-

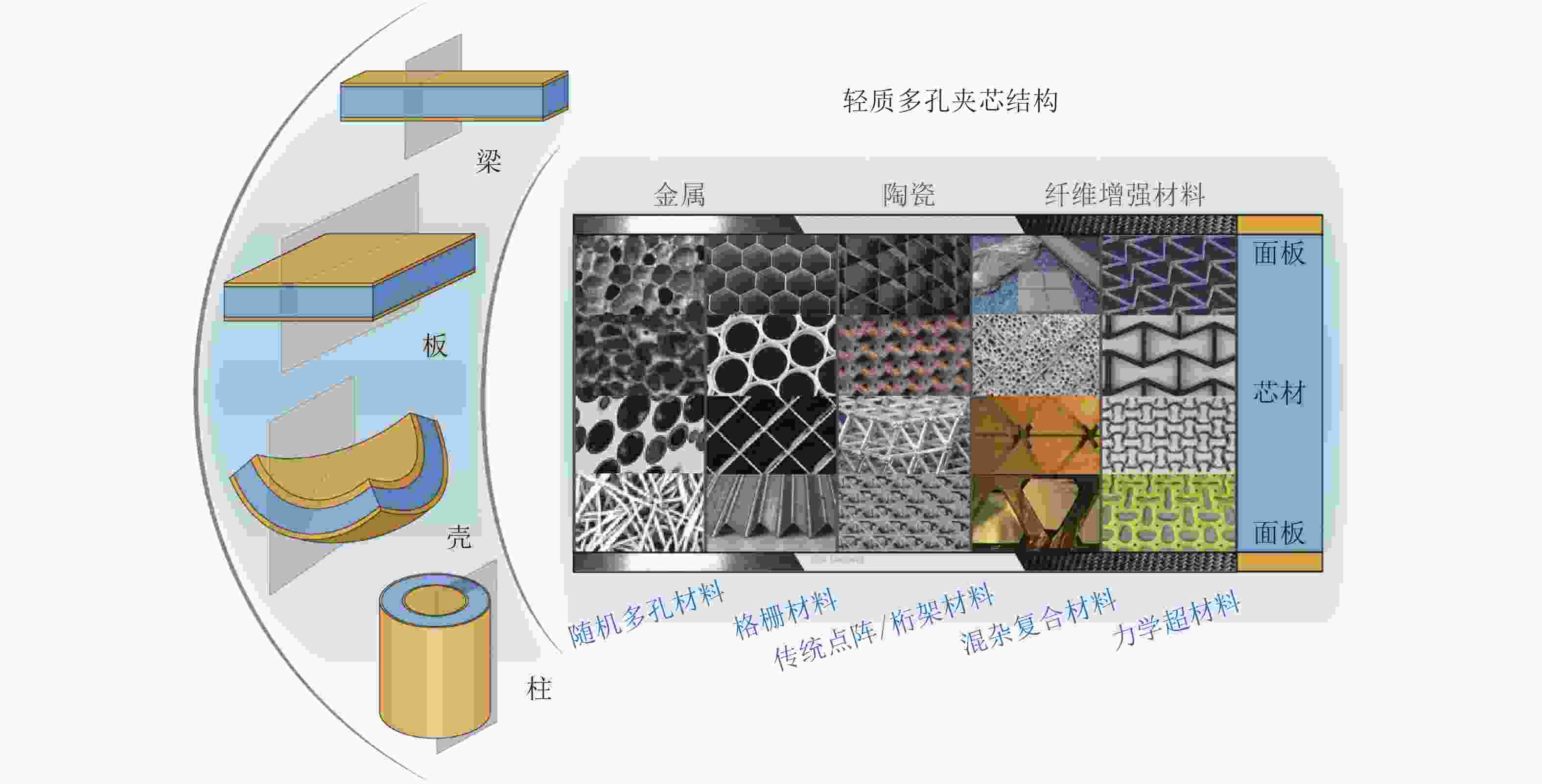

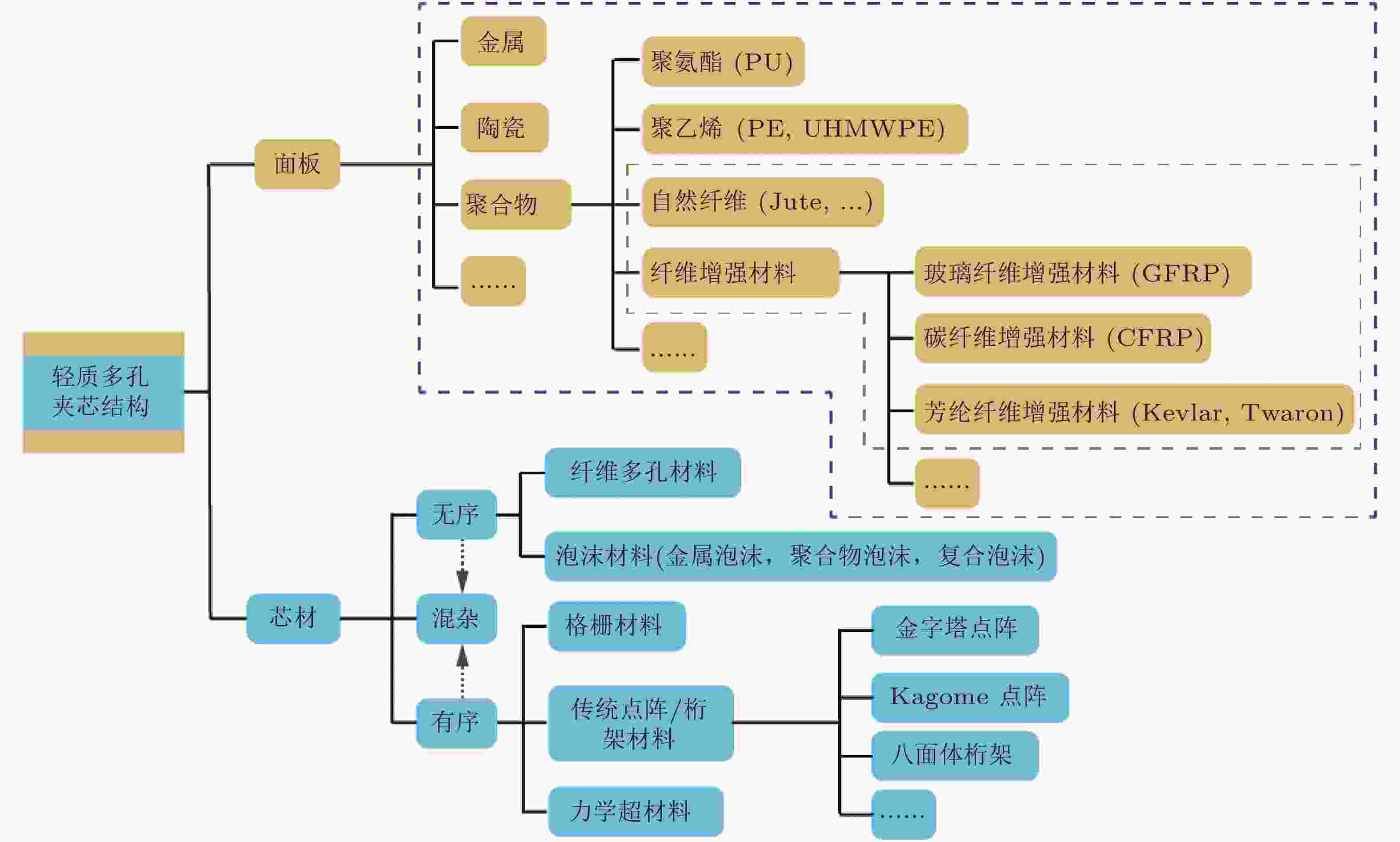

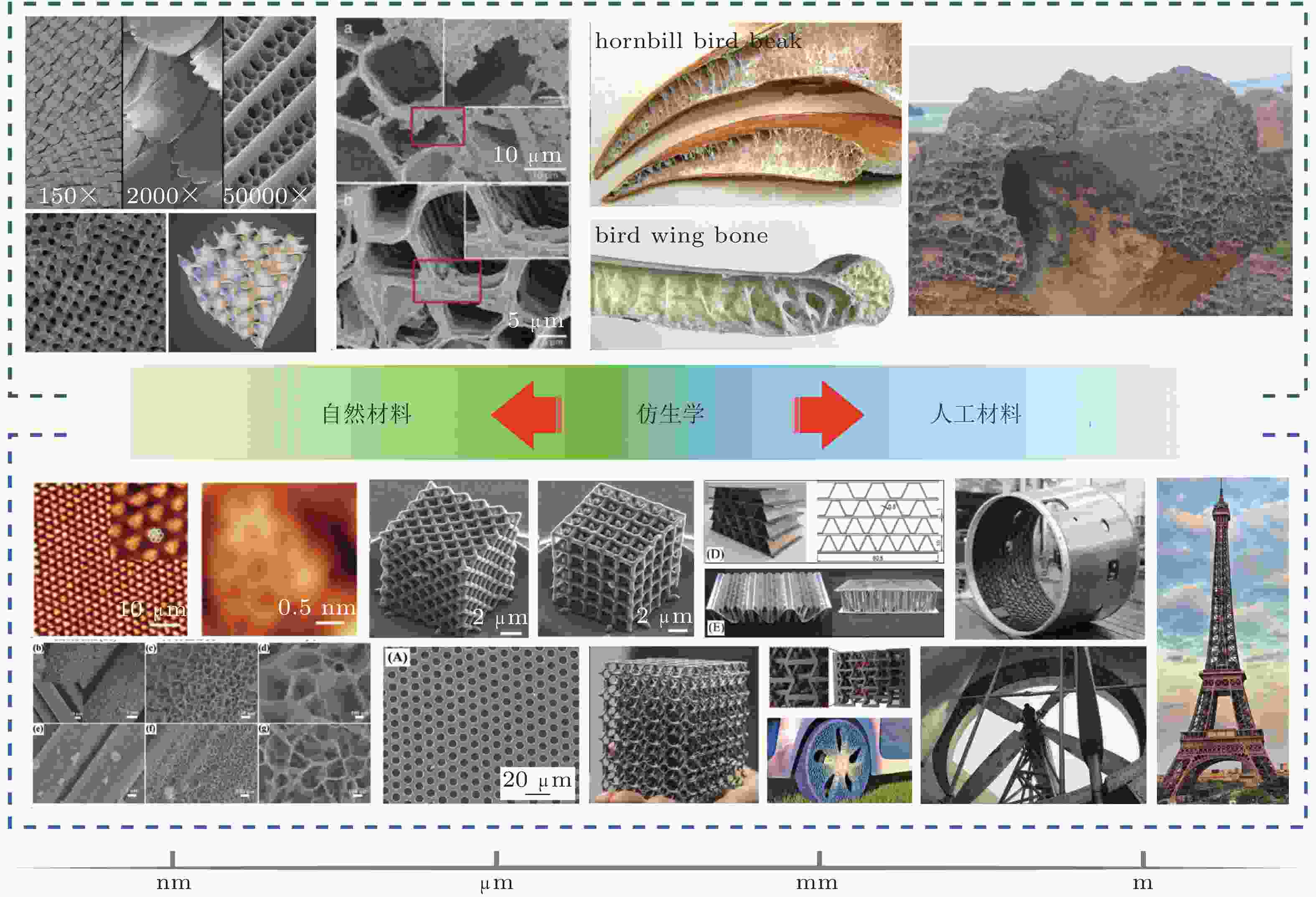

摘要: 多孔夹芯结构是一类由薄而刚硬的面板和多孔材料芯材构成的复合结构, 具有高比刚度、高比强度、缓冲吸能效果优异、可设计性强等特性, 在航空航天、交通运输、结构防护等诸多领域引起了广泛关注, 且已有诸多成功的工程应用案例, 是一类极具潜力的先进轻质高强多功能一体化结构. 为阐明轻质多孔夹芯结构的抗侵彻特性与耗能机理, 进一步拓展轻质多孔夹芯结构的工程应用范围, 对轻质多孔夹芯结构弹道侵彻行为的研究成果进行了系统的综述和展望, 依据轻质多孔夹芯结构的结构特征及类型, 分别评述了不同类型多孔夹芯结构的抗弹道侵彻破坏机制、能量耗散机理及轻量化设计等方面的研究, 展望了未来多孔夹芯结构在抗弹道侵彻研究领域面临的问题和挑战.Abstract: The classical cellular sandwich panels composed of two thin, stiff face sheets separated by a novel cellular core are a class of promising advanced lightweight multi-functional structures, possessing high specific stiffness, high specific strength, excellent mitigation and energy absorption, and high designability. Cellular sandwich structures have been paid much attention in many fields, such as the aerospace industry, transportation and structural protection. Moreover, the success cases have been presented in practical engineering applications. In order to clarify the mechanisms of penetration and energy dissipation and extend the application ranges, investigations on ballistic performance of lightweight cellular sandwich structures are reviewed and prospected. Firstly, the structural features and types of lightweight cellular sandwich structures are summarized. Next, mechanisms of penetration and energy dissipation, and lightweight design are reviewed systematically. Finally, the problems and challenges existing in the current research on ballistic performance of lightweight cellular sandwich structures are prospected.

-

Key words:

- sandwich structure /

- cellular material /

- ballistic limit /

- penetration /

- energy dissipation /

- damage mechanism /

- lightweight.

-

图 2 轻质多孔夹芯结构的应用. (a) CYCOM®EP2750复合材料夹芯结构 (图自索尔维公司) , (b) Pendolino高速列车车头(王杰 2013), (c) CH-46E海骑士运输直升机(Jackson et al. 2015), (d) 联盟号载人飞船返回舱座椅(荣伟 2018)和(e) 嫦娥三号探测器着陆支架(荣伟 2018)

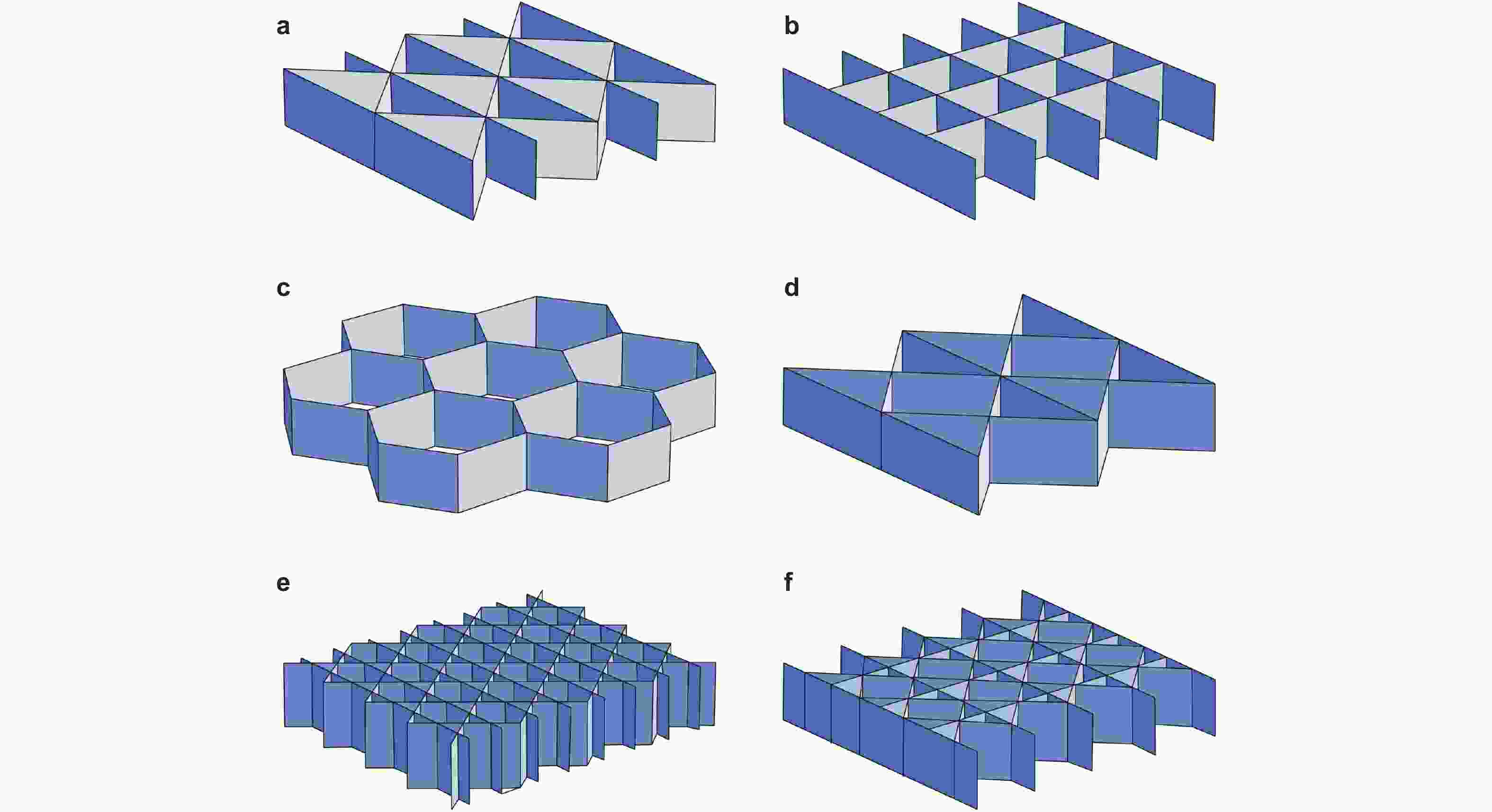

图 5 蜂窝夹芯结构的常见芯材构型(方岱宁等 2009). (a)三角形, (b)四边形, (c)六边形, (d)菱形, (e) Kagome型和(f) 正方静不定型

图 6 波纹夹芯结构的常见芯材构型. (a)三角形(Valdevit et al. 2004), (b)四边形(Valdevit et al. 2004), (c)梯形(Valdevit et al. 2004), (d)圆弧形(Valdevit et al. 2004), (e)正交波纹(Zhu et al. 2021)和(f)双向波纹(Yang et al. 2017)

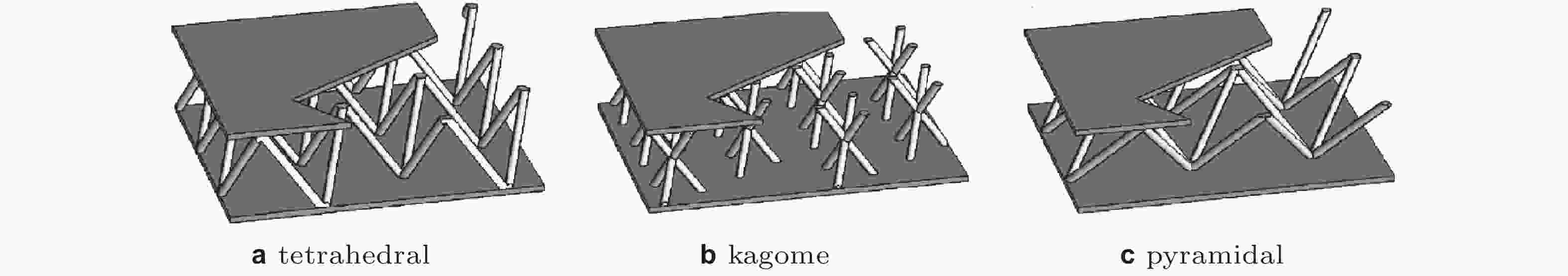

图 7 常见点阵材料构型(Wadley 2006)

图 8 力学超材料创新构型. (a) 平板点阵力学超材料(Berger et al. 2017), (b) TPMS力学超材料(Ketan et al. 2018), (c) 拉胀超材料(Rafsanjani & Pasini 2016), (d) 手性超材料(Zhu et al. 2016)和(e) 多稳态超材料(Shan et al. 2015)

图 9 多级力学超材料构型. (a)~(c)蜂窝多级超材料(Babak et al. 2013, Qin et al. 2020), (d)波纹多级超材料(Kooistra et al. 2007), (e)点阵多级超材料(Wang et al. 2023), (f)~(g) TPMS多级超材料(Zhang L et al. 2021)和(h)~(i)折纸超材料(Heimbs et al. 2009, Schenk et al. 2014)

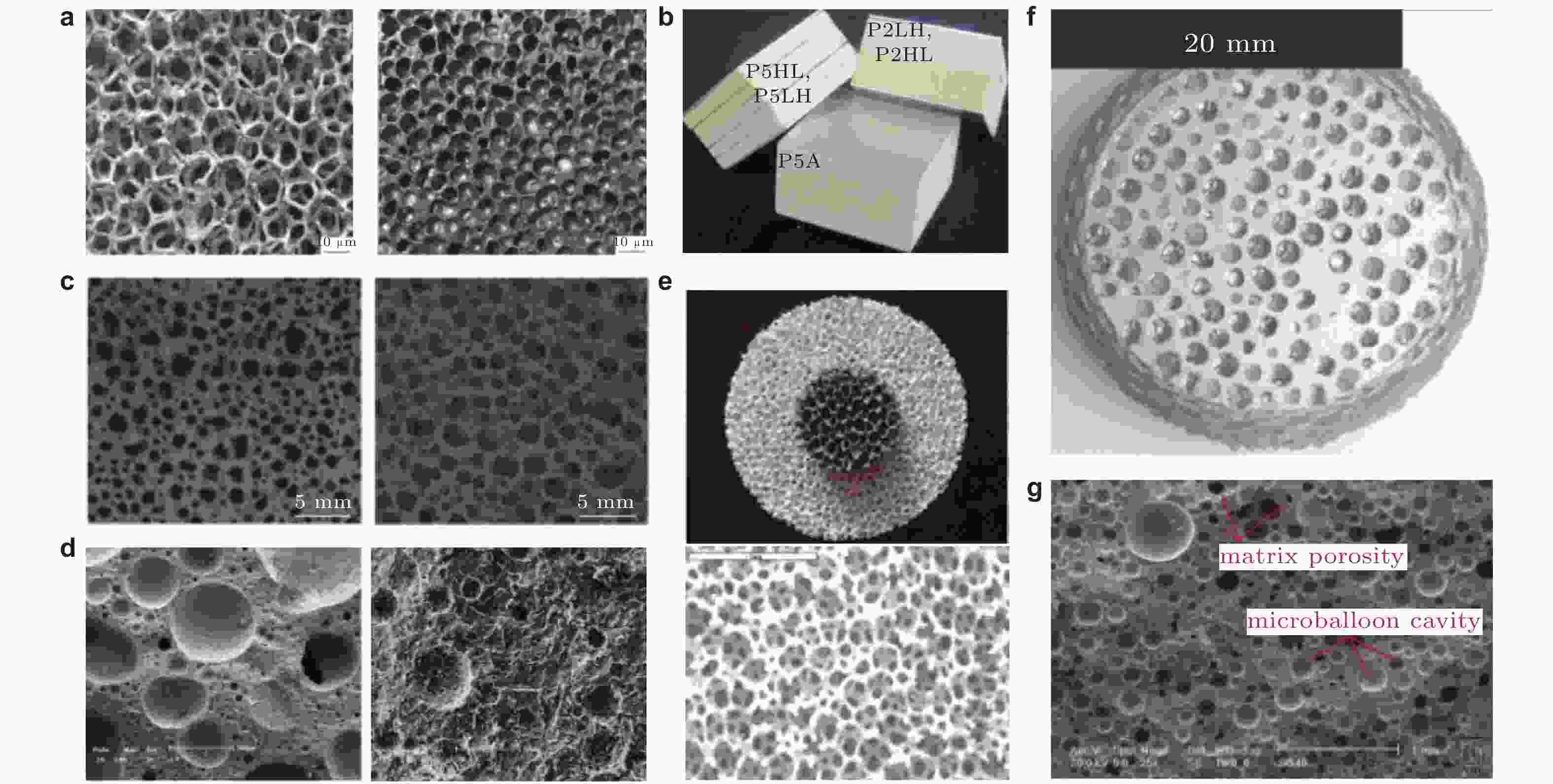

图 10 常见的泡沫材料. (a) 金属泡沫(张红英 等 2021), (b) 聚合物泡沫(Nia & Kazemi 2020), (c) 混凝土泡沫(张巍 和 王浩杰 2020), (d) 玻璃泡沫(冯宗玉 等 2008), (e) 陶瓷泡沫(郭秀荣 和 王雅慧 2012), (f) 金属复合泡沫(Alvandi-Tabrizi et al. 2015), (g) 聚合物复合泡沫(Ahmadi et al. 2020)

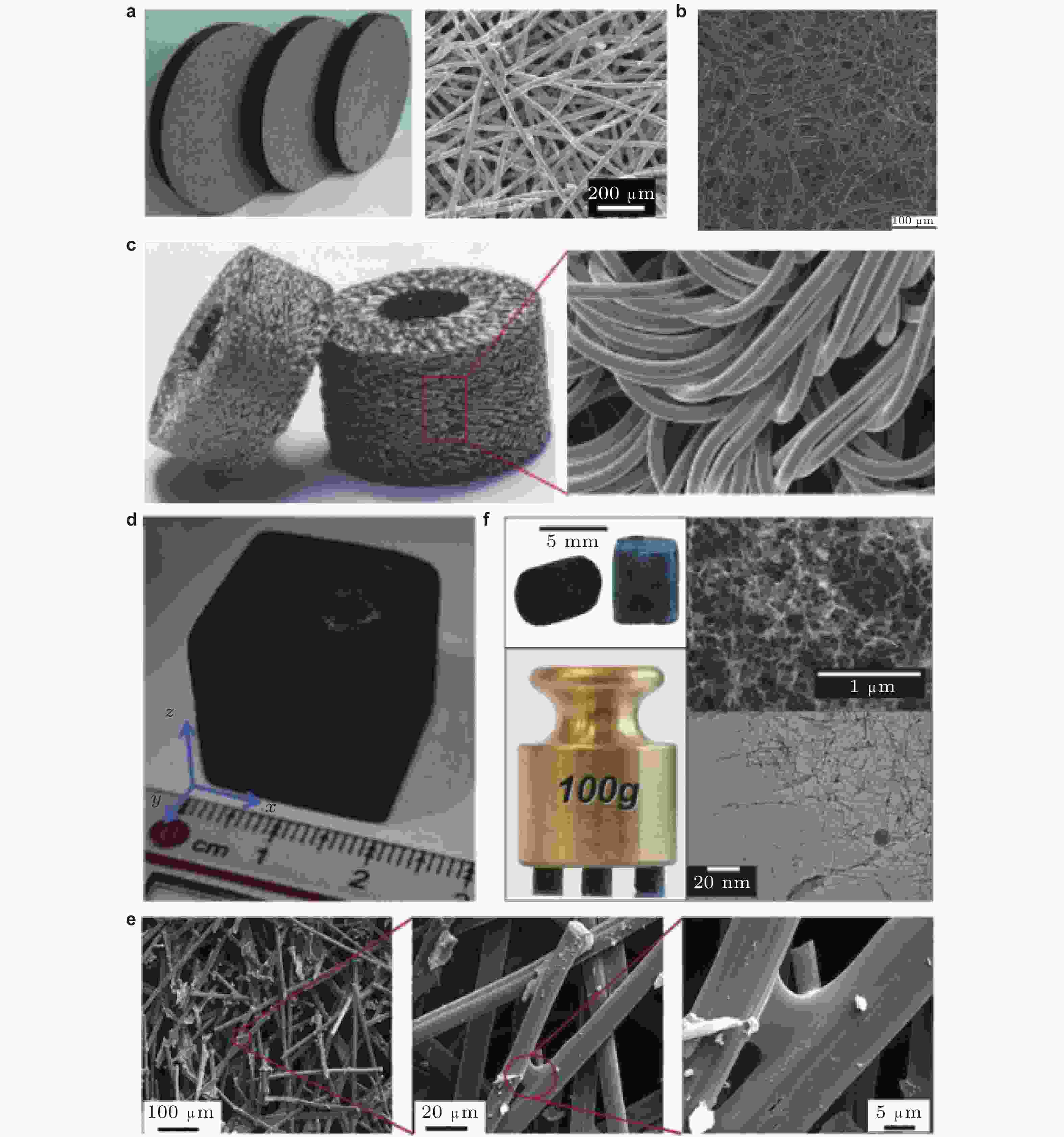

图 11 纤维多孔材料. (a) 金属纤维多孔材料(Cao et al. 2018), (b) 硅纤维多孔材料(Li et al. 2017), (c) 金属橡胶多孔材料(Ren et al. 2021)和(d)~(f)泡沫碳/碳纳米管纤维多孔材料(Bryning et al. 2007, Zhang et al. 2017)

图 12 常见的混杂轻质多孔夹芯结构. (a) 金属面板-聚合物泡沫混杂夹芯结构(Alavi Nia et al. 2017), (b) 复合面板-金属蜂窝混杂夹芯结构(Ryan et al. 2008), (c) 聚合物泡沫填充蜂窝混杂夹芯结构(Hassanpour Roudbeneh et al. 2018), (d) 陶瓷/聚合物填充点阵混杂夹芯结构(Ni et al. 2013), (e)金属泡沫填充格栅混杂夹芯结构(Yan et al. 2013), (f) 蜂窝填充格栅混杂夹芯结构(Han et al. 2016)和 (g) 泡沫填充点阵混杂夹芯结构(Han et al. 2017)

图 14 金属蜂窝夹芯结构在 (a~d) 面外(Goldsmith et al., 1997, Khaire et al. 2021, Kolopp et al. 2013, Sun et al. 2018)和 (e) 面内(Qi et al. 2013)侵彻作用下的典型失效模式

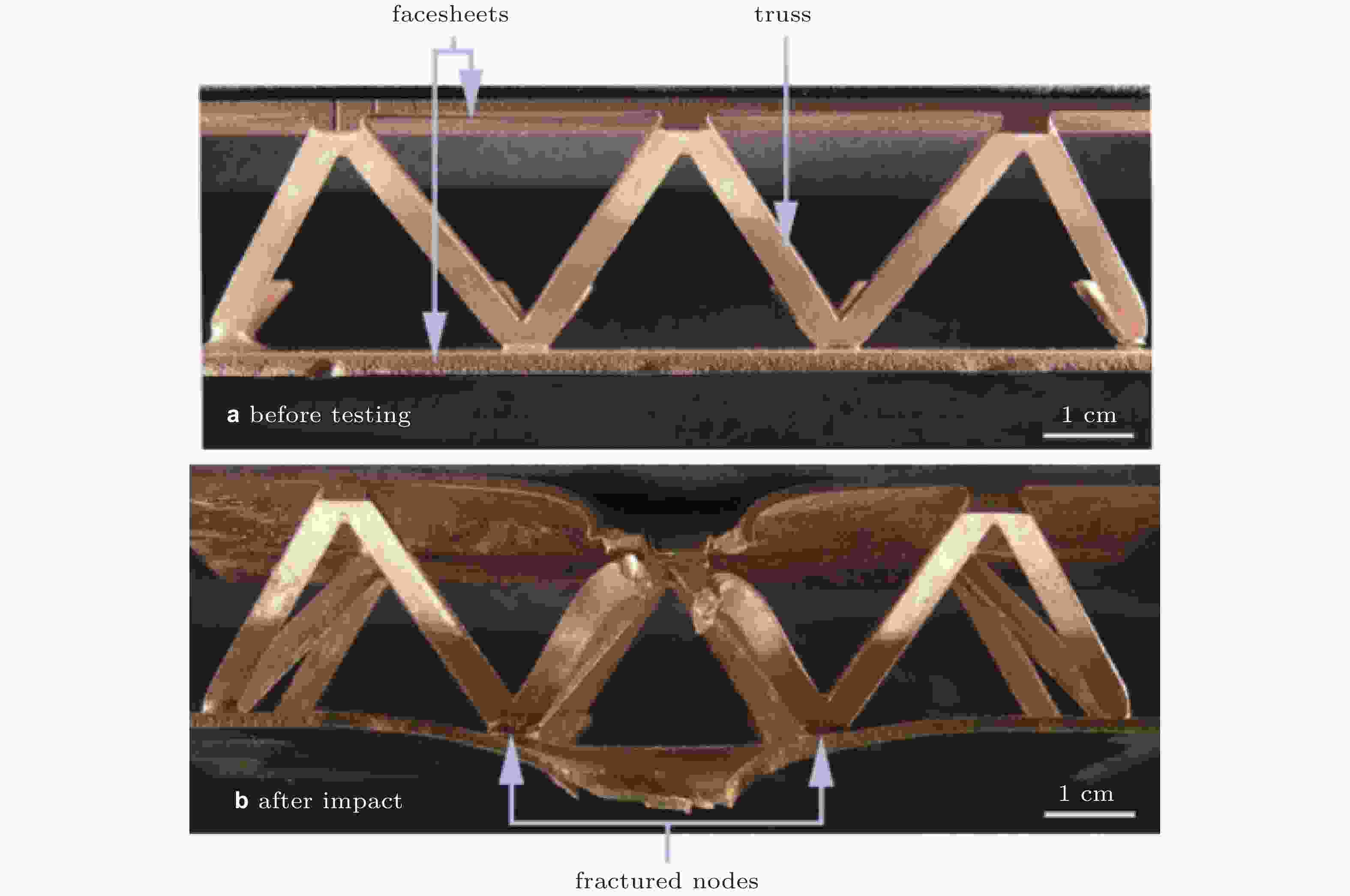

图 15 三角形金属波纹夹芯结构不同弹着点对应的 (a) 失效模式和 (b) 剩余速度曲线(Wadley et al. 2013)

图 16 铝合金金字塔点阵夹芯板在钢球侵彻作用下的失效模式(Yungwirth et al. 2008a)

图 17 (a) 压阻效应(杨德庆 等 2018), (b)二维内凹型负泊松比夹芯结构的侵彻过程数值模拟(Yang et al. 2013), (c)三维内凹型负泊松比夹芯结构的侵彻过程数值模拟(Imbalzano et al. 2017)以及(d)折纸型夹芯结构的侵彻失效模式(Zhang et al. 2021)

图 18 金属泡沫夹芯板在侵彻作用下的典型失效模式. (a) 不同面板厚度对夹芯板失效模式的影响(Hou et al. 2010), (b)夹芯板在球形弹侵彻作用下的花瓣型失效模式(郭亚周 等 2019), (c)夹芯板前面板在中高速弹体侵彻作用下出现的绝热剪切失效(方志威 等 2017), 以及(d)夹芯板后面板分别在锥头和平头弹侵彻作用下出现的花瓣型拉伸失效模式和翻盖型混合失效模式(Cui et al. 2022)

图 19 具有不同面板厚度配置的金属泡沫夹芯板在锥头弹体侵彻作用下的 (a) 变形失效过程和 (b) 各部件能量吸收变化规律以及平头弹体侵彻作用下的 (c) 变形失效过程和 (d) 各部件能量吸收变化规律(Cui et al. 2022)

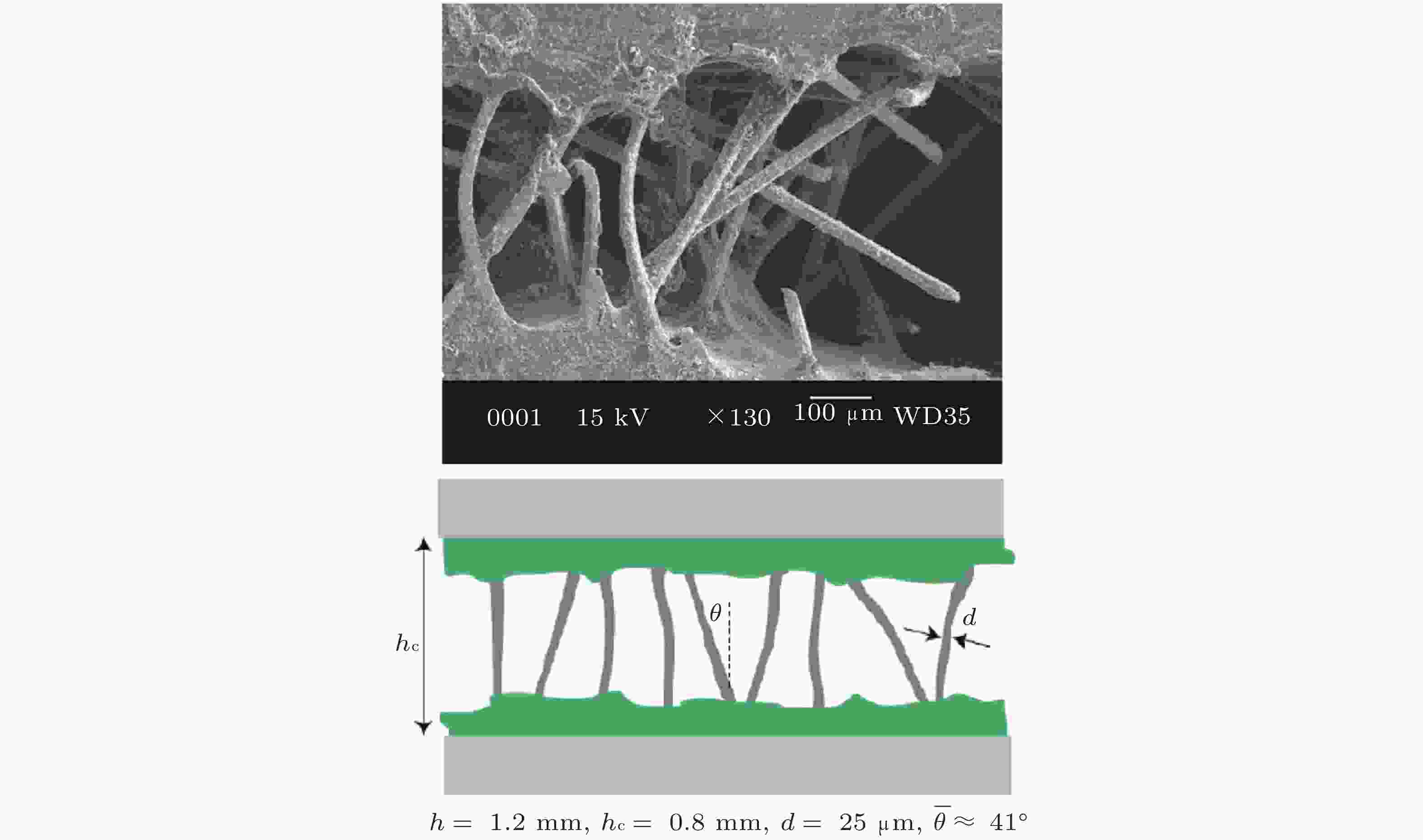

图 20 芯材厚度仅为0.8mm的金属纤维多孔夹芯板(Zhou & Stronge 2008)

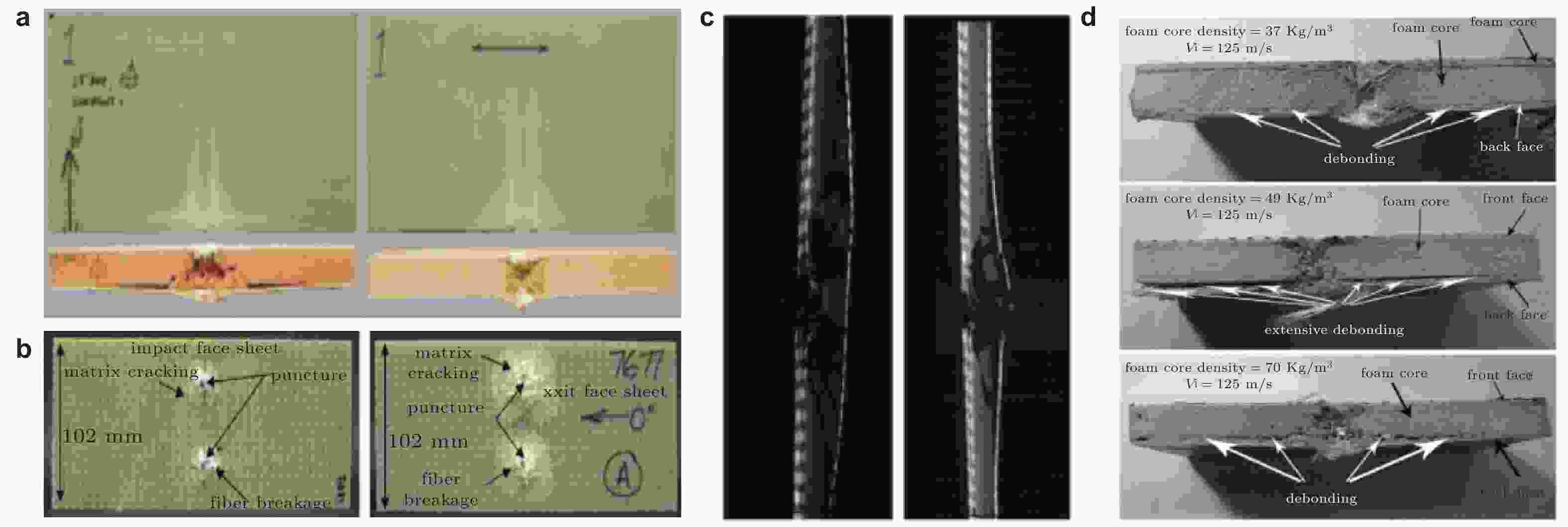

图 21 聚合物泡沫夹芯板在侵彻作用下的典型失效模式. (a) GFRP面板/PVC泡沫夹芯板(Kepler & Hansen 2007), (b) GFRP面板/SAN泡沫夹芯板(Jackson & Shukla 2011), (c) GFRP面板/空心球复合泡沫夹芯板(Paul et al. 2020), 以及(d)GFRP面板/PU泡沫夹芯板(Nasirzadeh & Sabet 2014)

图 22 具有中等密度聚合物泡沫芯材的夹芯板具有较强的抗弹道侵彻能力(Nasirzadeh & Sabet 2014)

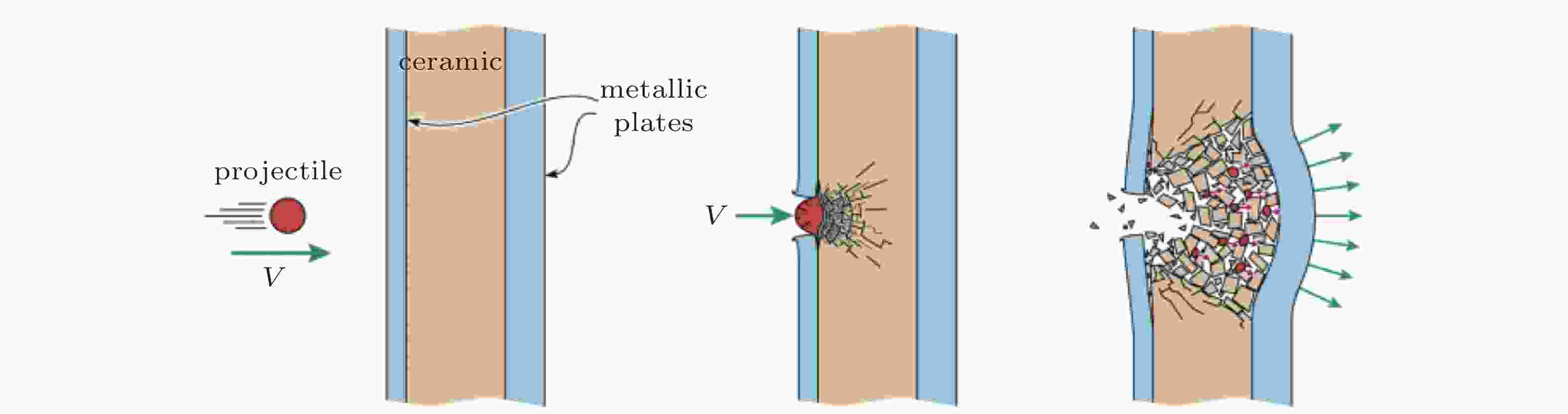

图 23 轻质混杂格栅多孔夹芯结构在侵彻作用下的典型失效模式. (a) Glare面板/金属蜂窝夹芯板(Hebsur et al. 2003), (b) PU泡沫填充金属蜂窝夹芯板(Hassanpour Roudbeneh et al. 2020), (c) 陶瓷填充金属波纹夹芯板(Wadley et al. 2013), 以及(d)复合材料包覆的陶瓷填充金属波纹夹芯板(O Masta et al. 2015)

图 24 轻质混杂点阵多孔夹芯结构在侵彻作用下的典型失效模式(Yungwirth et al. 2008a, Yungwirth et al. 2011). (a) 聚合物填充金字塔金属点阵夹芯板, (b)含有凯夫拉纤维层的聚合物填充金字塔金属点阵夹芯板, (c) 陶瓷填充金字塔金属点阵夹芯板, 以及(d)含有金属管的金字塔金属点阵夹芯板

图 25 陶瓷材料在弹体侵彻过程中的局部裂纹扩展吸能示意图(Yungwirth et al. 2011)

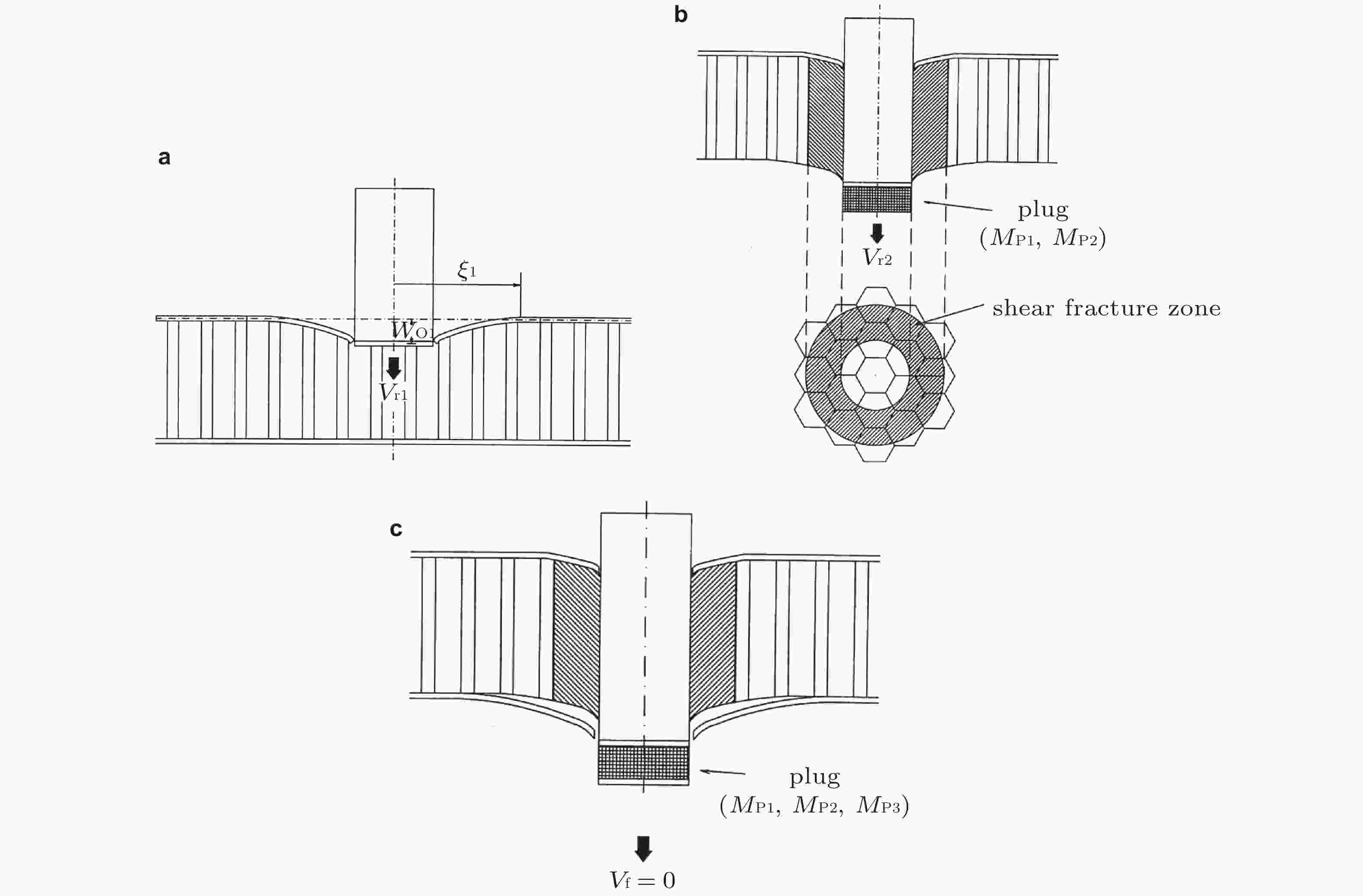

图 26 平头弹体侵彻蜂窝夹芯结构的三阶段侵彻模型(Hoo Fatt & Park 2000)

-

[1] 陈小伟. 2019. 穿甲/侵彻力学的理论建模与分析. 北京: 科学出版社Chen X W. 2019. Modelling on the Perforation and Penentration. Beijing: Science Press [2] 崔天宁. 2022. 轻质金属多孔夹芯结构的弹道极限行为研究[博士论文], 西安: 西安交通大学Cui T N. 2022. Investigation on ballistic limit of light-weighted sandwich structures with a metal foam core[PhD Thesis], Xi`an: Xi`an Jiaotong University. [3] 德米特里耶夫斯基. 2000. 外弹道学. 北京: 国防工业出版社 (Dmitryevsky. 2000. Exterior ballistics. Beijing: National defense industry press) [4] 邓云飞, 贾惠茹, 路明建, 张银波. 2021. 2A12铝合金圆波纹夹芯板抗平头弹冲击特性的试验研究. 中国机械工程, 32: 357-362 (Deng Y F, Jia H R, Lu M J, Zhang Y B. 2021. Experimental study of impact resistance of 2a12 aluminum alloy circular corrugated sandwich plates to blunt-nosed projectile. China Mechanical Engineering, 32: 357-362). doi: 10.3969/j.issn.1004-132X.2021.03.014Deng Y F, Jia H R, Lu M J, Zhang Y B. 2021. Experimental study of impact resistance of 2a12 aluminum alloy circular corrugated sandwich plates to blunt-nosed projectile. China Mechanical Engineering, 32: 357-362. doi: 10.3969/j.issn.1004-132X.2021.03.014 [5] 范华林, 金丰年, 方岱宁. 2008. 格栅结构力学性能研究进展. 力学进展, 38: 35-52 (Fan H L, Jin F N, Fang D N. 2008. Structural mechanics of lattice grids. Advances in Mechanics, 38: 35-52). doi: 10.6052/1000-0992-2008-1-J2007-068Fan H L, Jin F N, Fang D N. 2008. Structural mechanics of lattice grids. Advances in Mechanics, 38: 35-52. doi: 10.6052/1000-0992-2008-1-J2007-068 [6] 方岱宁, 张一慧, 崔晓东. 2009. 轻质点阵材料力学与多功能设计. 北京: 科学出版社 (Fang D N, Zhang Y H, Cui X D. 2009. Mechanics and multifunctional design of lightweight lattice materials. Beijing: Science press) [7] 方志威, 侯海量, 张元豪, 陈长海, 胡年明. 2017. 中高速弹体侵彻下泡沫铝夹芯结构抗侵彻性能实验研究. 舰船科学技术, 39: 12-17 (Fang Z W, Hou H L, Zhang Y H, Chen C H, Hu N M. 2017. Experimental investigation on aluminum foam sandwich structure under medium and high velocity bullet impact. Ship Science and Technology, 39: 12-17). doi: 10.3404/j.issn.1672-7649.2017.08.003Fang Z W, Hou H L, Zhang Y H, Chen C H, Hu N M. 2017. Experimental investigation on aluminum foam sandwich structure under medium and high velocity bullet impact. Ship Science and Technology, 39: 12-17. doi: 10.3404/j.issn.1672-7649.2017.08.003 [8] 冯宗玉, 薛向欣, 李勇. 2008. 利用油页岩渣制备微晶泡沫玻璃的研究. 材料导报, 22: 131-134 (Feng Z Y, Xue X X, Li Y. 2008. Study on preparation of foam glass-ceramic by oil shale residue. Materials Review, 22: 131-134).Feng Z Y, Xue X X, Li Y. 2008. Study on preparation of foam glass-ceramic by oil shale residue. Materials Review, 22: 131-134. [9] 郭锐, 周昊, 刘荣忠, 朱荣, 姜炜. 2016. 陶瓷棒填充点阵金属夹层结构的制备及抗侵彻实验. 复合材料学报, 33: 921-928 (Guo R, Zhou H, Liu R Z, Zhu R, Jiang W. 2016. Preparation and anti-penetration experiment of metal lattice truss cored sandwich structures filled with ceramic rods. Acta Materiae Compositae Sinica, 33: 921-928).Guo R, Zhou H, Liu R Z, Zhu R, Jiang W. 2016. Preparation and anti-penetration experiment of metal lattice truss cored sandwich structures filled with ceramic rods. Acta Materiae Compositae Sinica, 33: 921-928. [10] 郭秀荣, 王雅慧. 2012. 常用DPF过滤体材料发展现状及特性研究. 现代科学仪器, 1: 74-79 (Guo X R, Wang Y H. 2012. The development dtatus and characteristics of commonly used DPF filter material. Modern Scientific Instruments, 1: 74-79).Guo X R, Wang Y H. 2012. The development dtatus and characteristics of commonly used DPF filter material. Modern Scientific Instruments, 1: 74-79. [11] 郭亚周, 刘小川, 何思渊, 王计真, 杨海. 2019. 不同弹形撞击下泡沫铝夹芯结构动力学性能研究. 兵工学报, 40: 2032-2041 (Guo Y Z, Liu X C, He S Y, Wang J Z, Yang H. 2019. Research on dynamic properties of aluminum foam sandwich structure impacted by projectiles with different shapes. Acta Armamentarii, 40: 2032-2041). doi: 10.3969/j.issn.1000-1093.2019.10.008Guo Y Z, Liu X C, He S Y, Wang J Z, Yang H. 2019. Research on dynamic properties of aluminum foam sandwich structure impacted by projectiles with different shapes. Acta Armamentarii, 40: 2032-2041. doi: 10.3969/j.issn.1000-1093.2019.10.008 [12] 过超强, 赵桂平. 2013. 复合装甲抗侵彻性能的数值分析. 应用力学学报, 30: 96-99 (Guo C Q, Zhao G P. 2013. Numerical simulation of ballistic impact on composite armours. Chinese Journal of Applied Mechanics, 30: 96-99). doi: 10.11776/cjam.30.01.B126Guo C Q, Zhao G P. 2013. Numerical simulation of ballistic impact on composite armours. Chinese Journal of Applied Mechanics, 30: 96-99. doi: 10.11776/cjam.30.01.B126 [13] 胡波, 薛金星, 闫大庆. 2004. 空间站结构材料及设计研究. 纤维复合材料, 21: 60-64 (Hu B, Xue J X, Yan D Q. 2004. Structural materials and design study for space station. Fiber Composites, 21: 60-64).Hu B, Xue J X, Yan D Q. 2004. Structural materials and design study for space station. Fiber Composites, 21: 60-64. [14] 胡静, 路明建, 张永, 张银波. 2018. 弹体头部形状对铝蜂窝夹芯板侵彻特性的影响. 机械强度, 40: 822-826 (Hu J, Lu M J, Zhang Y, Zhang Y B. 2018. Influence of the nose shape of projectiles on the penetration characteristics of aluminum honeycomb sandwich plates. Journal of Mechanical Strength, 40: 822-826).Hu J, Lu M J, Zhang Y, Zhang Y B. 2018. Influence of the nose shape of projectiles on the penetration characteristics of aluminum honeycomb sandwich plates. Journal of Mechanical Strength, 40: 822-826. [15] 金声明, 袁亚雄. 1983. 内弹道气动力原理. 北京: 国防工业出版社 (Jin S M, Yuan Y X. 1983. Interior ballistic aerodynamic principle. Beijing: National defense industry press) [16] 倪长也, 金峰, 卢天健. 2009. 超轻金属点阵三明治板结构抗侵彻性能分析. 兵工学报, 30: 94-97 (Ni C Y, Jin F, Lu T J. 2009. Numerical simulation of the ballistic performance of composite pyramidal lattice truss structure. Acta Armamentarii, 30: 94-97).Ni C Y, Jin F, Lu T J. 2009. Numerical simulation of the ballistic performance of composite pyramidal lattice truss structure. Acta Armamentarii, 30: 94-97. [17] 倪长也, 金峰, 卢天健, 李裕春. 2010. 3种点阵金属三明治板的抗侵彻性能模拟分析. 力学学报, 42: 1125-1137 (Ni C Y, Jin F, Lu T J, Li Y C. 2010. Penetration and perforation performance of three pyramidal lattice-cored sandwich plates: numerical simulations. Chinese Journal of Theoretical and Applied Mechanics, 42: 1125-1137).Ni C Y, Jin F, Lu T J, Li Y C. 2010. Penetration and perforation performance of three pyramidal lattice-cored sandwich plates: numerical simulations. Chinese Journal of Theoretical and Applied Mechanics, 42: 1125-1137. [18] 牛卫晶. 2015. 冲击载荷下泡沫铝夹芯防护结构的侵彻动力学行为研究[博士论文], 太原: 太原理工大学Niu W J. 2015. Research on the penetration behavior of sandwich protective structures with aluminum foam cores under impact loading [PhD Thesis], Taiyuan: Taiyuan University of Technology. [19] 牛正一, 安振涛, 王维娜. 2021. 典型泡沫铝夹芯材料的枪弹侵彻仿真与实验. 兵工自动化, 40: 50-54 (Niu Z Y, An Z T, Wang W N. 2021. Simulation and experiment of projectile penetration of typical sandwich materials with aluminum foam core. Ordnance Industry Automation, 40: 50-54).Niu Z Y, An Z T, Wang W N. 2021. Simulation and experiment of projectile penetration of typical sandwich materials with aluminum foam core. Ordnance Industry Automation, 40: 50-54. [20] 彭捷, 路明建, 邓云飞. 2018. 钝头弹撞击不同材质蜂窝夹芯板的损伤特性研究. 机械设计与制造, S2: 126-129 (Peng J, Lu M J, Deng Y F. 2018. Study on damage characteristics of honeycomb sandwich plates with different material lmpacted by blunt-nosed projectiles. Machinery Design & Manufacture, S2: 126-129). doi: 10.19356/j.cnki.1001-3997.2018.s2.034Peng J, Lu M J, Deng Y F. 2018. Study on damage characteristics of honeycomb sandwich plates with different material lmpacted by blunt-nosed projectiles. Machinery Design & Manufacture, S2 : 126-129. doi: 10.19356/j.cnki.1001-3997.2018.s2.034 [21] 钱伟长. 1984. 穿甲力学. 北京: 国防工业出版社 (Qian W C. 1984. Armor piercing mechanics. Beijing: National defense industry press) [22] 荣伟. 2018. 航天器进入下降与着陆技术. 北京: 北京理工大学出版社Rong W. 2018. Spacecraft Entry, Descent and Landing Technology. Beijing: Beijing Institute of Technology Press. [23] 夏元明, 张威, 崔天宁, 张建勋, 王彬文, 刘小川, 白春玉, 秦庆华. 2019. 金属多级类蜂窝的压溃行为研究. 力学学报, 51: 873-883 (Xia Y M, Zhang W, Cui T N, Zhang J X, Wang B W, Liu X C, Bai C Y, Qin Q H. 2019. Investigation on crushing behavior of metal honeycomb-like hierarchical structures. Chinese Journal of Theoretical and Applied Mechanics, 51: 873-883). doi: 10.6052/0459-1879-18-434Xia Y M, Zhang W, Cui T N, Zhang J X, Wang B W, Liu X C, Bai C Y, Qin Q H. 2019. Investigation on crushing behavior of metal honeycomb-like hierarchical structures. Chinese Journal of Theoretical and Applied Mechanics, 51: 873-883. doi: 10.6052/0459-1879-18-434 [24] 王杰. 2013. 复合材料泡沫夹层结构低速冲击与冲击后压缩性能研究[博士论文], 上海: 上海交通大学Wang J. 2013. Study on the low-velocity impact and compression after impact behavior of foam core sandwich panels[PhD Thesis], Shanghai: Shanghai Jiao Tong University. [25] 王树山. 2019. 终点效应学 第2版. 北京: 科学出版社Wang S S. 2019. Terminal Effects. Beijing: Science Press. [26] 吴志恩. 2008. 波音787的复合材料构件生产. 航空制造技术, 1: 92-94 (Wu Z E. 2008. Production for composite component of boeing 787. Aeronautical Manufacturing Technology, 1: 92-94). doi: 10.3969/j.issn.1671-833X.2008.03.020Wu Z E. 2008. Production for composite component of boeing 787. Aeronautical Manufacturing Technology, 1: 92-94. doi: 10.3969/j.issn.1671-833X.2008.03.020 [27] 杨德庆, 马涛, 张梗林. 2015. 舰艇新型宏观负泊松比效应蜂窝舷侧防护结构. 爆炸与冲击, 35: 243-248 (Yang D Q, Ma T, Zhang G L. 2015. A novel auxetic broadside defensive structure for naval ships. Explosion and Shock Waves, 35: 243-248). doi: 10.11883/1001-1455(2015)02-0243-06Yang D Q, Ma T, Zhang G L. 2015. A novel auxetic broadside defensive structure for naval ships. Explosion and Shock Waves, 35: 243-248. doi: 10.11883/1001-1455(2015)02-0243-06 [28] 杨德庆, 张相闻, 吴秉鸿. 2018. 负泊松比效应防护结构抗爆抗冲击性能影响因素. 上海交通大学学报, 52: 379-387 (Yang D Q, Wu B H, Zhang X W. 2018. The influence factors of explosion and shock resistance performance of auxetic sandwich defensive structures. Journal of Shanghai Jiaotong University, 52: 379-387).Yang D Q, Wu B H, Zhang X W. 2018. The influence factors of explosion and shock resistance performance of auxetic sandwich defensive structures. Journal of Shanghai Jiaotong University, 52: 379-387. [29] 杨德庆, 吴秉鸿, 张相闻. 2019. 星型负泊松比超材料防护结构抗爆抗冲击性能研究. 爆炸与冲击, 39: 122-133 (Yang D Q, Wu B H, Zhang X W. 2019. Anti-explosion and shock resistance performance of sandwich defensive structure with star-shaped auxetic material core. Explosion and Shock Waves, 39: 122-133).Yang D Q, Wu B H, Zhang X W. 2019. Anti-explosion and shock resistance performance of sandwich defensive structure with star-shaped auxetic material core. Explosion and Shock Waves, 39: 122-133. [30] 杨飞, 王志华, 赵隆茂. 2011. 泡沫铝夹芯板抗侵彻性能的数值研究. 科学技术与工程, 11: 3377-3383Yang F, Wang Z H, Zhao L M. 2011. Numerical simulation on anti-penetration performance of aluminum foam. based sandwich panels. Science Technology and Engineering, 11: 3377-3383. [31] 于天淼, 高华兵, 王春鹤, 范琦琪, 曹梦馨, 姜风春, 果春焕. 2019. 金属空心球复合材料的研究进展. 中国材料进展, 38: 1102-1112 (Yu T M, Gao H B, Wang C H, Fan Q Q, Cao M X, Jiang F C, Guo C H. 2019. Research progress of metallic hollow sphere composites. Materials China, 38: 1102-1112). doi: 10.7502/j.issn.1674-3962.201804012Yu T M, Gao H B, Wang C H, Fan Q Q, Cao M X, Jiang F C, Guo C H. 2019. Research progress of metallic hollow sphere composites. Materials China, 38: 1102-1112. doi: 10.7502/j.issn.1674-3962.201804012 [32] 余同希, 朱凌, 许骏. 2021. 结构冲击动力学进展(2010-2020). 爆炸与冲击, 41: 4-64 (Yu T X, Zhu L, Xu J. 2021. Progress in structural impact dynamics during 2010−2020. Explosion and Shock Waves, 41: 4-64).Yu T X, Zhu L, Xu J. 2021. Progress in structural impact dynamics during 2010−2020. Explosion and Shock Waves, 41: 4-64. [33] 张红英, 欧阳八生, 朱国军. 2021. 泡沫铝材料的研究与应用. 粉末冶金技术, 39: 69-75 (Zhang H Y, Ouyang B S, Zhu G J. 2021. Research and application of aluminum foam materials. Powder Metallurgy Technology, 39: 69-75).Zhang H Y, Ouyang B S, Zhu G J. 2021. Research and application of aluminum foam materials. Powder Metallurgy Technology, 39: 69-75. [34] 张俊, 郭锐, 刘荣忠, 胡志鹏, 孙学武. 2012. 金属桁架增强陶瓷复合装甲抗弹性能研究. 南京理工大学学报, 36: 773-778 (Zhang J, Guo R, Liu R Z, Hu Z P, Sun X W. 2012. Anti-bullet property of metal truss structures enhanced ceramic composite armor. Journal of Nanjing University of Science and Technology, 36: 773-778).Zhang J, Guo R, Liu R Z, Hu Z P, Sun X W. 2012. Anti-bullet property of metal truss structures enhanced ceramic composite armor. Journal of Nanjing University of Science and Technology, 36: 773-778. [35] 张巍, 王浩杰. 2020. 掺稻壳灰泡沫混凝土的制备与性能研究. 硅酸盐通报, 39: 2795-2799 (Zhang W, Wang H J. 2020. Preparation and Properties of Foam Concrete Containing Rice Husk Ash. Bulletin of the Chinese Ceramic Society, 39: 2795-2799).Zhang W, Wang H J. 2020. Preparation and Properties of Foam Concrete Containing Rice Husk Ash. Bulletin of the Chinese Ceramic Society, 39: 2795-2799. [36] 张璇, 李晓雁. 2021. 微纳米点阵力学超材料的设计和性能. 力学与实践, 43: 164-168 (Zhang X, Li X Y. 2021. Design and mechanical property of micro-/nano-scale architected metamaterials. Mechanics in Engineering, 43: 164-168). doi: 10.6052/1000-0879-20-100Zhang X, Li X Y. 2021. Design and mechanical property of micro-/nano-scale architected metamaterials. Mechanics in Engineering, 43: 164-168. doi: 10.6052/1000-0879-20-100 [37] 张元豪, 程忠庆, 方志威, 侯海量, 朱锡. 2019. 泡沫铝夹芯结构对中低速FSP的抗侵彻特性研究. 振动与冲击, 38: 231-235 (Zhang Y H, Cheng Z Q, Fang Z W, Hou H L, Zhu X. 2019. Aluminum foam sandwich structures subjected to the impact by low-medium velocity FSP. Journal of Vibration and Shock, 38: 231-235). doi: 10.13465/j.cnki.jvs.2019.22.033Zhang Y H, Cheng Z Q, Fang Z W, Hou H L, Zhu X. 2019. Aluminum foam sandwich structures subjected to the impact by low-medium velocity FSP. Journal of Vibration and Shock, 38: 231-235. doi: 10.13465/j.cnki.jvs.2019.22.033 [38] 赵桂平, 卢天健. 2008. 多孔金属夹层板在冲击载荷作用下的动态响应. 力学学报, 40: 194-206 (Zhao G P, Lu T J. 2008. Dynamic response of cellular metallic sandwich plates under impact loading. Chinese Journal of Theoretical and Applied Mechanics, 40: 194-206). doi: 10.6052/0459-1879-2008-2-2007-129Zhao G P, Lu T J. 2008. Dynamic response of cellular metallic sandwich plates under impact loading. Chinese Journal of Theoretical and Applied Mechanics, 40: 194-206. doi: 10.6052/0459-1879-2008-2-2007-129 [39] 赵文宣. 1989. 终点弹道学. 北京: 兵器工业出版社. [40] 朱源, 张建勋, 秦庆华. 2020. 金属正交波纹夹芯结构的动态压缩响应. 爆炸与冲击, 40: 54-65 (Zhu Y, Zhang J, Qin Q H. 2020. Dynamic compressive response of metal orthogonal corrugated sandwich structure. Explosion and Shock Waves, 40: 54-65).Zhu Y, Zhang J, Qin Q H. 2020. Dynamic compressive response of metal orthogonal corrugated sandwich structure. Explosion and Shock Waves, 40: 54-65. [41] Ahmadi H, Liaghat G. 2019. Analytical and experimental investigation of high velocity impact on foam core sandwich panel. Polymer Composites, 40: 2258-2272. doi: 10.1002/pc.25034 [42] Alvandi-Tabrizi Y, Whisler D A, Kim H, Rabiei A. 2015. High strain rate behavior of composite metal foams. Materials Science and Engineering:A, 631: 248-257. doi: 10.1016/j.msea.2015.02.027 [43] Ahmadi H, Liaghat G, Charandabi S C. 2020. High velocity impact on composite sandwich panels with nano-reinforced syntactic foam core. Thin-Walled Struct., 148: 106599. doi: 10.1016/j.tws.2019.106599 [44] Alavi Nia A, Ranjbarzadeh H, Kazemi M. 2017. An empirical study on ballistic resistance of sandwich targets with aluminum facesheets and composite core. Lat. Am. J. Solids Struct., 14: 1085-1105. doi: 10.1590/1679-78253390 [45] Arslan K, Gunes R, Apalak M K, Reddy J N. 2017. Experimental tests and numerical modeling of ballistic impact on honeycomb sandwich structures reinforced by functionally graded plates. J. Compos Mater., 51: 4009-4028. doi: 10.1177/0021998317695423 [46] Aryal B, Morozov E V, Shankar K. 2020. Effects of ballistic impact damage on mechanical behaviour of composite honeycomb sandwich panels. J. Sandw. Struct. Mater., 23: 2064-2085. [47] Buitrago B L, García-Castillo S K, Barbero E. 2010. Experimental analysis of perforation of glass/polyester structures subjected to high-velocity impact. Mater, Lett.: 64,1052-1054. [48] Babak H, Ramin O, Jim P, Ashkan V. 2013. Self-similar hierarchical honeycombs. Proceedings:Mathematical, Physical and Engineering Sciences, 469: 1-19. [49] Berger J B, Wadley H N G, Mcmeeking R M. 2017. Mechanical metamaterials at the theoretical limit of isotropic elastic stiffness. Nature, 543: 533-537. doi: 10.1038/nature21075 [50] Børvik T, Clausen A H, Eriksson M, Berstad T, Sture Hopperstad O, Langseth M. 2005. Experimental and numerical study on the perforation of AA6005-T6 panels. Int. J. Impact Eng., 32: 35-64. doi: 10.1016/j.ijimpeng.2005.05.001 [51] Bryning M B, Milkie D E, Islam M F, Hough L A, Kikkawa J M, Yodh A G. 2007. Carbon Nanotube Aerogels. Adv. Mater., 19: 661-664. doi: 10.1002/adma.200601748 [52] Cao L T, Fu Q X, Si Y, Ding B, Yu J Y. 2018. Porous materials for sound absorption. Compos. Commun., 10: 25-35. doi: 10.1016/j.coco.2018.05.001 [53] Chen L M, Du B, Zhang J, Zhou H, Li D S, Fang D N. 2016. Numerical Study on the Projectile Impact Resistance of Multi-Layer Sandwich Panels with Cellular Cores. Lat. Am. J. Solids Struct., 13: 2876-2895. doi: 10.1590/1679-78252905 [54] Chen P C, Niu W J, Yan X P, Lu G Y. 2018. Theoretical model for dynamic response of aluminum foam sandwich targets by truncated cone-nosed projectiles. J. Sandw. Struct. Mater., 20: 249-267. doi: 10.1177/1099636216664288 [55] Cui T N, Zhang J H, Li K K, Peng J X, Chen H E, Qin Q H, Poh L H. 2022. Ballistic limit of sandwich plates with a metal foam core. J. Appl. Mech. -Trans. ASME, 89: 1-21. [56] Cui J, Ye R C, Zhao N, Wu J, Wang M H. 2018. Assessment on energy absorption of double layered and sandwich plates under ballistic impact. Thin-Walled Struct, 130: 520-534. doi: 10.1016/j.tws.2018.06.007 [57] Dean J, S-Fallah A, Brown P M, Louca L A, Clyne T W. 2011. Energy absorption during projectile perforation of lightweight sandwich panels with metallic fibre cores. Compos. Struct., 93: 1089-1095. [58] Dahiwale N B, Panigrahi S K, Akella K. 2015. Numerical analyses of sandwich panels with triangular core subjected to impact loading. J. Sandw. Struct. Mater., 17: 238-257. doi: 10.1177/1099636214565190 [59] Deshpande V S, Fleck N A, Ashby M F. 2001. Effective properties of the octet-truss lattice material. J. Mech. Phys. Solids, 49: 1747-1769. doi: 10.1016/S0022-5096(01)00010-2 [60] Evans A G, Hutchinson J W, Fleck N A, Ashby M F, Wadley H N. 2001. The topological design of multifunctional cellular metals. Prog. Mater. Sci., 46: 309-327. doi: 10.1016/S0079-6425(00)00016-5 [61] Fang J G, Sun G Y, Qiu N, Pang T, Li S F, Li Q. 2018. On hierarchical honeycombs under out-of-plane crushing. International Journal of Solids & Structures, 135: 1-13. [62] Feli S, Namdari Pour M H. 2012. An analytical model for composite sandwich panels with honeycomb core subjected to high-velocity impact. Composites Part B:Engineering, 43: 2439-2447. doi: 10.1016/j.compositesb.2011.11.028 [63] Garcia-Avila M, Portanova M, Rabiei A. 2015. Ballistic performance of composite metal foams. Compos. Struct., 125: 202-211. [64] Goldsmith W, Wang G T, Li K, Crane D. 1997. Perforation of cellular sandwich plates. Int J Impact Eng, 19, 361-379. [65] Ghalami-Choobar M, Sadighi M. 2014. Investigation of high velocity impact of cylindrical projectile on sandwich panels with fiber–metal laminates skins and polyurethane core. Aerosp. Sci. Technol., 32: 142-152. doi: 10.1016/j.ast.2013.12.005 [66] Gibson L J, Ashby M F. 1988. Cellular solids: Structure and properties. UK: Oxford Press. [67] Gu Z P, Wu X Q, Li Q M. 2020. Dynamic compressive behaviour of sandwich panels with lattice truss core filled by shear thickening fluid. Int. J. Impact Eng., 143: 103616. doi: 10.1016/j.ijimpeng.2020.103616 [68] Hoo Fatt M S, Park K S. 2000. Perforation of honeycomb sandwich plates by projectiles. Compos Pt A-Appl Sci Manuf, 31, 889-899. [69] Hebsur M G, Noebe R D, Revilock D M. 2003. Impact resistance of lightweight hybrid structures for gas turbine engine fan containment applications. J. Mater. Eng. Perform., 12, 470-479. [70] Hoo Fatt M S, Sirivolu D. 2010. A wave propagation model for the high velocity impact response of a composite sandwich panel. Int. J. Impact Eng., 37, 117-130. [71] Hou W H, Zhu F, Lu G X, Fang D N. 2010. Ballistic impact experiments of metallic sandwich panels with aluminium foam core. Int. J. Impact Eng., 37, 1045-1055. [72] Han B, Qin K, Yu B, Wang B, Zhang Q, Lu T J. 2016. Honeycomb-corrugation hybrid as a novel sandwich core for significantly enhanced compressive performance. Mater. Des., 93: 271-282. doi: 10.1016/j.matdes.2015.12.158 [73] Han B, Zhang Z J, Zhang Q C, Zhang Q, Lu T J, Lu B H. 2017. Recent advances in hybrid lattice-cored sandwiches for enhanced multifunctional performance. Extreme. Mech. Lett., 10: 58-69. doi: 10.1016/j.eml.2016.11.009 [74] Hassan M Z, Cantwell W J. 2012. The influence of core properties on the perforation resistance of sandwich structures – An experimental study. Composites Part B:Engineering, 43: 3231-3238. doi: 10.1016/j.compositesb.2012.03.012 [75] Hassanpour Roudbeneh F, Liaghat G, Sabouri H, Hadavinia H. 2018. Experimental investigation of impact loading on honeycomb sandwich panels filled with foam. Int. J. Crashworthiness, 24: 199-210. [76] Hassanpour Roudbeneh F, Liaghat G, Sabouri H, Hadavinia H. 2020. High-velocity impact loading in honeycomb sandwich panels reinforced with polymer foam: a numerical approach study. Iran. Polym. J., 29: 707-721. doi: 10.1007/s13726-020-00833-5 [77] Heimbs S, Cichosz J, Klaus M, Kilchert S, Johnson A F. 2009. Sandwich structures with textile- reinforced composite foldcores under impact loads. Compos. Struct., 92: 1485-1497. [78] Imbalzano G, Tran P, Ngo T D, Lee P V. 2017. Three-dimensional modelling of auxetic sandwich panels for localised impact resistance. J. Sandw. Struct. Mater., 19: 291-316. doi: 10.1177/1099636215618539 [79] Ivañez I, Sánchez-Saez S, Garcia-Castillo S K, Barbero E, Amaro A, Reis P N B. 2020. High-velocity impact behaviour of damaged sandwich plates with agglomerated cork core. Compos. Struct., 248: 112520. doi: 10.1016/j.compstruct.2020.112520 [80] Jover N, Shafiq B, Vaidya U. 2014. Ballistic impact analysis of balsa core sandwich composites. Composites Part B:Engineering, 67: 160-169. doi: 10.1016/j.compositesb.2014.07.002 [81] Jackson K E, Littell J D, Fasanella E L, Annett M S, Seal M D. 2015. Multi-level experimental and analytical evaluation of two composite energy absorbers. United States: NASA Langley Research Center Hampton. [82] Jackson M, Shukla A. 2011. Performance of sandwich composites subjected to sequential impact and air blast loading. Composites Part B:Engineering, 42: 155-166. doi: 10.1016/j.compositesb.2010.09.005 [83] Kepler J A, Hansen M R. 2007. Numerical modeling of sandwich panel response to ballistic loading — energy balance for varying impactor geometries. J. Sandw. Struct. Mater., 9: 553-570. doi: 10.1177/1099636207069251 [84] Ketan O A, Rezgui R, Rowshan R, Du H. 2018. Microarchitected stretching‐dominated mechanical metamaterials with minimal surface topologies. Adv. Eng. Mater., 20: 1800029. doi: 10.1002/adem.201800029 [85] Khaire N, Tiwari G, Iqbal M A. 2021. Energy absorption characteristic of sandwich shell structure against conical and hemispherical nose projectile. Compos. Struct., 258: 113396. doi: 10.1016/j.compstruct.2020.113396 [86] Khodaei M, Haghighi-Yazdi M, Safarabadi M. 2020. Numerical modeling of high velocity impact in sandwich panels with honeycomb core and composite skin including composite progressive damage model. J. Sandw. Struct. Mater., 22: 2768-2795. doi: 10.1177/1099636218817894 [87] Kim J, Swanson S R. 2004. Effect of unequal face thickness on load resistance of sandwich beams. The Journal of Sandwich Structures & Materials, 6: 145-166. [88] Kolopp A, Rivallant S, Bouvet C. 2013. Experimental study of sandwich structures as armour against medium-velocity impacts. Int. J. Impact Eng., 61: 24-35. doi: 10.1016/j.ijimpeng.2013.05.007 [89] Khaire N, Tiwari G. 2020. Ballistic response of hemispherical sandwich shell structure against ogive nosed projectile. Thin-Walled Struct, 154: 106869. doi: 10.1016/j.tws.2020.106869 [90] Kooistra G W, Deshpande V, Wadley H N G. 2007. Hierarchical corrugated core sandwich panel concepts. Journal of Applied Mechanics, 74: 259-268. doi: 10.1115/1.2198243 [91] Landkof B, Goldsmith W. 1985. Petalling of thin, metallic plates during penetration by cylindro-conical projectiles. Int. J. Solids Struct., 21, 245-266. [92] Lin C, Hoo Fatt M S. 2005. Perforation of sandwich panels with honeycomb cores by hemispherical nose projectiles. J. Sandw. Struct. Mater., 7, 133-172. [93] Lin C, Hoo Fatt M S. 2006. Perforation of composite plates and sandwich panels under quasi-static and projectile loading. J. Compos Mater., 40, 1801-1840. [94] Liu C, Zhang Y X, Ye L. 2017. High velocity impact responses of sandwich panels with metal fibre laminate skins and aluminium foam core. Int. J. Impact Eng., 100, 139-153. [95] Li D T, Xia W, Fang Q Z, Yu W S, Shen S P. 2017. Experimental and numerical investigations on the tensile behavior of 3D random fibrous materials at elevated temperature. Compos. Struct., 160: 292-299. doi: 10.1016/j.compstruct.2016.10.075 [96] Liu Q Q, Wang S P, Lin X, Cui P, Zhang S. 2020. Numerical simulation on the anti-penetration performance of polyurea-core Weldox 460 E steel sandwich plates. Compos. Struct., 236: 111852. doi: 10.1016/j.compstruct.2019.111852 [97] Nasirzadeh R, Sabet A R. 2014. Study of foam density variations in composite sandwich panels under high velocity impact loading. Int. J. Impact Eng., 63, 129-139. [98] Ni C Y, Li Y C, Xin F X, Jin F, Lu T J. 2013. Ballistic resistance of hybrid-cored sandwich plates: Numerical and experimental assessment. Composites Part A:Applied Science and Manufacturing, 46: 69-79. doi: 10.1016/j.compositesa.2012.07.019 [99] Nalla Mohamed M, Ananthapadmanaban D, Selvaraj M. 2016. Numerical modeling of energy absorption behaviour of aluminium foam cored sandwich panels with different fibre reinforced polymer (FRP) composite facesheet skins. Applied Mechanics and Materials, 852: 66-71. doi: 10.4028/www.scientific.net/AMM.852.66 [100] Neelakantan S, Bosbach W, Woodhouse J, Markaki A E. 2014. Characterization and deformation response of orthotropic fibre networks with auxetic out-of-plane behaviour. Acta Mater., 66: 326-339. doi: 10.1016/j.actamat.2013.11.020 [101] Ni C Y, Jin F, Lu T J. 2014. Penetration of sandwich plates with hybrid-cores under oblique ballistic impact. Theor. Appl. Mech. Lett., 4: 21001. doi: 10.1063/2.1402101 [102] Nia A A, Kazemi M. 2020. Experimental study of ballistic resistance of sandwich targets with aluminum face-sheet and graded foam core. J. Sandw. Struct. Mater., 22: 461-479. doi: 10.1177/1099636218757669 [103] Novak N, Vesenjak M, Kennedy G, Thadhani N, Ren Z. 2020. Response of chiral auxetic composite sandwich panel to fragment simulating projectile impact. Physica Status Solidi (B) , 257: 1-6. [104] O Masta M R, Compton B G, Gamble E A, Zok F W, Deshpande V S, Wadley H N G. 2015. Ballistic impact response of an UHMWPE fiber reinforced laminate encasing of an aluminum-alumina hybrid panel. Int. J. Impact Eng., 86, 131-144. [105] Odacı L K, Kılıçaslan C, Taşdemirci A, Güden M. 2012. Projectile impact testing of glass fiber-reinforced composite and layered corrugated aluminium and aluminium foam core sandwich panels: a comparative study. Int. J. Crashworthiness, 17: 508-518. doi: 10.1080/13588265.2012.690215 [106] Paul D, R V, Gupta N K. 2020. Experimental and analytical studies of syntactic foam core composites for impact loading. Int. J. Crashworthiness, 1-18. [107] Qi C, Yang S, Wang D, Yang L J. 2013. Ballistic resistance of honeycomb sandwich panels under in-plane high-velocity impact. The Scientific World Journal, 1-20. [108] Qin Q H, Xia Y M, Li J F, Chen S J, Zhang W, Li K K, Zhang J X. 2020. On dynamic crushing behavior of honeycomb-like hierarchical structures with perforated walls: Experimental and numerical investigations. Int. J. Impact Eng., 145: 103674. doi: 10.1016/j.ijimpeng.2020.103674 [109] Qiu X M, Yu T X. 2012. Some topics in recent advances and applications of structural impact dynamics. Appl. Mech. Rev., 64: 24001. [110] Reddy T Y, Wen H M, Reid S R, Soden P D. 1998. Penetration and perforation of composite sandwich panels by hemispherical and conical projectiles. J. Press. Vessel Technol. -Trans. ASME, 120, 186-194. [111] Roisman I V, Weber K, Yarin A L, Hohler V, Rubin M B. 1999. Oblique penetration of a rigid projectile into a thick elastic-plastic target: theory and experiment. Int. J. Impact Eng., 22, 707-726. [112] Ryan S, Schaefer F, Destefanis R, Lambert M. 2008. A ballistic limit equation for hypervelocity impacts on composite honeycomb sandwich panel satellite structures. Adv. Space Res., 41, 1152-1166. [113] Rabiei A, Portanova M, Marx J, Scott C, Schwandt J. 2020. A study on puncture resistance of composite metal foam core sandwich panels. Adv. Eng. Mater., 22: 2000693. doi: 10.1002/adem.202000693 [114] Rafsanjani A, Pasini D. 2016. Bistable auxetic mechanical metamaterials inspired by ancient geometric motifs. Extreme. Mech. Lett., 291-296. [115] Rahimijonoush A, Bayat M. 2020. Experimental and numerical studies on the ballistic impact response of titanium sandwich panels with different facesheets thickness ratios. Thin-Walled Struct., 157: 107079. doi: 10.1016/j.tws.2020.107079 [116] Ren Z, Shen L, Bai H, Pan L, Zhong S. 2021. Constitutive model of disordered grid interpenetrating structure of flexible microporous metal rubber. Mech. Syst. Signal Proc., 154: 107567. doi: 10.1016/j.ymssp.2020.107567 [117] Reyes Villanueva G, Cantwell W J. 2004. The high velocity impact response of composite and FML-reinforced sandwich structures. Compos. Sci. Technol., 64: 35-54. doi: 10.1016/S0266-3538(03)00197-0 [118] Schonberg W P, Schaefer F, Putzar R. 2009. Predicting the perforation response of honeycomb sandwich panels using ballistic limit equations. J. Spacecr. Rockets, 46, 976-981. [119] Skvortsov V, Kepler J, Bozhevolnaya E. 2003. Energy partition for ballistic penetration of sandwich panels. Int. J. Impact Eng., 28, 697-716. [120] Sun G, Chen D, Wang H, Hazell P J, Li Q. 2018. High-velocity impact behaviour of aluminium honeycomb sandwich panels with different structural configurations. Int. J. Impact Eng., 122, 119-136. [121] Schäfer F K, Ryan S, Lambert M, Putzar R. 2008. Ballistic limit equation for equipment placed behind satellite structure walls. Int. J. Impact Eng., 35: 1784-1791. doi: 10.1016/j.ijimpeng.2008.07.074 [122] Schenk M, Guest S D, Mcshane G J. 2014. Novel stacked folded cores for blast-resistant sandwich beams. Int. J. Solids Struct., 51: 4196-4214. doi: 10.1016/j.ijsolstr.2014.07.027 [123] Shan S C, Kang S H, Raney J R, Wang P, Fang L C, Candido F, Lewis J A, Bertoldi K. 2015. Multistable architected materials for trapping elastic strain energy. Adv. Mater., 27: 4296-4301. doi: 10.1002/adma.201501708 [124] Tang E L, Zhang X Q, Han Y F. 2019. Experimental research on damage characteristics of CFRP/aluminum foam sandwich structure subjected to high velocity impact. Journal of Materials Research and Technology, 8: 4620-4630. doi: 10.1016/j.jmrt.2019.08.006 [125] Taylor E A, Herbert M K. 1999. Hypervelocity impact on carbon fibre reinforced plastic / aluminium honeycomb: Comparison with whipple bumper shields. Int. J. Impact Eng., 23: 883-893. doi: 10.1016/S0734-743X(99)00132-3 [126] Thomson W T. 1955. An approximate theory of armor penetration. J. Appl. Phys., 26: 80-82. doi: 10.1063/1.1721868 [127] Vaidya U K, Pillay S, Bartus S, Ulven C A, Grow D T, Mathew B. 2006. Impact and post-impact vibration response of protective metal foam composite sandwich plates. Materials Science and Engineering:A, 428: 59-66. doi: 10.1016/j.msea.2006.04.114 [128] Valdevit L, Hutchinson J, Evans A. 2004. Structurally optimized sandwich panels with prismatic cores. Int. J. Solids Struct., 41: 5105-5124. doi: 10.1016/j.ijsolstr.2004.04.027 [129] Velmurugan R, Babu M G, Gupta N K. 2006. Projectile impact on sandwich panels. Int. J. Crashworthiness, 11: 153-164. doi: 10.1533/ijcr.2005.0385 [130] Vinson J R. 2001. Sandwich structures. Appl. Mech. Rev., 54: 201-214. doi: 10.1115/1.3097295 [131] Wierzbicki T. 1999. Petalling of plates under explosive and impact loading. Int. J. Impact Eng., 22, 935-954. [132] Wadley H N G. 2006. Multifunctional periodic cellular metals. Philosophical Transactions of the Royal Society A:Mathematical, Physical and Engineering Sciences, 364: 31-68. doi: 10.1098/rsta.2005.1697 [133] Wadley H N G, Dharmasena K P, O'Masta M R, Wetzel J J. 2013. Impact response of aluminum corrugated core sandwich panels. Int. J. Impact Eng., 62: 114-128. doi: 10.1016/j.ijimpeng.2013.06.005 [134] Wang B, Zhang G Q, Wang S X, Ma L, Wu L Z. 2014. High velocity impact response of composite lattice core sandwich structures. Appl. Compos. Mater., 21: 377-389. doi: 10.1007/s10443-013-9345-4 [135] Wang Y J, Xu F, Gao H J, Li X Y. 2023. Elastically isotropic truss‐plate‐hybrid hierarchical microlattices with enhanced modulus and strength. Small, 2023: 2206024. [136] Wang Y L, Yu Y, Wang C Y, Zhou G, Karamoozian A, Zhao W Z. 2020. On the out-of-plane ballistic performances of hexagonal, reentrant, square, triangular and circular honeycomb panels. Int. J. Mech. Sci., 173: 105402. doi: 10.1016/j.ijmecsci.2019.105402 [137] Wang Z J, Qin Q H, Chen S J, Yu X H, Li H M, Wang T J. 2017. Compressive crushing of novel aluminum hexagonal honeycombs with perforations: Experimental and numerical investigations. Int. J. Solids Struct., 126: 187-195. [138] Wu Q Q, Yang C L, Ohrndorf A, Christ H J, Han J C, Xiong J. 2020. Impact behaviors of human skull sandwich cellular bones: Theoretical models and simulation. J. Mech. Behav. Biomed. Mater., 104: 103669. doi: 10.1016/j.jmbbm.2020.103669 [139] Yungwirth C J, O'Connor J, Zakraysek A, Deshpande V S, Wadley H N G. 2011. Explorations of hybrid sandwich panel concepts for projectile impact mitigation. J. Am. Ceram. Soc, 94: 62-75. [140] Yungwirth C J, Radford D D, Aronson M, Wadley H N G. 2008a. Experiment assessment of the ballistic response of composite pyramidal lattice truss structures. Composites Part B:Engineering, 39: 556-569. doi: 10.1016/j.compositesb.2007.02.029 [141] Yungwirth C J, Wadley H N G, O Connor J H, Zakraysek A J, Deshpande V S. 2008b. Impact response of sandwich plates with a pyramidal lattice core. Int. J. Impact Eng., 35, 920-936. [142] Yan L L, Yu B, Han B, Chen C Q, Zhang Q C, Lu T J. 2013. Compressive strength and energy absorption of sandwich panels with aluminum foam-filled corrugated cores. Compos. Sci. Technol., 86: 142-148. doi: 10.1016/j.compscitech.2013.07.011 [143] Yang F, Niu W J, Jing L, Wang Z H, Zhao L M, Ma H W. 2015. Experimental and numerical studies of the anti-penetration performance of sandwich panels with aluminum foam cores. Acta Mech. Solida Sin., 28: 735-746. doi: 10.1016/S0894-9166(16)30013-1 [144] Yang S, Qi C, Wang D, Gao R J, Hu H T, Shu J. 2013. A comparative study of ballistic resistance of sandwich panels with aluminum foam and auxetic honeycomb cores. Adv. Mech. Eng., 5: 589216. doi: 10.1155/2013/589216 [145] Yang X F, Ma J X, Shi Y L, Sun Y X, Yang J L. 2017. Crashworthiness investigation of the bio-inspired bi-directionally corrugated core sandwich panel under quasi-static crushing load. Mater. Des., 135: 275-290. doi: 10.1016/j.matdes.2017.09.040 [146] Zhou D W, Stronge W J. 2008. Ballistic limit for oblique impact of thin sandwich panels and spaced plates. Int. J. Impact Eng., 35, 1339-1354. [147] Zhang J J, Lu G X, Zhang Y, You Z. 2021. A study on ballistic performance of origami sandwich panels. Int. J. Impact Eng., 156: 103925. doi: 10.1016/j.ijimpeng.2021.103925 [148] Zhang L, Hu Z H, Wang M Y, Feih S. 2021. Hierarchical sheet triply periodic minimal surface lattices: design, geometric and mechanical performance. Mater. Des., 209: 109931. doi: 10.1016/j.matdes.2021.109931 [149] Zhang Q N, Zhang X W, Lu G X, Ruan D. 2018. Ballistic impact behaviors of aluminum alloy sandwich panels with honeycomb cores: An experimental study. J. Sandw. Struct. Mater., 20: 861-884. doi: 10.1177/1099636216682166 [150] Zhang Y, Lu Z X, Yang Z Y, Zhang D H, Shi J J, Yuan Z S, Liu Q. 2017. Compression behaviors of carbon-bonded carbon fiber composites: Experimental and numerical investigations. Carbon, 116: 398-408. doi: 10.1016/j.carbon.2017.02.012 [151] Zhao N, Ye R C, Tian A L, Cui J, Ren P, Wang M H. 2020. Experimental and numerical investigation on the anti-penetration performance of metallic sandwich plates for marine applications. J. Sandw. Struct. Mater., 22: 494-522. doi: 10.1177/1099636219855335 [152] Zhu D W, Huang X C, Hua H X, Zheng H. 2016. Vibration isolation characteristics of finite periodic tetra-chiral lattice coating filled with internal resonators. Proc. Inst. Mech Eng Pt C-J. Mech. Eng. Sci, 16: 2840-2850. [153] Zhu S Q, Chai G B. 2013. Impact of aluminum, CFRP laminates, fibre-metal laminates and sandwich panels. In: Composite Materials and Joining Technologies for Composites. Volume 7. New York, NY: Springer New York. [154] Zhu Y, Qin Q H, Zhang J X. 2021. On effective mechanical properties of an orthogonal corrugated sandwich structure. Mater. Des., 201: 109491. doi: 10.1016/j.matdes.2021.109491 -

下载:

下载: