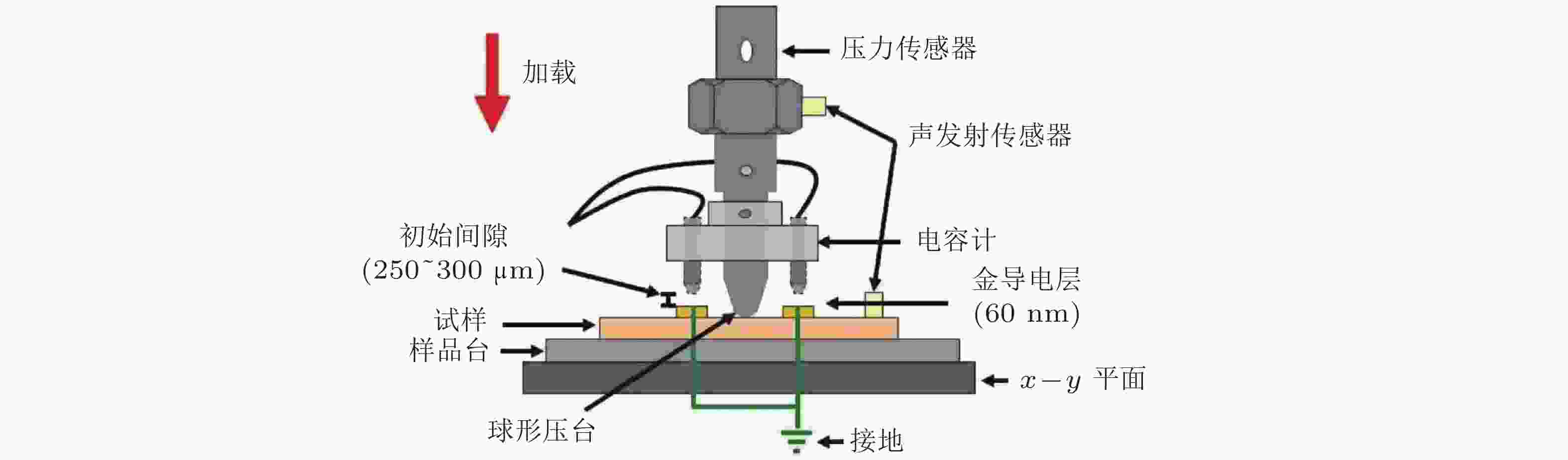

图 8 仪器化压痕测试设置示意图(Mccauley & Patel 2013)

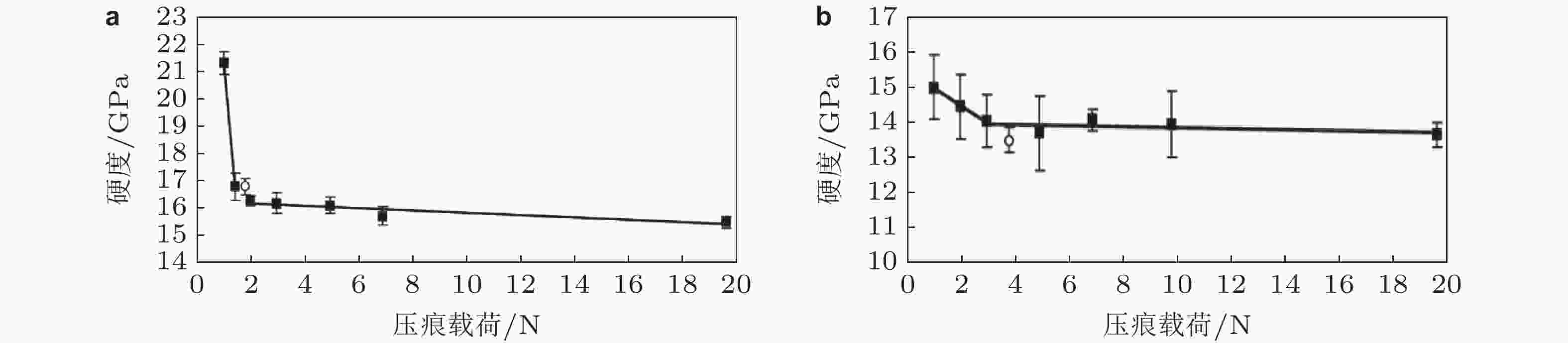

图 9 透明陶瓷维氏硬度结果(Patel et al. 2006). (a) AlON透明陶瓷的硬度−载荷曲线, (b) MgAl2O4透明陶瓷的硬度−载荷曲线

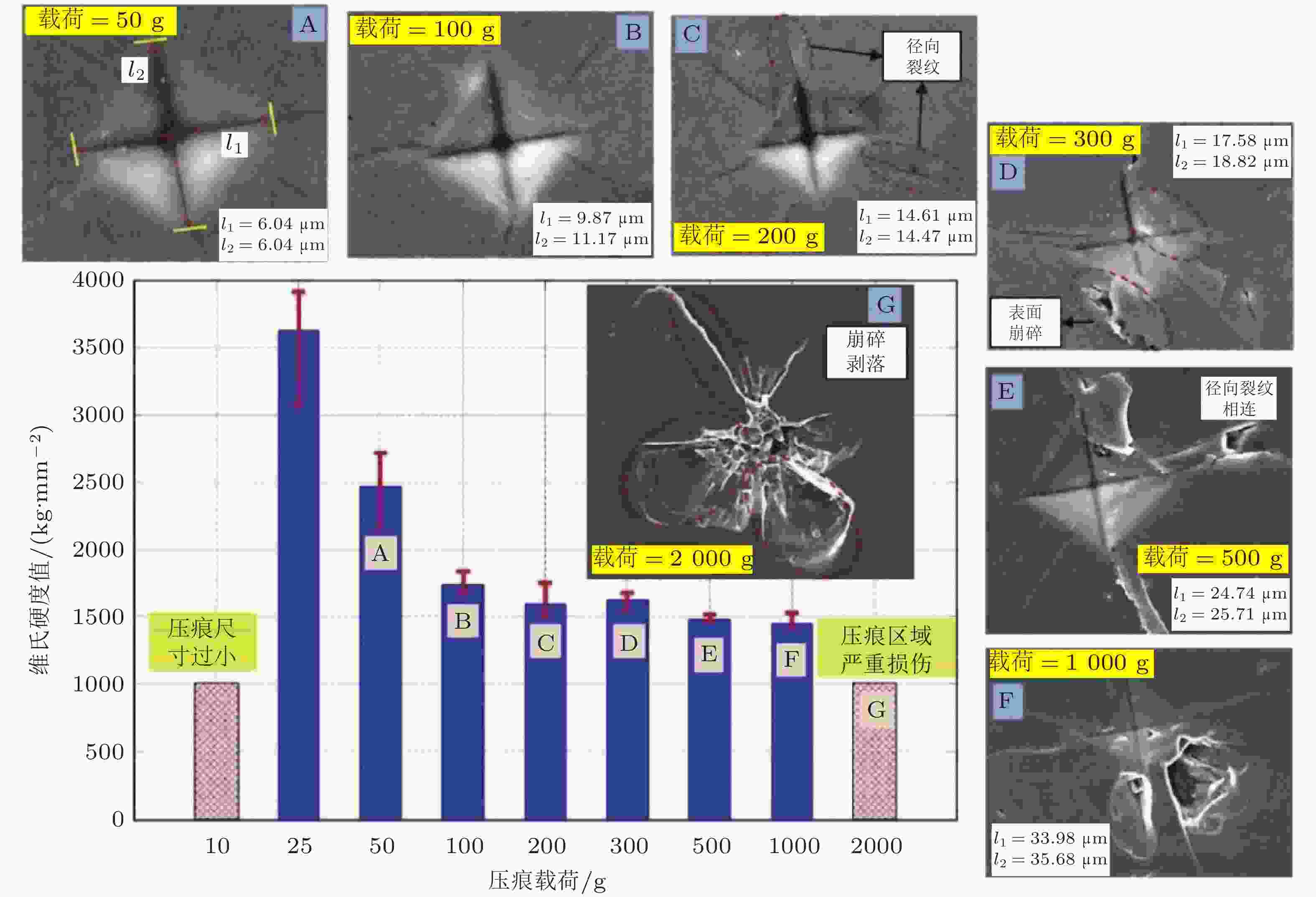

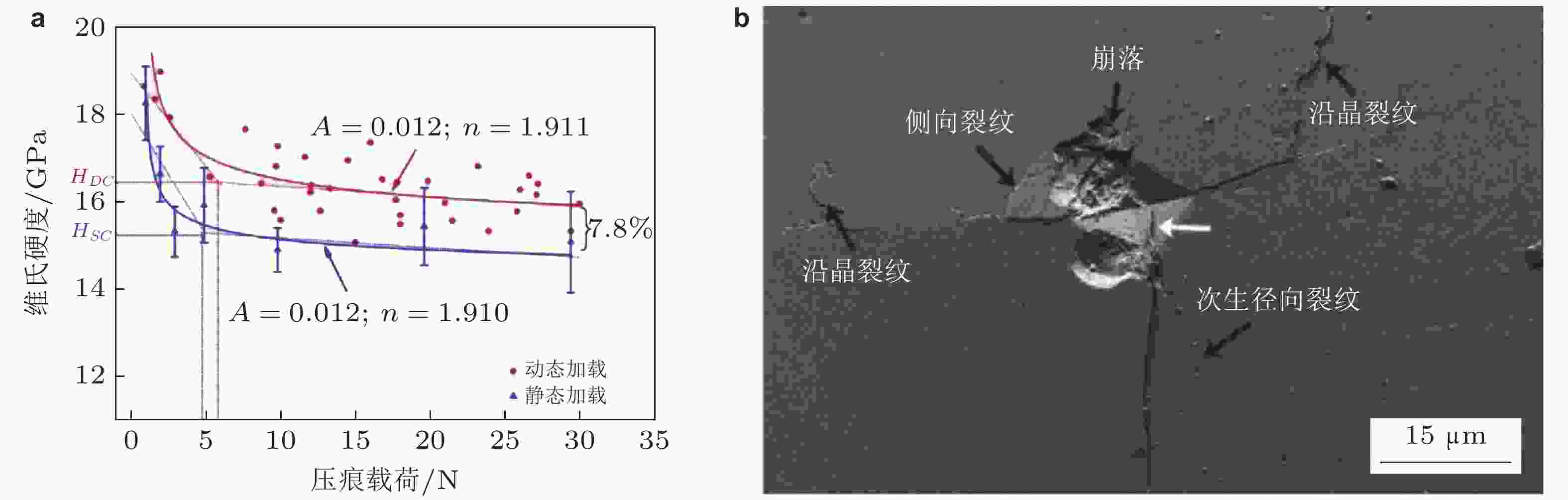

图 10 尖晶石透明陶瓷在不同压头载荷下的硬度值和压痕形貌(Shi et al. 2020)

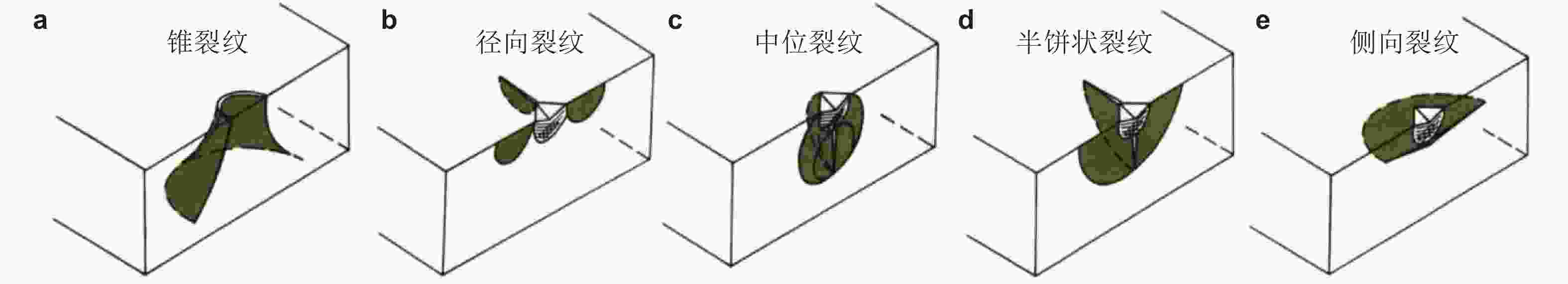

图 11 压痕加载下的理想裂纹形态的几何截面(Cook & Pharr 1990). (a)锥裂纹, (b)径向裂纹, (c)中位裂纹, (d)半饼状裂纹, (e)侧向裂纹

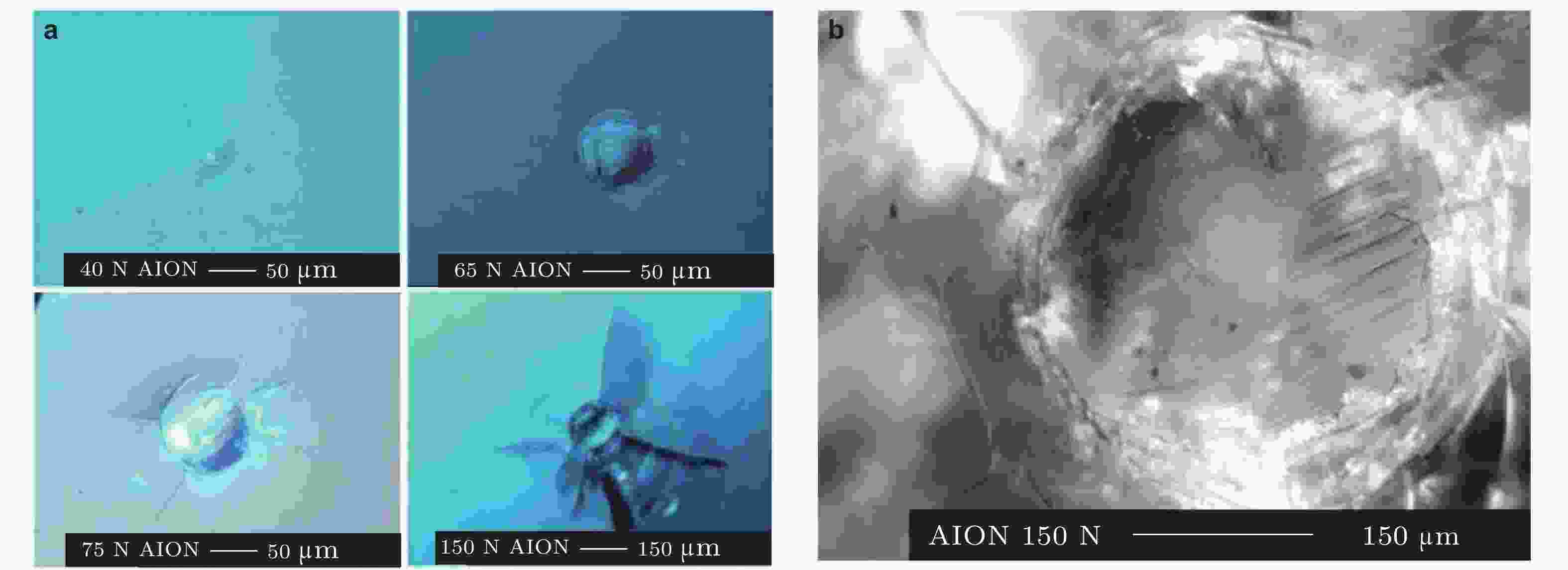

图 12 AlON透明陶瓷静态压痕破坏特征(Wilantewicz 2010). (a) 不同载荷下的压痕形貌, (b) 150 N载荷下的变形孪晶

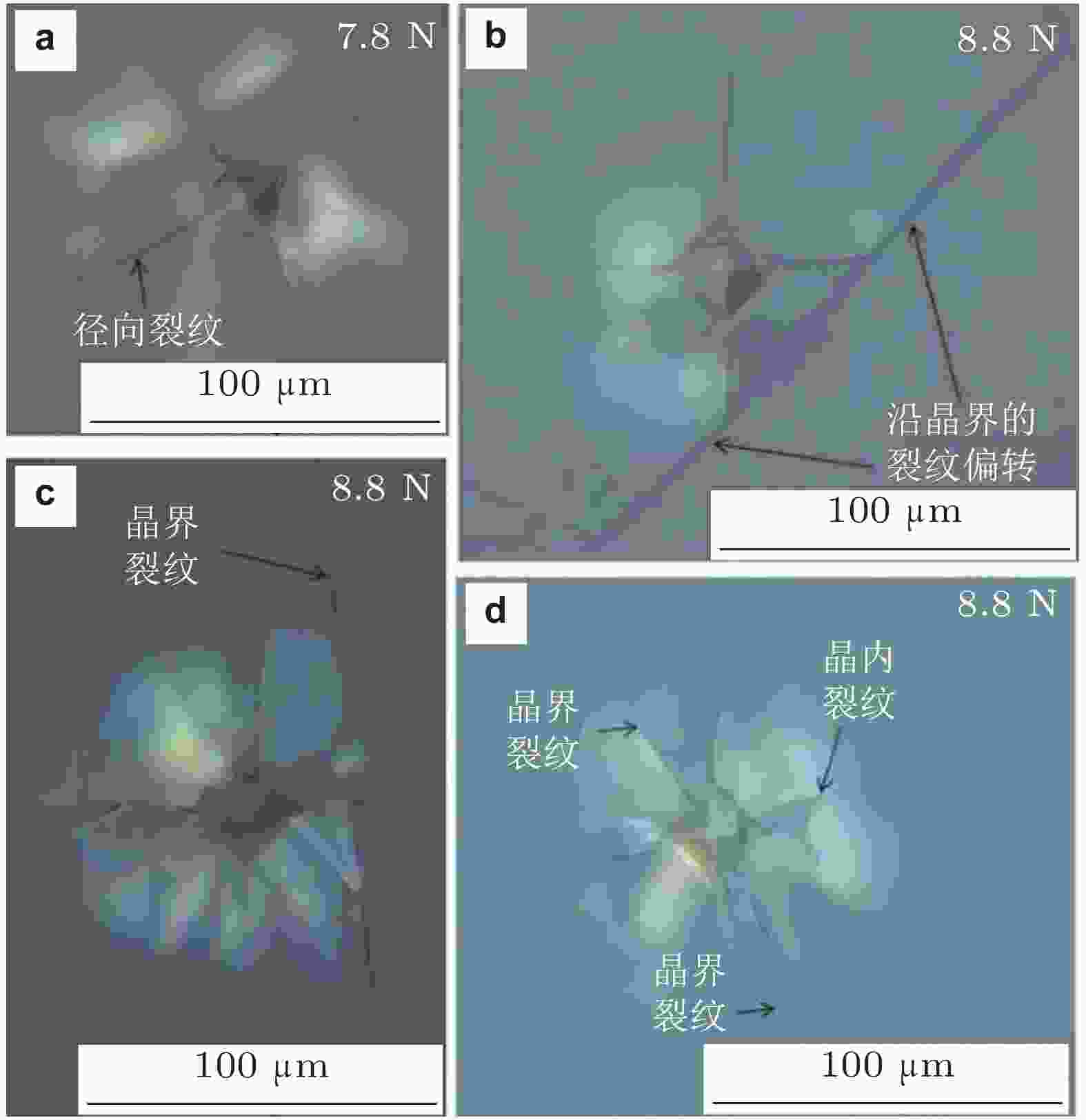

图 13 透明陶瓷不同位置处的静态压痕光学图像(Haney & Subhash 2011a) . (a) 晶粒内部, (b) 晶界附近(压痕接近角较小), (c) 晶界附近(压痕接近角较大), (d) 沿晶界处

图 14 蓝宝石晶体结构及压痕形貌示意图(Haney & Subhash 2011b). (a)蓝宝石晶向示意图, (b)蓝宝石a晶面上的维氏压痕产生的裂纹示意图, (c)相对于a晶面的裂纹平面方向示意图, (d)蓝宝石晶体结构

图 15 连续压痕相互作用过程(Haney & Subhash 2011b). (a) 沿 90°连续压痕引起的裂纹的光学图像, (b) “B型裂纹”连通示意图, (c) a晶面蓝宝石在不同方向和距离上压痕的损伤敏感性

图 16 边缘冲击 (EOI) 实验中假设的动态冲击应力波/能量分布(McCauley et al. 2013)

图 17 陶瓷材料SHPB 示意图(高玉波等 2019)

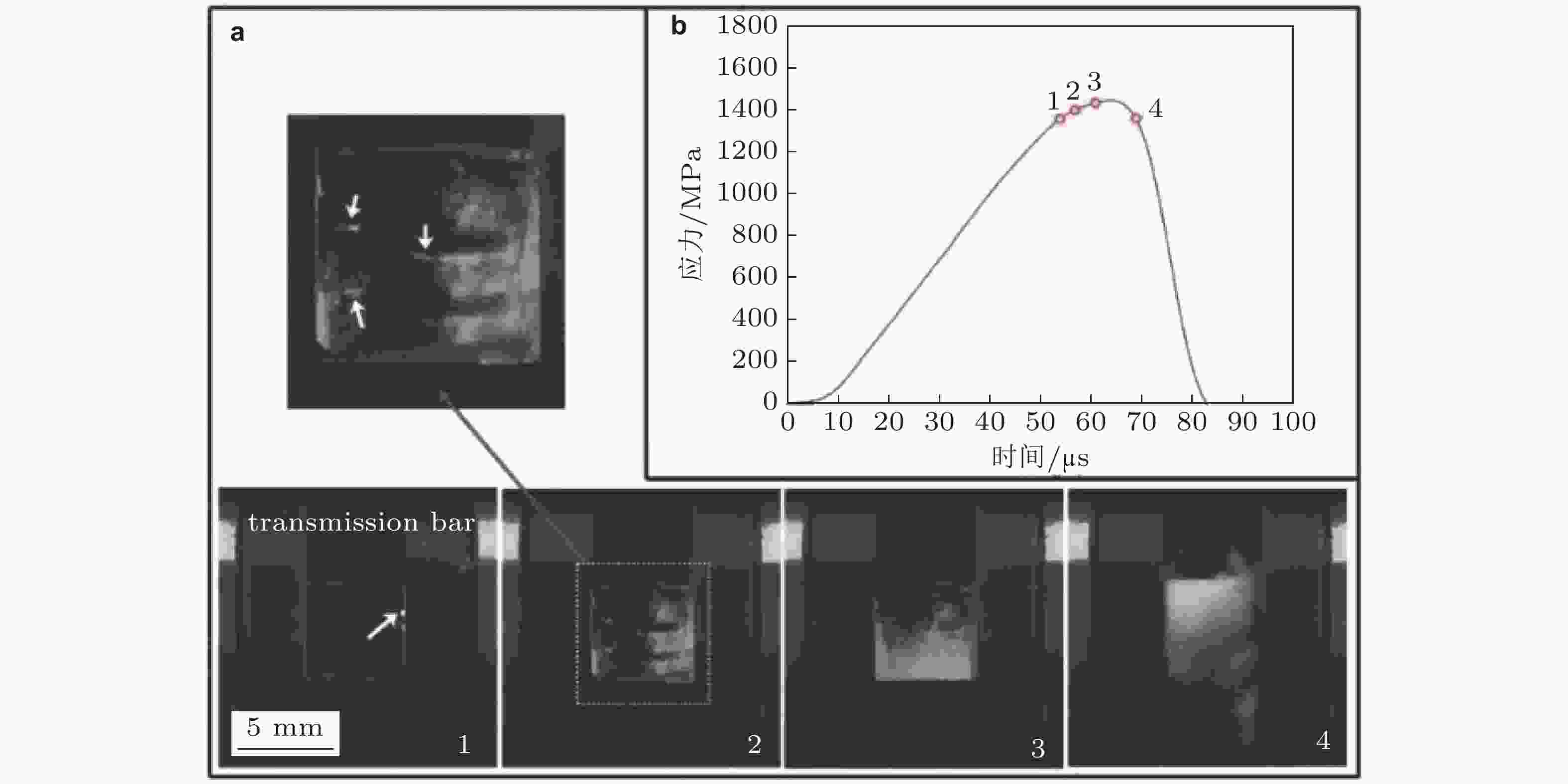

图 18 镁铝尖晶石透明陶瓷动态压缩加载过程(Jiang et al. 2018). (a)立方体试件破坏过程的高速图像, (b)应力−时间曲线(每幅图像的应力状态对应于曲线上的红点)

图 19 AlON透明陶瓷动态压缩加载材料失效过程及相应的应力-时程曲线(Paliwal et al. 2008). (a)受约束状态试样, (b)无约束状态试样(每幅图像的应力状态对应于曲线上的黑点)

图 20 动态加载下镁铝尖晶石透明陶瓷的细观破坏特征(Jiang et al. 2019a)

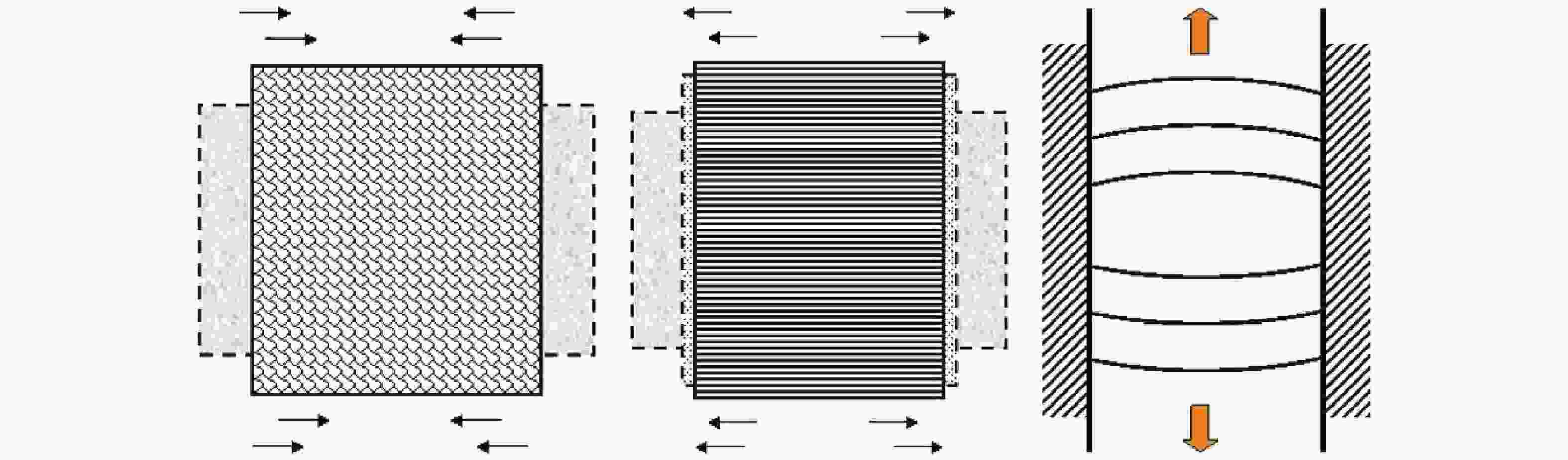

图 21 脆性材料压缩加载破坏原理示意图(Zhang et al. 2020)

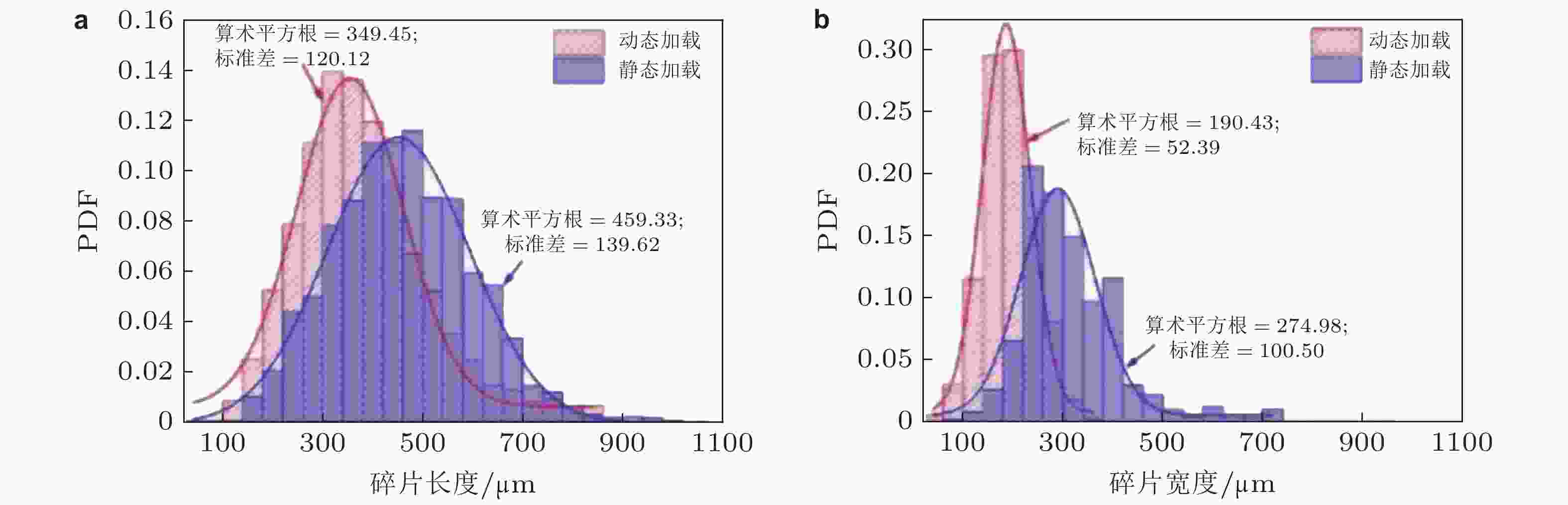

图 22 不同加载应变率加载后回收试样碎片的尺寸(Jiang et al. 2019b). (a)长度尺寸, (b)宽度尺寸

图 23 不同晶粒度大小镁铝尖晶石透明陶瓷的应变率效应(Mccauley & Patel 2013, Nie et al. 2011, Kimberley & Ramesh 2011)

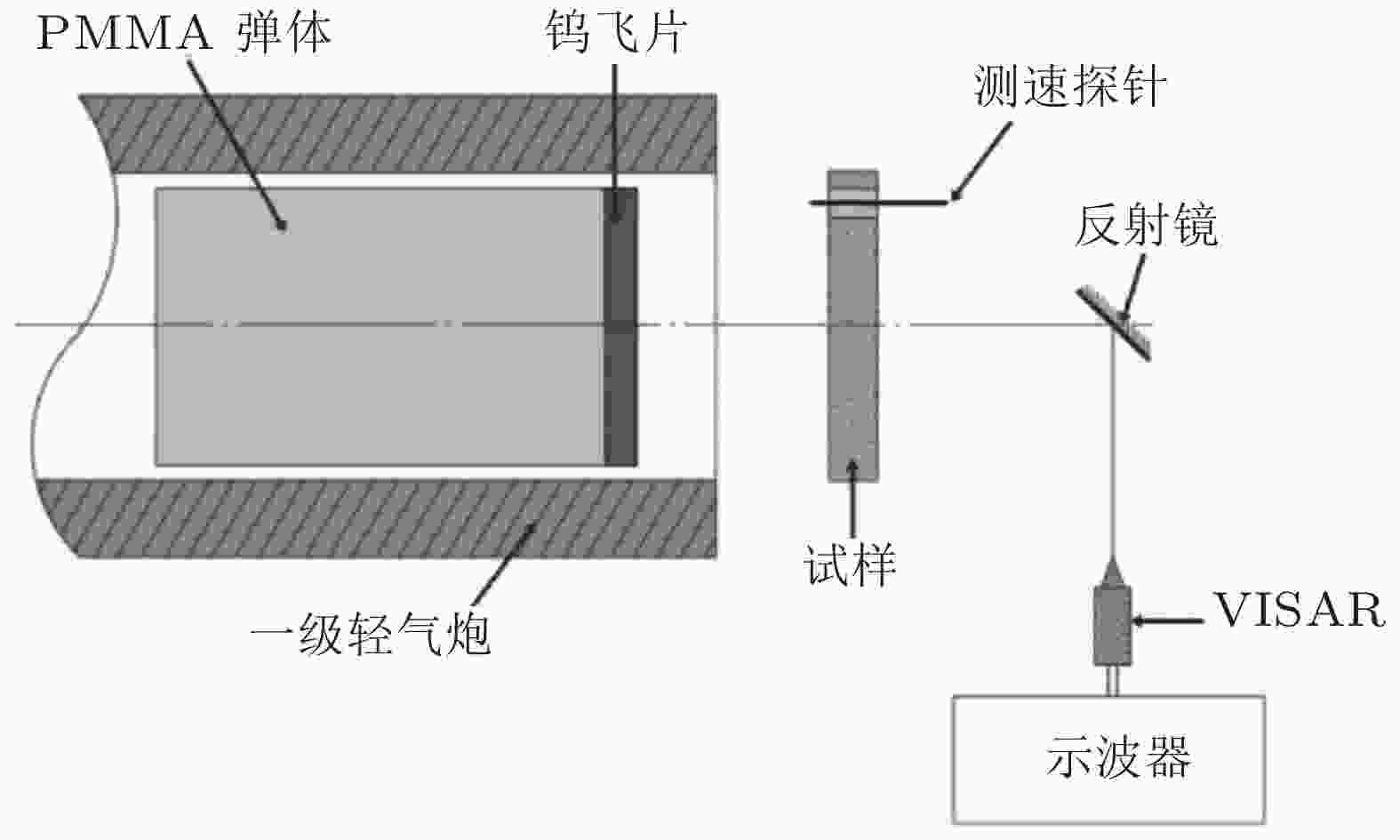

图 24 使用VISAR传感器的飞片碰撞实验装置(Jiang et al. 2019b)

图 25 冲击压缩加载下陶瓷材料的力学响应区间(Bourne et al. 2007)

图 26 平板冲击实验中不同冲击速度下的自由面速度−时间历程(Jiang et al. 2019b)

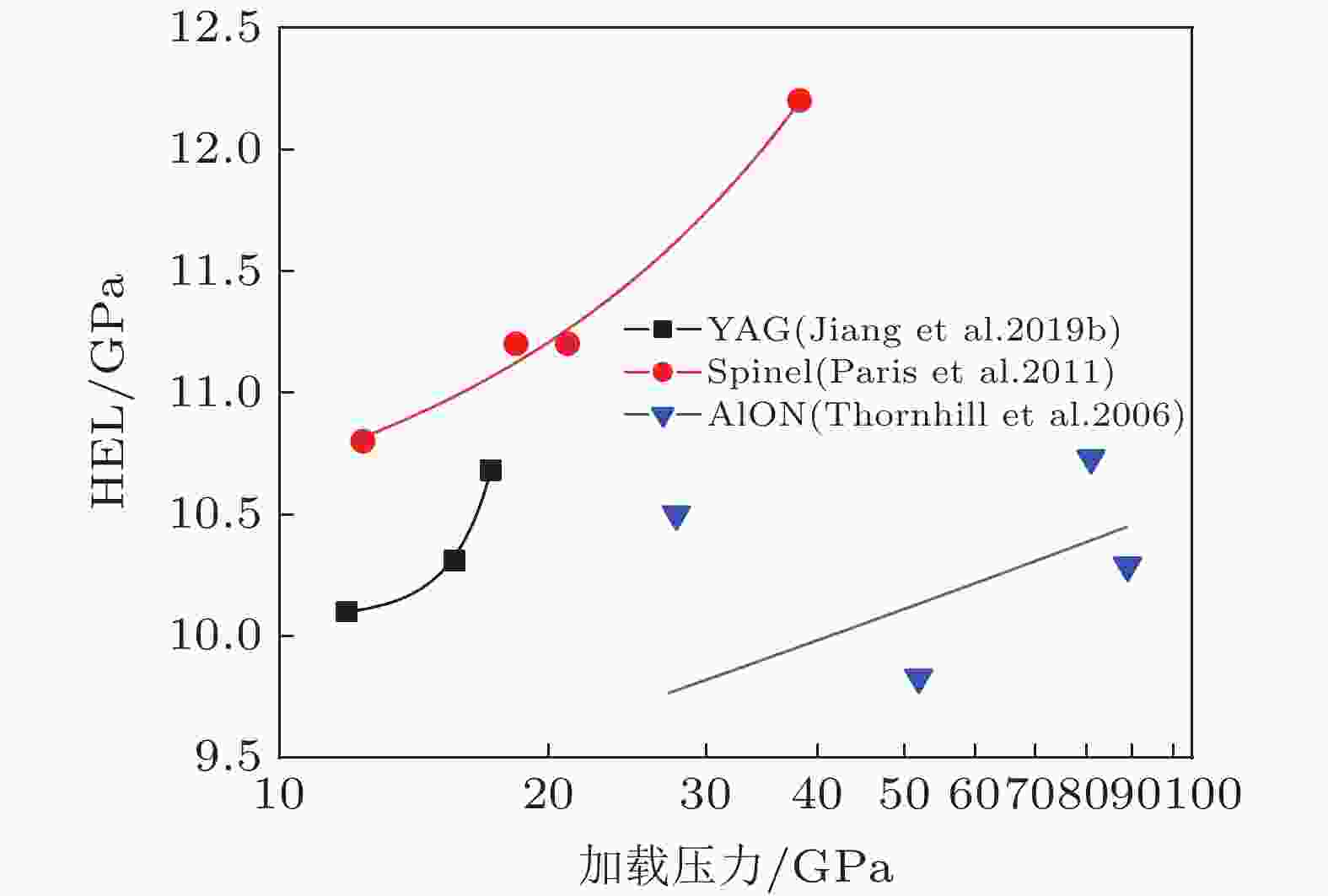

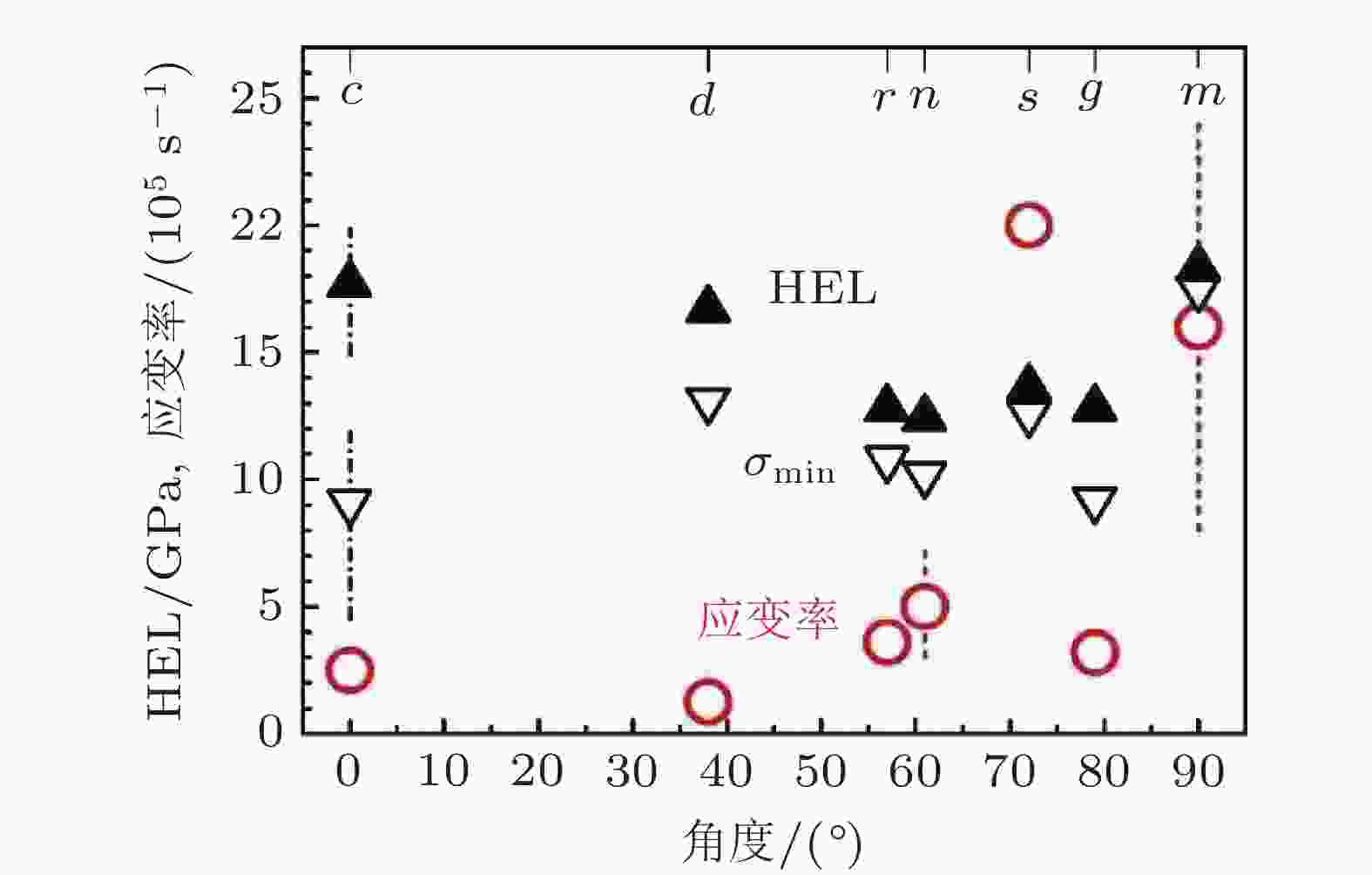

图 27 不同加载压力下典型透明陶瓷的HEL (Jiang et al. 2019b, Paris et al. 2011, Thornhill et al. 2006)

图 28 不同加载应变率下单晶蓝宝石HEL (Kanel et al. 2009)

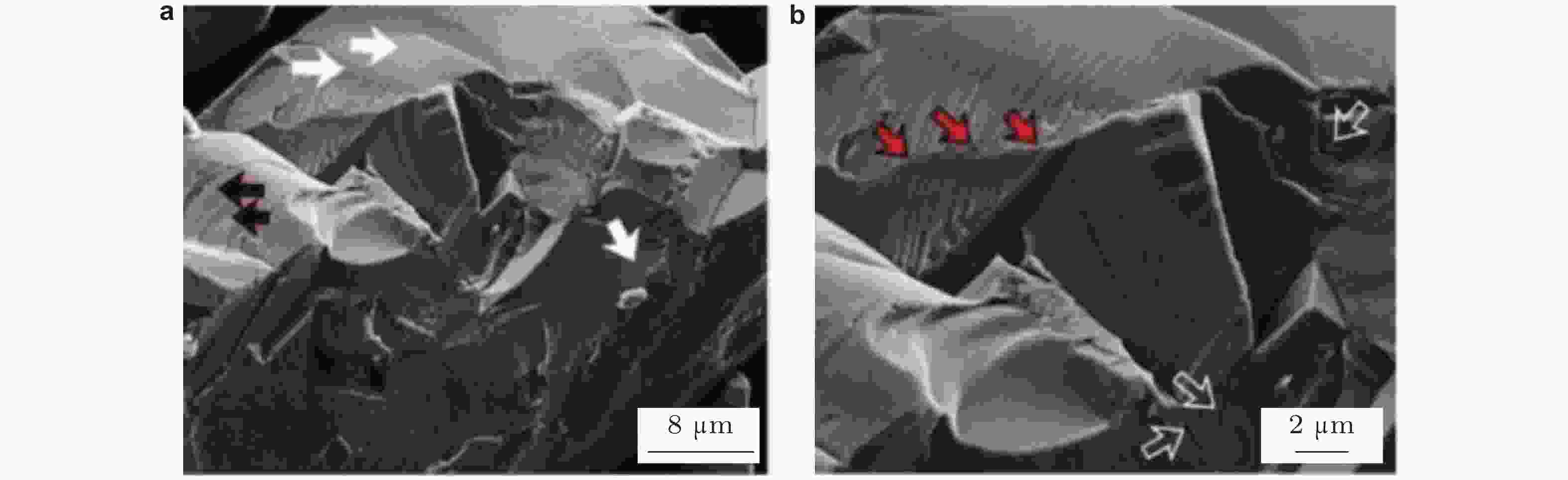

图 29 平板冲击加载下YAG透明陶瓷的细观破坏特征(Jiang et al. 2019b). (a) SEM图像, (b)局部放大结果

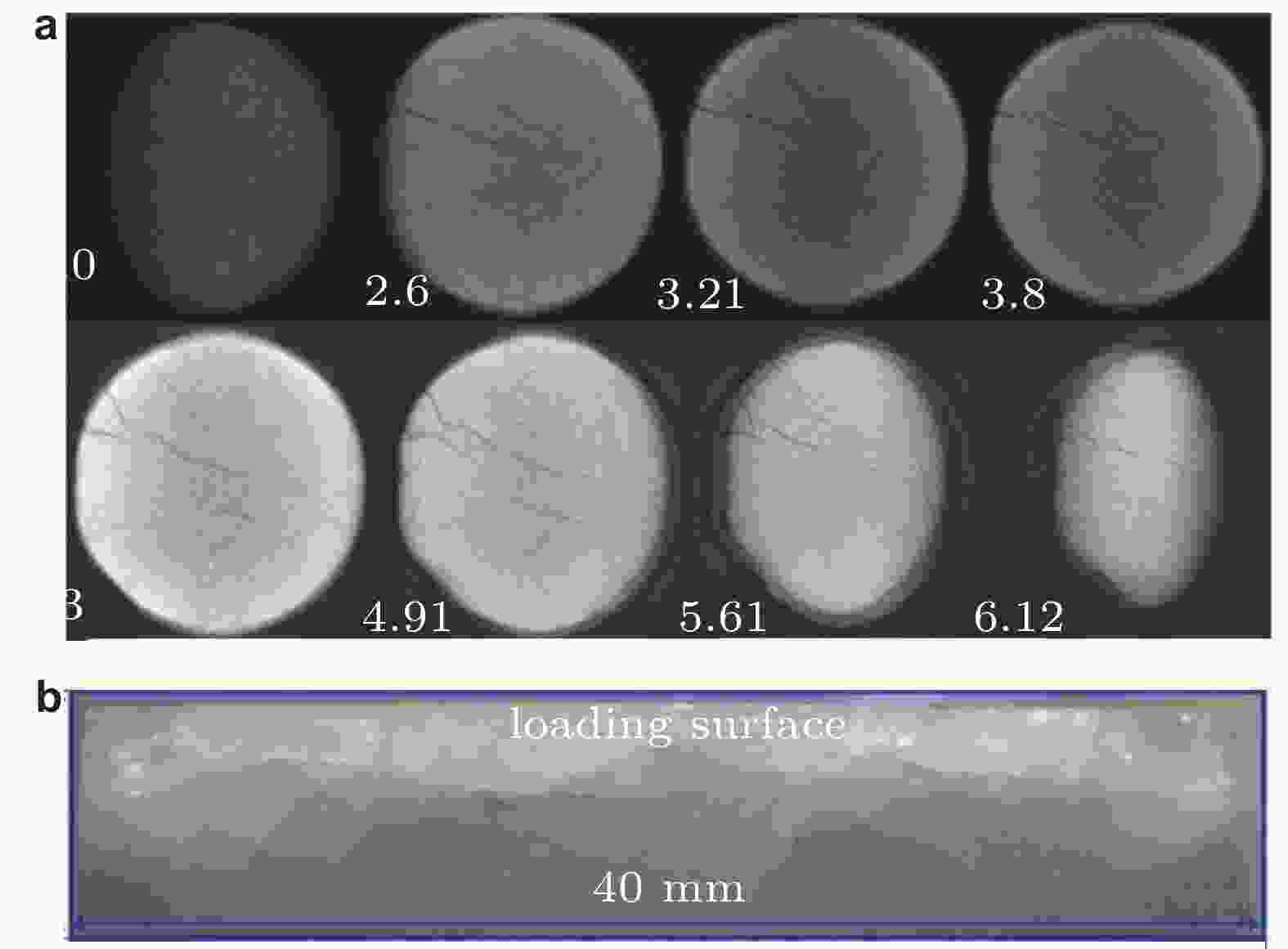

图 30 平板冲击加载后软回收样品的CT图像(Bao et al. 2022). (a)沿轴向扫描结果, (b)截面剖切扫描结果

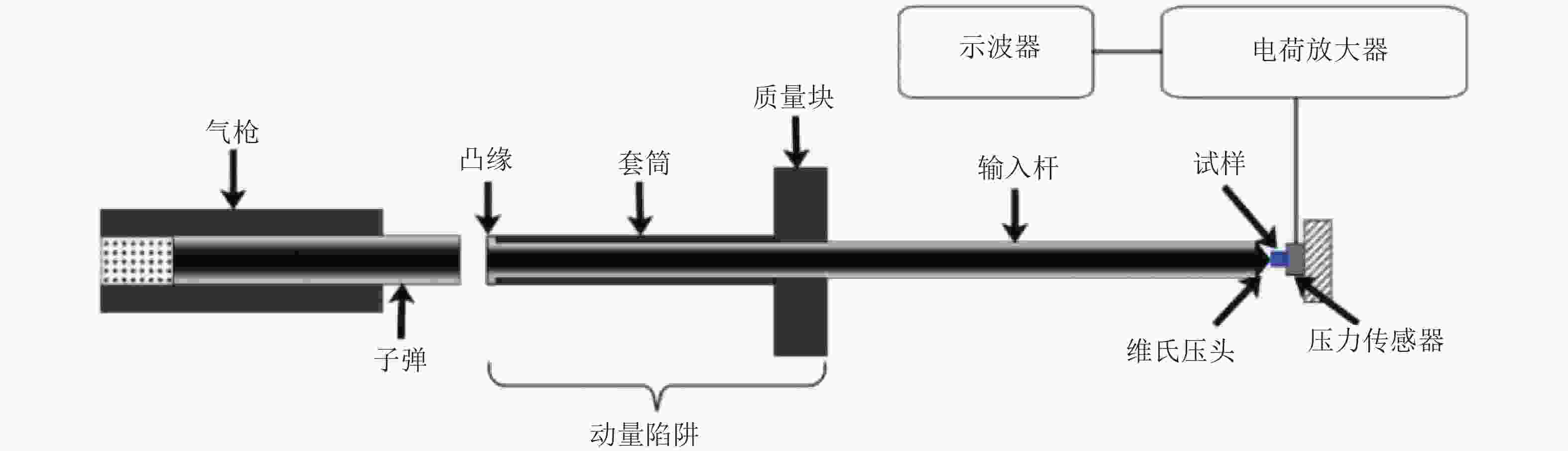

图 31 动态压痕实验示意图(Jiang et al. 2019b)

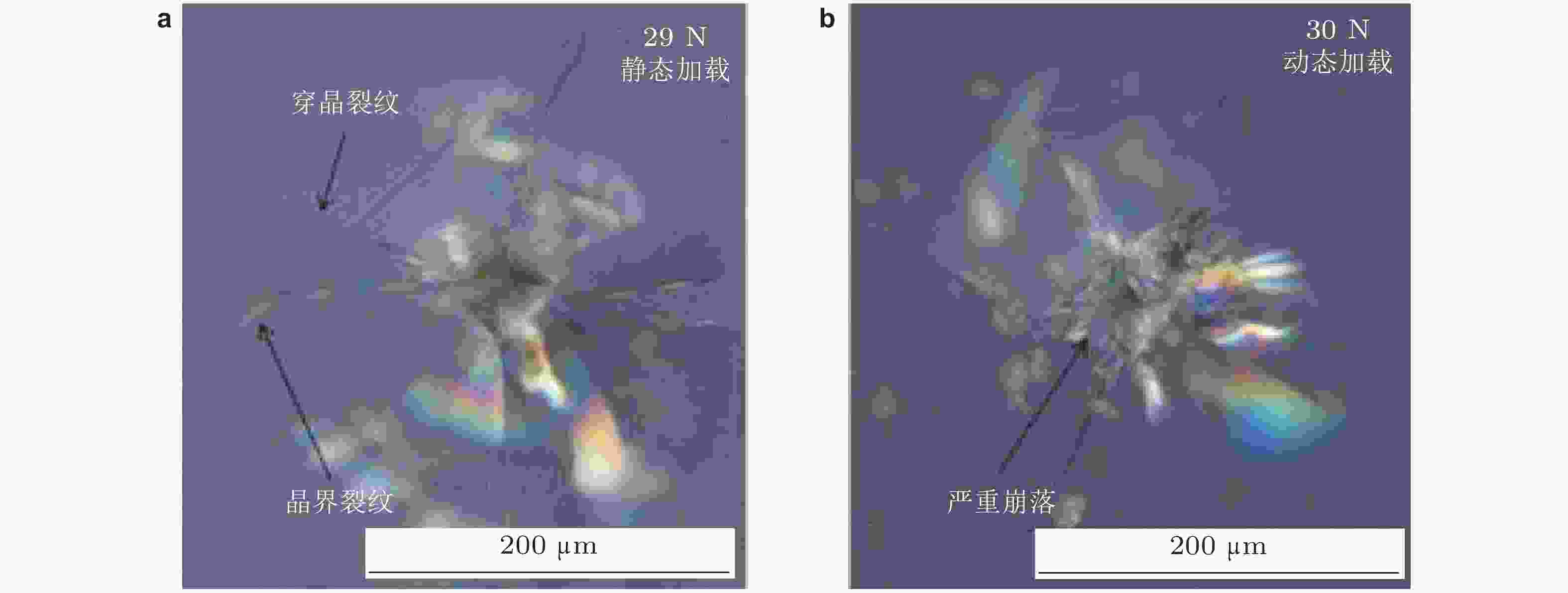

图 32 YAG透明陶瓷的静、动态压痕实验(Jiang et al. 2019b). (a) 静、动态硬度结果, (b) YAG透明陶瓷动态压痕典型裂纹形貌

图 33 静、动态压痕损伤演化结果比较(Haney & Subhash 2011a). (a)静态压痕破坏形貌, (b)动态压痕破坏形貌

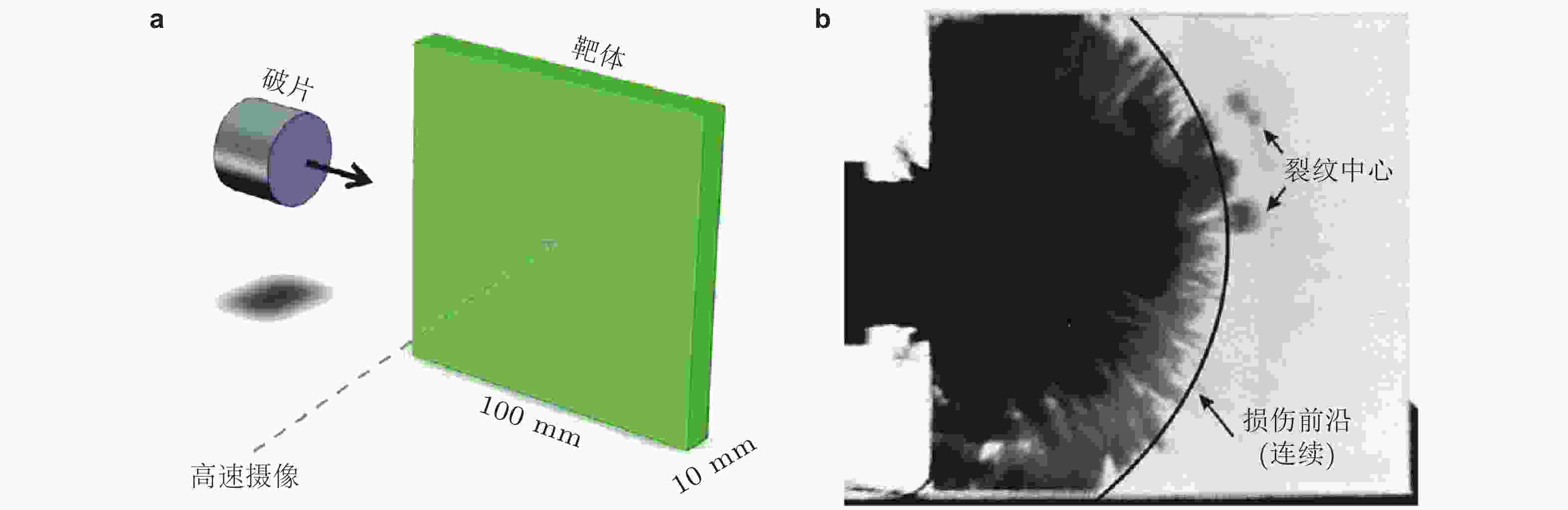

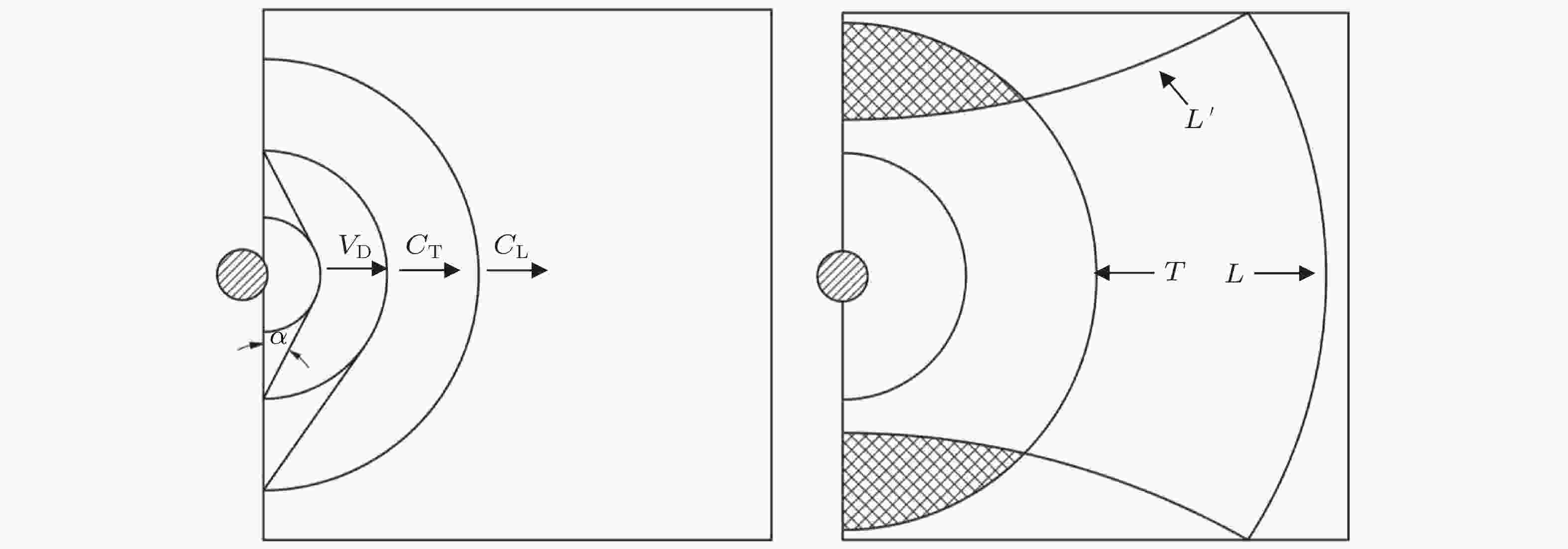

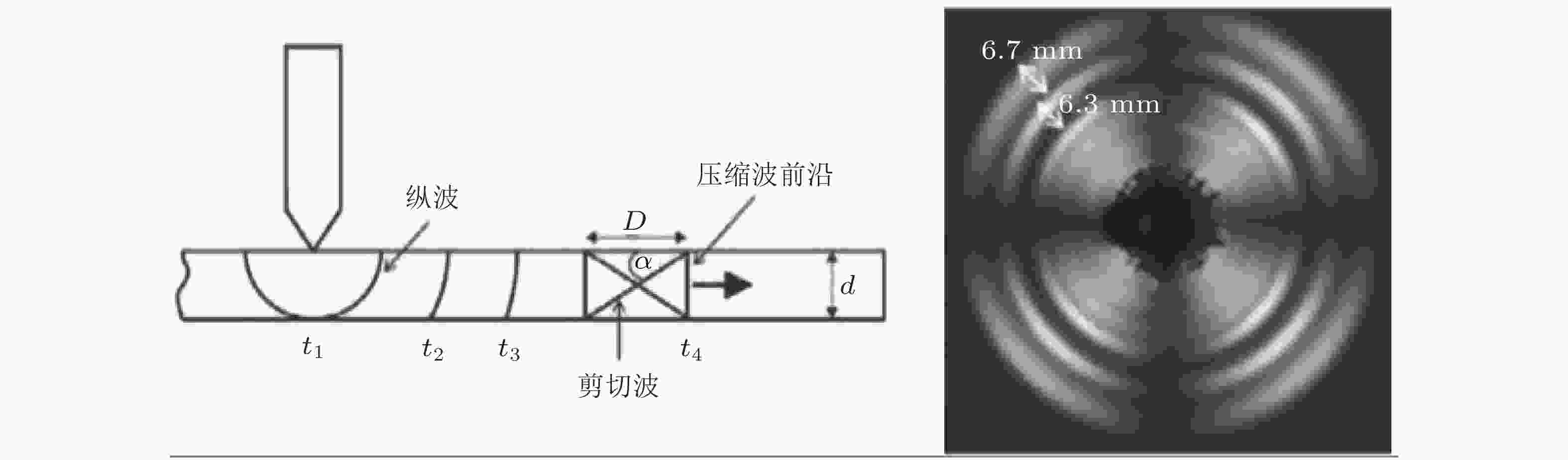

图 34 边缘冲击实验(Leavy et al. 2013). (a) 边缘冲击实验原理图, (b)冲击后陶瓷的典型损伤破坏形貌

图 35 阴影成像技术捕获的材料损伤结果(McCauley et al. 2013). (a)浮法玻璃的典型损伤模式, (b)浮法玻璃的典型损伤模式, (c) AlON透明陶瓷的典型损伤模式

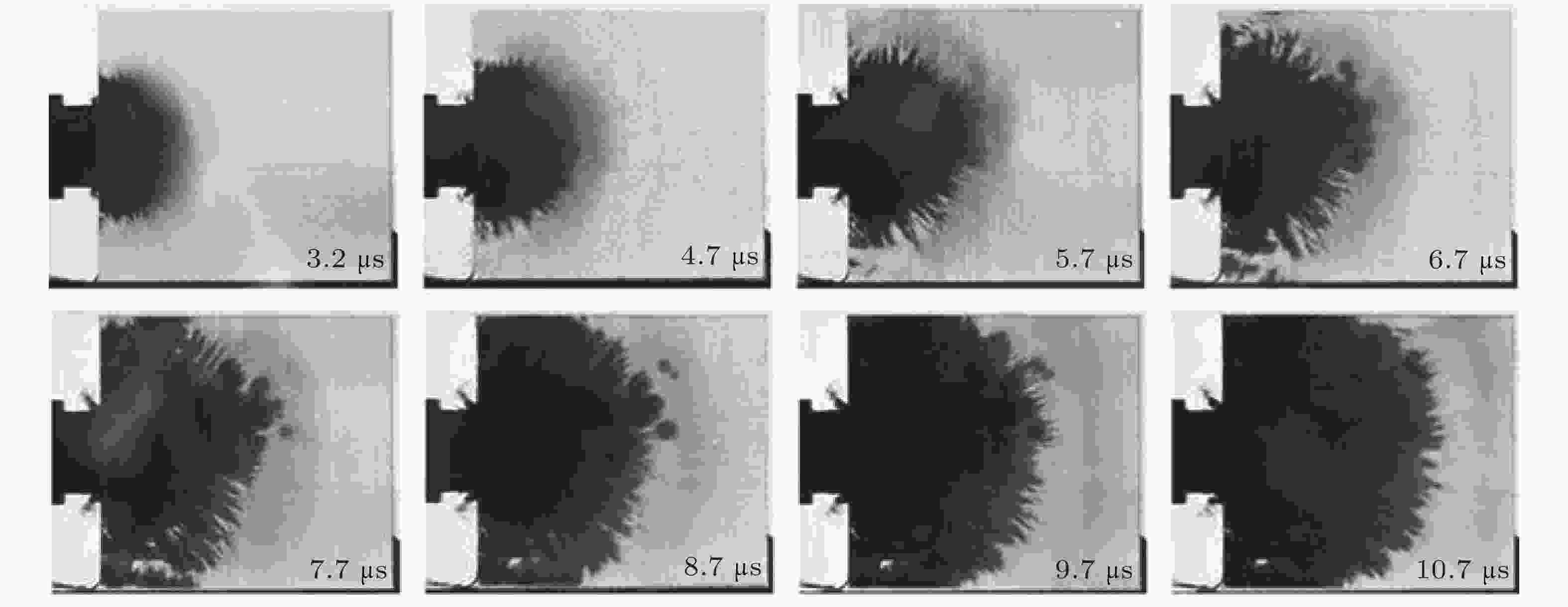

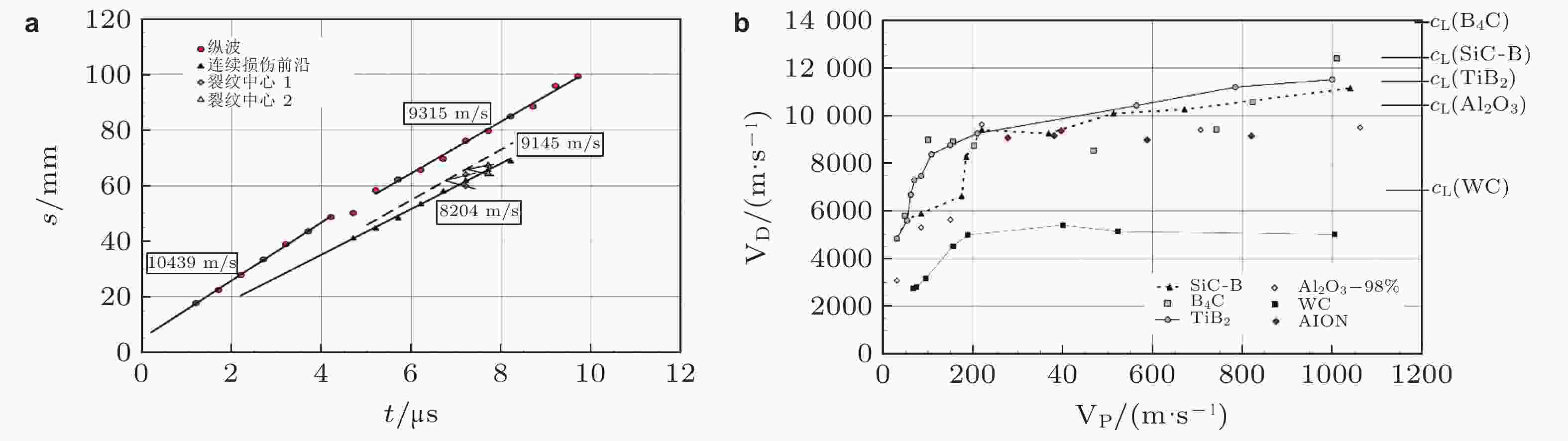

图 36 AlON透明陶瓷的损伤演化过程(Straßburger 2006)

图 37 边缘冲击实验中损伤传播速度(Straßburger 2006). (a)破片撞击速度为820 m/s和925 m/s时AlON透明陶瓷材料内波以及裂纹传播的距离−时间曲线, (b)不同装甲陶瓷的损伤速度VD与破片撞击速度VP关系

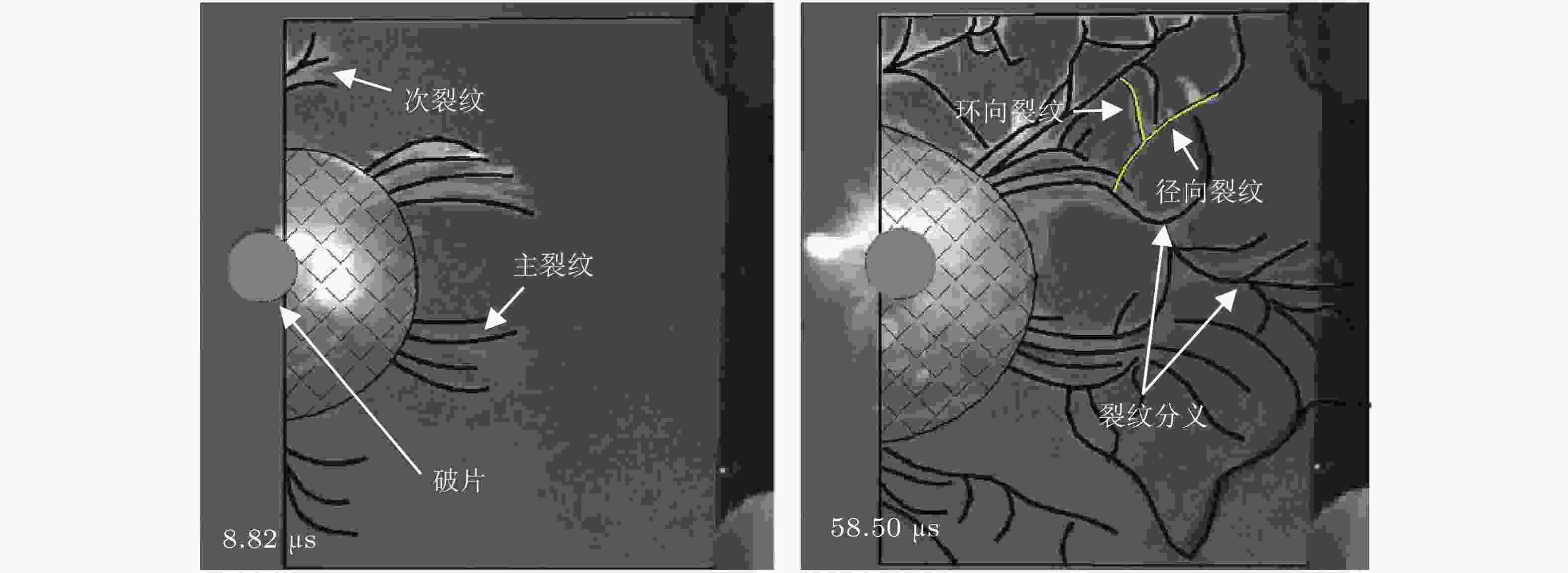

图 38 镁铝尖晶石透明陶瓷在边缘冲击实验下的破坏特征(韩国庆等 2022)

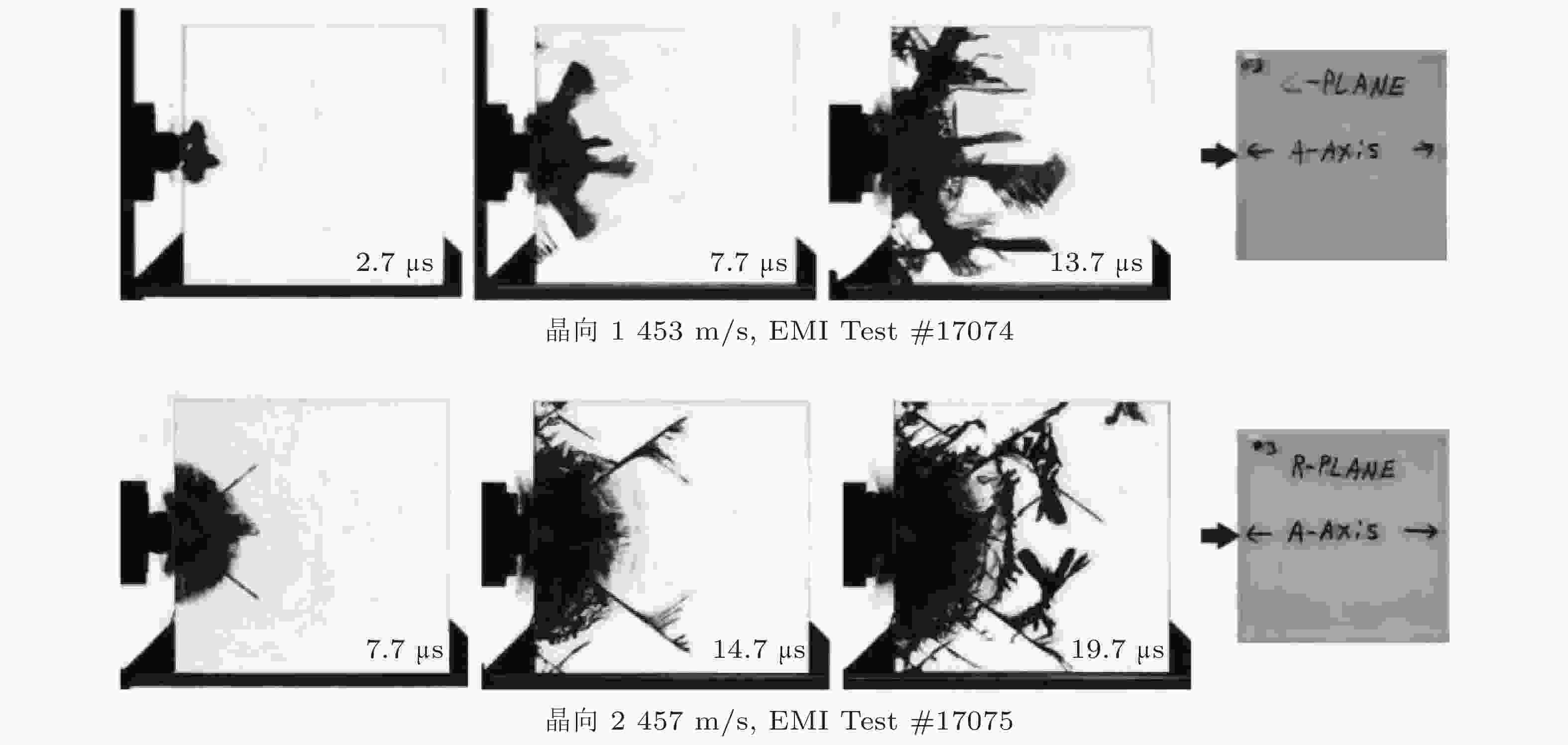

图 39 不同晶面蓝宝石材料的损伤和裂纹形貌对比(Strassburger et al. 2011)

图 40 破片撞击过程中材料内的损伤传播过程(Haney & Subhash 2013). (a)镁铝尖晶石, (b)蓝宝石

图 41 带有正交偏振片的边缘冲击实验示意图(Grujicic et al. 2009)

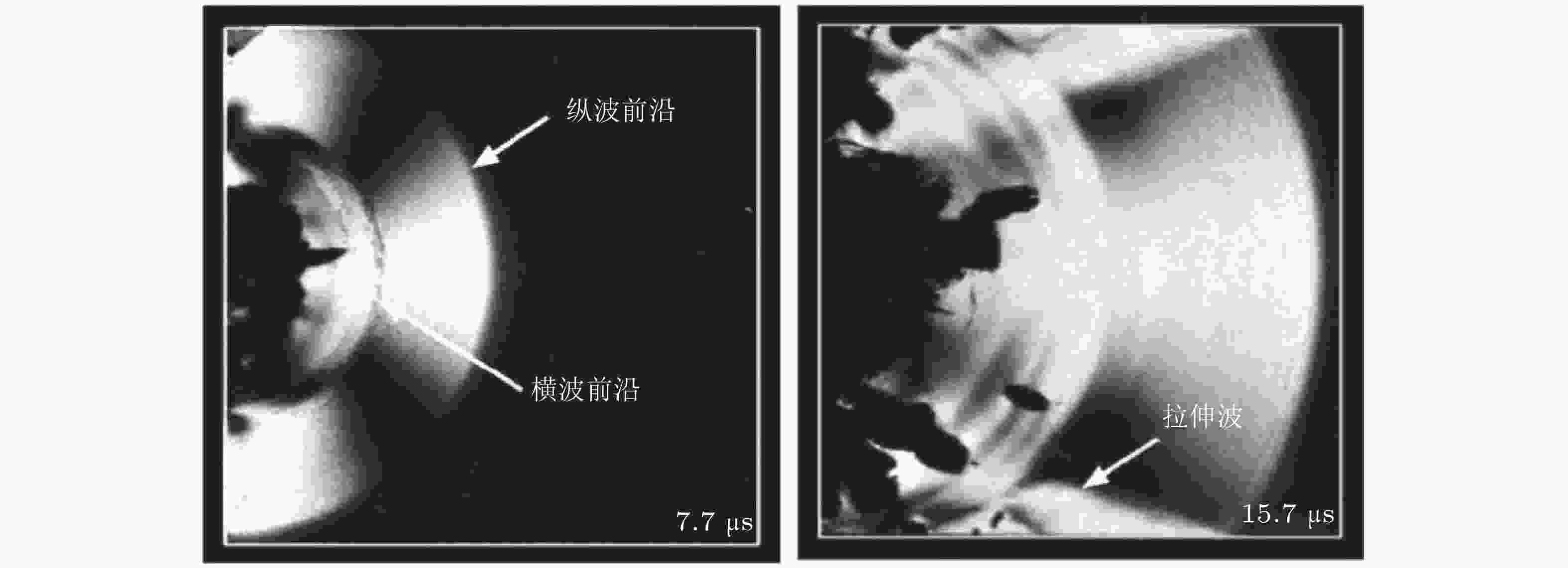

图 42 球型钢破片以 440 m/s 的速度撞击Starphire玻璃时应力波的传播和损伤前沿演化图像(Grujicic et al. 2009)

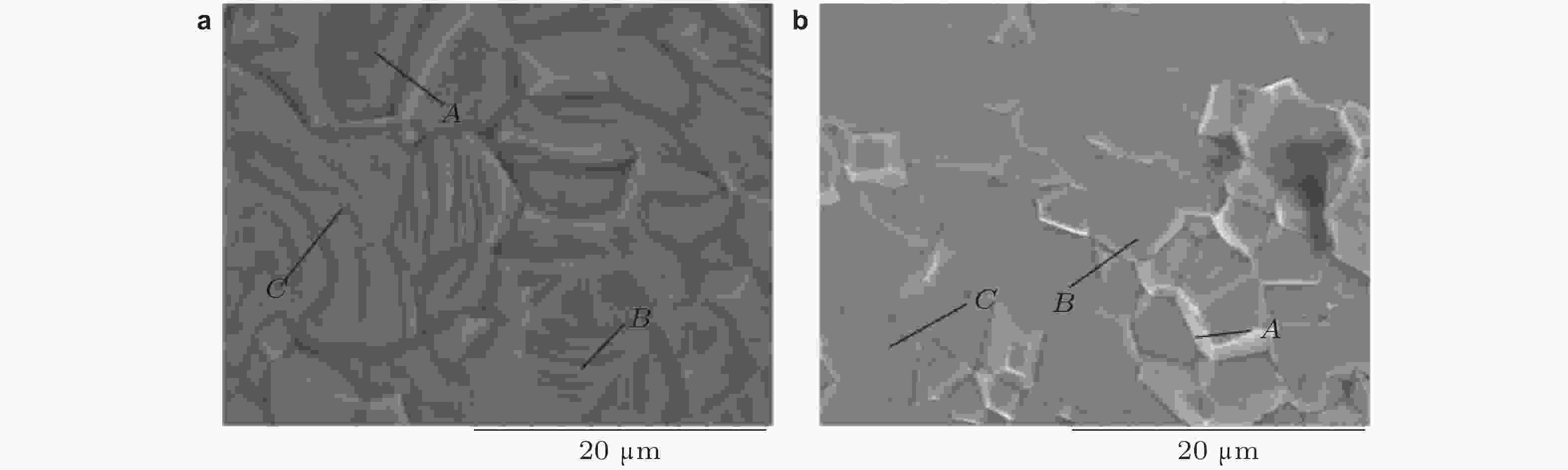

图 43 边缘冲击中应力波的传播及纵波的反射(韩国庆 等 2022)

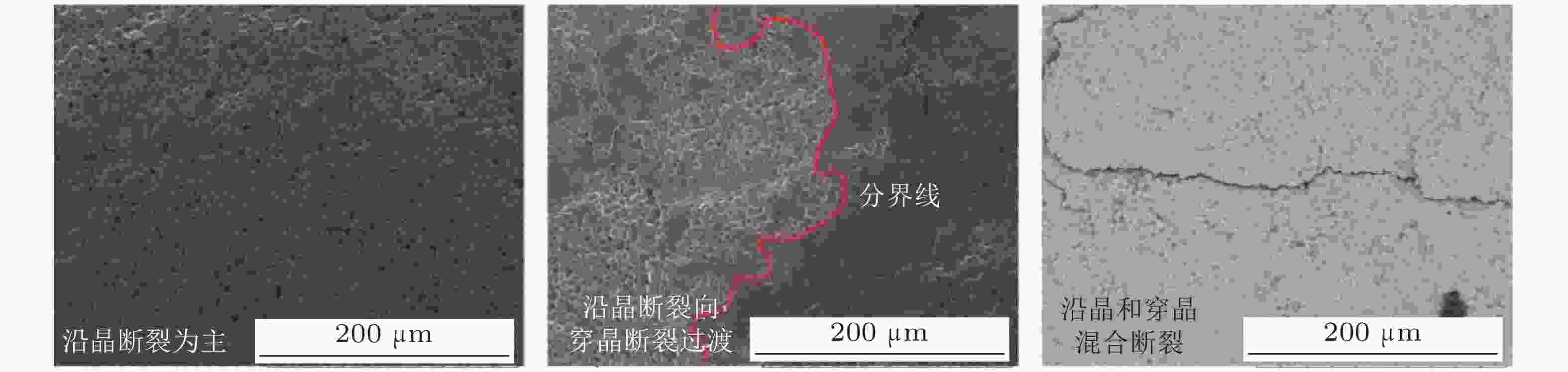

图 44 透明陶瓷断面的典型细观破坏特征(韩国庆 等 2022). (a)镁铝尖晶石透明陶瓷, (b)YAG透明陶瓷

图 45 镁铝尖晶石透明陶瓷径向断裂面上沿晶及穿晶变化(韩国庆等 2022)

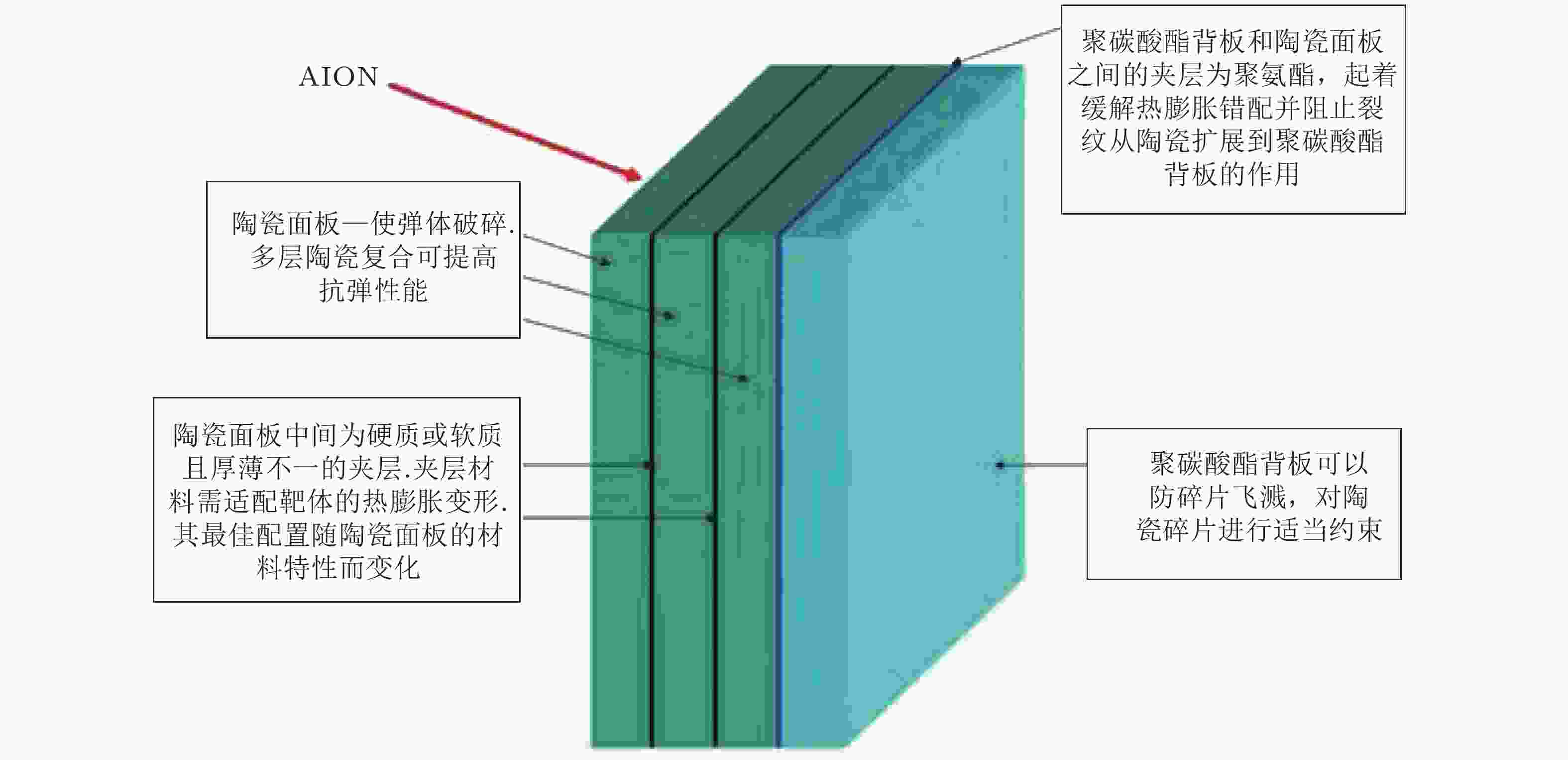

图 46 透明装甲结构示意图(McCauley et al. 2013)

图 47 子弹撞击陶瓷面板过程(Strassburger & Bauer 2018). (a) 4.5 mm厚尖晶石透明陶瓷受冲击过程中的4张高速录像照片, (b)应力波及裂纹扩展的距离−时间曲线图片示例

图 48 压缩波传播示意图和应力脉冲间的距离(Strassburger & Bauer 2018)

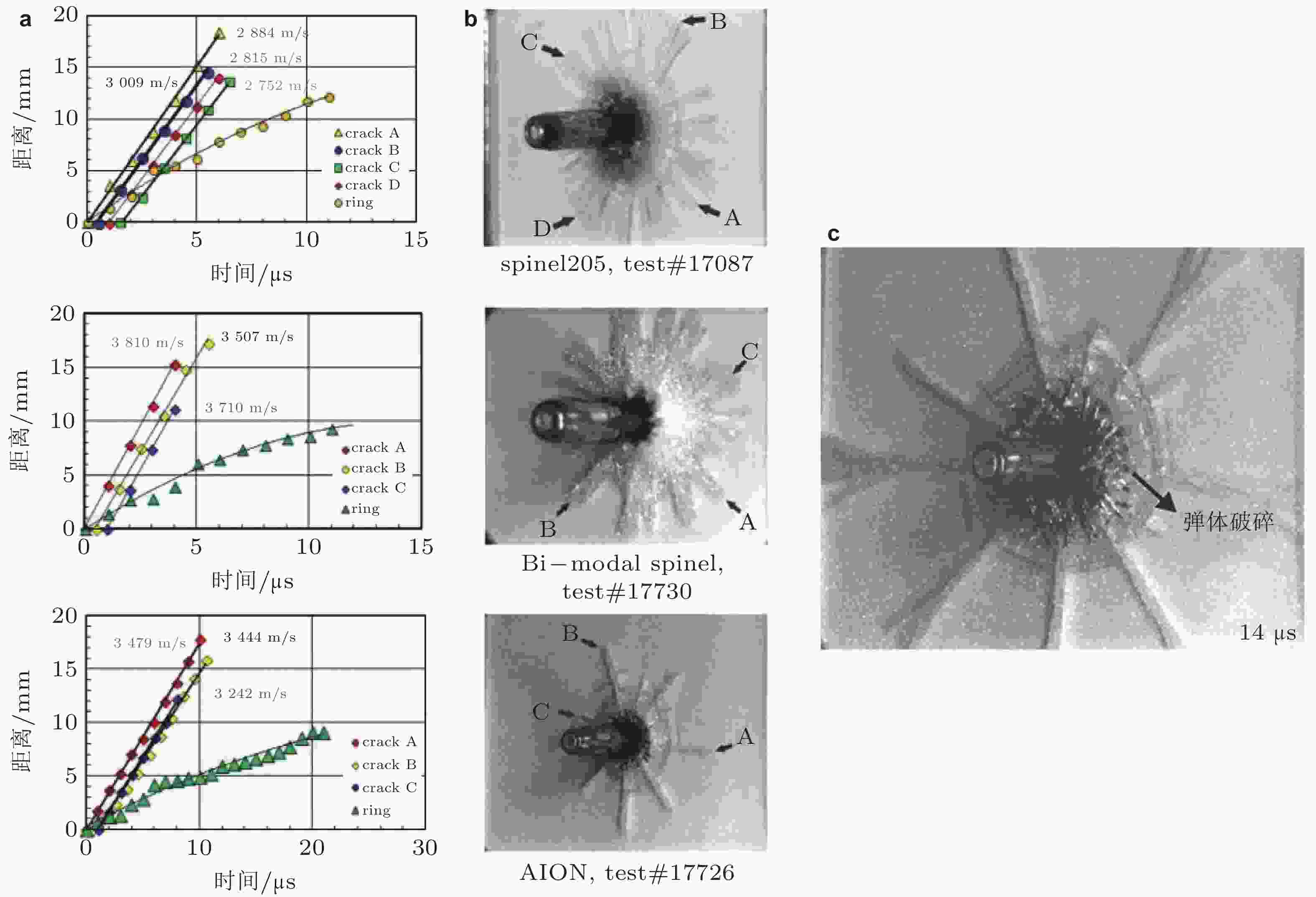

图 49 晶粒度大小对抗弹过程的影响(Strassburger et al. 2013). (a) 0.6 μm晶粒度尖晶石、双峰晶粒度尖晶石和AlON透明陶瓷在850 m/s子弹冲击下的径、环向裂纹扩展距离时程图, (b)相应的损伤演化形貌, (c)撞击过程中的界面击溃现象

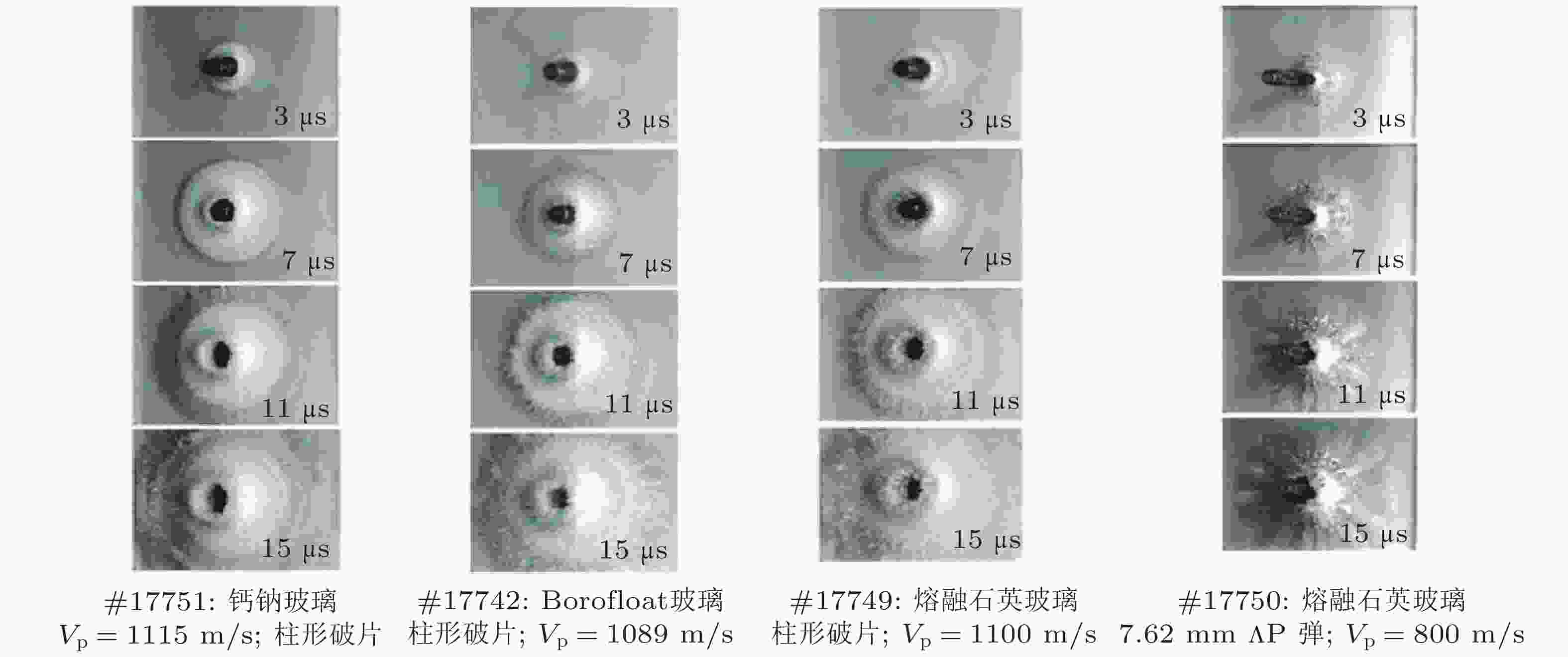

图 50 不同速度的球形弹丸对整体玻璃冲击后的正面高速照片(Sathananthan et al. 2019). (a) 100 m/s, (b) 500 m/s, (c) 800 m/s

图 51 各种玻璃受冲击下的高速录像照片(Gazonas et al. 2013)

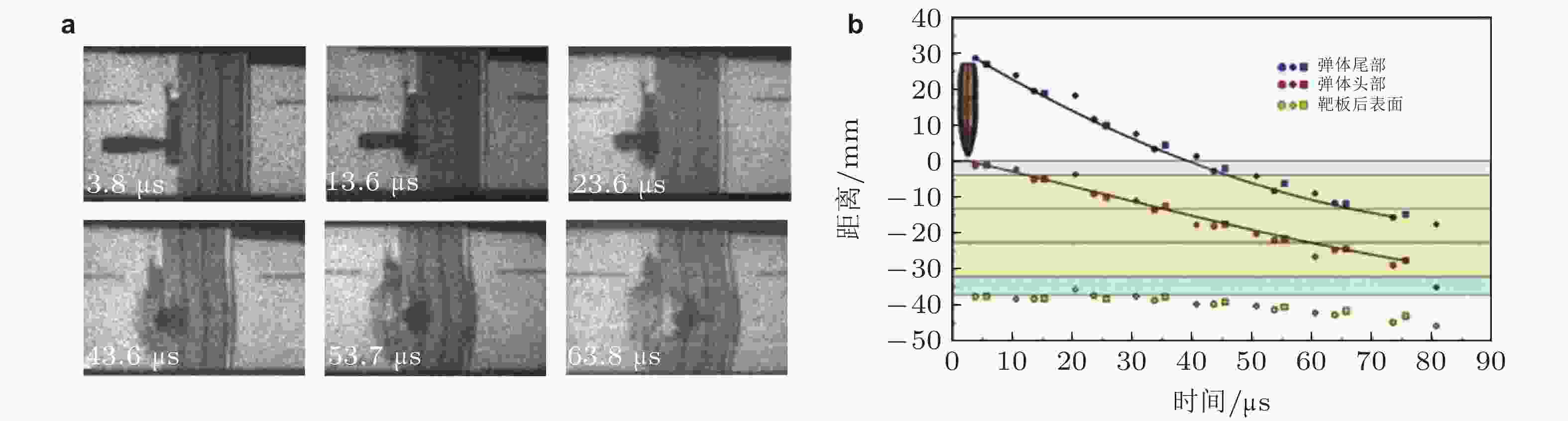

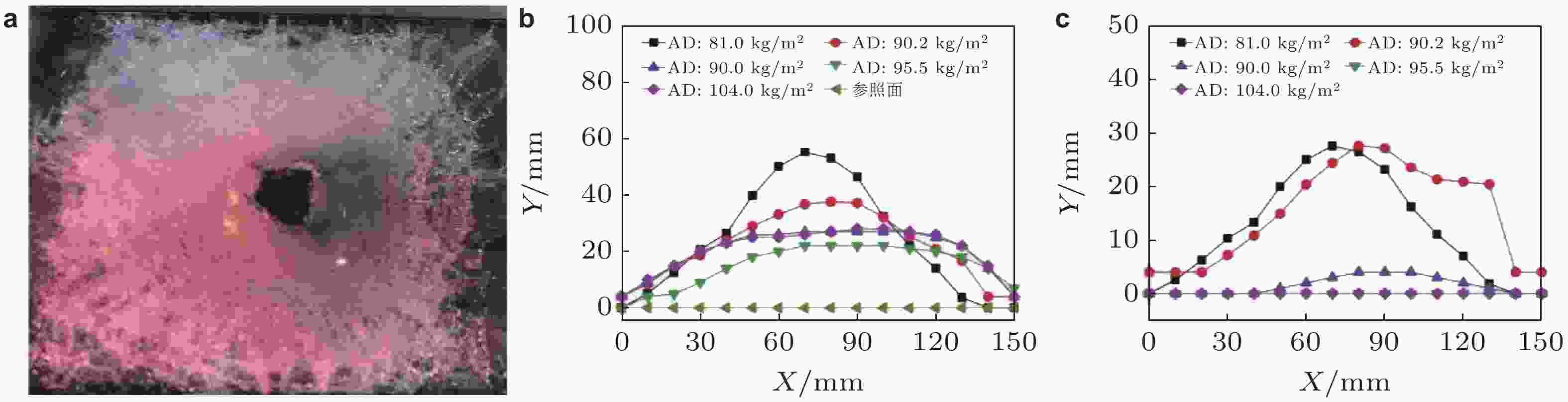

图 52 7.62 mm穿甲射弹侵彻陶瓷/玻璃/聚合物复合装甲过程(Straßburger 2009). (a) X光图像, (b) 弹丸头、尾部和靶体表面的位置−时间历程

图 53 (10.0 mm YAG 透明陶瓷/14 mm 玻璃/6 mm 聚碳酸酯)透明陶瓷复合装甲背板破坏响应(邓佳杰等 2022). (a)复合装甲背板破坏情况, (b)复合装甲背板最大背突, (c)复合装甲背板残余背突

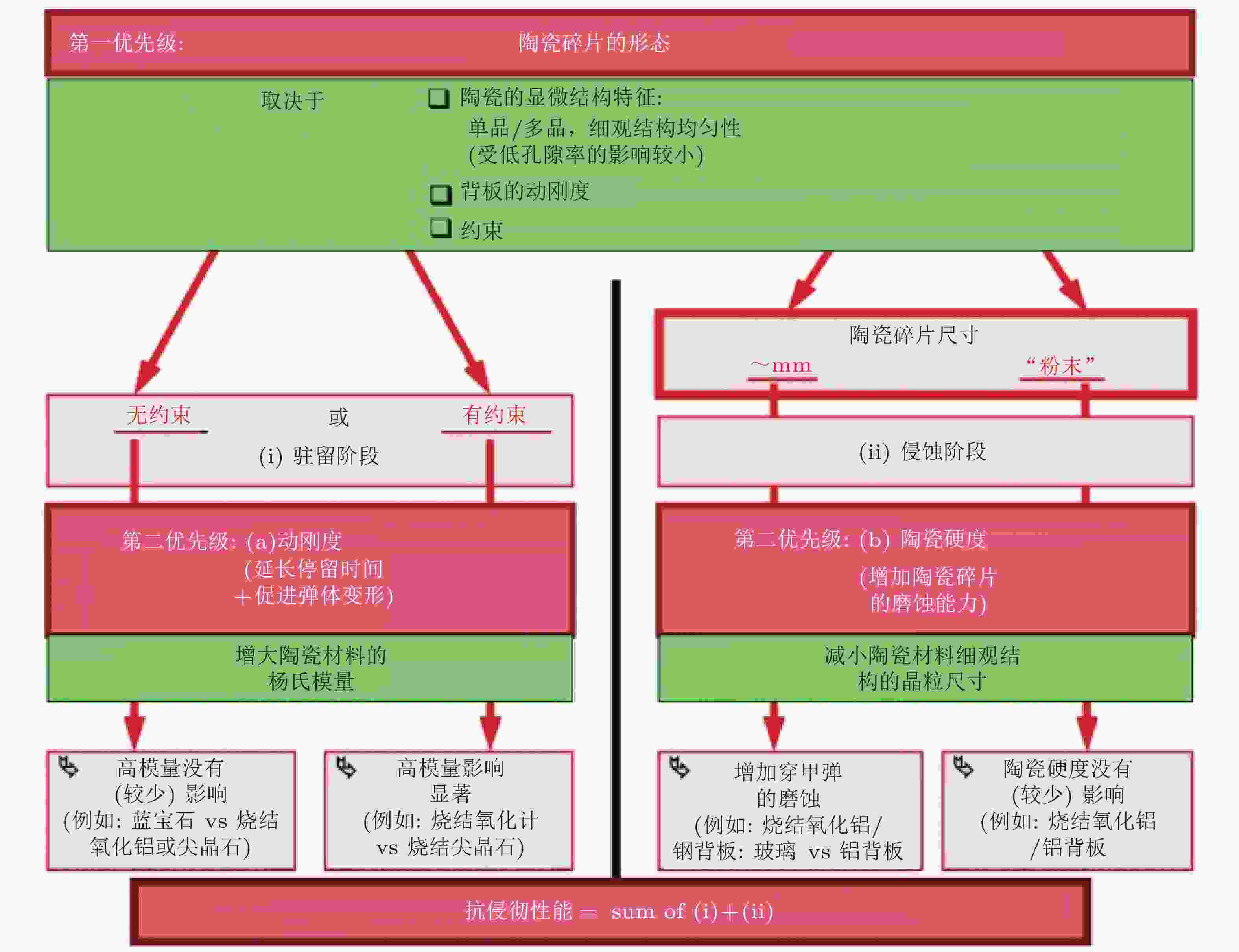

图 54 细观结构和力学性能对装甲陶瓷抗弹性能影响规律(Krell & Strassburger 2014)

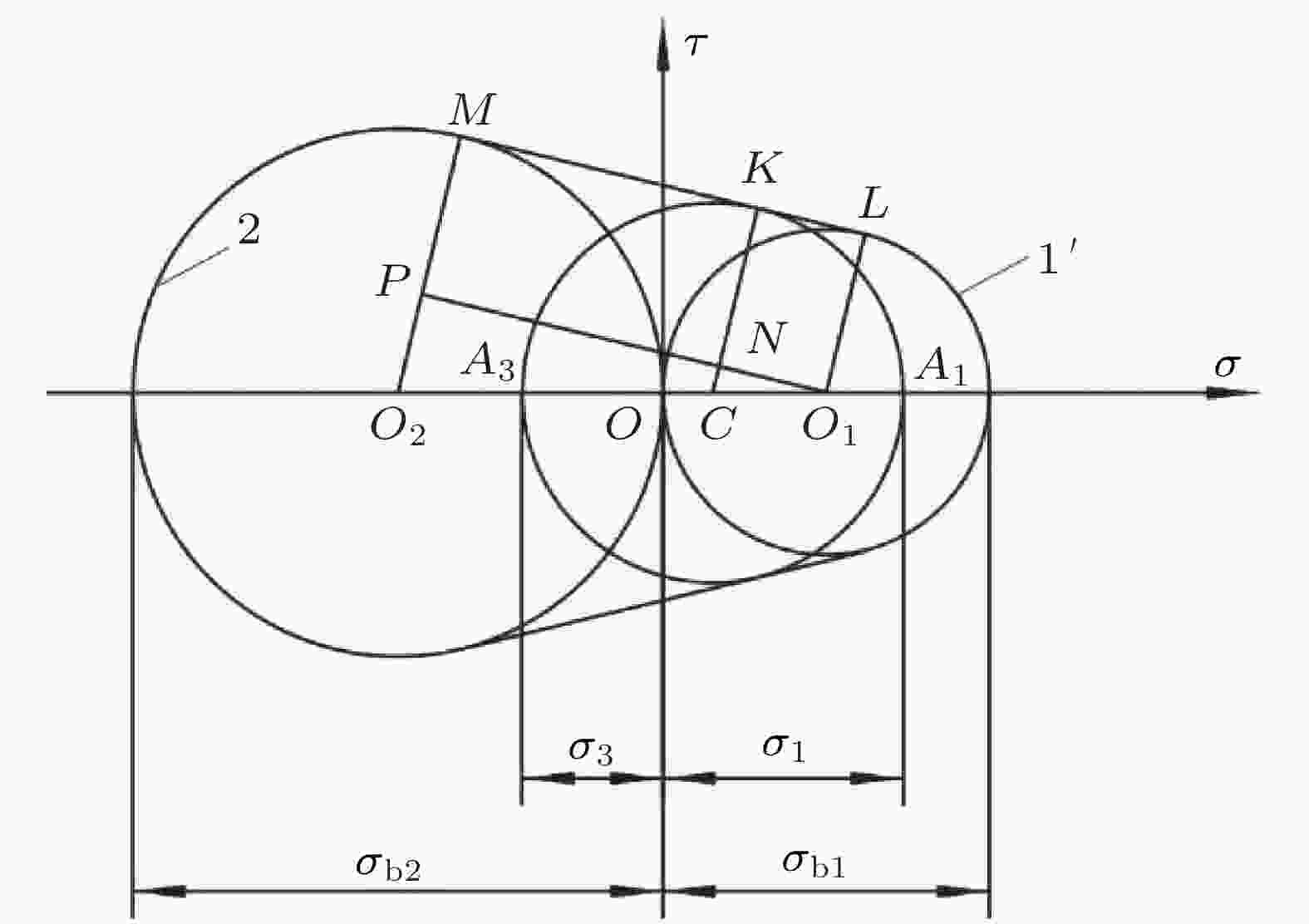

图 55 Mohr-Coulomb准则(苏翼林 1979)

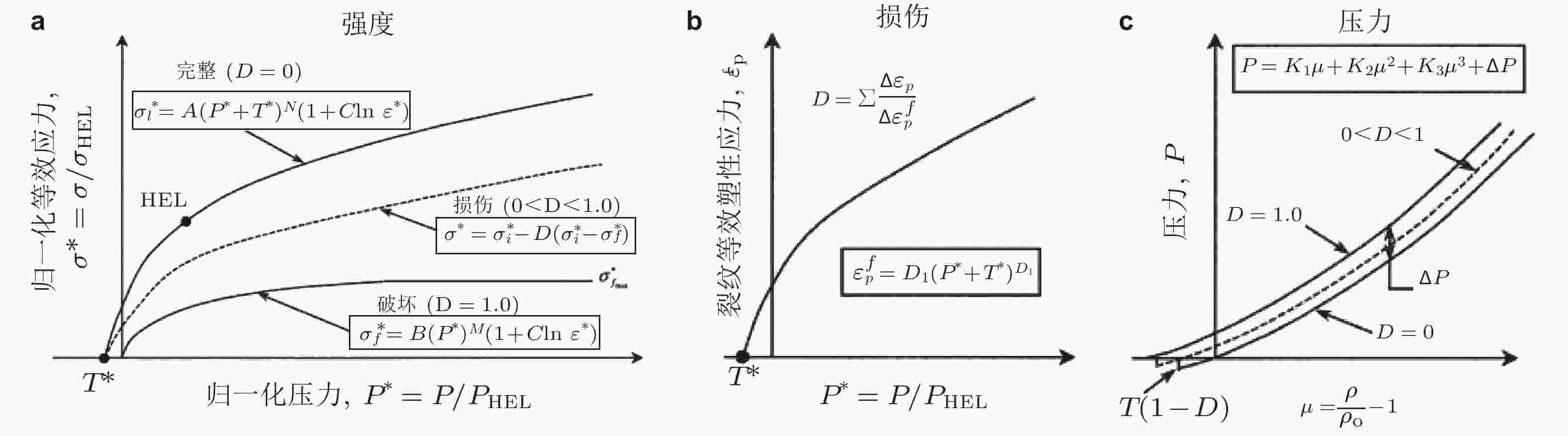

图 56 JH-2 本构模型描述(Holmquist et al. 2001) . (a)陶瓷应力与压力关系曲线, (b)陶瓷损伤模型, (c)不同损伤程度陶瓷压力−应变关系

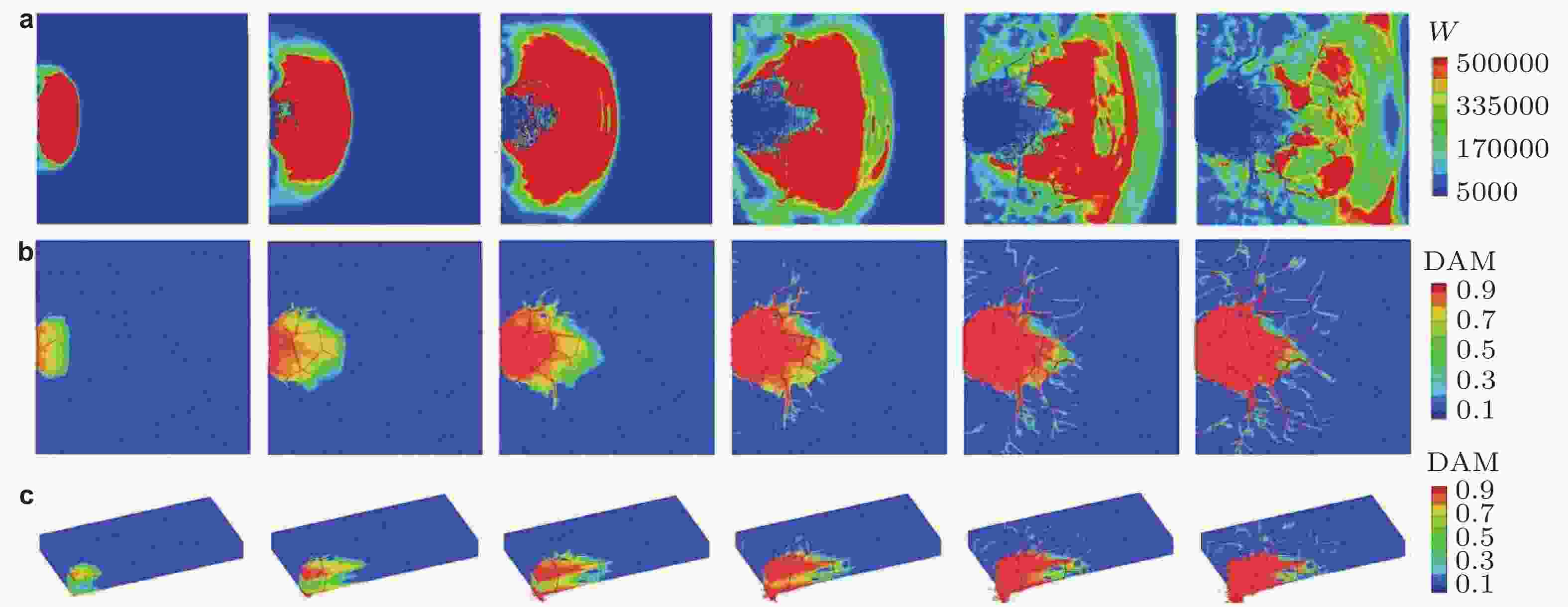

图 57 AlON透明陶瓷边缘冲击的近场动力学模拟(Zhang et al. 2018). (a)表面应变能密度, (b)表面损伤度, (c)破片撞击方向横截面损伤度

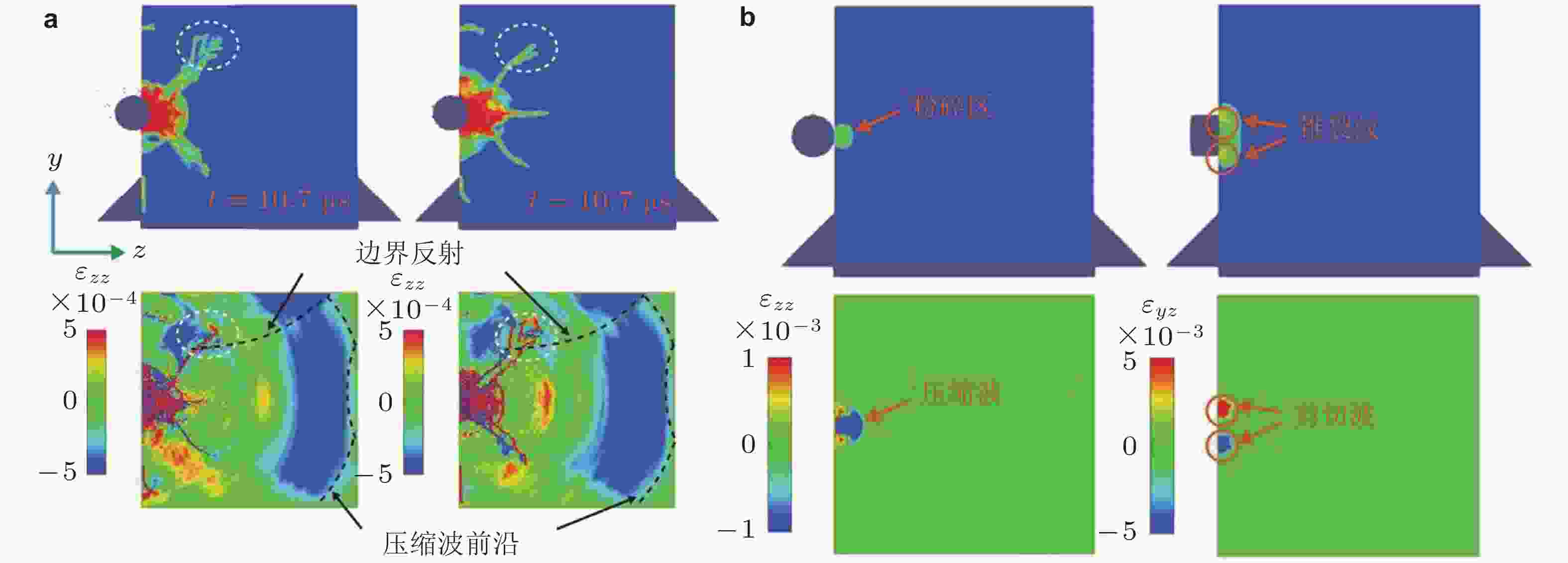

图 58 蓝宝石边缘冲击的近场动力学模拟(Huang et al. 2023). (a)样品表面损伤形貌及z方向εzz应变场, (b)球形破片冲击下样品初始损伤形貌及z方向εzz应变场, (c)柱形破片冲击下样品初始损伤形貌及z方向εzz应变场

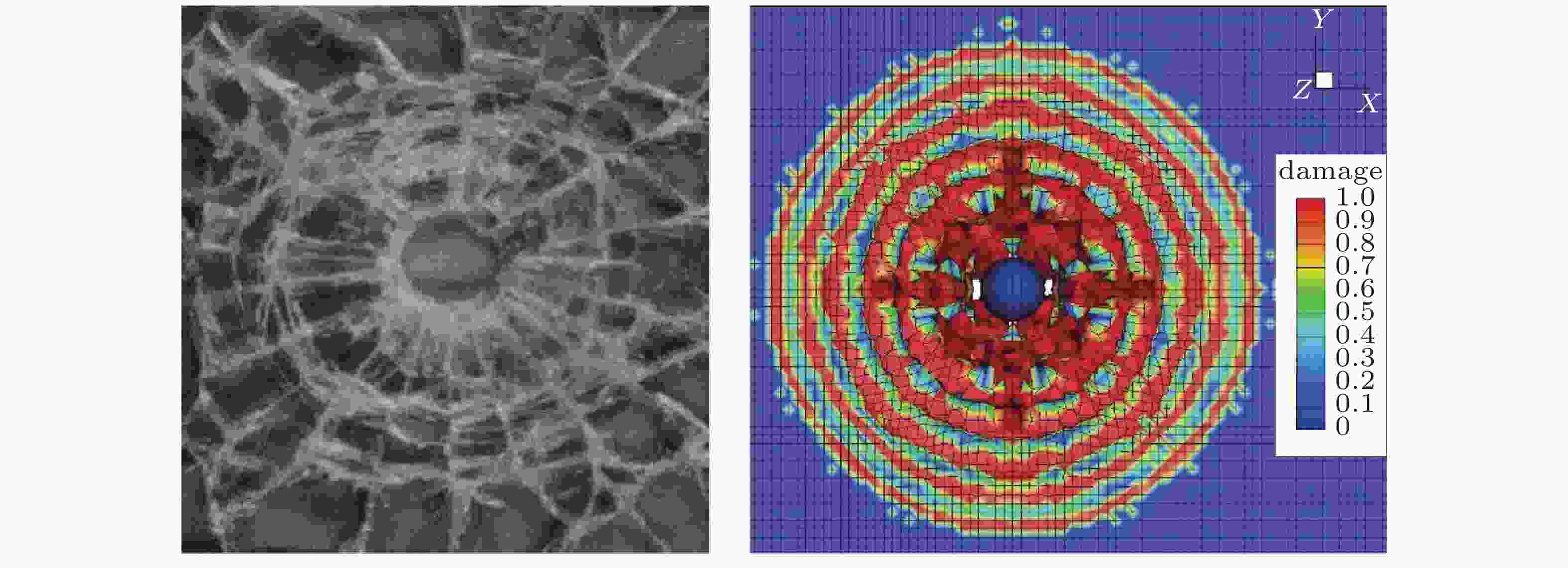

图 59 浮法玻璃落球实验及数值模拟结果(Lai et al. 2018)

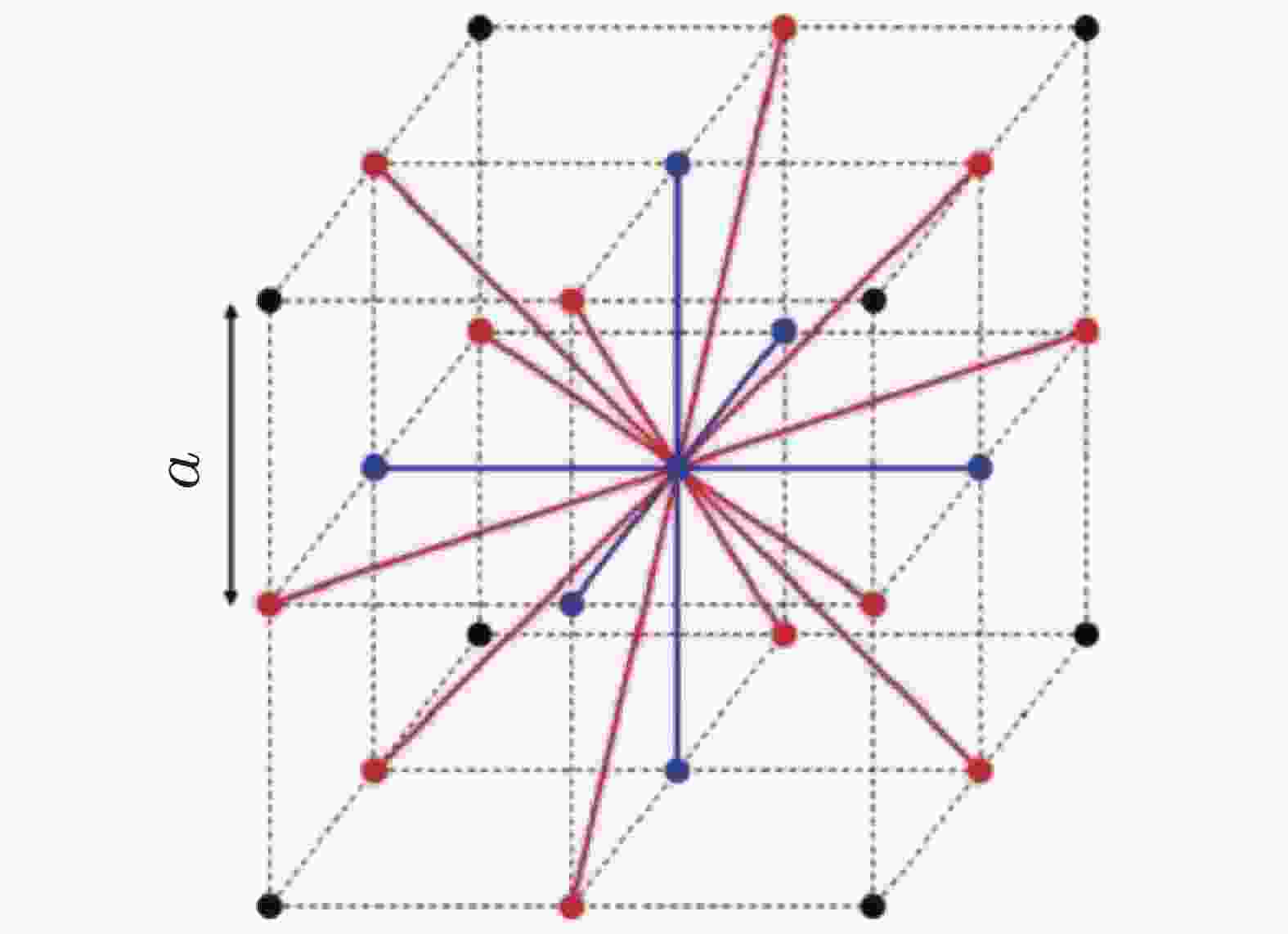

图 60 格点−弹簧模型示意图: 圆点表示介质的质点, 蓝色线条表示中心颗粒与最近邻颗粒发生相互作用, 红色线条表示中心颗粒与次近邻颗粒发生相互作用(Pazdniakou & Adler 2012)

图 61 不同平板冲击速度下样品内部裂纹扩展特征(Li et al. 2021)

图 62 粒子速度剖面随冲击波传播距离的演化(Cao et al. 2022). (a) 多晶YAG透明陶瓷, (b) 单晶YAG透明陶瓷

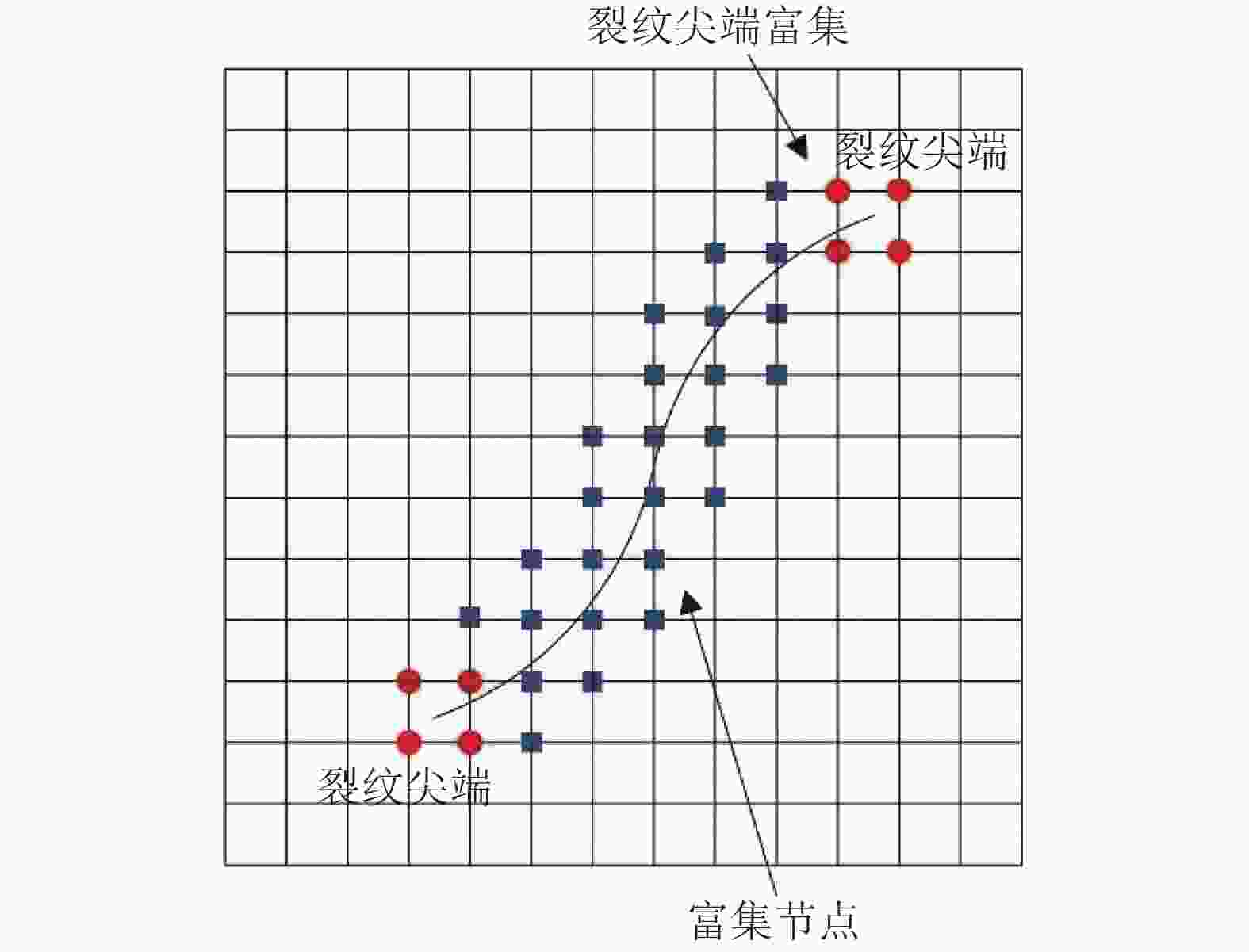

图 63 X-FEM裂纹扩展路径示意图(Xu et al. 2010)

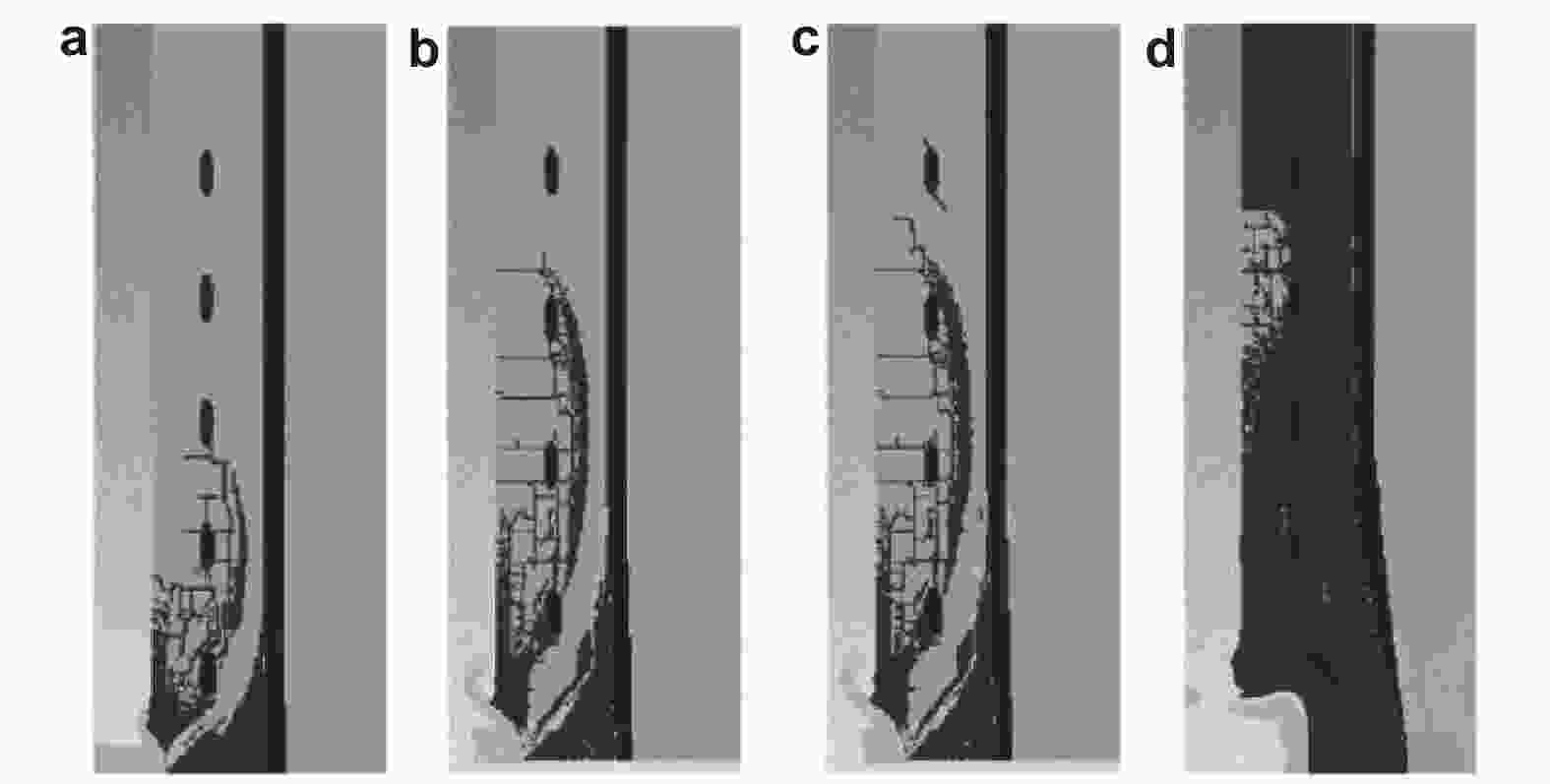

图 64 冲击后玻璃材料内部裂纹轨迹和环向应力场分布(Xu et al. 2010)

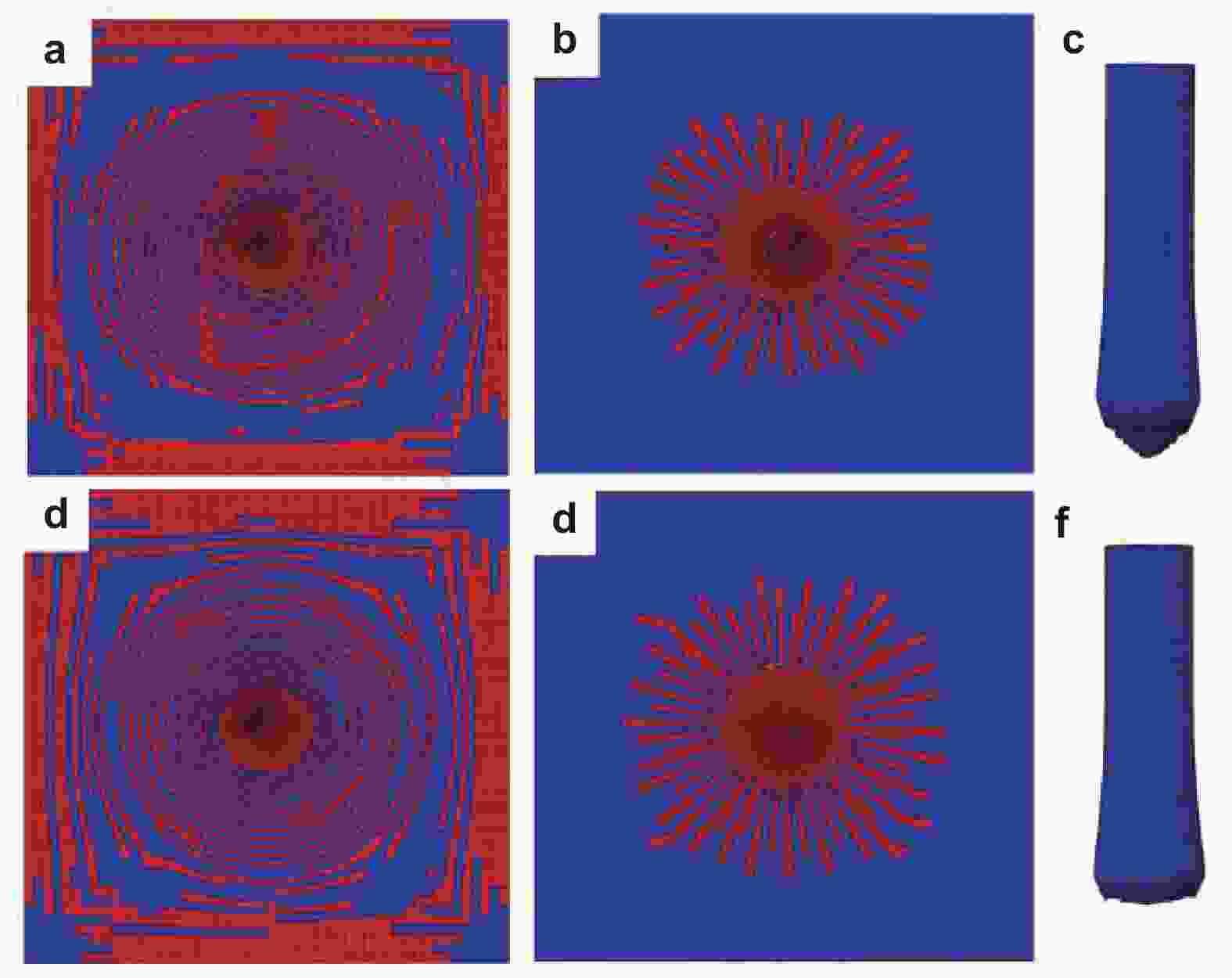

图 65 含缺陷透明陶瓷复合装甲抗侵彻数值模拟结果(Sands et al. 2009)

图 66 不同中间层厚度蓝宝石透明复合装甲数值模拟结果(Zhang et al. 2021)

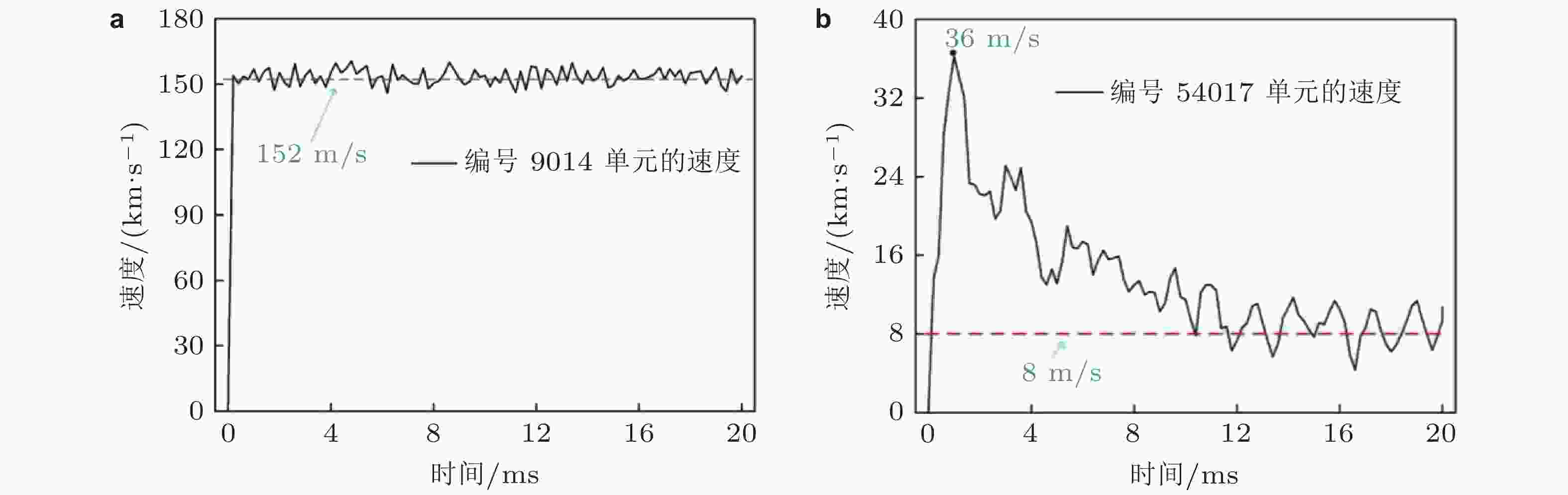

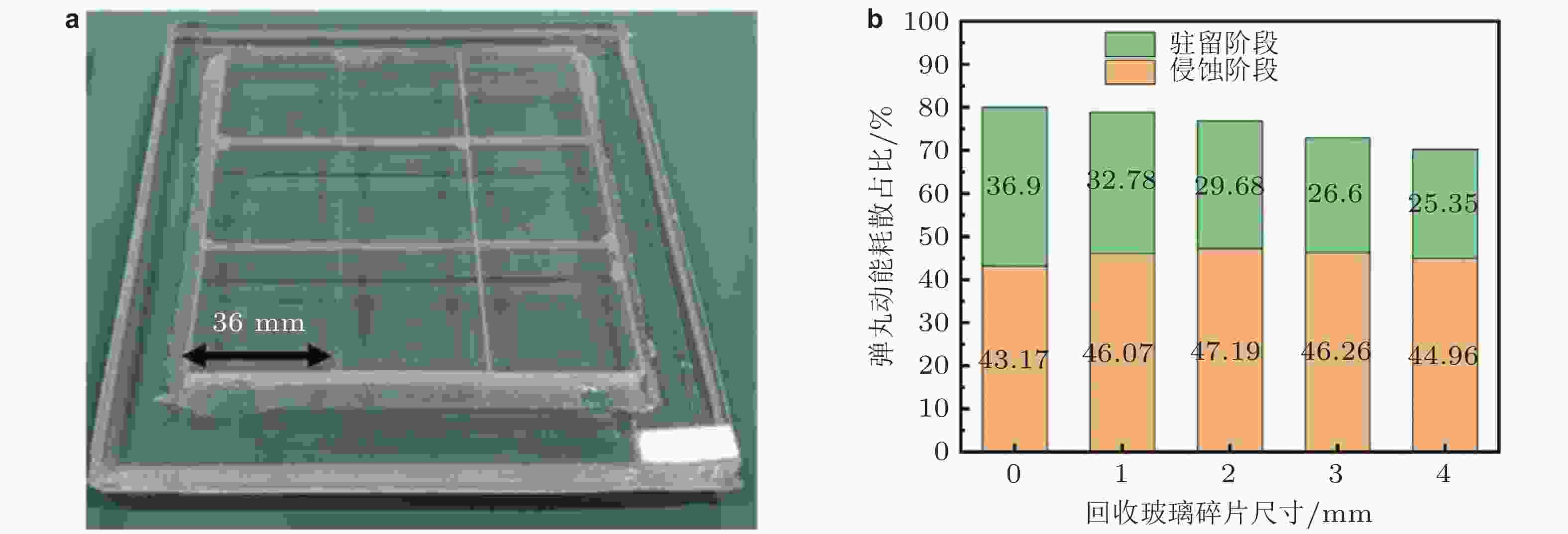

图 67 透明陶瓷复合装甲中典型单元速度变化图(Wang et al. 2022) . (a) 9014号陶瓷单元, (b) 54017号无机玻璃单元

图 68 盖板对透明陶瓷复合装甲抗弹性能的影响(Xin et al. 2021). (a) 拼接式陶瓷复合装甲结构, (b) 不同厚度玻璃盖板下陶瓷的能量耗散

-

[1] 艾月霞, 张国轩, 蔡懿, 李景镇. 2017. 光学分幅成像仪图像采集系统及其实验研究. 激光杂志, 38: 28-31 (Ai Yuexia, Zhang Guoxuan, Cai Yi, Li Jingzhen. 2017. Research on image acquisition system of optical framing camera,. Laser Journal, 38: 28-31).Ai Yuexia, Zhang Guoxuan, Cai Yi, Li Jingzhen. 2017. Research on Image Acquisition System of Optical Framing Camera. Laser Journal, 38: 28-31 [2] 包阔, 张先锋, 王桂吉, 邓佳杰, 韩丹, 谈梦婷, 魏海洋. 2021. 破片撞击下YAG透明陶瓷复合靶的破坏特性. 爆炸与冲击, 41: 24-36 (Bao Kuo, Zhang Xianfeng, Wang Guiji, Deng Jiajie, Han Dan, Tan Mengting, Wei Haiyang. 2021. Fracture characteristics of YAG transparent ceramic composite targets subjected to impact of sphere fragments. Explosion and Shock Waves, 41: 24-36).Bao Kuo, Zhang Xianfeng, Wang Guiji, Deng Jiajie, Han Dan, Tan Mengting, Wei Haiyang. 2021. Fracture characteristics of YAG transparent ceramic composite targets subjected to impact of sphere fragments. Explosion And Shock Waves, 41: 24-36 [3] 畅里华, 谭显祥, 汪伟, 尚长水, 李剑, 田建华. 2006. 纹影技术用于爆轰与冲击波物理实验研究. 激光与光电子学进展, 43: 58 (Chang Lihua, Tan Xianxiang, Wang Wei, Shang Changshui, Li Jian, Tian Jianhua. 2006. Schlieren techniques in experiments of shock wave and detonation physics. Laser & Optoelectronics Progress, 43: 58).Chang Lihua, Tan Xianxiang, Wang Wei, Shang Changshui, Li Jian, Tian Jianhua. 2006. Schlieren Techniques in Experiments of Shock Wave and Detonation Physics. Laser & Optoelectronics Progress, 43: 58 [4] 陈小伟, 陈裕泽. 2006. 脆性陶瓷靶高速侵彻/穿甲动力学的研究进展. 力学进展, 36: 85-102 (Chen Xiaowei, Chen Yuze. 2006. Review on the Penetration/Perforation of Ceramics Targets. Advances in Mechanics, 36: 85-102). doi: 10.6052/1000-0992-2006-1-J2004-086Chen Xiaowei, Chen Yuze. 2006. REVIEW ON THE PENETRATION/PERFORATION OF CERAMICS TARGETS. Advances in Mechanics, 36: 85-102 doi: 10.6052/1000-0992-2006-1-J2004-086 [5] 邓佳杰, 章健, 张先锋, 包阔. 2022. YAG透明陶瓷复合靶抗弹机理研究. 北京理工大学学报, 42: 620-628 (Deng Jiajie, Zhang Jian, Zhang Xianfeng, Bao Kuo. 2022. Investigation on Bullet Proof Mechanism of YAG Transparent Ceramic Composite Targets. Transactions of Beijing institute of Technology, 42: 620-628). doi: 10.15918/j.tbit1001-0645.2021.230Deng Jiajie, Zhang Jian, Zhang Xianfeng, Bao Kuo. 2022. Investigation on Bullet Proof Mechanism of YAG Transparent Ceramic Composite Targets. Transactions of Beijing institute of Technology, 42: 620-628 doi: 10.15918/j.tbit1001-0645.2021.230 [6] 段锦霞, 王程民, 王修慧, 高宏, 杨金龙. 2017. 镁铝尖晶石透明陶瓷研究进展. 粉末冶金技术, 35: 358-362 (Duan Jinxia, Wang Chengmin, Wang Xiuhui, Gao Hong, Yang Jinlong. 2017. Research progress of magnesium aluminate spinel transparent ceramic. Powder Metallurgy Technology, 35: 358-362).Duan Jinxia, Wang Chengmin, Wang Xiuhui, Gao Hong, Yang Jinlong. 2017. Research progress of magnesium aluminate spinel transparent ceramic. Powder Metallurgy Technology, 35: 358-362 [7] 高玉波, 秦国华, 张伟, 宜晨虹, 邓勇军. 2019. TiB2-B4C复合陶瓷动态压缩特性研究. 兵工学报, 40: 2304-2310 (Gao Yubo, Qin Guohua, Zhang Wei, Yi Chenhong, Deng Yongjun. 2019. Research on Dynamic Compression Properties of TiB2-B4C Composite. Acta Armamentarii, 40: 2304-2310). doi: 10.3969/j.issn.1000-1093.2019.11.015Gao Yubo, Qin Guohua, Zhang Wei, Yi Chenhong, Deng Yongjun. 2019. Research on Dynamic Compression Properties of TiB2-B4C Composite. Acta Armamentarii, 40: 2304-2310 doi: 10.3969/j.issn.1000-1093.2019.11.015 [8] 韩国庆, 张先锋, 谈梦婷, 包阔, 李逸. 2022. 边缘冲击(EOI)作用下透明陶瓷破坏特性研究. 爆炸与冲击, 42: 053102-053101 (Han Guoqing, Zhang Xianfeng, Tan Mengting, Bao Kuo, Li Yi. 2022. Failure characteristics of three transparent ceramics materials under the edge-on impact loading. Explosion and Shock Waves, 42: 053102-053101). doi: 10.11883/bzycj-2021-0292Han Guoqing, Zhang Xianfeng, Tan Mengting, Bao Kuo, Li Yi. 2022. Failure characteristics of three transparent ceramics materials under the edge-on impact loading. Explosion and Shock Waves, 42: 053102-053101 doi: 10.11883/bzycj-2021-0292 [9] 靳玲玲, 蒋志君, 章健, 王士维. 2010. 氧化钇透明陶瓷的研究进展. 硅酸盐学报, 38: 521-526 (Jin Lingling, Jiang Zhijun, Zhang Jian, Wang Shiwei. 2010. Research Progress of Yttria Transparent Ceramics. Journal of the Chinese Ceramic Society, 38: 521-526).Jin Lingling, Jiang Zhijun, Zhang Jian, Wang Shiwei. 2010. RESEARCH PROGRESS OF YTTRIA TRANSPARENT CERAMICS. Journal of the Chinese Ceramic Society, 38: 521-526 [10] 李鹏杰, 白雪, 刘宇阳, 王星明, 孙悦, 储茂友. 2021. 钇铝石榴石(YAG)透明陶瓷的研究进展. 中国稀土学报: 1-25Li Pengjie, Bai Xue, Liu Yuyang, Wang Xingming, Sun Yue, Chu Maoyou. 2021. A Review of Yttrium Aluminum Garnet (YAG) Transparent Ceramics Researching. Journal of the Chinese Society of Rare Earths, 1-25 [11] 李旺辉, 奉兰西, 张晓晴, 姚小虎. 2021. 极端条件下碳化硅的变形, 损伤与破坏研究进展. 高压物理学报, 35: 41 (Li Wanghui, Feng Lanxi, Zhang Xiaoqing, Yao Xiaohu. 2021. Brief Review of Research Progress on the Deformation, Damage and Failure of Silicon Carbide under Extreme Conditions. Chinese Journal of High Pressure Physics, 35: 41).Li Wanghui, Feng Lanxi, Zhang Xiaoqing, Yao Xiaohu. 2021. Brief Review of Research Progress on the Deformation, Damage and Failure of Silicon Carbide under Extreme Conditions. Chinese Journal of High Pressure Physics, 35: 41 [12] 李玉龙, 聂海亮, 汤忠斌, 索涛, 吴蓓蓓. 基于电磁力加载的分离式霍普金森压杆实验装置: CN201410161610: X. 2014-07-09Li Yulong, Nie Hailiang, Tang Zhongbin, Suo Tao, Wu Beibei. 2014. The discrete Hopkinson bar experimental setup based on electromagnetic force loading [13] 刘江丽, 黄志文. 2022. 蓝宝石单晶材料的抗弹仿真分析. 直升机技术, 3: 10-15 (Liu Jiangli, Huang Zhiwen. 2022. Experimental Study on Penetration Resistance of the Sapphire Single Crystal. Helicopter Technique, 3: 10-15). doi: 10.3969/j.issn.1673-1220.2022.03.003Liu Jiangli, Huang Zhiwen. 2022. Experimental Study on Penetration Resistance of the Sapphire Single Crystal. Helicopter Technique, 3: 10-15 doi: 10.3969/j.issn.1673-1220.2022.03.003 [14] 卢芳云, 陈荣. 2013. 霍普金森杆实验技术. 北京: 科学出版社Lu Fangyun, Chen Rong. 2013. Hopkinson Bar Techniques. Beijing: Science Press [15] 牛欢欢, 闫晓鹏, 罗浩舜, 陈佳君, 李志强. 2022. 不同应变率下蓝宝石透明陶瓷玻璃的力学响应. 爆炸与冲击, 42: 74-83 (Niu Huanhuan, Yan Xiaopeng, Luo Haoshun, Chen Jiajun, Li Zhiqiang. 2022. Mechanical response of sapphire transparent ceramic glass at different strain rates. Explosion and Shock Waves, 42: 74-83). doi: 10.11883/bzycj-2021-0434Niu Huanhuan, Yan Xiaopeng, Luo Haoshun, Chen Jiajun, Li Zhiqiang. 2022. Mechanical response of sapphire transparent ceramic glass at different strain rates. Explosion and Shock Waves, 42: 74-83 doi: 10.11883/bzycj-2021-0434 [16] 施剑林, 冯涛. 2008. 无机光学透明材料: 透明陶瓷. 上海: 上海科学普及出版社Shi Jianlin, Feng Tao. 2008. Inorganic optically clear material: transparent ceramics. Shanghai: Shanghai Popular Science Press [17] 苏翼林. 1979. 材料力学. 北京: 高等教育出版社Su Yilin. 1979. Mechanics of materials. Beijing: Higher Education Press [18] 谈梦婷, 张先锋, 包阔, 伍杨, 吴雪. 2019. 装甲陶瓷的界面击溃效应. 力学进展, 49: 201905 (Tan Mengting, Zhang Xianfeng, Bao Kuo, Wu Yang, Wu Xue. 2019. Interface defeat of ceramic armor. Advances in Mechanics, 49: 201905). doi: 10.6052/1000-0992-17-015Tan Mengting, Zhang Xianfeng, Bao Kuo, Wu Yang, Wu Xue. 2019. Interface defeat of ceramic armor. Advances in Mechanics, 49: 201905 doi: 10.6052/1000-0992-17-015 [19] 万林林, 邓泽辉, 邓朝晖, 李乐. 2020. 冲击载荷下氧化锆陶瓷的弹脆性损伤本构关系. 材料科学与工程学报, 38: 785-790, 784 (Wan Linlin, Deng Zehui, Deng Zhaohui, Li Le. 2020. Constitutive Relationship of Elastic-brittle Damage of Zirconia Ceramics under Impact Load. Journalor of Materials Science and Engineering, 38: 785-790, 784).Wan Linlin, Deng Zehui, Deng Zhaohui, Li Le. 2020. Constitutive Relationship of Elastic-brittle Damage of Zirconia Ceramics under Impact Load. Journalor of Materials Science and Engineering, 38: 785-790 + 784 [20] 王维斌, 索涛, 郭亚洲, 李玉龙, 聂海亮, 刘会芳, 金康华, 杜冰, 江斌. 2021. 电磁霍普金森杆实验技术及研究进展. 力学进展, 51: 729-754 (Wang Weibin, Suo Tao, Guo Yazhou, Li Yulong, Nie Hailiang, Liu Huifang, Jin Kanghua, Du Bing, Jiang Bin. 2021. Experimental technique and research progress of electromagnetic Hopkinson bar. Advances in Mechanics, 51: 729-754). doi: 10.6052/1000-0992-20-024Wang Weibin, Suo Tao, Guo Yazhou, Li Yulong, Nie Hailiang, Liu Huifang, Jin Kanghua, Du Bing, Jiang Bin. 2021. Experimental technique and research progress of electromagnetic Hopkinson bar. Advances in Mechanics, 51: 729-754 doi: 10.6052/1000-0992-20-024 [21] 魏化震, 于广, 钟蔚华. 2020. 高分子复合材料在装甲防护领域的研究与应用进展. 材料工程, 48: 25-32Wei Huazhen, Yu Guang, Zhong Weihua. 2020. Research and application progress of polymer composites in armor protection. Journal of Materials Engineering, 48: 25-32. [22] 吴建, 王卓健, 胡智臣, 刘兴亮, 谭敦强, 戴煜, 耿东生. 2022. 透明AlON陶瓷发展现状综述(英文). 中国有色金属学报(英文版): 1-27Wu Jian, Wang Zhuojian, Hu Zhichen, Liu Xingliang, Tan Dunqiang, Dai Yu, Geng Dongsheng. 2022. Recent progress and challenges of transparent AlON ceramics. Transactions of Nonferrous Metals Society of China, 1-27 [23] 杨迪, 李福欣. 1988. 显微硬度试验. 北京: 中国计量出版社Yang Di, Li Fuxin. 1988. Microhardness test. Beijing: China Metrology Publishing House [24] 岳中文, 王煦, 杨仁树, 邱鹏, 胡庆文, 陈程. 2017. 一种动光弹模型材料的制作方法及其应用. 实验力学, 32: 10 (Yue Zhongwen, Wang Xu, Yang Renshu, Qiu Peng, Hu Qingwen, Chen Cheng. 2017. A Method of Dynamic Photoelastic Experimental Model Material and its Application. Journal of Experimental Mechanics, 32: 10).Yue Zhongwen, Wang Xu, Yang Renshu, Qiu Peng, Hu Qingwen, Chen Cheng. 2017. A Method of Dynamic Photoelastic Experimental Model Material and its Application. Journal of Experimental Mechanics, 32: 10 [25] 张泰华, 杨业敏. 2002. 纳米硬度技术的发展和应用. 力学进展, 32: 16 (Zhang Taihua, Yang Yemin. 2002. Developments and Applications of Nano Hardness Techniques. Advances in Mechanics, 32: 16).Zhang Taihua, Yang Yemin. 2002. DEVELOPMENTS AND APPLICATIONS OF NANO-HARDNESS TECHNIQUES. Advances in Mechanics, 32: 16 [26] 郑颖人, 沈珠江, 龚晓南. 2002. 岩土塑性力学原理. 北京: 中国建筑工业出版社(Zheng Yingren, Shen Zhujiang, Gong Xiaonan. 2002. Geotechnical plastic mechanics theory. Beijing: China Architecture & Building Press) [27] Addessio F L, Johnson J N. 1990. A constitutive model for the dynamic response of brittle materials. Journal of Applied Physics, 67: 3275-3286. doi: 10.1063/1.346090 [28] Antoun T, Seaman L, Curran D R, Kanel G I, Razorenov S V, Utkin A V. 2003. Spall fracture [M]. Springer Science & Business Media. [29] Ashby M F, Hallam S D. 1986. The failure of brittle solids containing small cracks under compressive stress states. Acta Metallurgica, 34: 497-510. doi: 10.1016/0001-6160(86)90086-6 [30] Bao K, Zhang X-f, Wang G-j, Deng J-j, Chong T, Han D, Luo B-q, Tan M-t. 2022. Damage characteristics of YAG transparent ceramics under different loading conditions. Defence Technology, 18: 1394-1404. doi: 10.1016/j.dt.2021.06.010 [31] Belytschko T, Black T. 1999. Elastic crack growth in finite elements with minimal remeshing. International Journal for Numerical Methods in Engineering, 45: 601-620. doi: 10.1002/(SICI)1097-0207(19990620)45:5<601::AID-NME598>3.0.CO;2-S [32] Borst R d, Remmers J J C, Needleman A. 2006. Mesh-independent discrete numerical representations of cohesive-zone models. Engineering Fracture Mechanics, 73: 160-177. doi: 10.1016/j.engfracmech.2005.05.007 [33] Bourne N K, Millett J C F, Chen M, Mccauley J W, Dandekar D P. 2007. On the Hugoniot elastic limit in polycrystalline alumina. Journal of Applied Physics, 102: 073514. doi: 10.1063/1.2787154 [34] Bouzid S, Nyoungue A, Azari Z, Bouaouadja N, Pluvinage G. 2001. Fracture criterion for glass under impact loading. International Journal of Impact Engineering, 25: 831-845. doi: 10.1016/S0734-743X(01)00023-9 [35] Brannon R M, Lee M Y, Bronowski D R. 2005. Uniaxial and triaxial compression tests of silicon carbide ceramics under quasi-static loading condition//; City. [36] Brocca M, Bažant Z P. 2000. Microplane Constitutive Model and Metal Plasticity. Applied Mechanics Reviews, 53: 265-281. doi: 10.1115/1.3097329 [37] Cao X, Li T, Yu Y, Li X, Qi J, Meng C, He H, Hu J, Wu Q. 2022. Dynamic response of YAG polycrystalline and single-crystal transparent ceramics: Experiments and mesoscopic simulations. Journal of the American Ceramic Society, 105: 6864-6875. doi: 10.1111/jace.18647 [38] Chessa J, Belytschko T. 2006. A local space–time discontinuous finite element method. Computer Methods in Applied Mechanics and Engineering, 195: 1325-1343. doi: 10.1016/j.cma.2005.05.022 [39] Clinton D J, Morrell R. 1987. Hardness testing of ceramic materials. Materials Chemistry and Physics, 17: 461-473. doi: 10.1016/0254-0584(87)90096-4 [40] Cook R F, Pharr G M. 1990. Direct Observation and Analysis of Indentation Cracking in Glasses and Ceramics. Journal of the American Ceramic Society, 73: 787-817. doi: 10.1111/j.1151-2916.1990.tb05119.x [41] Davison L, Stevens A L, M. B B, M. B L, E. M D, D. L C. 1972. Continuum Measures of Spall Damage. Journal of Applied Physics, 43: 988-994. doi: 10.1063/1.1661319 [42] Dumerac M, Kleebe H-J, Mueller M, Reimanis I. 2013. Fifty Years of Research and Development Coming to Fruition; Unraveling the Complex Interactions During Processing of Transparent Magnesium Aluminate (MgAl2O4) Spinel. Journal of the American Ceramic Society, 96: 3341-3365. doi: 10.1111/jace.12637 [43] Erzar B, Forquin P. 2011. Experiments and mesoscopic modelling of dynamic testing of concrete. Mechanics of Materials, 43: 505-527. doi: 10.1016/j.mechmat.2011.05.002 [44] Fahrenthold E P. 1991. A continuum damage model for fracture of brittle solids under dynamic loading. Journal of Applied Mechanics, 58: 904-909. doi: 10.1115/1.2897704 [45] Forquin P, Tran L, Louvigne P F, Rota L, Hild F. 2003. Effect of aluminum reinforcement on the dynamic fragmentation of SiC ceramics. International Journal of Impact Engineering, 28: 1061-1076. doi: 10.1016/S0734-743X(03)00034-4 [46] Fountzoulas C G, Cheeseman B A, Lasalvia J C. 2009. Simulation of Ballistic Impact of a Tungsten Carbide Sphere on a Confined Silicon Carbide Target//; City. [47] Fredrich J T, Evans B, Wong T T. 1990. Effect of grain size on brittle and semibrittle strength: Implications for micromechanical modelling of failure in compression. Journal of Geophysical Research, 95: 10907-10920. doi: 10.1029/JB095iB07p10907 [48] Gallo L S A, Villas Boas M O C, Rodrigues A C M, Melo F C L, Zanotto E D. 2019. Transparent glass–ceramics for ballistic protection: materials and challenges. Journal of Materials Research and Technology, 8: 3357-3372. doi: 10.1016/j.jmrt.2019.05.006 [49] Ganesh I. 2013. A review on magnesium aluminate (MgAl2O4) spinel: synthesis, processing and applications. International Materials Reviews, 58: 63-112. doi: 10.1179/1743280412Y.0000000001 [50] Ganesh I, Srinivas B, Johnson R, Saha B P, Mahajan Y R. 2002. Effect of fuel type on morphology and reactivity of combustion synthesised MgAl2O4 powders. British Ceramic Transactions, 101: 247-254. doi: 10.1179/096797802225004063 [51] Gazonas G, Mccauley J, Batyrev I, Becker R, Izvekov S, Jenkins T, Patel P, Rice B, Schuster B, Weingarten N, Wildman R. 2013. Multiscale Modeling of Non-crystalline Ceramics (Glass) (Final Report). [52] Ghosh D, Subhash G, Sudarshan T S, Radhakrishnan R, Gao X L. 2007. Dynamic Indentation Response of Fine-Grained Boron Carbide. Journal of the American Ceramic Society, 90: 1850-1857. doi: 10.1111/j.1551-2916.2007.01652.x [53] Gilman J J, Tuler F R. 1970. Dynamic fracture by spallation in metals. International Journal of Fracture Mechanics, 6: 169-182. doi: 10.1007/BF00189824 [54] Grady D E. 1998. Shock-wave compression of brittle solids. Mechanics of Materials, 29: 181-203. doi: 10.1016/S0167-6636(98)00015-5 [55] Grange S, Forquin P, Mencacci S, Hild F. 2008. On the dynamic fragmentation of two limestones using edge-on impact tests. International Journal of Impact Engineering, 35: 977-991. doi: 10.1016/j.ijimpeng.2007.07.006 [56] Griffith A A. 1921. The Phenomena of Rupture and Flow in Solids. Philosophical Transactions of the Royal Society A, 221: 163-198. [57] Grujicic M, Bell W C, Pandurangan B. 2012. Design and material selection guidelines and strategies for transparent armor systems. Materials & Design, 34: 808-819. [58] Grujicic M, Pandurangan B, Coutris N, Cheeseman B A, Fountzoulas C, Patel P, Templeton D W, Bishnoi K D. 2009. A simple ballistic material model for soda-lime glass. International Journal of Impact Engineering, 36: 386-401. doi: 10.1016/j.ijimpeng.2008.08.001 [59] Haney E J, Subhash G. 2011a. Rate Sensitive Indentation Response of a Coarse-Grained Magnesium Spinel. Journal of the American Ceramic Society, 94: 3960-3966. doi: 10.1111/j.1551-2916.2011.04756.x [60] Haney E J, Subhash G. 2011b. Analysis of interacting cracks due to sequential indentations on sapphire. Acta Materialia, 59: 3528-3536. doi: 10.1016/j.actamat.2011.02.026 [61] Haney E J, Subhash G. 2011c. Static and dynamic indentation response of basal and prism plane sapphire. Journal of the European Ceramic Society, 31: 1713-1721. doi: 10.1016/j.jeurceramsoc.2011.03.006 [62] Haney E J, Subhash G. 2013. Damage Mechanisms Perspective on Superior Ballistic Performance of Spinel over Sapphire. Experimental Mechanics, 53: 31-46. doi: 10.1007/s11340-012-9634-0 [63] Hazell P J, Edwards M R, Longstaff H, Erskine J. 2009. Penetration of a glass-faced transparent elastomeric resin by a lead–antimony-cored bullet. International Journal of Impact Engineering, 36: 147-153. doi: 10.1016/j.ijimpeng.2007.12.009 [64] Hertz H. 1880. On the contact of elastic solids. Journal für die reine und angewandte Mathematik (Crelles Journal), 92. [65] Holmquist T J, Anderson C E, Behner T, Orphal D L. 2010. Mechanics of dwell and post-dwell penetration. Advances in Applied Ceramics, 109: 467-479. doi: 10.1179/174367509X12535211569512 [66] Holmquist T J, Johnson G R. 2011. A Computational Constitutive Model for Glass Subjected to Large Strains, High Strain Rates and High Pressures. Journal of Applied Mechanics, 78. [67] Holmquist T J, Templeton D W, Bishnoi K D. 2001. Constitutive modeling of aluminum nitride for large strain, high-strain rate, and high-pressure applications. International Journal of Impact Engineering, 25: 211-231. doi: 10.1016/S0734-743X(00)00046-4 [68] Espinosa H D, Xu Y P, Brar N S. 1997. Micromechanics of Failure Waves in Glass: II, Modeling. Journal of the American Ceramic Society, 80: 2074-2085. [69] Huang J, Zhang X, Long S, Yao X. 2023. Damage and failure mechanism of sapphire under ballistic loading based on a modified bond-based peridynamic model. Journal of the American Ceramic Society, 106: 2095-2117. doi: 10.1111/jace.18904 [70] Huang X, Zhang W, Deng Y, Jiang X. 2018. Experimental investigation on the ballistic resistance of polymer-aluminum laminated plates. International Journal of Impact Engineering, 113: 212-221. doi: 10.1016/j.ijimpeng.2017.12.002 [71] Jiang W, Cheng X, Cai H, Zhang J. 2018. Static and dynamic failure behavior of transparent polycrystalline spinel (MgAl2O4) under compression/shear loading experiments. Materials Research Express, 6: 015204. doi: 10.1088/2053-1591/aae4ba [72] Jiang W, Cheng X, Xiong Z, Ali T, Cai H, Zhang J. 2019a. Bimodal grain structure effect on the static and dynamic mechanical properties of transparent polycrystalline magnesium aluminate (spinel). Ceramics International, 45: 20362-20367. doi: 10.1016/j.ceramint.2019.07.010 [73] Jiang W, Cheng X, Xiong Z, Ma Z, Ali T, Cai H, Zhang J. 2019b. Static and dynamic mechanical properties of Yttrium Aluminum Garnet (YAG). Ceramics International, 45: 12256-12263. doi: 10.1016/j.ceramint.2019.03.136 [74] Johnson G R, Holmquist T J. 1994. An Improved Computational Constitutive Model for Brittle Materials. American Institute of Physics (AIP). [75] Johnson G R, Holmquist T J. 1994b. An improved computational constitutive model for brittle materials. 309: 981-984. [76] Johnson G R, Holmquist T J. 1999. Response of boron carbide subjected to large strains, high strain rates, and high pressures. Journal of Applied Physics, 85: 8060-8073. doi: 10.1063/1.370643 [77] Johnson G R, Holmquist T J, Beissel S R. 2003. Response of aluminum nitride (including a phase change) to large strains, high strain rates, and high pressures. Journal of Applied Physics, 94: 1639-1646. doi: 10.1063/1.1589177 [78] Kanel G I, Nellis W J, Savinykh A S, Razorenov S V, Rajendran A M. 2009. Response of seven crystallographic orientations of sapphire crystals to shock stresses of 16–86 GPa. Journal of Applied Physics, 106: 043524. doi: 10.1063/1.3204940 [79] Kanel G I, Razorenov S V, Fortov V E, Fortov V. 2004. Shock-wave phenomena and the properties of condensed matter. Springer Science & Business Media. [80] Kimberley J, Ramesh K T. 2011. Dynamic response of transparent ceramic MgAl2O4 spinel. Scripta Materialia, 65: 830-833. doi: 10.1016/j.scriptamat.2011.07.044 [81] Klecka M A, Subhash G. 2010. Rate-Dependent Indentation Response of Structural Ceramics. Journal of the American Ceramic Society, 93: 2377-2383. doi: 10.1111/j.1551-2916.2010.03729.x [82] Klement R, Rolc S, Mikulikova R, Krestan J. 2008. Transparent armour materials. Journal of the European Ceramic Society, 28: 1091-1095. doi: 10.1016/j.jeurceramsoc.2007.09.036 [83] Klopp R W, Shockey D A, A. S D, H. M A, R. S S, E. C G, W. B M, R. P. 1991. The strength behavior of granulated silicon carbide at high strain rates and confining pressure. Journal of Applied Physics, 70: 7318-7326. doi: 10.1063/1.349750 [84] Krell A, Strassburger E. 2014. Order of influences on the ballistic resistance of armor ceramics and single crystals. Materials Science and Engineering:A, 597: 422-430. doi: 10.1016/j.msea.2013.12.101 [85] Lai X, Liu L, Li S, Zeleke M, Liu Q, Wang Z. 2018. A non-ordinary state-based peridynamics modeling of fractures in quasi-brittle materials. International Journal of Impact Engineering, 111: 130-146. doi: 10.1016/j.ijimpeng.2017.08.008 [86] Lawn B R, Evans A G. 1977. A model for crack initiation in elastic/plastic indentation fields. Journal of Materials Science, 12: 2195-2199. doi: 10.1007/BF00552240 [87] Lawn B R, Evans A G, Marshall D B. 1980. Elastic / Plastic Indentation Damage in Ceramics: The MediadRadial Crack System. Journal of the American Ceramic Society, 63: 574-581. doi: 10.1111/j.1151-2916.1980.tb10768.x [88] Lawn B R, Jensen T, Arora A. 1976. Brittleness as an Indentation Effect. Journal of Materials Science, 11: 573-575. doi: 10.1007/BF00540940 [89] Lawn B R, Marshall D B. 2010. Hardness, Toughness, and Brittleness: An Indentation Analysis. Journal of the American Ceramic Society, 62: 347-350. [90] Leavy R B, Clayton J D, Strack O E, Brannon R M, Strassburger E. 2013. Edge on Impact Simulations and Experiments. Procedia Engineering, 58: 445-452. doi: 10.1016/j.proeng.2013.05.051 [91] Li H, Bradt R C. 1992. The indentation load/size effect and the measurement of the hardness of vitreous silica. Journal of Non-Crystalline Solids, 146: 197-212. doi: 10.1016/S0022-3093(05)80492-2 [92] Li H, Bradt R C. 1993. The microhardness indentation load/size effect in rutile and cassiterite single crystals. Journal of Materials Science, 28: 917-926. doi: 10.1007/BF00400874 [93] Li H, Bradt R C. 1996. The effect of indentation-induced cracking on the apparent microhardness. Journal of Materials Science, 31: 1065-1070. doi: 10.1007/BF00352908 [94] Li T, Cao X, Wang Q, Li Y, He H, Yu Y, Li Y, Jin X. 2021. Numerical modeling of dynamic response and microcracking in shock-loaded polycrystalline transparent ceramic. Journal of Applied Physics, 129: 205103. doi: 10.1063/5.0046248 [95] Li Y, Zhou S, Lin H, Hou X, Li W, Teng H, Jia T. 2010. Fabrication of Nd: YAG transparent ceramics with TEOS, MgO and compound additives as sintering aids. Journal of Alloys and Compounds, 502: 225-230. doi: 10.1016/j.jallcom.2010.04.151 [96] Lu Y, Xu K. 2004. Modelling of dynamic behaviour of concrete materials under blast loading. International Journal of Solids and Structures, 41: 131-143. doi: 10.1016/j.ijsolstr.2003.09.019 [97] Luo D, Wang Y, Wang F, Cheng H, Zhang B, Li Z. 2021. Influence of cover thickness on the ballistic performance of silicon carbide subjected to large-scale tungsten projectiles. Ceramics International, 47: 15783-15791. doi: 10.1016/j.ceramint.2021.02.150 [98] Marshall D B, Evans A G, Nisenholz Z. 1983. Measurement of Dynamic Hardness by Controlled Sharp-Projectile Impact. Journal of the American Ceramic Society, 66: 580-585. doi: 10.1111/j.1151-2916.1983.tb10095.x [99] Mccauley J W, Patel P J. 2013. Evaluation of IKTS Transparent Polycrystalline Magnesium Aluminate Spinel (MgAl2O4) for Armor and Infrared Dome/Window Applications//; City. [100] Mccauley J W, Strassburger E, Patel P, Paliwal B, Ramesh K T. 2013. Experimental Observations on Dynamic Response of Selected Transparent Armor Materials. Experimental Mechanics, 53: 3-29. doi: 10.1007/s11340-012-9658-5 [101] Melenk J M, Babuška I. 1996. The partition of unity finite element method: Basic theory and applications. Computer Methods in Applied Mechanics and Engineering, 139: 289-314. doi: 10.1016/S0045-7825(96)01087-0 [102] Moës N, Belytschko T. 2002. Extended finite element method for cohesive crack growth. Engineering Fracture Mechanics, 69: 813-833. doi: 10.1016/S0013-7944(01)00128-X [103] Mukhopadhyay A K, Joshi K D, Dey A, Chakraborty R, Mandal A K, Rav A, Ghosh J, Bysakh S, Biswas S K, Gupta S C. 2011. Electron microscopy of shock deformation in alumina. Ceramics International, 37: 2365-2376. doi: 10.1016/j.ceramint.2011.03.034 [104] Murray N H, Bourne N K, Rosenberg Z. 1998. The dynamic compressive strength of aluminas. Journal of Applied Physics, 84: 4866-4871. doi: 10.1063/1.368729 [105] Nie X, Wright J C, Chen W W, Fehrenbacher L, Vesnovsky I. 2011. Rate effects on the mechanical response of magnesium aluminate spinel. Materials Science and Engineering:A, 528: 5088-5095. doi: 10.1016/j.msea.2011.03.027 [106] Paliwal B, Ramesh K T. 2007. Effect of crack growth dynamics on the rate-sensitive behavior of hot-pressed boron carbide. Scripta Materialia, 57: 481-484. doi: 10.1016/j.scriptamat.2007.05.028 [107] Paliwal B, Ramesh K T. 2008. An interacting micro-crack damage model for failure of brittle materials under compression. Journal of the Mechanics and Physics of Solids, 56: 896-923. doi: 10.1016/j.jmps.2007.06.012 [108] Paliwal B, Ramesh K T, Mccauley J W. 2006. Direct Observation of the Dynamic Compressive Failure of a Transparent Polycrystalline Ceramic (AlON). Journal of the American Ceramic Society, 89: 2128-2133. [109] Paliwal B, Ramesh K T, Mccauley J W, Chen M. 2008. Dynamic Compressive Failure of AlON Under Controlled Planar Confinement. Journal of the American Ceramic Society, 91: 3619-3629. doi: 10.1111/j.1551-2916.2008.02712.x [110] Paris V, Kalabukhov S, Dariel M P, Frage N, Zaretsky E. 2011. High strain rate behavior of spark plasma sintered magnesium aluminate spinel. International Journal of Impact Engineering, 38: 910-917. doi: 10.1016/j.ijimpeng.2011.06.005 [111] Patel P J, Swab J J, Staley M E, Quinn G D. 2006. Indentation Size Effect (ISE) of Transparent AION and MgAl2O4//; City. [112] Pazdniakou A, Adler P M. 2012. Lattice Spring Models. Transport in Porous Media, 93: 243-262. doi: 10.1007/s11242-012-9955-6 [113] Rajendran A M, Kroupa J L. 1989. Impact damage model for ceramic materials. Journal of Applied Physics, 66: 3560-3565. doi: 10.1063/1.344085 [114] Sands J M, Fountzoulas C G, Gilde G A, Patel P J. 2009. Modelling transparent ceramics to improve military armour. Journal of the European Ceramic Society, 29: 261-266. doi: 10.1016/j.jeurceramsoc.2008.03.010 [115] Sathananthan P, Sirois A, Singh D, Cronin D. 2019. Sphere on Tile Ballistic Impact Experiment to Characterize the Response of Soda Lime Glass. International Journal of Impact Engineering, 133: 103321. doi: 10.1016/j.ijimpeng.2019.103321 [116] Schardin H. 1950. Results of cinematographic investigation of the fracture process in glass. Glastech. Ber., 23: 325-336. [117] Schultz R A, Bradt R C 1992. Cleavage of Ceramic and Mineral Single Crystals//; City. [118] Shah Q H. 2009. Impact resistance of a rectangular polycarbonate armor plate subjected to single and multiple impacts. International Journal of Impact Engineering, 36: 1128-1135. doi: 10.1016/j.ijimpeng.2008.12.005 [119] Shi Z, Wang H, Zhao Q, Ji T, Wang Y, Pan Y, Guo B. 2020. Damage mechanisms of polycrystalline aluminate magnesium spinel (PAMS) under different loading conditions of indentation and micro-cutting tests. Ceramics International, 46: 7235-7252. doi: 10.1016/j.ceramint.2019.11.218 [120] Silling S A, Askari E. 2005. A meshfree method based on the peridynamic model of solid mechanics. Computers & Structures, 83: 1526-1535. [121] Simha C H M, Bless S J, Bedford A. 2002. Computational modeling of the penetration response of a high-purity ceramic. International Journal of Impact Engineering, 27: 65-86. doi: 10.1016/S0734-743X(01)00036-7 [122] Stanag N. 2004. Protection levels for occupants of logistic and light armoured vehicles. [123] Straßburger E. 2006. High-speed photographic study of wave propagation and impact damage in transparent aluminum oxynitride (AION). Fraunhofer-gesellschaft Zur Foerderung Der Angewandten Forschung Ev Munich …. [124] Straßburger E. 2009. Ballistic testing of transparent armour ceramics. Journal of the European Ceramic Society, 29: 267-273. doi: 10.1016/j.jeurceramsoc.2008.03.049 [125] Straßburger E, Steinhauser M. 2008. High-Speed Photographic Study of Wave Propagation and Impact Damage in Transparent Laminates//; City. [126] Strassburger E, Bauer S 2018. Analysis of the Interaction of Projectiles with Ceramic Targets by Means of Flash X-Ray Cinematography and Optical Methods//; City. [127] Strassburger E, Hunzinger M, Patel P, Mccauley J W. 2013. Analysis of the Fragmentation of AlON and Spinel Under Ballistic Impact. Journal of Applied Mechanics, 80. [128] Strassburger E, Patel P J, Mccauley J W. 2011. Visualization and Analysis of Impact Damage in Sapphire//; City. [129] Taylor L M, Chen E P, Kuszmaul J S. 1986. Microcrack-induced damage accumulation in brittle rock under dynamic loading. Computer Methods in Applied Mechanics & Engineering, 55: 301-320. [130] Thornhill T F, Vogler T J, Reinhart W D, Chhabildas L C. 2006. Polycrystalline Aluminum Oxynitride Hugoniot and Optical Properties. AIP Conference Proceedings, 845: 143-146. doi: 10.1063/1.2263285 [131] Tonge A L, Ramesh K T. 2016. Multi-scale defect interactions in high-rate brittle material failure: Part I: Model formulation and application to ALON. Journal of the Mechanics and Physics of Solids, 86: 117-149. doi: 10.1016/j.jmps.2015.10.007 [132] Wang M, Li Y, Luo H, Zheng X, Li Z. 2022. Experiment and Numerical Simulation of Damage Progression in Transparent Sandwich Structure under Impact Load. Materials, 15: 3809. doi: 10.3390/ma15113809 [133] Wang S F, Zhang J, Luo D W, Gu F, Tang D Y, Dong Z L, Tan G E B, Que W X, Zhang T S, Li S, Kong L B. 2013. Transparent ceramics: Processing, materials and applications. Progress in Solid State Chemistry, 41: 20-54. doi: 10.1016/j.progsolidstchem.2012.12.002 [134] Weiss A, Borenstein A, Ben- Melech G, Ravid M, Shapira N. 2017. Ballistic Performance of Ceramic Targets against 25mm APDS-T Projectile. [135] Wilantewicz T E. 2010. Failure Behavior of Glass and Aluminum Oxynitride (AlON) Tiles Under Spherical Indenters//; City. [136] Winkler S, Senf H, Rothenhausler H B. 1989. Wave and Fracture Phenomena in Impacted Ceramics//; City. [137] Xiao Z, Yu S, Li Y, Ruan S, Kong L B, Huang Q, Huang Z, Zhou K, Su H, Yao Z, Que W, Liu Y, Zhang T, Wang J, Liu P, Shen D, Allix M, Zhang J, Tang D. 2020. Materials development and potential applications of transparent ceramics: A review. Materials Science and Engineering:R:Reports, 139: 100518. doi: 10.1016/j.mser.2019.100518 [138] Xin Z, Wang Y, Fu Q, Cheng H, Cheng X, Zhang J. 2021. Effect of glass cover layer on the ballistic performance of transparent ceramic armor. Ceramics International, 47: 29277-29284. doi: 10.1016/j.ceramint.2021.07.092 [139] Xu J, Li Y, Chen X, Yan Y, Ge D, Zhu M, Liu B. 2010. Characteristics of windshield cracking upon low-speed impact: Numerical simulation based on the extended finite element method. Computational Materials Science, 48: 582-588. doi: 10.1016/j.commatsci.2010.02.026 [140] Yang H, Qin X, Zhang J, Ma J, Tang D, Wang S, Zhang Q. 2012. The effect of MgO and SiO2 codoping on the properties of Nd: YAG transparent ceramic. Optical Materials, 34: 940-943. doi: 10.1016/j.optmat.2011.05.029 [141] Zeng Q, Tonge A L, Ramesh K T. 2019. A multi-mechanism constitutive model for the dynamic failure of quasi-brittle materials: Part I: Amorphization as a failure mode. Journal of the Mechanics and Physics of Solids, 130: 370-392. doi: 10.1016/j.jmps.2019.06.012 [142] Zhang B, Guo X, Liu Y, Lang L, Tan S. 2021. Study of glass laminate configurations on ballistic resistance of novel lightweight sapphire transparent laminated structures. International Journal of Lightweight Materials and Manufacture, 4: 397-404. doi: 10.1016/j.ijlmm.2021.05.002 [143] Zhang G, Gazonas G A, Bobaru F. 2018. Supershear damage propagation and sub-Rayleigh crack growth from edge-on impact: A peridynamic analysis. International Journal of Impact Engineering, 113: 73-87. doi: 10.1016/j.ijimpeng.2017.11.010 [144] Zhang Q, Zheng Y, Zhou F, Yu T. 2020. Fragmentations of Alumina(Al2O3) and Silicon Carbide(SiC) under quasi-static compression. International Journal of Mechanical Sciences, 167: 105119. doi: 10.1016/j.ijmecsci.2019.105119 [145] Zhou F, Molinari J F. 2004. Stochastic fracture of ceramics under dynamic tensile loading. International Journal of Solids and Structures, 41: 6573-6596. doi: 10.1016/j.ijsolstr.2004.05.029 [146] Zi G, Belytschko T. 2003. New crack-tip elements for XFEM and applications to cohesive cracks. International Journal for Numerical Methods in Engineering, 57: 2221-2240. doi: 10.1002/nme.849 -

下载:

下载: