Numerical simulations for microstructure evolution during metal additive manufacturing

-

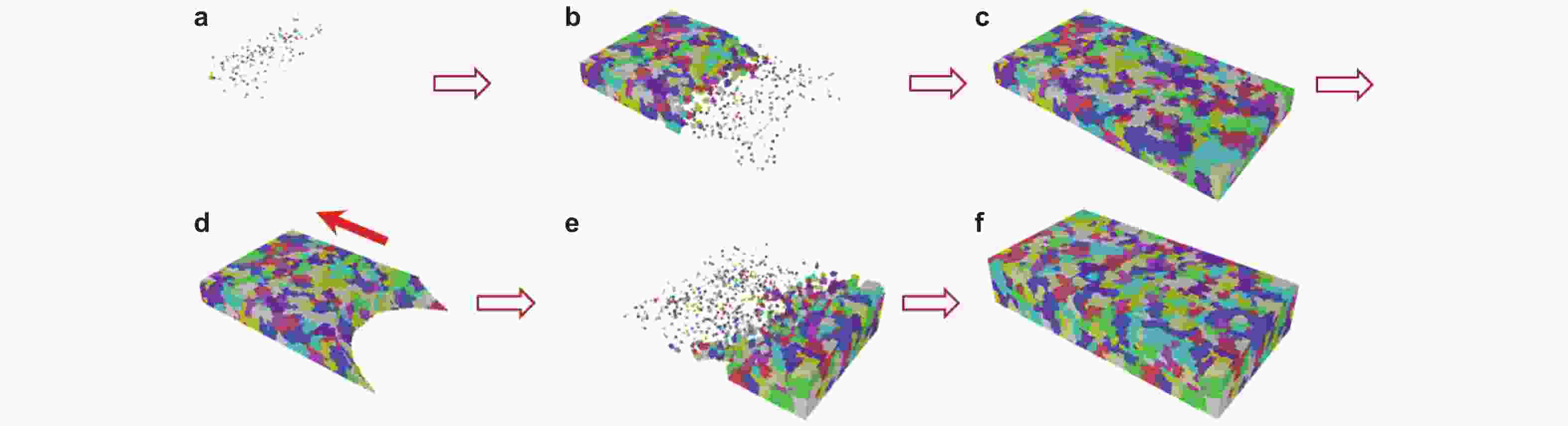

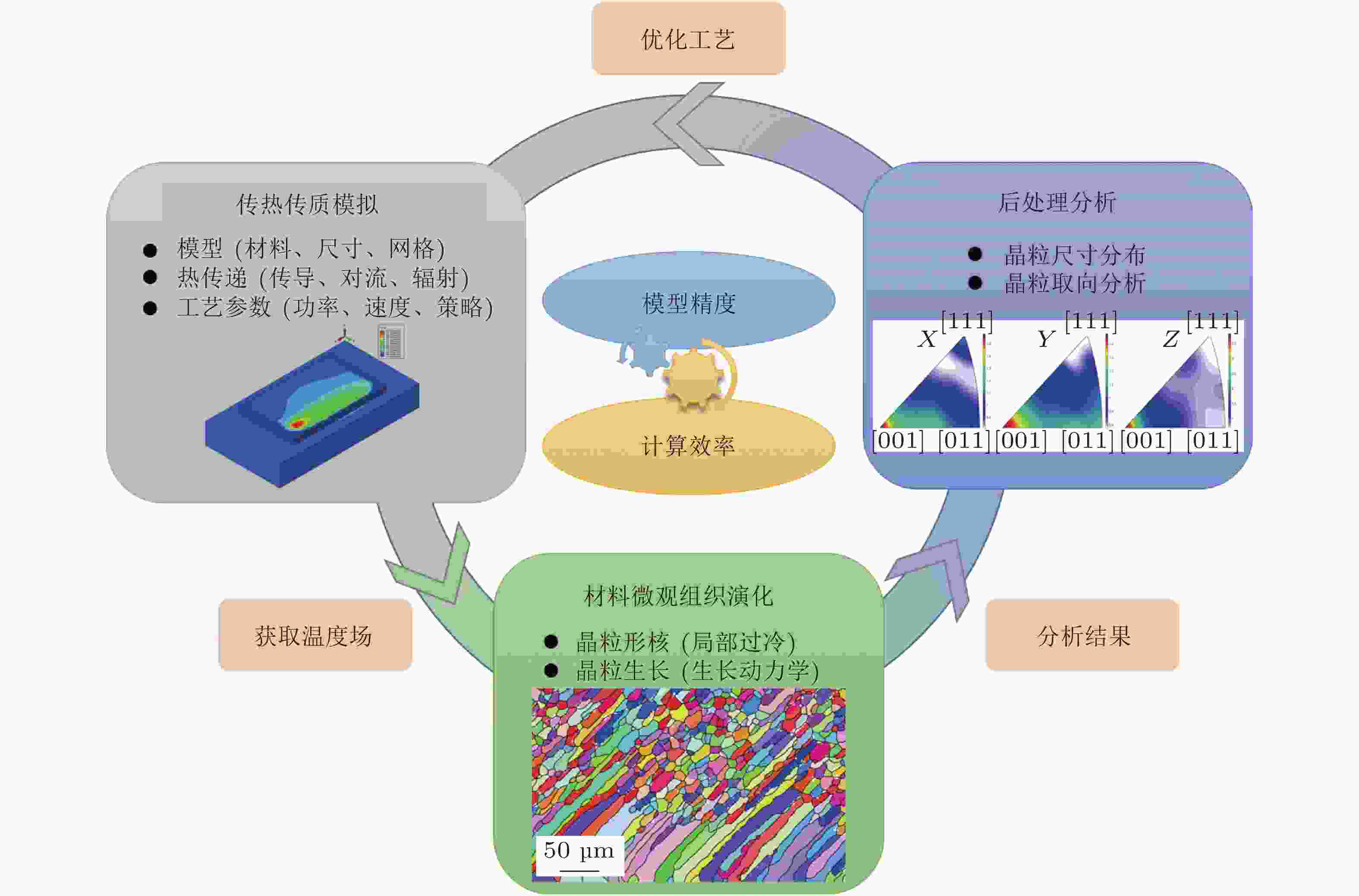

摘要: 金属增材制造是集设计、制造一体化的一种新型金属构件制造技术, 在航天航空、交通运输、生物医疗等领域具有广阔的应用前景. 金属增材制造材料的力学性能与其材料微观组织密切相关. 因此, 发展金属增材制造过程中材料微观组织的模拟方法, 有助于指导和优化金属增材制造的工艺参数和流程, 从而制备出性能优异的金属材料. 本文发展了基于连续体假设的热传导模型与元胞自动机相结合的模拟方法, 并利用生死单元方法, 考虑晶粒的重熔和再生长过程, 解决了金属增材制造中多层粉末制造的数值模拟问题. 本文采用该方法模拟了镍基合金IN718、不锈钢316L和高熵合金FeCoCrNiMn的增材制造过程, 并获得了这些增材制造合金的典型材料微观组织, 其模拟结果与实验结果相吻合. 同时, 将该方法拓展到三维尺度的模拟, 研究了镍基合金IN718增材制造过程中三维晶粒的形核和生长. 最后, 对金属增材制造过程中材料微观组织演化的模拟研究中的主要问题进行了总结和展望.Abstract: As an emerging manufacturing technology, metal additive manufacturing has broad application prospects in aerospace and aeronautics, transportation, and biomedical engineering. The mechanical properties and performances of materials produced through metal additive manufacturing are determined by their microstructures. It is of great importance to develop the numerical simulations for microstructure evolution during metal additive manufacturing. These simulations can guide and optimize the processing (especially the processing parameters), leading to fabricating the metallic materials with excellent properties and performances. Here, we develop a numerical method for metal additive manufacturing that integrates the heat conduction model with the cellular automaton method. This method can be used for the simulations of multilayers powder fabrication in metal additive manufacturing by utilizing the element birth and death technique and by considering both remelting and regrowth processes of grains. We use this method to predict the typical microstructures of nickel-based superalloy IN718, stainless steel 316L, and FeCoCrNiMn high-entropy alloys fabricated through metal additive manufacturing. The predictions from numerical simulations are consistent with the experimental results. Furthermore, we extend this method to simulate the three-dimensional microstructure evolution of nickel-based superalloy IN718 during metal additive manufacturing. Finally, we point out some important issues and challenges for future research on the numerical simulations for the process of metal additive manufacturing.

-

图 3 模拟结果与实验结果的对比. (a)镍基合金IN718的微观组织(实验, Parimi et al. 2014), (b)不锈钢316L的微观组织(实验, Wang Y M et al. 2018), (c)高熵合金FeCoCrNiMn的微观组织(实验, Zheng et al. 2021), (d)镍基合金IN718的微观组织(本文的模拟), (e)不锈钢316L的微观组织(本文的模拟), (f)高熵合金FeCoCrNiMn的微观组织(本文的模拟). (BD: building direction, 构件方向; SD: scanning direction, 扫描方向; TD: transverse direction, 横截面方向)

表 1 三种增材制造合金的模拟参数

材料 激光

功率/

W打印

速度/

(m·s−1)铺粉

层厚/

m元胞

尺寸/

m形核

密度/

m−2平均过冷

度ΔTm/

K标准差

ΔTσ/

K生长系数 λ1/

(m·s−1·K−1)λ2/

(m·s−1·K−2)λ2/

(m·s−1·K−3)IN718 390 3.33×10−3 3×10−4 5×10−6 2×109 9.5 2.0 1.77×10−5 1.58×10−5 2.29×10−6 316L 250 1 3×10−5 2×10−6 1.24×1010 10.0 1.0 −1.20×10−3 −3.08×10−4 3.02×10−5 FeCoCrNiMn 200 4×10−3 4×10−4 2×10−6 6.06×108 9.5 2.0 2.23×10−3 −1.30×10−4 6.94×10−6 -

[1] 陈嘉伟, 熊飞宇, 黄辰阳, 廉艳平. 2020. 金属增材制造数值模拟. 中国科学:物理学 力学 天文学, 50: 090007 (Chen J W, Xiong F Y, Huang C Y, Lian Y P. 2020. Numerical simulation on metallic additive manufacturing. Science Sinica Physica Mechanics & Astronomica, 50: 090007). doi: 10.1360/SSPMA-2020-0182(Chen J W, Xiong F Y, Huang C Y, Lian Y P. 2020. Numerical simulation on metallic additive manufacturing. Science Sinica Physica Mechanics & Astronomica, 50: 090007). doi: 10.1360/SSPMA-2020-0182 [2] 郭洪民, 危仁杰, 杨湘杰. 2003. 一种改进的模拟凝固微观组织的宏微观耦合模型. 特种铸造及有色合金, 5: 26-28 (Guo H M, Wei R J, Yang X J. 2003. A modeling of solidification microstructure of aluminum alloy. Special Casting & Nonferrous Alloys, 5: 26-28). doi: 10.3321/j.issn:1001-2249.2003.02.010(Guo H M, Wei R J, Yang X J. 2003. A modeling of solidification microstructure of aluminum alloy. Special Casting & Nonferrous Alloys, 5: 26-28). doi: 10.3321/j.issn:1001-2249.2003.02.010 [3] 廉艳平, 王潘丁, 高杰, 刘继凯, 李取浩, 刘长猛, 贺小帆, 高亮, 李好, 雷红帅, 李会民, 肖登宝, 郭旭, 方岱宁. 2021. 金属增材制造若干关键力学问题研究进展. 力学进展, 51: 648-701 (Lian Y P, Wang P D, Gao J, Liu J K, Li Q H, Liu C M, He X F, Gao L, Li H, Lei H S, Li H M, Xiao D B, Guo X, Fang D N. 2021. Fundamental mechanics problems in metal additive manufacturing: A state-of-art review. Advances in Mechanics, 51: 648-701). doi: 10.6052/1000-0992-21-037(Lian Y P, Wang P D, Gao J, Liu J K, Li Q H, Liu C M, He X F, Gao L, Li H, Lei H S, Li H M, Xiao D B, Guo X, Fang D N. 2021. Fundamental mechanics problems in metal additive manufacturing: A state-of-art review. Advances in Mechanics, 51: 648-701). doi: 10.6052/1000-0992-21-037 [4] 许庆彦, 柳百成. 2001. 采用Cellular Automaton法模拟铝合金的微观组织. 中国机械工程, 12: 328-331 (Xu Q Y, Liu B C. 2001. Microstructure simulation of Al alloy with cellular automaton method. China Mechanical Engineering, 12: 328-331). doi: 10.3321/j.issn:1004-132X.2001.03.329(Xu Q Y, Liu B C. 2001. Microstructure simulation of Al alloy with cellular automaton method. China Mechanical Engineering, 12: 328-331). doi: 10.3321/j.issn:1004-132X.2001.03.329 [5] 赵明, 武传松, 陈茂爱. 2006. 焊接热过程数值分析中相变潜热的三种解决方案. 焊接学报, 27: 55-58 (Zhao M, Wu C S, Chen M A. 2006. Solutions for latent heat of phase change in numerical analysis of arc welding. Transactions of the China Welding Institution, 27: 55-58). doi: 10.3321/j.issn:0253-360X.2006.09.014(Zhao M, Wu C S, Chen M A. 2006. Solutions for latent heat of phase change in numerical analysis of arc welding. Transactions of the China Welding Institution, 27: 55-58). doi: 10.3321/j.issn:0253-360X.2006.09.014 [6] 支颖, 王振范, 刘相华. 2020. 元胞自动机在金属材料研究中的应用. 北京: 科学出版社Zhi Y, Wang Z F, Liu X H. 2020. Application of Cellular Automata in Research on Metal Materials. Beijing: Science Press [7] 朱鸣芳, 汤倩玉, 张庆宇, 潘诗琰, 孙东科. 2016. 合金凝固过程中显微组织演化的元胞自动机模拟. 金属学报, 52: 1297-1310 (Zhu M F, Tang Q Y, Zhang Q Y, Pan S Y, Sun D K. 2016. Cellular automaton modeling of microstructure evolution during alloy solidification. Acta Metallurgica Sinica, 52: 1297-1310). doi: 10.11900/0412.1961.2016.00361(Zhu M F, Tang Q Y, Zhang Q Y, Pan S Y, Sun D K. 2016. Cellular automaton modeling of microstructure evolution during alloy solidification. Acta Metallurgica Sinica, 52: 1297-1310). doi: 10.11900/0412.1961.2016.00361 [8] Cheng B, Shrestha S, Chou K. 2016. Stress and deformation evaluations of scanning strategy effect in selective laser melting. Additive Manufacturing, 12: 240-251. doi: 10.1016/j.addma.2016.05.007 [9] Fayazfar H, Salarian M, Rogalsky A, Sarker D, Russo P, Paserin V, Toyserkani E. 2018. A critical review of powder-based additive manufacturing of ferrous alloys: Process parameters, microstructure and mechanical properties. Materials and Design, 144: 98-128. doi: 10.1016/j.matdes.2018.02.018 [10] Foroozmehr A, Badrossamay M, Foroozmehr E, Golabi S. 2016. Finite element simulation of selective laser melting process considering optical penetration depth of laser in powder bed. Materials and Design, 89: 255-263. doi: 10.1016/j.matdes.2015.10.002 [11] Gandin C A, Rappaz M. 1994. A coupled finite-element cellular-automaton model for the prediction of dendritic grain structures in solidification processes. Acta Metallurgica, 42: 2233-2246. doi: 10.1016/0956-7151(94)90302-6 [12] Gandin C A, Rappaz M. 1997. A 3D cellular automaton algorithm for the prediction of dendritic grain growth. Acta Materialia, 45: 2187-2195. doi: 10.1016/S1359-6454(96)00303-5 [13] Godec M, Zaefferer S, Podgornik B, Sinko M, Tchernychova E. 2020. Quantitative multiscale correlative microstructure analysis of additive manufacturing of stainless steel 316L processed by selective laser melting. Materials Characterization, 160: 110074. doi: 10.1016/j.matchar.2019.110074 [14] Han C, Fang Q, Shi Y, Tor S B, Chua C K, Zhou K. 2020. Recent advances on high-entropy alloys for 3D printing. Advanced Materials, 32: 1903855. doi: 10.1002/adma.201903855 [15] Koepf J A, Soldner D, Ramsperger M, Mergheim J, Markl M, Korner C. 2019. Numerical microstructure prediction by a coupled finite element cellular automaton model for selective electron beam melting. Computational Materials Science, 162: 148-155. doi: 10.1016/j.commatsci.2019.03.004 [16] Kurnsteiner P, Wilms M B, Weisheit A, Gault B, Jagle E A, Raabe D. 2020. High-strength damascus steel by additive manufacturing. Nature, 582: 515-519. doi: 10.1038/s41586-020-2409-3 [17] Kurz W, Giovanola B, Trivedi R. 1986. Theory of microstructural development during rapid solidification. Acta Metallurgica, 34: 823-830. doi: 10.1016/0001-6160(86)90056-8 [18] Lee K-H, Yun G J. 2020. A novel heat source model for analysis of melt pool evolution in selective laser melting process. Additive Manufacturing, 36: 101497. doi: 10.1016/j.addma.2020.101497 [19] Lian Y, Gan Z, Yu C, Kats D, Liu W K, Wagner G J. 2019. A cellular automaton finite volume method for microstructure evolution during additive manufacturing. Materials and Design, 169: 107672. doi: 10.1016/j.matdes.2019.107672 [20] Lian Y, Lin S, Yan W, Liu W K, Wagner G J. 2018. A parallelized three-dimensional cellular automaton model for grain growth during additive manufacturing. Computational Mechanics, 61: 543-558. doi: 10.1007/s00466-017-1535-8 [21] Lipton J, Glicksman M, Kurz W. 1984. Dendritic growth into undercooled alloy metals. Materials Science and Engineering, 65: 57-63. doi: 10.1016/0025-5416(84)90199-X [22] Liu G, Zhang X, Chen X, He Y, Cheng L, Huo M, Yin J, Hao F, Chen S, Wang P, Yi S, Wan L, Mao Z, Chen Z, Wang X, Cao Z, Lu J. 2021. Additive manufacturing of structural materials. Materials Science and Engineering:R:Reports, 145: 100596. doi: 10.1016/j.mser.2020.100596 [23] Liu S, Zhu H, Peng G, Yin J, Zeng X. 2018. Microstructure prediction of selective laser melting AlSi10Mg using finite element analysis. Materials and Design, 142: 319-328. doi: 10.1016/j.matdes.2018.01.022 [24] Mohebbi M S, Ploshikhin V. 2020. Implementation of nucleation in cellular automaton simulation of microstructural evolution during additive manufacturing of Al alloys. Additive Manufacturing, 36: 101726. doi: 10.1016/j.addma.2020.101726 [25] Panwisawas C, Tang Y T, Reed R C. 2020. Metal 3D printing as a disruptive technology for superalloys. Nature Communications, 11: 2327. doi: 10.1038/s41467-020-16188-7 [26] Parimi L L, Ravi G A, Clark D, Attallah M M. 2014. Microstructural and texture development in direct laser fabricated IN718. Materials Characterization, 89: 102-111. doi: 10.1016/j.matchar.2013.12.012 [27] Rai A, Helmer H, Korner C. 2017. Simulation of grain structure evolution during powder bed based additive manufacturing. Additive Manufacturing, 13: 124-134. doi: 10.1016/j.addma.2016.10.007 [28] Rappaz M, Gandin C A. 1993. Probabilistic modeling of microstructure formation in solidification processes. Acta Metallurgica, 41: 345-360. doi: 10.1016/0956-7151(93)90065-Z [29] Rodgers T M, Madison J D, Tikare V. 2017. Simulation of metal additive manufacturing microstructures using kinetic Monte Carlo. Computational Materials Science, 135: 78-89. doi: 10.1016/j.commatsci.2017.03.053 [30] Shi R, Khairallah S A, Roehling T T, Heo T W, McKeown J T, Matthews M J. 2020. Microstructural control in metal laser powder bed fusion additive manufacturing using laser beam shaping strategy. Acta Materialia, 184: 284-305. doi: 10.1016/j.actamat.2019.11.053 [31] Wang W, Ji C, Luo S, Zhu M. 2018. Modeling of dendritic evolution of continuously cast steel billet with cellular automaton. Metallurgical and Materials Transactions B, 49: 200-212. doi: 10.1007/s11663-017-1131-5 [32] Wang Y M, Voisin T, McKeown J T, Ye J, Calta N P, Li Z, Zeng Z, Zhang Y, Chen W, Roehling T T, Ott R T, Santala M K, Depond P J, Matthews M J, Hamza A V, Zhu T. 2018. Additively manufactured hierarchical stainless steels with high strength and ductility. Nature Materials, 17: 63-71. doi: 10.1038/nmat5021 [33] Xiong F, Gan Z, Chen J, Lian Y. 2022. Evaluate the effect of melt pool convection on grain structure of IN625 in laser melting process using experimentally validated process-structure modeling. Journal of Materials Processing Technology, 303: 117538. doi: 10.1016/j.jmatprotec.2022.117538 [34] Xiong F, Huang C, Kafka O L, Lian Y, Yan W, Chen M, Fang D. 2021. Grain growth prediction in selective electron beam melting of Ti-6Al-4V with a cellular automaton method. Materials and Design, 199: 109410. doi: 10.1016/j.matdes.2020.109410 [35] Yan W, Lin S, Kafka O L, Lian Y, Yu C, Liu Z, Yan J, Wolff S, Wu H, Ndip-Agbor E, Mozaffar M, Ehmann K, Cao J, Wagner G J, Liu W K. 2018. Data-driven multi-scale multi-physics models to derive process–structure–property relationships for additive manufacturing. Computational Mechanics, 61: 521-541. doi: 10.1007/s00466-018-1539-z [36] Yang J, Yu H, Yang H, Li F, Wang Z, Zeng X. 2018. Prediction of microstructure in selective laser melted Ti6Al4V alloy by cellular automaton. Journal of Alloys and Compounds, 748: 281-290. doi: 10.1016/j.jallcom.2018.03.116 [37] Zhang D, Qiu D, Gibson M A, Zheng Y, Fraser H L, StJohn D H, Easton M A. 2019. Additive manufacturing of ultrafine-grained high-strength titanium alloys. Nature, 576: 91-95. doi: 10.1038/s41586-019-1783-1 [38] Zheng M, Li C, Zhang X, Ye Z, Yang X, Gu J. 2021. The influence of columnar to equiaxed transition on deformation behavior of FeCoCrNiMn high entropy alloy fabricated by laser-based directed energy deposition. Additive Manufacturing, 37: 101660. doi: 10.1016/j.addma.2020.101660 [39] Zinoviev A, Zinovieva O, Ploshikhin V, Romanova V, Balokhonov R. 2016. Evolution of grain structure during laser additive manufacturing simulation by a cellular automata method. Materials and Design, 106: 321-329. doi: 10.1016/j.matdes.2016.05.125 [40] Zinovieva O, Zinoviev A, Ploshikhin V. 2018. Three-dimensional modeling of the microstructure evolution during metal additive manufacturing. Computational Materials Science, 141: 207-220. doi: 10.1016/j.commatsci.2017.09.018 [41] Zinovieva O, Zinoviev A, Ploshikhin V, Romanova V, Balokhonov R. 2015. A solution to the problem of the mesh anisotropy in cellular automata simulations of grain growth. Computational Materials Science, 108: 168-176. doi: 10.1016/j.commatsci.2015.06.026 -

下载:

下载: