-

摘要:

如何对蠕变裂纹扩展寿命进行准确预测和评价是高温结构完整性评定、寿命设计和运行维护中需要解决的核心问题.基于宏观单参数C*的蠕变断裂行为的评价方法,未有效纳入裂尖拘束效应的影响,因而其评价结果过于保守或非保守.目前国内外还未建立起有效纳入裂尖拘束效应的高温结构蠕变寿命评价的理论体系和技术方法,还没有纳入蠕变拘束效应的高温结构完整性评定规范.本文综述了作者近年来在高温蠕变断裂拘束效应方面的研究工作.主要包括:裂尖拘束对材料蠕变裂纹扩展行为的影响及机理;蠕变裂尖场和拘束参数R的定义和影响因素;载荷无关的蠕变拘束参数R*的提出及其应用基础;承压管道表面裂纹的拘束参数R*解及纳入裂尖拘束的蠕变寿命评价方法;试样与管道轴向裂纹蠕变裂尖拘束的关联;基于裂尖等效蠕变应变的面内与面外蠕变裂尖拘束的统一表征参数Ac的研究;材料拘束相关的蠕变裂纹扩展速率的建立;宽范围C*区蠕变裂纹扩展速率及其拘束效应的数值预测;材料拘束对焊接接头蠕变裂纹扩展行为的影响及机理等.这些研究为建立纳入裂尖拘束效应的高温部件的蠕变裂纹扩展寿命评价方法奠定了理论和技术基础.论文对后续拟开展的工作也进行了展望.

Abstract:Accurate prediction and assessment of creep crack growth life are key problems for structural integrity assessment, life design, and service maintenance of high temperature components. The life assessment method based on a single-parameter C* in creep fracture mechanics cannot effectively incorporate crack-tip constraint effect, thus the assessment result is either over-conservative or non-conservative. At present, theoretical framework and technical methodology for creep life assessment of high temperature structures have not been established, and there is yet no high temperature structure integrity assessment codes incorporating the creep constraint effect. This paper reviews our recent research work on the constraint effect in high temperature creep fracture. It includes:effect and mechanism of the crack-tip constraint on creep crack growth behavior of materials; the creep crack-tip field, and definition and influencing factors of a constraint parameter R; proposition of a load-independent creep constraint parameter R* and its applications; the creep constraint parameter R* solutions and creep life assessments incorporating the creep constraint effect for surface cracks in pressurized pipes; correlation of the creep crack-tip constraint between test specimens and axially cracked pipelines; study on a unified characterization parameter Ac of in-plane and out-of-plane creep constraints based on crack-tip equivalent creep strain; establishment of constraint-dependent creep crack growth rates of materials; numerical prediction of creep crack growth rate and its constraint effect in a wide range of C*; effect and mechanism of the material constraint on creep crack growth behavior in welded joints. The research work may lay foundation of theory and technology for establishing the life assessment methodology of creep crack growth incorporating the crack-tip constraint effect for high temperature structures. We also present prospects for future explorations.

-

Key words:

- creep /

- crack-tip constraint /

- crack growth /

- life assessment /

- specimen

-

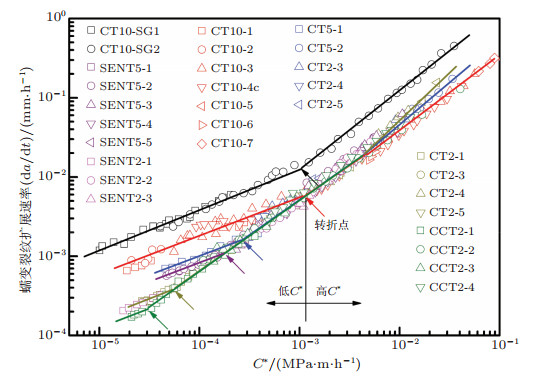

图 1 裂尖拘束对蠕变裂纹扩展速率的影响(Tan et al. 2013, Tan 2014)

图 2 低拘束低C*试样(CT2-1)的蠕变延性晶间断裂(Tan et al. 2013)

图 3 高拘束低C*试样(CT10-2)的蠕变脆性晶间断裂(Tan et al. 2013)

图 4 稳态蠕变条件下CT试样裂尖前的应力分布(Wang et al. 2010)

图 5 (a)不同裂纹深度CT试样的裂尖拘束参数R的分布, (b) R随载荷水平C*的变化(Sun et al. 2011)

图 6 (a)不同加载方式试样的裂尖拘束参数R随C*的变化, (b) R沿CT试样的厚度分布(Sun et al. 2012)

图 7 稳态蠕变时(t/tred=1), 不同载荷水平下拘束参数R*在裂尖前的分布. (a)各种加载方式试样和管道, (b)不同厚度CT试样(Tan et al. 2014)

图 8 拘束参数R*随蠕变时间t/tred的变化. (a)不同裂纹深度(a/W)的CT试样, (b)裂纹深度为a/W=0.35的不同加载方式的试样(Tan et al. 2014)

图 9 典型径厚比Ri/t=10的管道轴向不同尺寸内表面半椭圆裂纹前沿的拘束参数R*的分布(t/tred=1). (a) a/t=0.2, (b) a/t=0.4, (c) a/t=0.6, (d) a/t=0.8 (Liu et al. 2014)

图 10 典型径厚比Ri/t=10的管道环向不同尺寸内表面半椭圆裂纹前沿的拘束参数R*的分布(t/tred=1). (a) a/t=0.2, (b) a/t=0.4, (c) a/t=0.6, (d) a/t=0.8 (Liu et al. 2015a)

图 11 典型径厚比Ri/t=10的管道裂纹的拘束相关的蠕变裂纹扩展速率比

图 12 FEM计算裂尖拘束的试样和管道几何. (a) CT试样, (b) SENB试样, (c) CST (C-shaped tension)试样, (d) CCT试样, (e)销式加载的SENT试样(SENTp), (f)钳式加载的SENT试样(SENTc), (g)轴向裂纹管道, (h)管道裂纹尺寸表征(Tan et al. 2015)

图 13 不同几何试样和轴向裂纹管道裂尖拘束的比较(Tan et al. 2012). (a) a/W=0.35, (b) a/W=0.2

图 14 B/W=0.5及W=25 mm的试样及t=25 mm的管道裂纹的平均拘束Ravg*值(Tan et al. 2015)

图 15 不同面内/面外拘束试样的蠕变裂纹扩展速率da/dt和拘束参数Ac的关联(Ma et al. 2015)

图 16 (a)不同拘束试样的CCG速率比

图 17 采用应力相关的蠕变本构和延性方法模拟得到的宽范围C*下的da/dt-C*曲线及与实验曲线的对比(Zhang et al. 2015a)

图 18 不同拘束试样在宽范围C*下模拟的蠕变裂纹扩展速率da/dt-C*曲线及与实验的对比(Zhang et al. 2015b)

图 19 焊接接头裂纹扩展损伤云图. (a)裂纹沿原始裂纹面直线扩展, (b)二次裂纹的形成(Chen et al. 2014)

图 20 (a) HAZ为蠕变软材料时不同HAZ宽度的焊接接头的△a-t曲线, (b)破断寿命随HAZ宽度的变化曲线(Chen et al. 2015a)

-

[1] Asadi M, Hegde S R, Sawatzky T, Guillot D, Koul A K, Saari H, Weck A. 2012. Constructing a validated deformation mechanisms map using low temperature creep strain accommodation processes for nickel-base alloy 718//Proceedings of the ASME 2012 Pressure Vessels and Piping Division Conference. Toronto, Ontario, Canada, PVP2012-78092. [2] Betegeon C, Hancock J W. 1991. Two parameter characterization of elastic plastic crack-tip fields. Journal of Applied Mechanics, 58:104-110. doi: 10.1115/1.2897135 [3] Bettinson A D, Nikbin K M, O' Dowd N P, Webster G A. 2000. The influence of constraint on the creep crack growth of 316H stainless steel//Proceedings 5th International Conference Structural Integrity Assessment.Cambridge, UK. [4] Bettinson A D, O'Dowd N P, Nikbin K M, Webster G A. 2001. Two parameter characterization of crack tip fields under creep conditions//IUTAM Symposium on creep in structures. Netherlands, 95-104. [5] Bettinson A D, O'Dowd N P, Nikbin K M, Webster G A. 2002. Experimental investigation of constraint effects on creep crack growth//ASME 2002 Pressure Vessels and Piping Conference. Vancouver, BC, Canada. [6] Budden, P J, Ainsworth, R A. 1999. The effect of constraint on creep fracture assessments. International Journal of Fracture, 97:237-247. doi: 10.1023/A:1018305919622 [7] Budden P J, Dean D W. 2007. Constraint effects on creep crack growth//Proceedings of eighth international conference on creep and fatigue at elevated temperatures. July 22-26, San Antonio, Texas. [8] Chao Y J, Ji W. 1995. Cleavage fracture quantified by J and A2//Constraint Effects in Fracture Theory and Applications, ASTM STP1244, vol. 2. Philadelphia, PA:American Society for Testing and Materials, 1-20. [9] Chen G, Wang G Z, Xuan F Z, Tu S T. 2014. Mismatch effect in creep properties on creep crack growth behavior in welded joints. Materials and Design, 63:600-608. doi: 10.1016/j.matdes.2014.06.047 [10] Chen G, Wang G Z, Xuan F Z, Tu S T. 2015a. Effects of HAZ widths on creep crack growth properties of welded joints. Welding in the World, 59:851-860. doi: 10.1007/s40194-015-0259-7 [11] Chen G, Wang G Z, Zhang J W, Xuan F Z, Tu S T. 2015b. Effects of initial crack positions and load levels on creep failure behavior in P92 steel welded joint. Engineering Failure Analysis, 47:56-66. doi: 10.1016/j.engfailanal.2014.10.005 [12] Davies C M, Mueller F, Nikbin K M, O'Dowd N P, Webster G A. 2006. Analysis of creep crack initiation and growth in different geometries for 316H and carbon manganese steels. Journal of ASTM International, 3:1-20. https://www.researchgate.net/profile/Noel_ODowd/publication/240757051_Analysis_of_Creep_Crack_Initiation_and_Growth_in_Different_Geometries_for_316H_and_Carbon_Manganese_Steels/links/557feaae08ae26eada8f7dc0.pdf?inViewer=true&disableCoverPage=true&origin=publication_detail [13] Dodds R H, Shih J C F, Anderson T L. 1993. Continuum and micromechanics treatment of constraint in fracture. International Journal of Fracture, 64:101-133. https://www.researchgate.net/publication/226442360_Continuum_and_micromechanics_treatment_of_constraint_in_fracture [14] Fan K, Wang G Z, Xuan F Z, Tu S T. 2016. Geometry and material constraint effects on fracture resistance behavior of bi-material interfaces. International Journal of Fracture, DOI:10.1007/s10704-016-0112-z. 1-13. [15] FITNET FFS Procedure. 2008. Final Draft MK8, Prepared by European fitness-for-service networkFITNET. [16] Guo W L. 1993a. Elastoplastic three dimensional crack border field-I. Singular structure of the field.Engineering Fracture Mechanics, 46:93-104. doi: 10.1016/0013-7944(93)90306-D [17] Guo W L. 1993b. Elastoplastic three dimensional crack border field-II. Asymptotic solution for the field.Engineering Fracture Mechanics, 46:105-113. https://www.researchgate.net/publication/222241669_Elastoplastic_three_dimensional_crack_border_field-II [18] Guo W L. 1995. Elasto-plastic three-dimensional crack border field-III. Fracture parameters. Engineering Fracture Mechanics, 51:51-71. doi: 10.1016/0013-7944(94)00215-4 [19] Guo W L. 2000. Recent advances in three-dimensional fracture mechanics. Key Engineering Materials, 183:193-198. https://www.researchgate.net/publication/269640253_Recent_Advances_in_Three-Dimensional_Fracture_Mechanics [20] Hales R. 1994. The role of cavity growth mechanisms in determining creep-rupture under multiaxial stresses.Fatigue & Fracture of Engineering Materials & Structures, 17:579-591. [21] Kim N H, Kim Y J, Davies C M, Nikbin K M, Dean D W. 2012. Creep failures simulations for 316H at 550°//Proceedings of the ASME 2012 Pressure Vessels and Piping Division Conference. Toronto, Ontario, Canada, PVP2012-78133. [22] Liu S, Wang G Z, Xuan F Z, Tu S T. 2014. Creep constraint analysis and constraint parameter solutions for axial semi-elliptical surface cracks in pressurized pipes. Engineering Fracture Mechanics, 132:1-15. doi: 10.1016/j.engfracmech.2014.10.019 [23] Liu S, Wang G Z, Tu S T, Xuan F Z. 2015a. Creep constraint analysis and constraint parameter solutions for circumferential surface cracks in pressurized pipes. Engineering Fracture Mechanics, 148:1-14. doi: 10.1016/j.engfracmech.2015.09.012 [24] Liu S, Wang G Z, Xuan F Z, Tu S T. 2015b. Three-dimensional finite element analyses of in-plane and outof-plane creep crack-tip constraints for different specimen geometries. Engineering Fracture Mechanics, 133:264-280. doi: 10.1016/j.engfracmech.2015.10.009 [25] Liu S, Wang G Z, Xuan F Z, Tu S T. 2016a. Effects of creep properties of materials on creep crack-tip constraint parameter R*. Materials at High Temperatures, 33:208-217. doi: 10.1080/09603409.2016.1145397 [26] Liu S, Wang G Z, Tu S T, Xuan F Z. 2016b. Creep crack growth prediction and assessment incorporating constraint effect for pressurized pipes with axial surface cracks. Engineering Fracture Mechanics, 154:92-110. doi: 10.1016/j.engfracmech.2016.01.009 [27] Ma H S, Wang GZ, Xuan F Z, Tu S T. 2015. Unified characterization of in-plane and out-of-plane creep constraint based on crack-tip equivalent creep strain. Engineering Fracture Mechanics, 142:1-20. doi: 10.1016/j.engfracmech.2015.05.044 [28] Ma H S, Wang G Z, Tu S T, Xuan F Z. 2016a. Unified correlation of in-plane and out-of-plane creep constraints with creep crack growth rate. International Journal of Pressure Vessels and Piping, 139-140:47-60. doi: 10.1016/j.ijpvp.2016.03.003 [29] Ma H S, Wang G Z, Liu S, Tu S T, Xuan F Z. 2016b. In-plane and out-of-plane unified constraint-dependent creep crack growth rate of 316H steel. Engineering Fracture Mechanics, 155:88-101. doi: 10.1016/j.engfracmech.2016.01.017 [30] Ma H S, Wang G Z, Liu S, Tu S T, Xuan F Z. 2016c. Three-dimensional analyses of unified characterization parameter of in-plane and out-of-plane creep constraint.Fatigue & Fracture of Engineering Materials and Structures, 39:251-263. [31] Mostafavi M, Smith D J, Pavier M J. 2011. Fracture of aluminum alloy 2024 under biaxial and triaxial loading. Engineering Fracture Mechanics, 78:1705-1716. doi: 10.1016/j.engfracmech.2010.11.006 [32] Mostafavi M, Pavier M J, Smith D J. 2009. Unified measure of constraint//International Conference on Engineering Structural Integrity Assessment. Manchester, UK:ESIA10. [33] Mostafavi M, Smith D J, Pavier M J. 2010. Reduction of measured toughness due to out-of-plane constraint in ductile fracture of aluminium alloy specimens. Fatigue & Fracture of Engineering Materials & Structures, 33:724-739. http://www.academia.edu/1607620/Reduction_of_measured_toughness_due_to_out-of-plane_constraint_in_ductile_fracture_of_aluminium_alloy_specimens [34] Mu M Y, Wang G Z, Xuan F Z, Tu S T. 2014. Unified parameter of in-plane and out-of-plane constraint effects and its correlation with brittle fracture toughness of steel. International Journal of Fracture, 190:87-98. doi: 10.1007/s10704-014-9976-y [35] Nikbin K M, Smith D J, Webster G A. 1984. Prediction of creep crack growth from uniaxial creep data.Procceedings of the Royal Society of London, Series A, 396:183-197. doi: 10.1098/rspa.1984.0116 [36] Nikbin K M, Smith D J, Webster G A. 1986. An engineering approach to the prediction of creep crack growth. Journal of Engineering Materials and Technology, 108:186-191. doi: 10.1115/1.3225859 [37] Nikbin K M. 2004. Justification for meso-scale modelling in quantifying constraint during creep crack growth.Materials Science Engineering A, 365:107-113 doi: 10.1016/j.msea.2003.09.014 [38] O'Dowd N P, Shih C F. 1991. Family of crack-tip fields characterized by a triaxiality parameter. I:Structure of fields. Journal of Mechanics and Physics of Solids, 39:989-1015. doi: 10.1016/0022-5096(91)90049-T [39] O'Dowd N P, Shih C F. 1992. Family of crack-tip fields characterized by a triaxiality parameter. II:Fracture Applications. Journal of Mechanics and Physics of Solids, 40:939-963. doi: 10.1016/0022-5096(92)90057-9 [40] Ozmat B, Argon A S, Parks D M. 1991. Growth modes of cracks in creeping type 304 stainless steel.Mechanics of Materials, 11:1-17. doi: 10.1016/0167-6636(91)90036-Y [41] R6 Revision 4, 2006. with amendments, Assessment of the integrity of structures containing defects, British Energy Genation Ltd., Gloucester, UK. [42] Shih C F, O'Dowd N P, Kirk M T. 1993. A framework for quantifying crack tip constraint//Constraint Effects in Fracture, American Society for Testing and Materials, Philadelphia, 2-20. [43] Sun P J, Wang G Z, Xuan F Z, Tu S T, Wang Z D. 2011. Quantitative characterization of creep constraint induced by crack depths in compact tension specimens. Engineering Fracture Mechanics, 78:653-665. doi: 10.1016/j.engfracmech.2010.11.017 [44] Sun P J, Wang G Z, Xuan F Z, Tu S T, Wang ZD. 2012. Three-dimensional numerical analyses of out-ofplane creep crack-tip constraint in compact tension specimens. International Journal of Pressure Vessels and Piping, 96-97:78-89. doi: 10.1016/j.ijpvp.2012.06.007 [45] Tabuchi M, Kubo K, Yagi K. 1991. Effect of specimen size on creep crack growth rate using ultra-large CT specimens for 1Cr-Mo-V steel. Engineering Fracture Mechanics, 40:311-321. doi: 10.1016/0013-7944(91)90266-4 [46] Takahashi Y, Igari T, Kawashima F, Date S, Titoh N I, Noguchi Y, Kobayashi K, Tabuchi M. 2005. High temperature crack growth behavior of high-chromium steels//18th International conference on structural mechanics in reactor technology. Beijing, China, 1904-1915. [47] Tan J P, Wang G Z, Xuan F Z, Tu S T. 2012a. Experimental investigation of in-plane constraint and out-of-plane constraint effects on creep crack growth//Proceedings of the ASME 2012 Pressure Vessels and Piping Division Conference. Toronto, Ontario, Canada, PVP2012-78478. [48] Tan J P, Wang G Z, Xuan F Z, Tu S T. 2012b. Correlation of creep crack-tip constraint between axially cracked pipelines and test specimens. International Journal of Pressure Vessels and Piping, 98:16-25. doi: 10.1016/j.ijpvp.2012.06.004 [49] Tan J P, Tu S T, Wang G Z, Xuan F Z. 2013. Effect and mechanism of out-of-plane constraint on creep crack growth behavior of a Cr-Mo-V steel. Engineering Fracture Mechanics, 99:324-34. doi: 10.1016/j.engfracmech.2013.01.017 [50] Tan J P. 2014. Creep life assessment of structures containing crack incorporating constraint effect.[PhD Thesis]. Shanghai:East China University of Science and Technology. [51] Tan J P, Tu S T, Wang G Z, Tu S T. 2014. Load-independent creep constraint parameter and its application.Engineering Fracture Mechanics, 116:41-57. doi: 10.1016/j.engfracmech.2013.12.015 [52] Tan J P, Tu S T, Wang G Z, Xuan F Z. 2015. Characterization and correlation of 3-D creep constraint between axially cracked pipelines and test specimens. Engineering Fracture Mechanics, 136:96-114. doi: 10.1016/j.engfracmech.2015.01.018 [53] Wang G Z, Liu X L, Xuan F Z, Tu S T. 2010. Effect of constraint induced by crack depth on creep crack-tip stress field in CT specimens. International Journal of Solids and Structures, 47:51-57. doi: 10.1016/j.ijsolstr.2009.09.015 [54] Wang G Z, Kui L B, Xuan F Z, Tu S T. 2012. Numerical investigation on the creep crack-tip constraint induced by loading configuration of specimens. Engineering Fracture Mechanics, 79:353-362. doi: 10.1016/j.engfracmech.2011.11.014 [55] Webster G A, Ainsworth R A. 1994. High Temperature Component Life Assessment. London:Chapman and Hall, Springer. [56] Xiang M J, Yu Z B, Guo W L. 2011. Characterization of three-dimensional crack border fields in creeping solids. International Journal of Solids and Structures, 48:2695-2705. doi: 10.1016/j.ijsolstr.2011.05.013 [57] Xiang M J, Guo W L. 2013. Formulation of the stress fields in power law solids ahead of three-dimensional tensile cracks. International Journal of Solids and Structures, 50:3067-3088. doi: 10.1016/j.ijsolstr.2013.05.011 [58] Yatomi M, O'Dowd N P, Nikbin K M, Webster G A. 2006. Theoretical and numerical modelling of creep crack growth in a carbon-manganese steel. Engineering Fracture Mechanics, 73:1158-1175. doi: 10.1016/j.engfracmech.2005.12.012 [59] Yamamoto M, Miura N, Ogata T. 2009. Effect of constraint on creep crack propagation of mod. 9Cr-1Mo steel weld joint//ASME 2009 Pressure Vessels and Piping Conference:American Society of Mechanical Engineers, 1533-1539. [60] Yang J, Wang G Z, Xuan F Z, Tu S T. 2012. Unified characterization of in-plane and out-of-plane constraint based on crack-tip equivalent plastic strain. Fatigue & Fracture of Engineering Materials & Structures, 36:504-514. https://www.researchgate.net/publication/264564305_Unified_characterisation_of_in-plane_and_out-of-plane_constraint_based_on_crack-tip_equivalent_plastic_strain?_sg=RICP_cu9Y6bDRW3C983HLgF0212X8Tr-gnJS6J9hjn2r00Bkih6A7rpTEJqHFM4rmQZd2nILqCD54W0d6VTLBw [61] Yang J, Wang G Z, Xuan F Z, Tu S T. 2014a. A Unified correlation of in-plane and out-of-plane constraint with fracture resistance of a dissimilar metal welded joint. Engineering Fracture Mechanics, 115:296-307. doi: 10.1016/j.engfracmech.2013.11.018 [62] Yang J, Wang G Z, Xuan F Z, Tu S T. 2014b. Unified correlation of in-plane and out-of-plane constraint with fracture toughness. Fatigue & Fracture of Engineering Materials & Structures, 37:132-145. https://www.researchgate.net/publication/261546507_Unified_correlation_of_in-plane_and_out-of-plane_constraint_with_fracture_toughness [63] Zhang J W, Wang G Z, Xuan F Z, Tu S T. 2014. Prediction of creep crack growth behavior in Cr-Mo-V steel specimens with different constraints for a wide range of C*. Engineering Fracture Mechanics, 132:70-84. doi: 10.1016/j.engfracmech.2014.10.025 [64] Zhang J W, Wang G Z, Xuan F Z, Tu S T. 2015a. The influence of stress-regime dependent creep model and ductility in the prediction of creep crack growth rate in Cr-Mo-V steel. Materials and Design, 65:644-651. doi: 10.1016/j.matdes.2014.09.070 [65] Zhang J W, Wang G Z, Xuan F Z, Tu S T. 2015b. Effect of stress dependent creep ductility on creep crack growth behavior of steels for wide range of C*. Materials at High Temperatures, 32:369-376. doi: 10.1179/1878641314Y.0000000027 [66] Zhang J W, Wang G Z, Xuan F Z, Tu S T. 2015c. In-plane and out-of-plane constraint effects on creep crack growth rate in Cr-Mo-V steel for a wide range of C*. Materials at High Temperatures, 32:512-523. doi: 10.1179/1878641314Y.0000000039 [67] Zhao L, Jing H, Xu L, Han Y, Xiu J. 2012. Evaluation of constraint effects on creep crack growth by experimental investigation and numerical simulation. Engineering Fracture Mechanics, 96:251-266. doi: 10.1016/j.engfracmech.2012.08.009 [68] Zhao L, Jing H Y, Xiu J, Han Y D, Xu L Y. 2014. Experimental investigation of specimen size effect on creep crack growth behavior in P92 steel welded joint. Materials & Design, 57:736-743. https://www.researchgate.net/publication/277531292_Experimental_investigation_of_specimen_size_effect_on_creep_crack_growth_behavior_in_P92_steel_welded_joint [69] Zhao L, Xu L Y, Han Y D, Jing H Y. 2015. Quantifying the constraint effect induced by specimen geometry on creep crack growth behavior in P92 steel. International Journal of Mechanicals Science, 94-95:63-74. doi: 10.1016/j.ijmecsci.2015.02.009 -

下载:

下载: