-

摘要: 温压炸药的爆炸涉及到起爆、爆轰、冲击波的传播与反射、多相湍流和多模化学反应等, 是一个多尺度、多物质、多因素、多物理场耦合过程, 深化温压炸药高效释能的关键基础理论, 揭示温压爆炸的反应机理并有效控制和利用是温压武器创新发展的关键科学问题, 对高威力温压炸药的配方设计、温压武器的研制和使用具有重要指导意义. 本文描述了温压爆炸的基本原理, 讨论了温压炸药的概念和内涵, 从炸药种类、释能特点、能量构成、爆炸反应机制、爆炸效应增强机理、杀伤机制等方面阐述了温压炸药的特征, 分析了温压炸药有限空间内部爆炸威力的评估方法以及温压炸药的研发状况, 并提出了相关发展建议, 以期为高威力温压炸药的设计、温压弹的研制及毁伤评估提供指导.Abstract: The detonation of thermobaric explosives involves ignition, detonation, propagation and reflection of shock wave, multi-phase turbulence, and multi-mode chemical reaction. It is a coupling process of multi-scale, multi-material, multi-factor, and multi-physical field. A deep understanding of the detonation mechanism of thermobaric explosion and effective control and utilization of the explosion are critical to the innovation and development of thermobaric weapons. It can guide the design, development and applications of high-power thermobaric explosives and weapons. Firstly, this paper describes the origin of thermobaric explosives and the basic principle of thermobaric explosion, and discusses the concept and connotation of thermobaric explosives. Secondly, the characteristics of thermobaric explosives from the aspects of explosive kinds, energy release characteristics, energy composition, blast reaction mechanism, blast effect enhancement mechanism and killing mechanism are elaborated. And then the evaluation method of explosion power of thermobaric explosives in confined space and the state of art of thermobaric explosives were summarized. Finally, we give some relevant suggestions that wcould provide guidance for the design of high power thermobaric explosive, the development of thermobaric bombs and damage assessment.

-

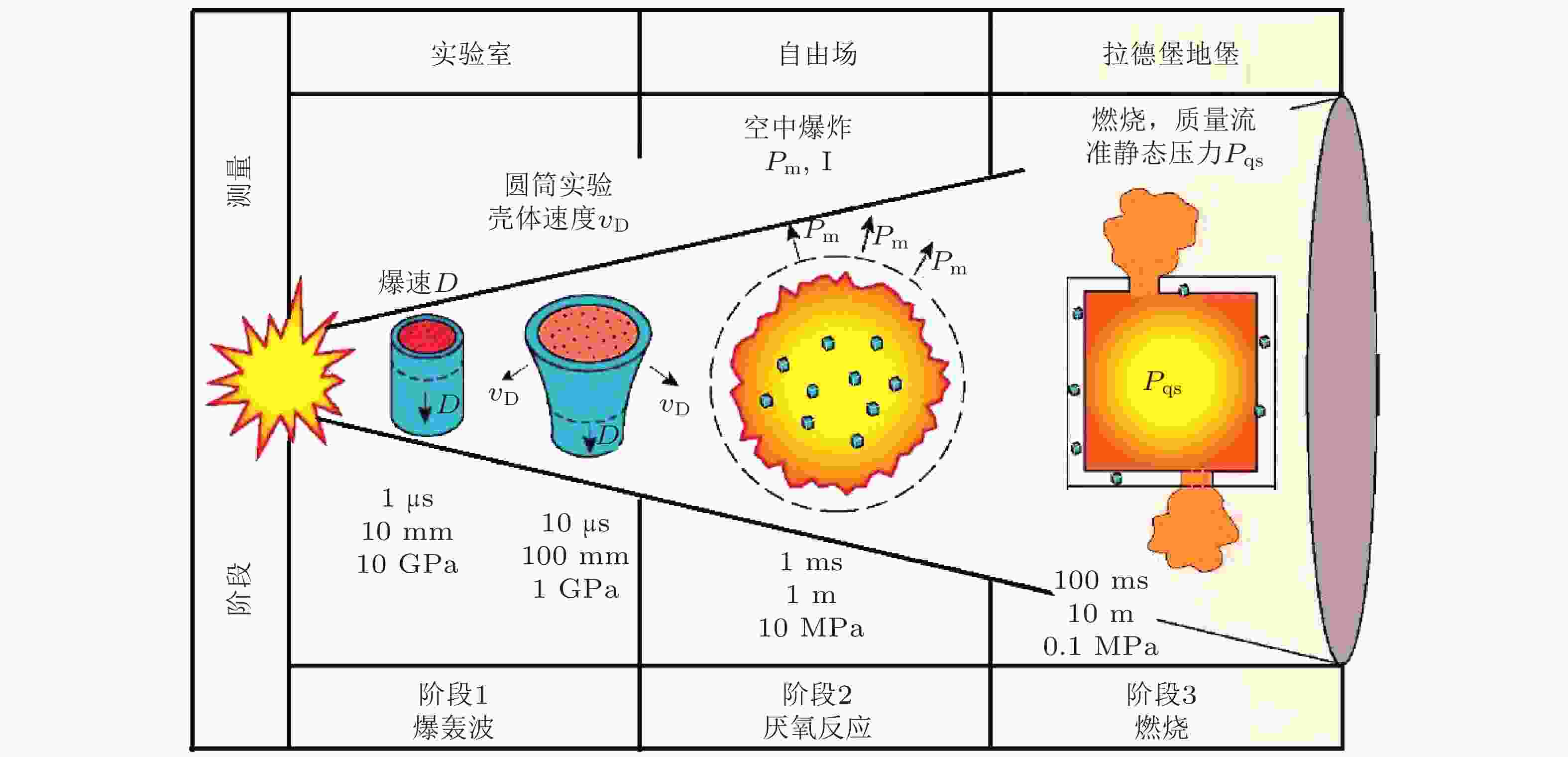

图 2 温压炸药有限空间内部爆炸的三个阶段(Arnold & Rottenkolber 2007, 2008)

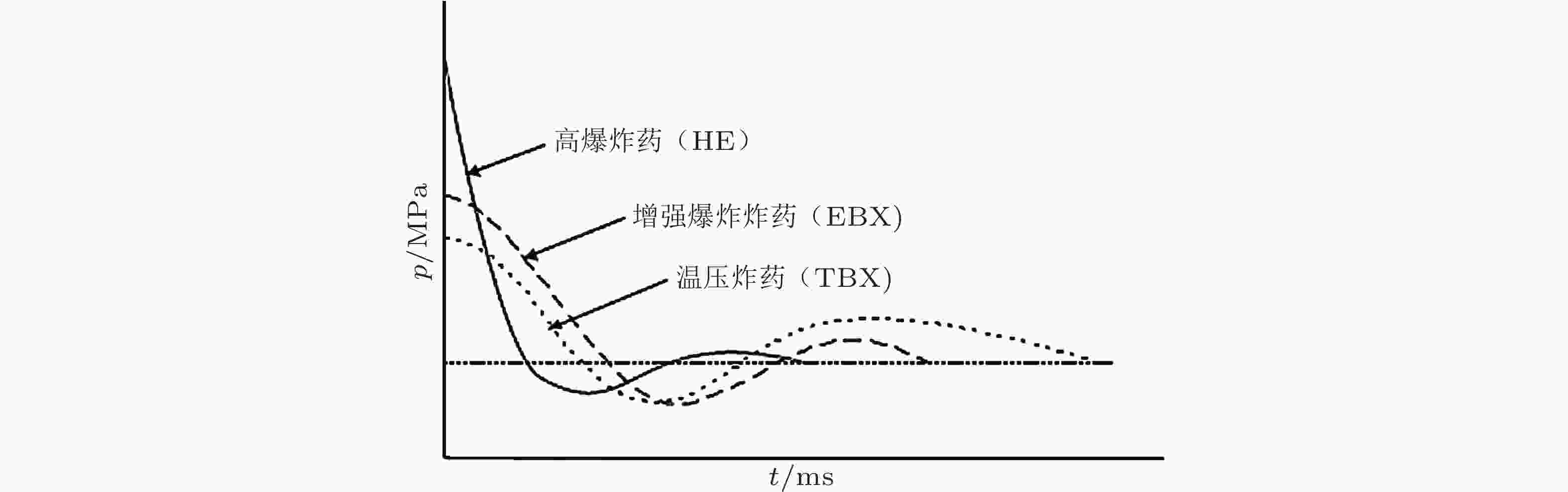

图 3 HE, TBX和EBX的爆炸波压力历程 (Trzciński et al. 2015)

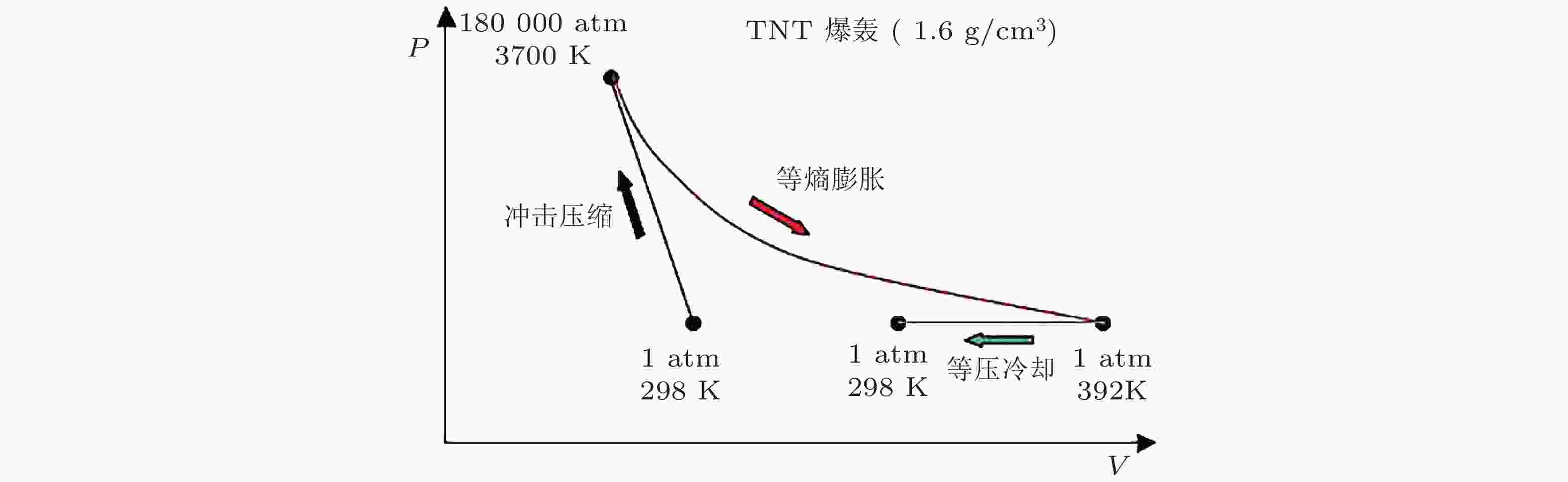

图 4 爆轰过程的热力学路径 (P-V图) (1 atm = 101.325 kPa) (Arnold & Rottenkolber 2007)

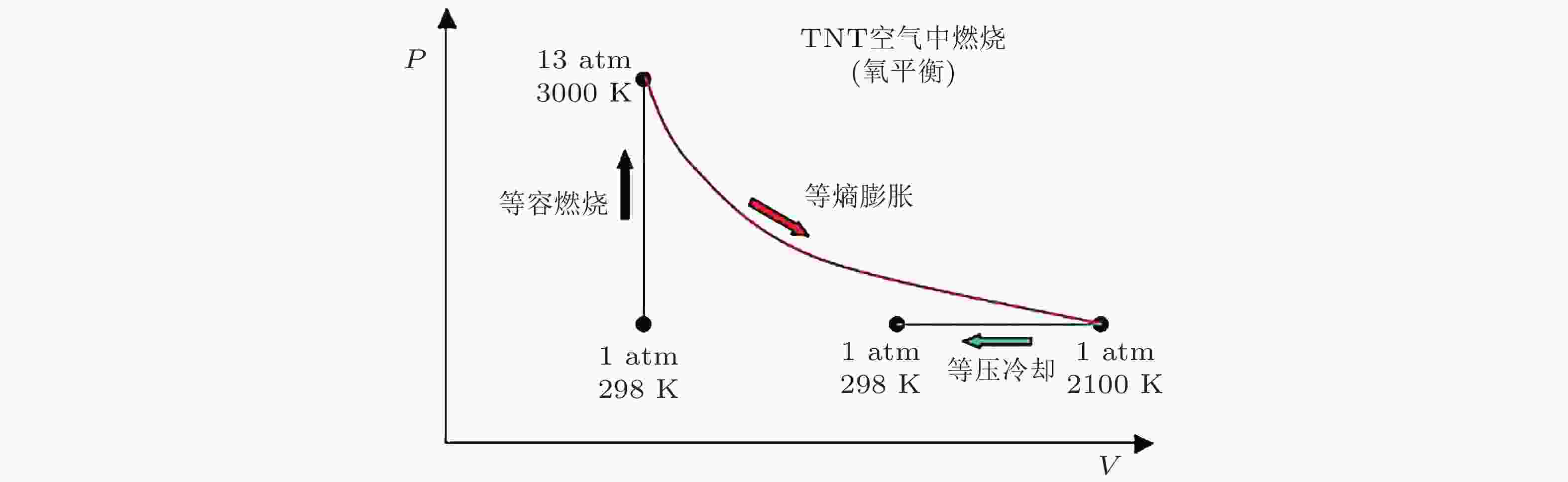

图 5 燃烧过程的热力学路径 (P-V图) (Arnold & Rottenkolber 2007)

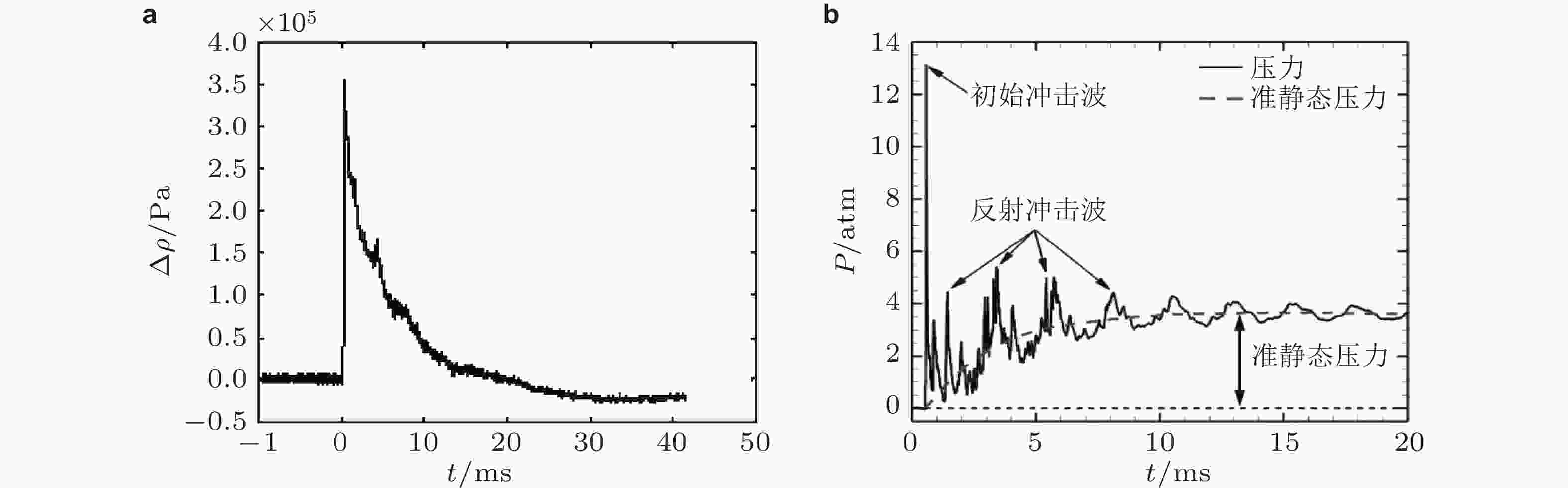

图 6 空中和有限空间内爆炸的压力−时间波形图. (a) 自由空气中(胡宏伟等2013), (b) 结构内部爆炸(Richard et al. 2006)

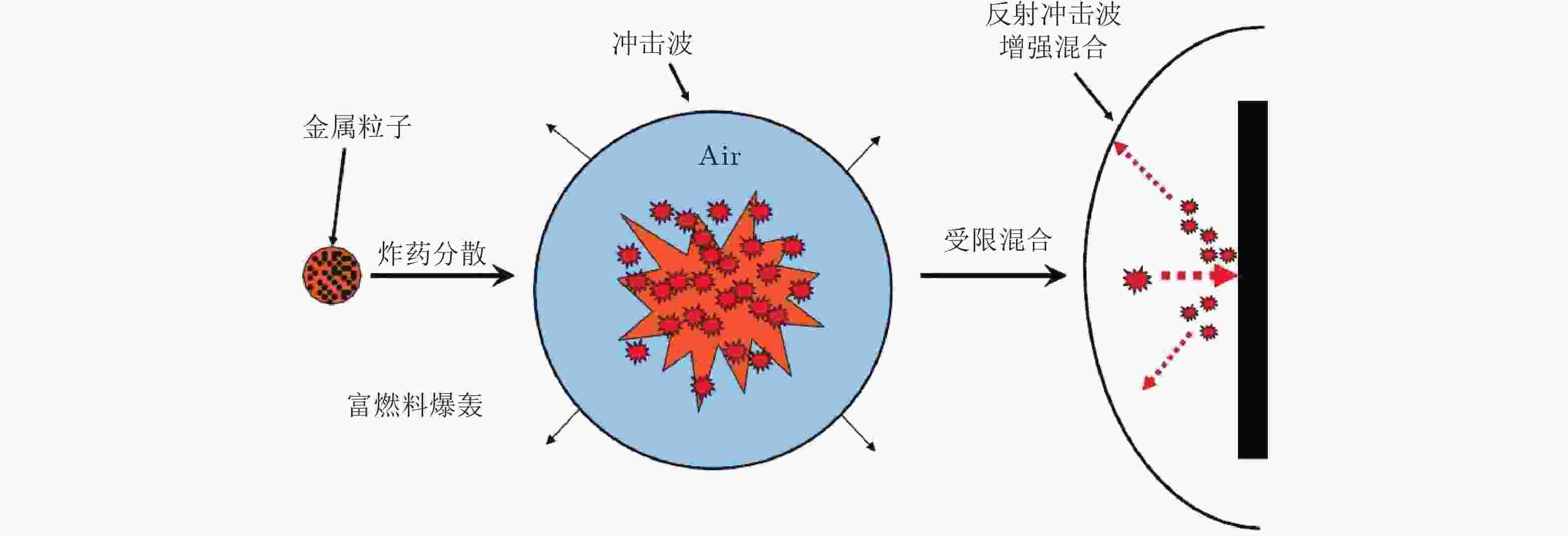

图 7 有限空间内反射冲击波对金属粒子和混合的影响(Michael et al. 2005)

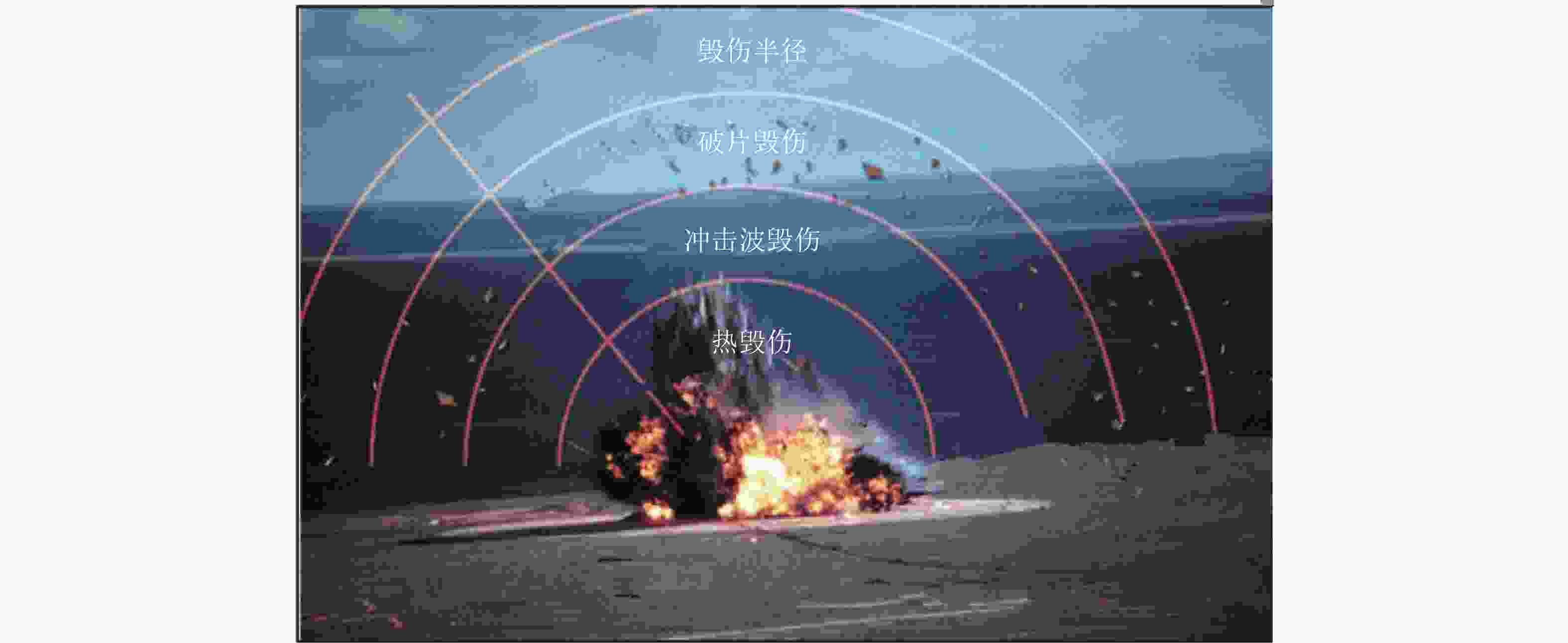

图 8 开放空间的杀伤机制 (Wildegger-Gaissmaier 2003)

图 9 坑道内爆炸的杀伤机理示意图 (Wildegger-Gaissmaier 2003)

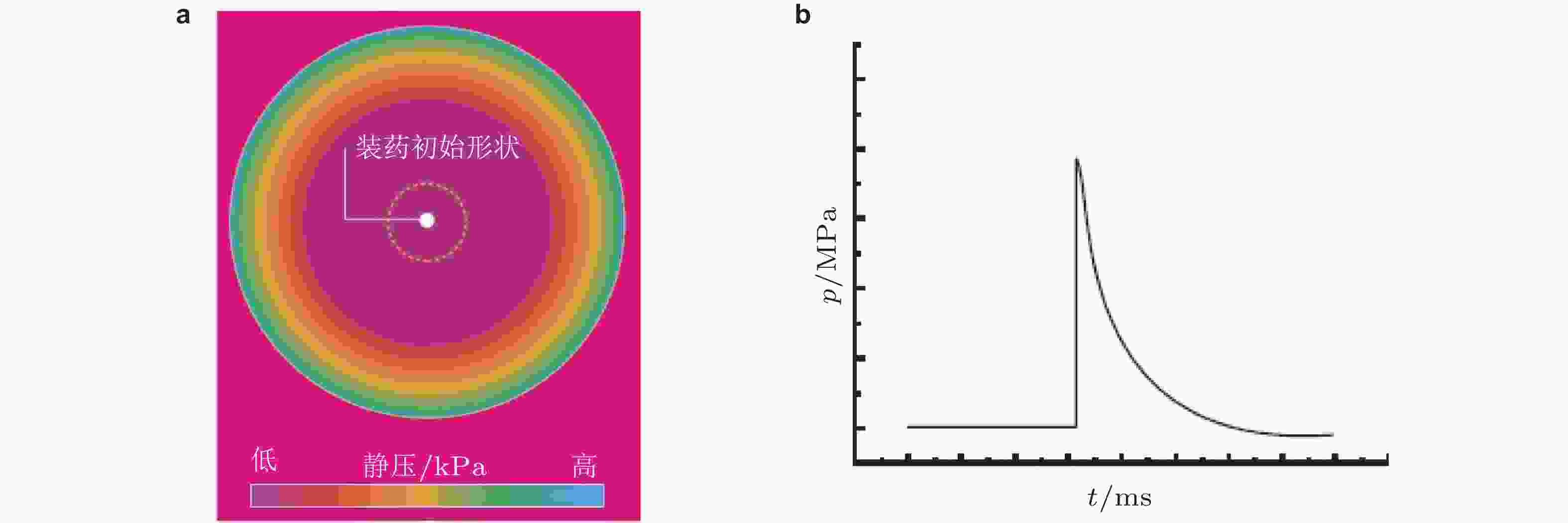

图 10 球型装药开放空间爆炸的冲击波扩展过程和压力-时间波形. (a) 冲击波扩展过程, (b) 冲击波压力-时间曲线 (Wildegger-Gaissmaier 2003)

图 11 球型装药密闭空间的冲击波扩展过程和波形. (a) 冲击波扩展过程, (b) 冲击波压力−时间曲线 (Wildegger-Gaissmaier 2003)

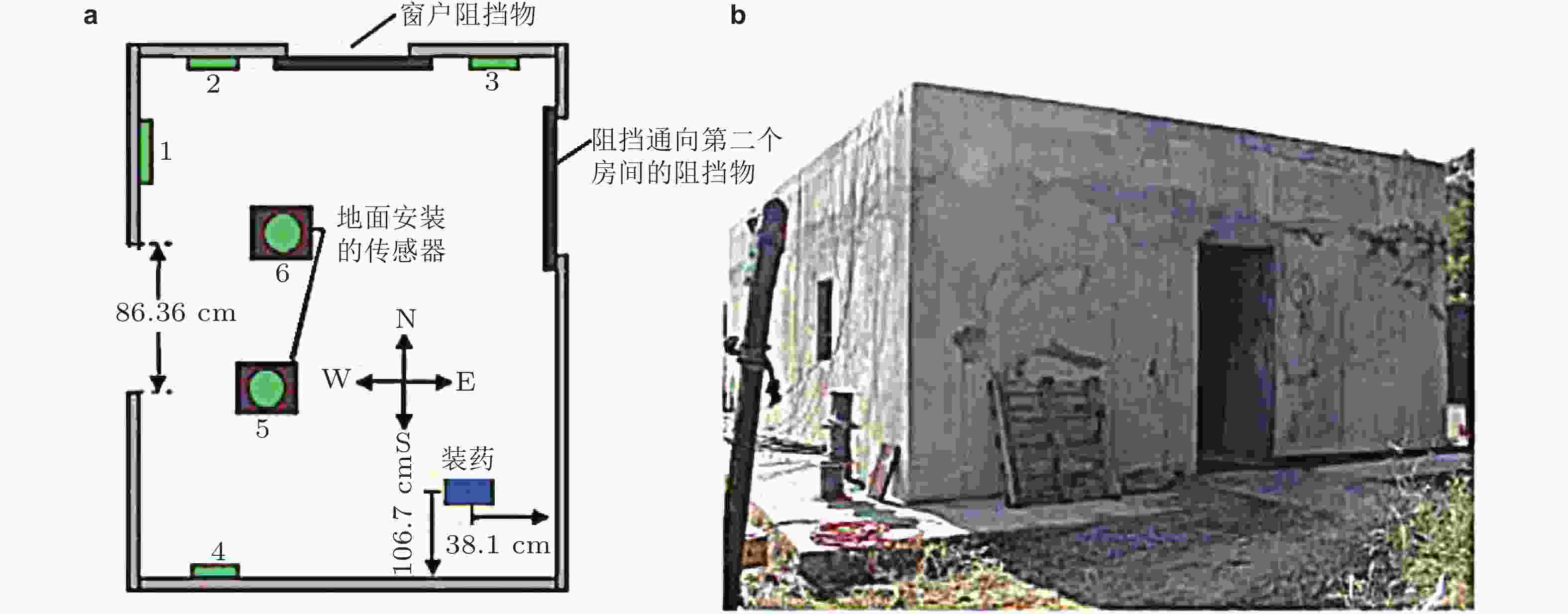

图 13 屋顶举起实验装置. (a) 起爆之前顶盖位置, (b) 起爆后顶盖位置. (胡宏伟等2016)

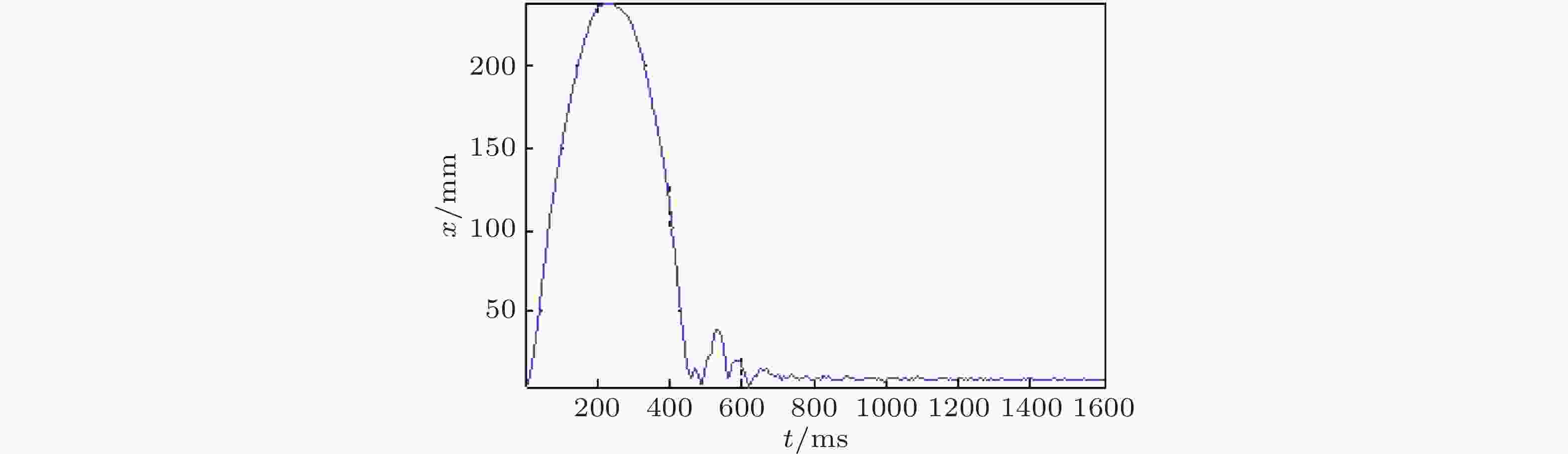

图 14 某炸药的顶盖位移−时间曲线 (胡宏伟等2016)

表 1 不同类型温压炸药/装药的反应特征及应用环境对比

类型 装药结构 作用过程 反应类型 反应尺度 应用环境 FAE 内外层结构, 内层高爆炸药,

外层液态或液固混合燃料抛洒、二次起爆、爆轰 爆轰 数百毫秒 开放环境 TBX 全固态装药

固液混合物爆轰、抛洒、引燃 爆轰、爆燃、燃烧 数微秒至秒 密闭环境 EBX 单一固体装药 爆轰、抛洒、引燃 爆轰、爆燃 数微秒至百毫秒 密闭环境 SFE 内外层结构, 内层高爆炸药,

外层固态粉末燃料爆轰、抛洒、引燃 爆燃、燃烧 数百毫秒 密闭环境 注: 表中FAE是为了对比温压炸药与燃料空气炸药的区别. 表 2 TNT爆轰能的计算值

过程 爆轰能量/(kJ·kg−1) 能量类型 冲击压缩 −1.41 等熵膨胀 5.94 等压冷却 4.53 4.53 爆轰机械能 0.08 爆轰热能 4.61 爆轰总能量 表 3 空气中燃烧热的计算值

过程 燃烧能量/(kJ·kg−1) 能量类型 冲击压缩 0.0 等熵膨胀 6.4 等压冷却 6.4 6.4 燃烧机械能 8.1 燃烧热能 14.5 燃烧总能量 表 4 典型炸药在自由空气中和密闭空间内爆炸威力

炸药 自由场 (TNT当量) 准静态压力 (Tritonal 当量) 平均压力 平均冲量 2.0 kg 3.0 kg 3.5 kg TNT 1 1 Tritonal 1 1 1 DXD-09 1.05 1.69 1.04 1.05 DXD-10 1.27 1.68 0.84 1.02 DXD-18 0.93 1.36 1.07 1.16 1.11 表 5 几种炸药的内爆炸试验结果

炸药 组分 ρ/(g·cm−3) Δpm/MPa I/(Pa·s) $x $max/m EAEI/(Pa·s) IH-135 HMX/Al/R45 1.33 0.414 896.4 0.356 1185.9 RAX-16 HMX/Al/GAP 1.62 0.276 868.8 0.312 1110.1 PBX-109 RDX/Al/R45 1.64 0.331 724.0 0.383 1227.3 YJ-15 proprietary 1.78 0.579 730.9 0.384 1227.3 表 6 候选炸药配方

炸药 组分 ρ/(g·cm−3) PBXIH-135 HMX/Al/HTPB 1.68 PBXIH-135EB HMX/Al/PCP-TMETN 1.79 PBXIH-136 RDX/AP/Al/PCP-TMETN 2.03 PBXIH-18 HMX/Al/Hytemperature/DOA 1.92 PBXIH-18 mod.1 HMX/Al/Hytemperature/DOA 1.77 PBXIH-18 mod.2 HMX/Al/Hytemperature/DOA 1.84 HAS-4 HMX/Al/HTPB 1.65 HAS-4 EB HMX/Al/PCP-TMETN 1.73 Talley Mix 5672 Al/Zr/IPN/Ethyl Cellulose(32/40/26.75/1.25) 2.21 -

[1] 曹威, 何中其, 陈网桦. 2014. TNT后燃反应的水下爆炸实验研究与数值模拟. 高压物理学报, 28: 443-449 (Cao W, He Z Q, Chen W H. 2014. Experimental research and numerical simulation of afterburning reaction of TNT explosive by underwater explosion. Chinese Journal of High Pressure Physics, 28: 443-449). doi: 10.11858/gywlxb.2014.04.009 [2] 曹威, 何中其, 陈网桦等. 2012. 水下爆炸法测量含铝炸药后燃效应. 含能材料, 20: 229-233 (Cao W, He Z Q, Chen W H, et al. 2012. Measurement of afterburning effect of aluminized explosives by underwater explosion method. Chinese Journal of Energetic Materials, 20: 229-233). doi: 10.3969/j.issn.1006-9941.2012.02.020 [3] 郭美芳. 2003. 战场新宠—温压弹. 现代兵器, 5: 14-16 (Guo M F. 2003. The darling of war. ModernWeapon, 5: 14-16). [4] 胡宏伟, 冯海云, 肖川等. 2016. 基于顶盖举起试验的炸药内爆炸性能评估. 火炸药学报, 39: 53-57 (Hu H W, Feng H Y, Xiao C, et al. 2016. Evaluation of the internal blast performance of explosives based on roof lift test. Chinese Journal of Explosives & Propellants, 39: 53-57). [5] 胡宏伟, 宋浦, 赵省向等. 2013. 有限空间内部爆炸研究进展. 含能材料, 21: 539-546 (Hu H W, Song P, Zhao S X, et al. 2013. Progress in explosion in confined space. Chinese Journal of Energetic Materials, 21: 539-546). doi: 10.3969/j.issn.1006-9941.2013.04.026 [6] 胡宏伟, 肖川, 李丽等. 2013. 有限空间炸药装药内爆炸威力的评估方法综述. 火炸药学报, 36: 1-6 (HU H W, XIAO C, LI L, et al. 2013. Review on evaluation methods of blast power in confined space. Chinese Journal of Explosives & Propellants, 36: 1-6). doi: 10.3969/j.issn.1007-7812.2013.01.001 [7] 李林. 2005. 温压弹的原理与实践. 现代军事, 1: 55-57 (Li L. 2005. Principle and practice of thermobaric bomb. Modern Military, 1: 55-57). [8] 朴忠杰, 张爱娥, 罗宇等. 2019. 铝粉粒度对奥克托今基空爆温压炸药能量释放的影响. 兵工学报, 40: 1190-1197 (Piao Z J, Zhang A E, Luo Y. 2019. Influence of aluminum powder on energy release of HMX-based air-blast thermobaric explosives. Acta Armamentaria, 40: 1190-1197). doi: 10.3969/j.issn.1000-1093.2019.06.009 [9] 裴明敬, 田朝阳, 胡华权等. 2013. 铝粉在温压炸药爆炸过程中的响应分析. 火炸药学报, 36: 7-12 (Pei M J, Tian C Y, Hu H Q, et al. 2013. Response analysis of aluminum in the process of thermobaric explosive detonation. Chinese Journal of Explosives & Propellants, 36: 7-12). doi: 10.3969/j.issn.1007-7812.2013.04.002 [10] 王明烨, 韩志伟, 李席等. 2018. 铝粉粒径对温压炸药爆炸性能及热安定性的影响. 高压物理学报, 32: 035201 (Wang M Y, Han Z W, Li X, et al. 2018. Influence of aluminum particle size on explosion performance and thermal stability of thermobaric explosive. Chinese Journal of High Pressure Physics, 32: 035201). [11] 王晓峰, 冯晓军. 2016. 温压炸药设计原则探讨. 含能材料, 24: 418-420 (Wang X F, Feng X J. 2016. Discussion on design principle of thermobaric explosives. Chinese Journal of Energetic Materials, 24: 418-420). doi: 10.11943/j.issn.1006-9941.2016.05.00X [12] 杨志剑, 刘晓波, 何冠松等. 2017. 混合炸药设计研究进展. 含能材料, 25: 2-11 (Yang J Z, Liu X B, He G S, et al. 2017. Advance in design and research of composite explosives. Chinese Journal of Energetic Materials, 25: 2-11). doi: 10.11943/j.issn.1006-9941.2017.01.001 [13] 郑朝民, 严蕊, 刘志伟等. 2014. 温压炸药耗氧效应的实验研究. 火炸药学报, 37: 33-36 (Zheng C M, Yan R, Liu Z W, et al. 2014. Experimental study on oxygen consumption effect of thermo-baric explosives. Chinese Journal of Explosives & Propellants, 37: 33-36). doi: 10.3969/j.issn.1007-7812.2014.03.008 [14] Andrew R D, Scott D H, Gregory D K. 2008. Detonation calorimeter: application and operation for thermobaric explosive characterization and evaluation// Proceeding of the 36th North American Thermal Analysis Society Conference, Atlanta: North American Thermal Analysis Society. [15] Arnold W, Rottenkolber E. 2007. Thermobaric charges: modeling and testing//38th International Annual Conference of ICT, Karlsruhe, Germany, V02. [16] Arnold, W. , Rottenkolber, E. 2008. Combustion of an aluminized explosive in a detonation chamber//39th International Annual Conference of ICT, Karlsruhe, Germany, V33. [17] Baker J J. 2010. Thermobaric explosives, articles of manufacture, and methods comprising the same. US Patent US 7807000 B1 20101005. [18] Barbara S. 2003. Tests massive bomb. CNN. [19] Carlson R W. 1945. Confinement of an explosion by a steel vessel. Los Alamos:LANL, LA-390. [20] Chabin P, Nouguez B. 2009. Insensitive enhanced blast formulations. Insensitive Munitions & Energetic Materials Technology Symposium, Tucson: NDIA. [21] Chan M L, Meyers G W. 2005. Advanced thermobaric explosive compositions. US Patent: US 6955732 B1, 2005-10-18. [22] Danica M S, Ivan D D, Radoslav S S. 2018. Thermobaric performance of cast PBX with nano-sized aluminum//49th International Annual Conference of the Fraunhofer ICT, Karlsruhe Germany, June 26-29, p131. [23] David L F, Samuel G, Robert R, et al. 2017. Interaction of a blast wave with a metalized explosive fireball//14th International Detonation Symposium. Idaho: Office of Naval Research, 42: 632-644 [24] David Tassia P E. 1996. Internal Blast Test to Support the Tomahawk and APET Programs//Insensitive Munitions & Energetic Materials Technology Symposium, San Diego: NDIA. [25] Donahue L, Whitehousel D R, Josey T, et al. 2004. Non-ideal blast effects for vulnerability/lethality analyses//21st International Symposium on Ballistics. Adelaide: South Australian Postgraduate Education Association. [26] Dreizin E L, Schoenitz M, Shoshin Y L, et al. 2005. Highly energetic nanocomposite powders produced by arrested reactive milling//36th Int. Annual Conference of ICT and 32nd International Pyrotechnics Seminar, Karlsruhe, Germany. [27] Gerber P, Kessler A, Eisele S, et al. 2010. Formulation and characterization of enhanced blast explosives//International Annual Conference of ICT (2010), 41th Energetic Materials: For High Performance, Insensitive Munitions and Zero Pollution, Karlsruhe Germany, gerbe1/1-gerbe1/8. [28] Gogulya M F, Brazhnikov M A. 2010. Pressure and temperature of the detonation products of explosive materials containing aluminum of various dispersities. Russian Journal of Physical Chemistry B; 4: 773–87. [29] Hahma A, Palovuori K, Romu H. 2002. Experimental studies on metal fueled thermobaric explosives// Proceedings of the Seminar, Levi, Finland, September 9–11, p 211-218. [30] Hall S, Knowlton G D. 2004. Development, characterization and testing of high blast thermobaric compositions//Proc. 31st Int. Pyrotech. Seminar. Fort Collins, 663-678. [31] Hilbert R, Tap F, Rabii HE Thvenin D. 2004. Impact of detailed chemistry and transport models on turbulent combustion simulations. Progress in Energy Combustion Science, 30: 61-117. doi: 10.1016/j.pecs.2003.10.001 [32] Jane’s Air-Launched Weapons, 26-May-2020. Weapons: Air Launched-BLU-121/B thermobaric warhead. www. janes. com. [33] Jane’s Air-Launched Weapons, 29-Apr-2015. BLU-118B thermobaric warhead. www. janes. com (accessed 7 Jan 2003). [34] Johnson N, Carpenter P, Newman K, et al. 2004. Evaluation of explosive candidates for a thermobaric M72 law shoulder launched weapon//NDIA 39th Annual Gun and Ammunition/Missiles and Rockets Conference, Baltimore, MD, USA. [35] Kellett R M. . 2009. Exothermic alloying Al-Ni bimetallic nanoparticles dispersed within explosives. PCT Int. Appl. (2009), WO 2009046287 A1 20090409. [36] Kim C K, Moon J G, Hwang J S, et al. 2008. Afterburning of TNT explosive products in air with aluminum particles//46th AIAA Aerospace Sciences Meeting and Exhibit, Reno , NV, USA, AIAA. [37] Kim S H, Park J S, Kim J K. 2004. Internal blast test on explosives developed in Korea//Proceedings of the 35th International Conference of ICT, Karlsruhe, Germany. [38] Lee K B, Lee K D, Kim J K. 2005. Relationship between combustion heat and blast performance of aluminized explosives//36th Int. Annual Conference of ICT, Karlsruhe, Germany. [39] Lin B Q, Li W X, Zhu C J, Lu H L, Lu Z G Li Q Z. 2010. Experimental investigation on explosion characteristics of nano-aluminum powder–air mixtures. Combustion Explosion Shock Waves, 46: 78-82. [40] Lips H, Helou S, Rittel R. 2010. Selection of an applicable SIBEX explosive for SLW//International Annual Conference of ICT (2010), 41st Energetic Materials: For High Performance, Insensitive Munitions and Zero Pollution, Karlsruhe, Germany, June 29-July 02, lips1/1-lips1/10. [41] Makhov M. 2004. Explosion heat of Boron-containing explosive compositions//35th International Conference of IC, Karlsruhe Germany: ICT. [42] McFadden D. 2003. Development and characterization of high heat Thermobaric composition. Doc No TR16006, Ialley Defense Systems. [43] Michael D, Andrews W S, Jaansalu K M. 2005. The Fragmentation of Metal Cylinders by Thermobaric Explosives. Kingston, CANADA: Royal Military College of Canada. [44] Mohamed A K, Mostafa H E, Elbasuney S. 2016. Nanoscopic fuel-rich thermobaric formulations: Chemical composition optimization and sustained secondary combustion shock wave modulation. Jourmal of Hazardous Materials, 301: 492-503. doi: 10.1016/j.jhazmat.2015.09.019 [45] Moir D C. 1979. Safety analysis of the M-2 comfinement systems. Los Alamos: LANL, LA-TM-264. [46] Muravyev N, Frolov Y, Pivkina A, et a1. 2010. Influence of particle size and mixing technology on combustion of HMX/A1 composition. Propellants Explosives Pyrotechnics, 35: 226232. [47] Nicolich S M, Capellos C, Balas W A, Akester J D, Hatch RL. 2012. High-blast explosive compositions containing particulate metal. US Patent: US 8168016 B1, 2012-05-01. [48] Peuker J M, Krier H, Glumac N. 2013. Particle size and gas environment effects on blast and overpressure enhancement in aluminized explosives. Proceedings of the Combustion Institute, 34: 2205-2212. doi: 10.1016/j.proci.2012.05.069 [49] Richard G A, Jason T D, Joseph S, et al. 2006. Quantitative distinction between detonation and after burn energy deposition using pressure-time histories in enclosed explosions//13th International Detonation Symposium, Norfolk Virginia. : Office of Naval Research. [50] Richard J L, Kirk E N, Douglas G B , et al. 2010. Combined initial air blast and quasi-static overpressure assessment for pressed aluminized explosives// Proceedings 14th International Detonation Symposium, Idaho: Office of Naval Research. [51] Schaefer R A, Nicolich S M. 2005. Development and evaluation of new high blast explosives//36th International Conference of ICT, Karlsruhe, Germany, June 28–July 1, V9. [52] Scott D H, Gregory D K. 2005. Development, characterization and testing of high Blast thermataric compositions// The 31th International Pyrotechnics Seminer, Fort Collins: AIDICO. [53] Sheridan E W, Hugus G D, Brooks G W. 2011. Enhanced blast explosive, US Patent: US 7998290 B2, 2011-07-05. [54] Simic D, Petkovic J, Milojkovic A, et al. 2013. Influence of composition on the processability of thermobaric explosives. Sci Tech Rev, 63: 3-8. [55] Trzciński W A, Barcz K. 2012. Investigation of blast wave characteristics for layered thermobaric charges. Shock Waves, 22: 119-127. doi: 10.1007/s00193-012-0357-z [56] Trzciński W A, Barcz K, et al. 2014. Investigation of blast performance and solid residues for layered thermobaric charges. Propellants Explosives Pyrotechnice, 39: 40-50. doi: 10.1002/prep.201300011 [57] Trzcinski W A, Cudzilo S, Paszula J, Callaway J. 2008. Study of the effect of additive particles size on non-ideal explosive performance. Propellants Explosives Pyrotechnics, 335: 227-35. [58] Trzciński W A, Maiz L. 2015. Thermobaric and enhanced blast explosives-properties and testing methods(review). Propellants, Explosives, Pyrotechnics, 40: 632-644. doi: 10.1002/prep.201400281 [59] Türker L. 2016. Thermobaric and enhanced blast explosives (TBX and EBX). Defence Technology, 12: 423-445. [60] van der Heijden A E D M, Creyghton Y L M, van de Peppel R J E, et al. 2010. Modification and characterization of (energetic) nanomaterials. Journal of Physics and Chemistry Solids, 71: 59-63. doi: 10.1016/j.jpcs.2009.09.007 [61] Vadhe P P, Pawar R B, Sinha R K, et al. 2008. Cast aluminized explosives (review). Combustion Explosion & Shock Waves, 44: 461-77. doi: 10.1007/s10573-008-0073-2 [62] Weiser V, Roth E, Raab A, et al. 2011. Combustion of fuel particles (Al, B, Mg, Si, Ti, Zr) in combination with RDX and the influence of additional air//37th International Pyrotechnics Seminar EUROPYRO 2011, Reims France, 36–53. [63] Wildegger-Gaissmaier A E. 2003. Aspects of thermobaric weaponry. ADF Health, 4: 3-6. [64] Wolan´ski P, Gut Z, Trzcin´ski WA, Szyman´czyk L, Paszula J. 2000. Visualization of turbulent combustion of TNT detonation products in steel vessel. Shock Waves, 10: 127-36. doi: 10.1007/s001930050186 -

下载:

下载: