| [1] |

Bu Y, Wu Y, Lei Z, et al. 2021. Local chemical fluctuation mediated ductility in body-centered-cubic high-entropy alloys. Mater. Today, 46: 28-34. doi: 10.1016/j.mattod.2021.02.022

|

| [2] |

Cantor B, Chang I, Knight P, et al. 2004. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A, 375: 213-218.

|

| [3] |

Chen B, Li S, Zong H, et al. 2020. Unusual activated processes controlling dislocation motion in body-centered-cubic high-entropy alloys. Proc. Natl. Acad. Sci., 117: 16199-16206. doi: 10.1073/pnas.1919136117

|

| [4] |

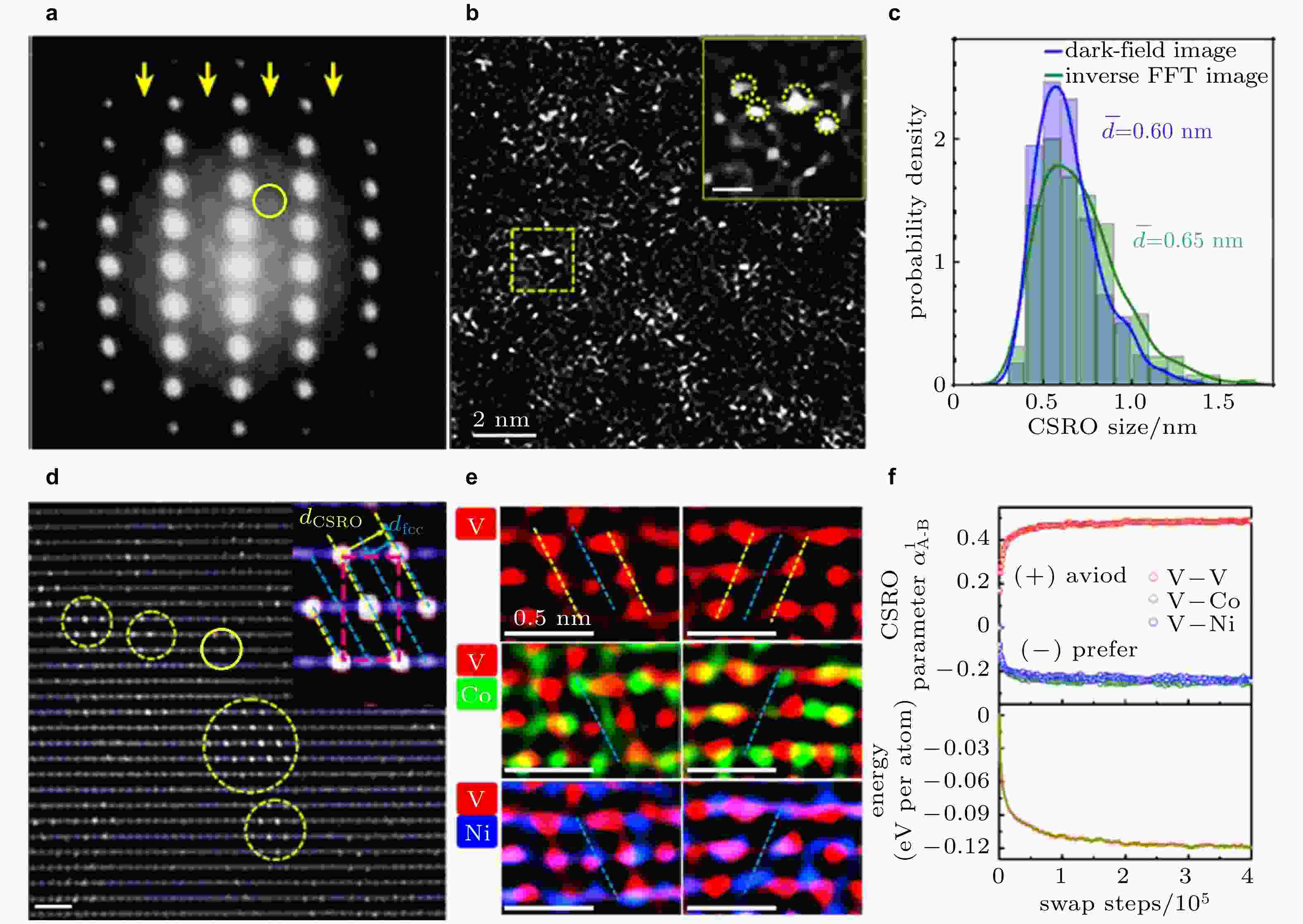

Chen X, Wang Q, Cheng Z, et al. 2021. Direct observation of chemical short-range order in a medium-entropy alloy. Nature, 592: 712-716. doi: 10.1038/s41586-021-03428-z

|

| [5] |

Ding Q, Zhang Y, Chen X, et al. 2019. Tuning element distribution, structure and properties by composition in high-entropy alloys. Nature, 574: 223-227. doi: 10.1038/s41586-019-1617-1

|

| [6] |

Fernández-Caballero A, Wróbel J, Mummery P, et al. 2017. Short-range order in high entropy alloys: Theoretical formulation and application to Mo-Nb-Ta-VW system. Journal of Phase Equilibria and Diffusion, 38: 391-403.

|

| [7] |

Gerold V, Karnthaler H. 1989. On the origin of planar slip in fcc alloys. Acta Metall., 37: 2177-2183. doi: 10.1016/0001-6160(89)90143-0

|

| [8] |

Gludovatz B, Hohenwarter A, Catoor D, et al. 2014. A fracture-resistant high-entropy alloy for cryogenic applications. Science, 345: 1153-1158. doi: 10.1126/science.1254581

|

| [9] |

Lei Z, Liu X, Wu Y, et al. 2018. Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Nature, 563: 546. doi: 10.1038/s41586-018-0685-y

|

| [10] |

Li Z, Pradeep KG, Deng Y, et al. 2016. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature, 534: 227-230. doi: 10.1038/nature17981

|

| [11] |

Liu S, Wei Y. 2017. The Gaussian distribution of lattice size and atomic level heterogeneity in high entropy alloys. Extreme Mech. Lett., 11: 84-88. doi: 10.1016/j.eml.2016.10.007

|

| [12] |

Ma E. 2020. Unusual dislocation behavior in high-entropy alloys. Scr. Mater., 181: 127-133. doi: 10.1016/j.scriptamat.2020.02.021

|

| [13] |

Singh P, Smirnov AV, Johnson DD. 2015. Atomic short-range order and incipient long-range order in high-entropy alloys. Phys. Rev. B, 91: 224204. doi: 10.1103/PhysRevB.91.224204

|

| [14] |

Ye Y, Wang Q, Lu J, et al. 2016. High-entropy alloy: challenges and prospects. Mater. Today, 19: 349-362. doi: 10.1016/j.mattod.2015.11.026

|

| [15] |

Yeh JW, Chen SK, Lin SJ, et al. 2004. Nanostructured high‐entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv. Eng. Mater., 6: 299-303. doi: 10.1002/adem.200300567

|

| [16] |

Zhang R, Zhao S, Ding J, et al. 2020. Short-range order and its impact on the CrCoNi medium-entropy alloy. Nature, 581: 283-287. doi: 10.1038/s41586-020-2275-z

|

下载:

下载: