-

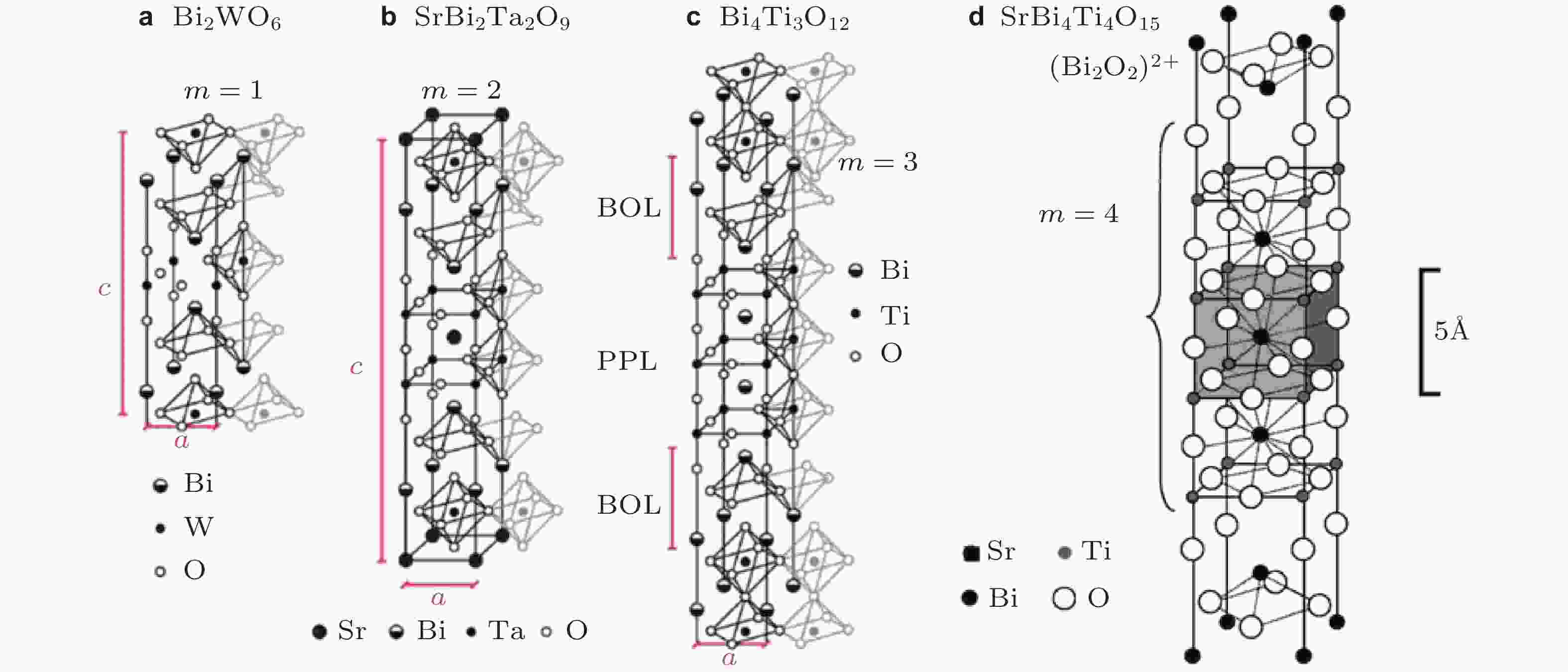

摘要: 在航空航天、核能发电等重大装备技术领域, 作为高温传感/驱动/能量收集器件的敏感材料——铋层状结构铁电(BLSF)陶瓷在复杂载荷环境下的疲劳失效问题严重限制着器件寿命和可靠性的提高. 本文以BLSF陶瓷的应用需求为背景, 围绕铁电材料的疲劳裂纹扩展与电畴极化翻转及其相互作用机制等关键问题, 综述了铁电材料在热、力、电三种载荷及其耦合作用下疲劳失效行为的研究现状, 并根据当前铁电材料的一些新发展、新应用对其未来研究方向进行了展望, 旨在为高性能、长寿命铁电/压电器件设计提供参考.Abstract: In the fields of some major equipment technology such as aerospace and nuclear power generation, as the sensitive elements of high-temperature transforming/actuating/energy harvesting devices, the fatigue failure of bismuth layered ferroelectric (BLSF) ceramics seriously restrict the improvement in the life and reliability of devices. This paper is set in the urgent demand of BLSF ceramics, sticking to the fatigue crack growth, domain polarization switching, and interaction mechanisms. It reviewed the progress in the fatigue failure behaviors of ferroelectric materials subjected to three kinds of loadings, including heat, stress, electricity, and their coupled effects. This paper also discusses the research directions of ferroelectric materials in the future according to their new developments and applications. This work aims at providing references for the design of ferroelectric/piezoelectric devices with long life and high performance.

-

Key words:

- ferroelectric materials /

- BLSF ceramics /

- fatigue failure /

- domain switching /

- multi-fields coupling

-

图 4 (a)涂覆Ni电极和Ag电极的PZT陶瓷的应力幅值与失效周次关系(S-N曲线), (b)涂覆Ni电极的PZT陶瓷的维氏硬度随载荷循环周次的变化关系(Okayasu et al. 2010)

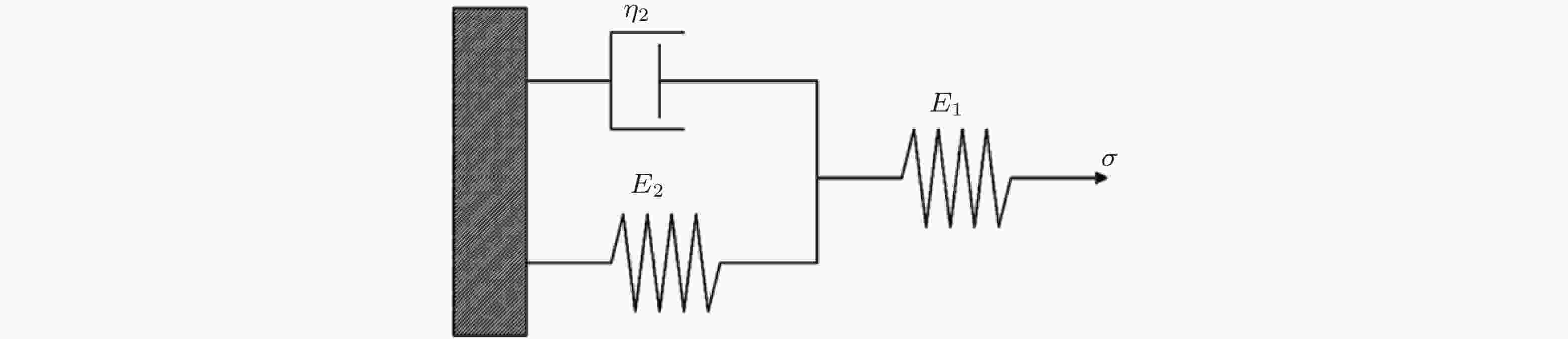

图 5 用于分析循环载荷下PZT试样累积铁弹应变存在频率效应的标准模型(Pojprapai et al. 2008)

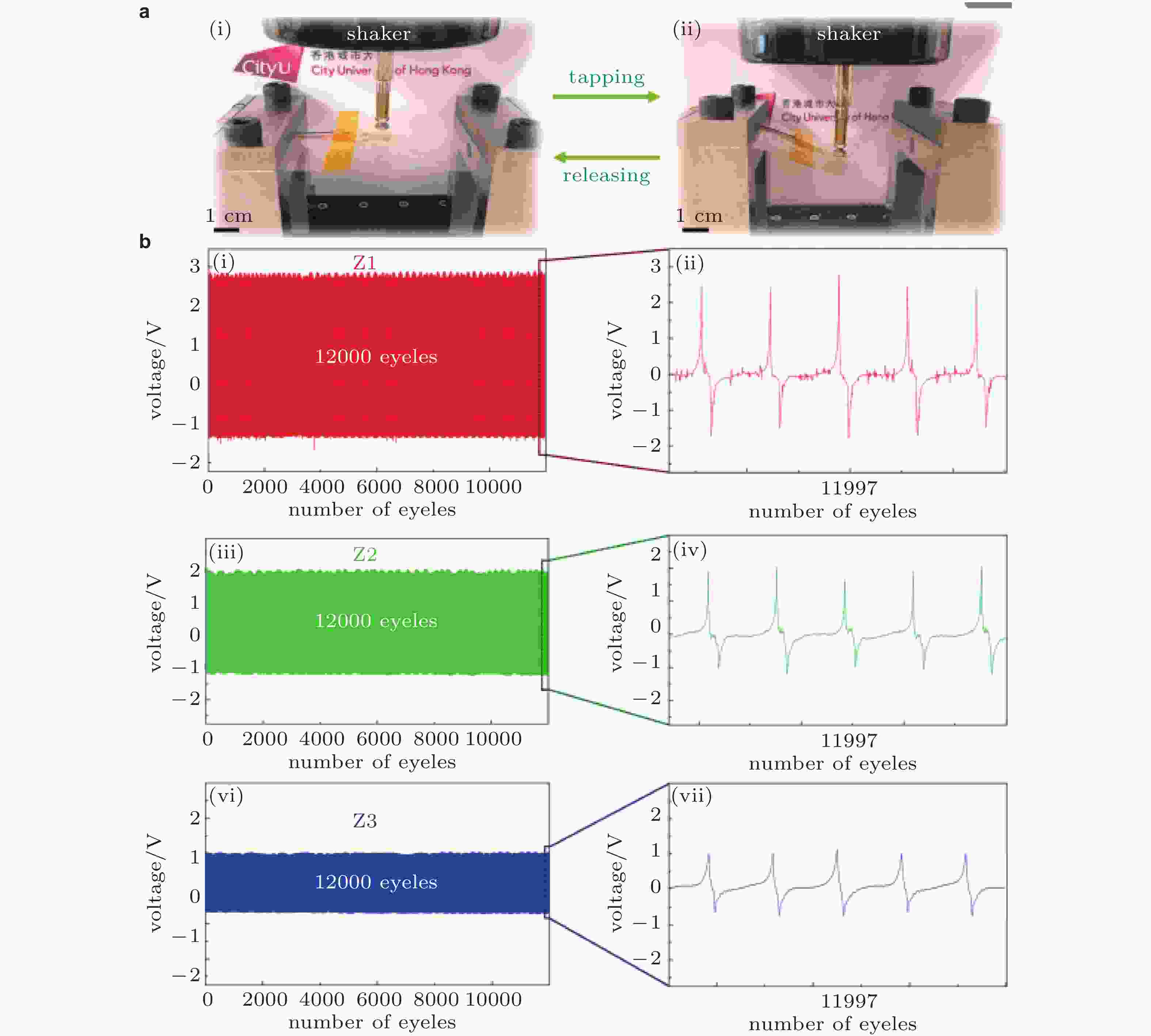

图 6 疲劳试验和敲击输出测试: (a)固定好的PZT薄膜样品及其敲击装置, (i)和(ii)PZT样品在敲击和松弛下的状态, (b) Z1, Z2和Z3的输出电压结果: 在30 Hz敲击幅度、12000次循环过程中每个样品的输出电压都展现出机械稳定性, (i)和(ii): Z1(上级成分梯度薄膜)、(iii)和(iv): Z2(52/48多层薄膜)和(vi)和(vii)Z1: (下级成分梯度薄膜)的测试(Zou et al. 2021)

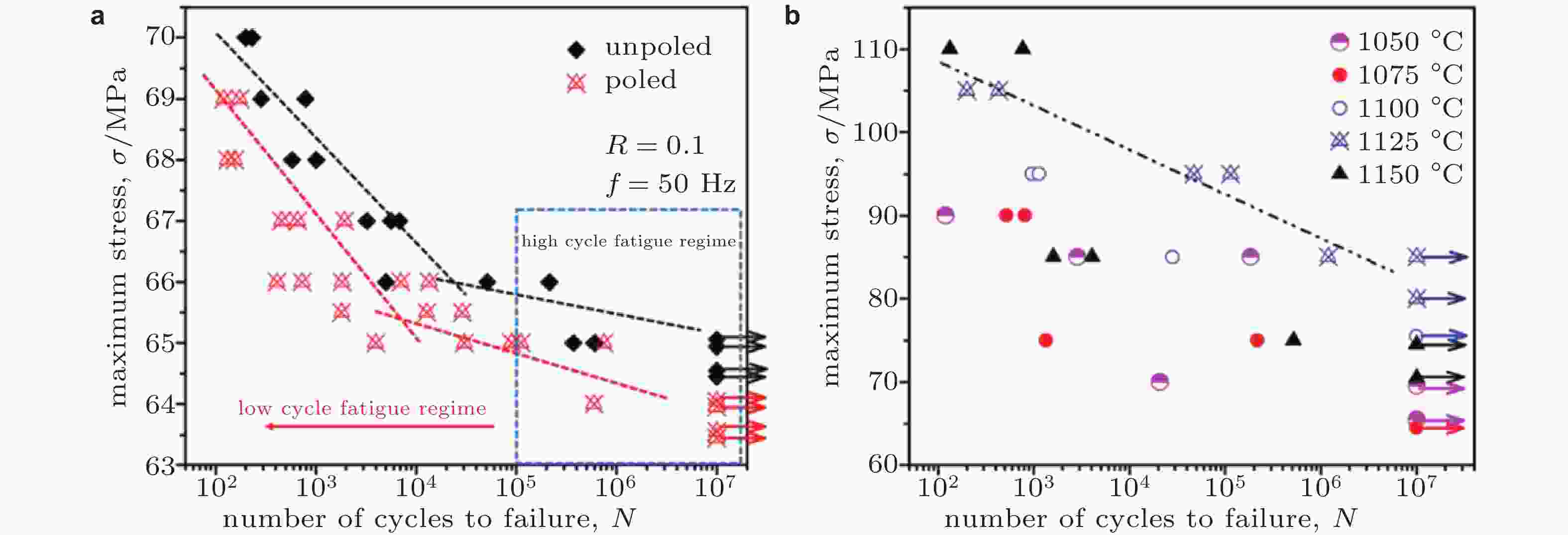

图 7 BiT陶瓷在不同载荷作用下的疲劳寿命曲线: (a)小杆冲压(Xie et al. 2018a), (b)三点弯曲(Xie et al. 2018b)

图 8 1075 ℃烧结的BiT陶瓷在三点弯曲载荷下的疲劳断口形貌(σ = 75 MPa, Nf = 2.18 × 105) (Xie et al. 2018b): (a)宏观断口, (b)裂纹扩展区

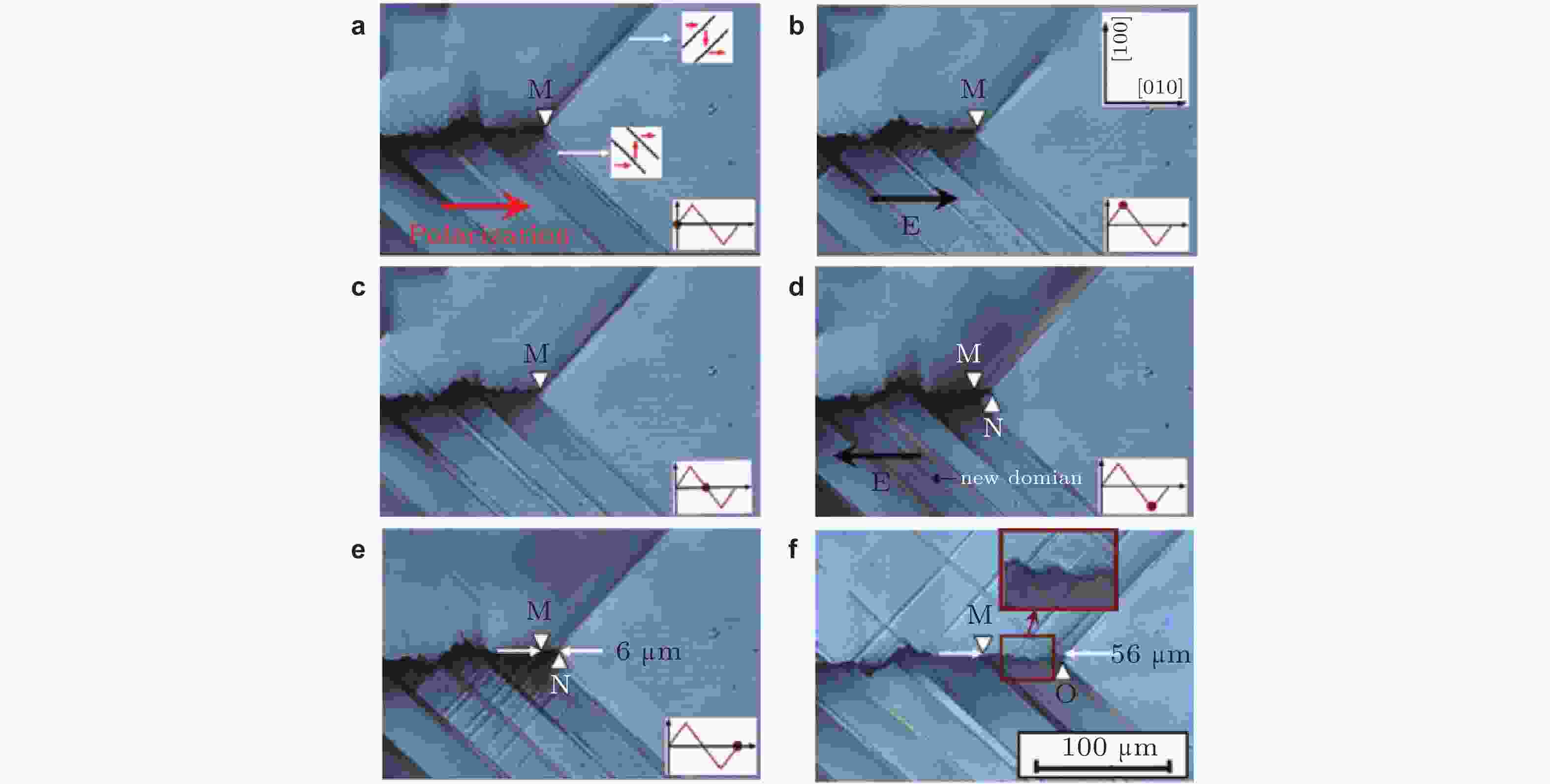

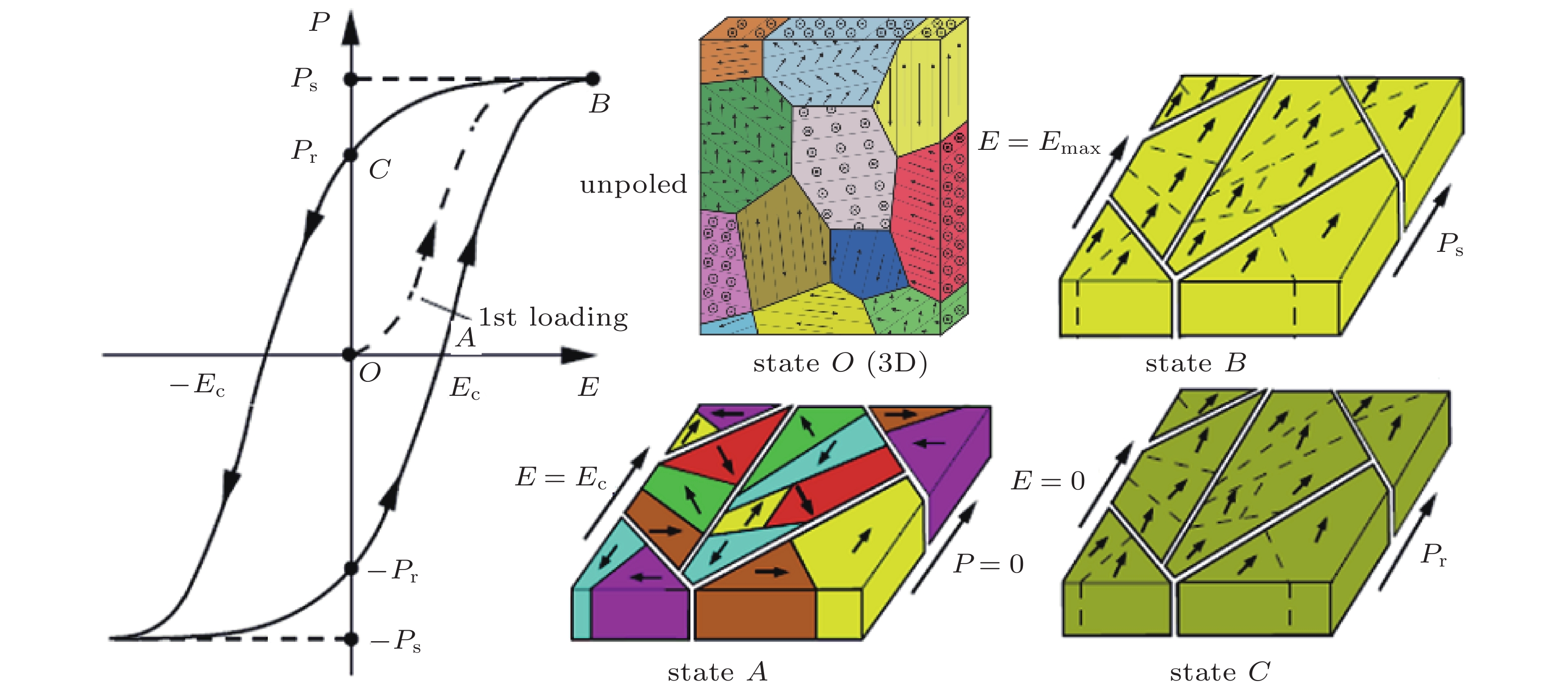

图 9 电场作用下电畴的极化翻转过程(Venkateshwarlu et al. 2020)

图 10 循环电场作用下c-电畴的形成过程(Huang et al. 2021)

图 11 (a) ~ (e) BaTiO3单晶在第一次双极循环后和(f) 10次双极循环后的电畴演化和裂纹扩展, 图片采自于偏振光显微镜(PLM) (Li & Li 2012)

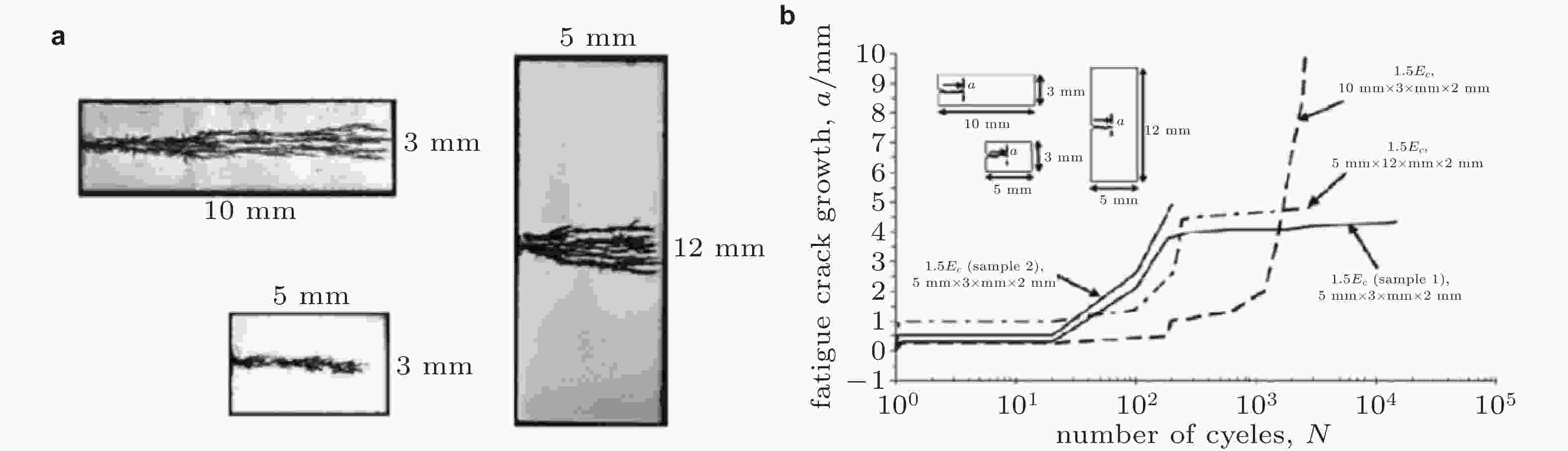

图 12 各种几何形状的PLZT 8/65/35样品中疲劳破坏区的生长: (a)疲劳试验后的样品照片, (b)疲劳破坏区生长量a与循环周次N的关系(Shieh et al. 2006)

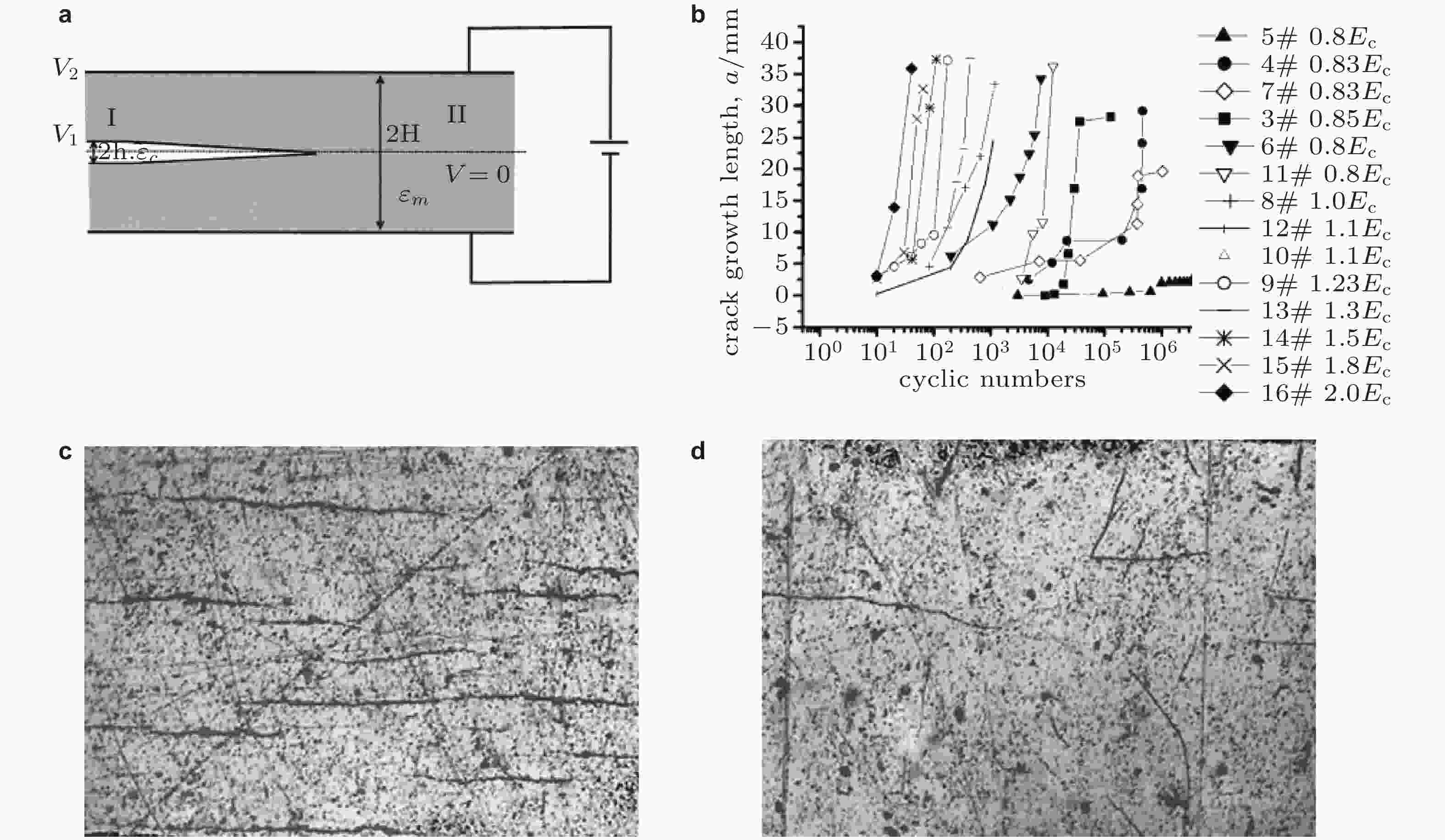

图 13 含预制裂纹的PZT-5铁电陶瓷由电场诱导的疲劳裂纹扩展行为: (a)实验原理图, (b)不同外加电场强度(Eappl)下裂纹扩展长度与电场循环周次的关系, (c)Eappl = 0.8Ec下主裂纹尖端附近的微裂纹分布, (d)Eappl = 1.0Ec下主裂纹的扩展情况(Fang & Liu 2004)

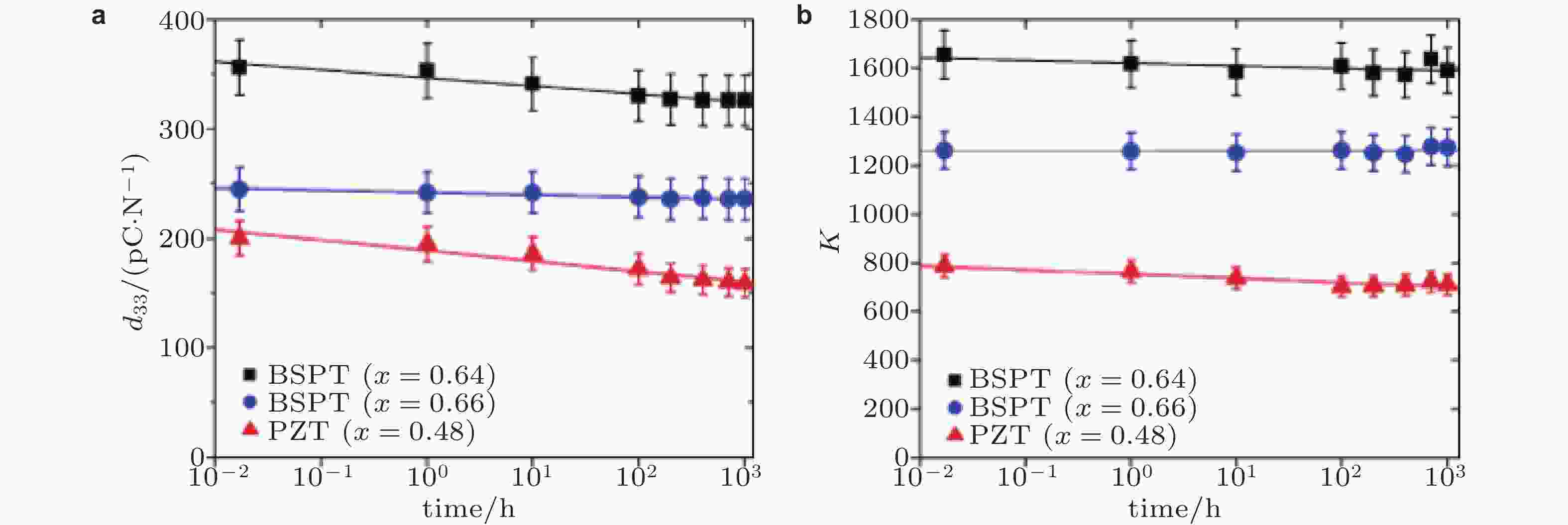

图 14 PZT和BSPT陶瓷中(a)压电系数(d33)和(b)介电常数(K)随老化时间的变化(Gotmare et al. 2010)

图 15 BaTiO3陶瓷和(Ba, Pb) TiO3陶瓷在热循环中电阻变化率γ与循环次数N的关系(张鸿等2007)

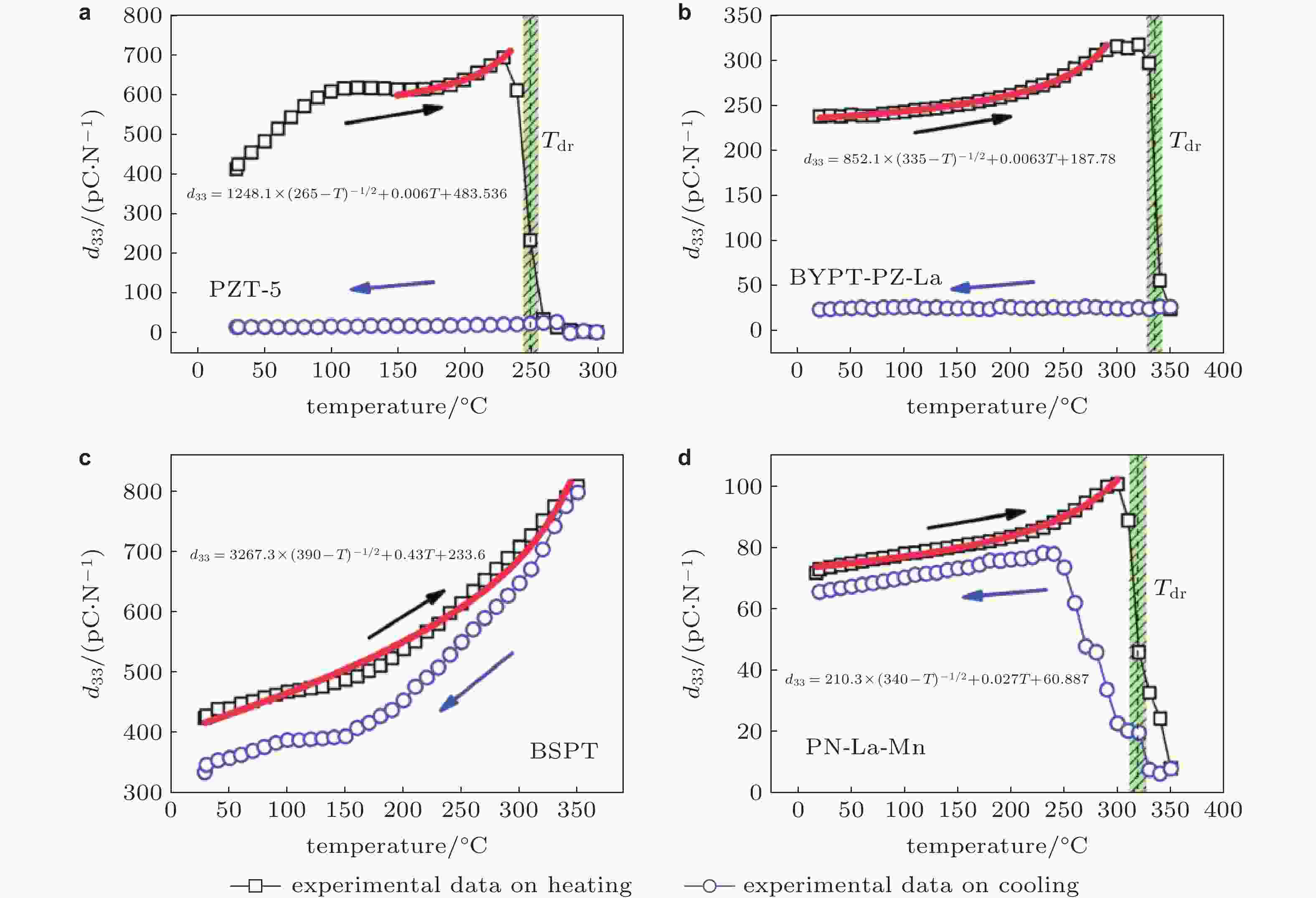

图 16 四种压电陶瓷在升降温过程中压电常数(d33)的变化(Huang et al. 2018)

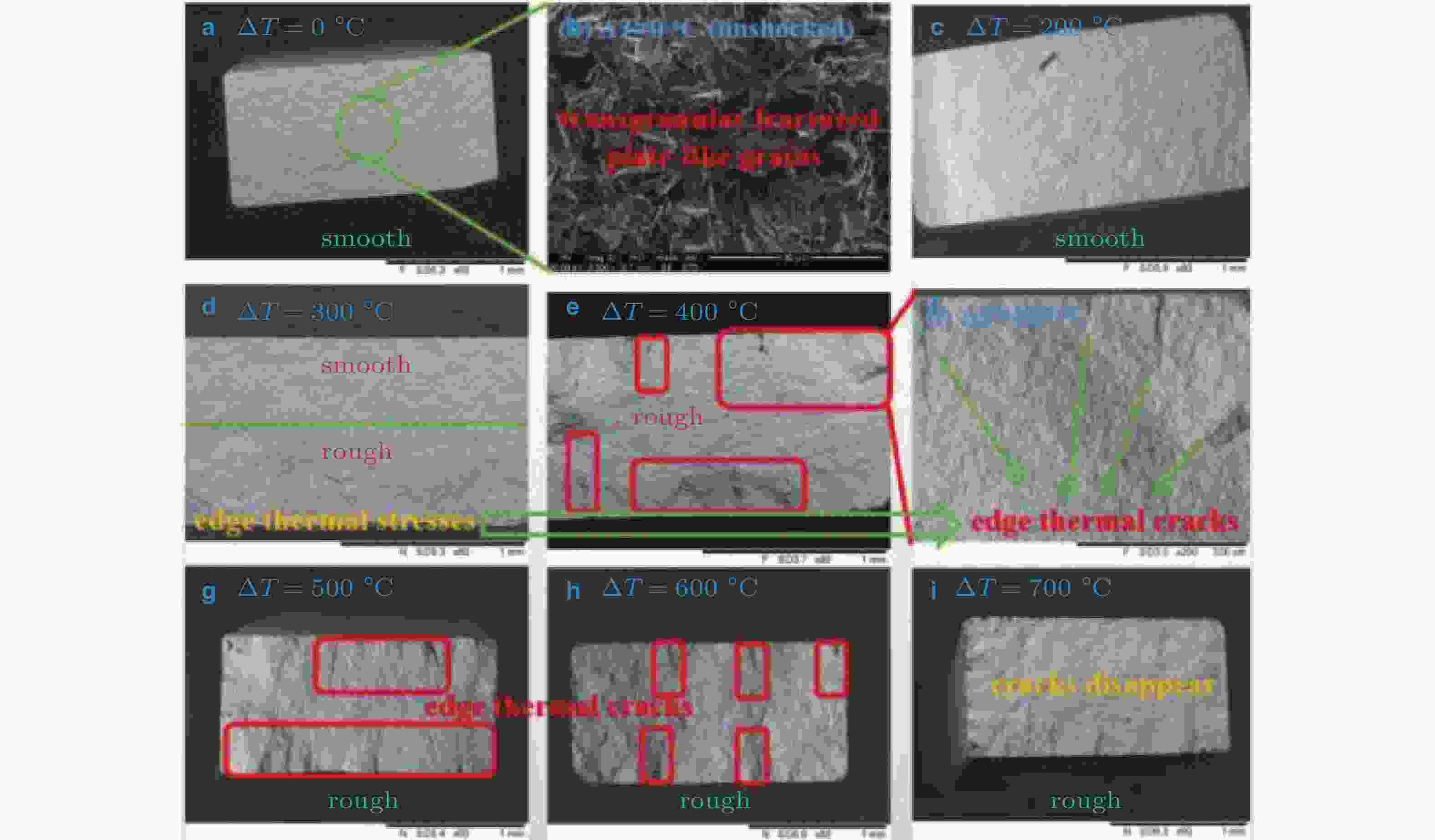

图 17 BiT铁电陶瓷经过不同温差热冲击后的断口形貌(Xu et al. 2021)

图 18 BiT铁电陶瓷经过不同温差热冲击后的电滞回线(Xu et al. 2021)

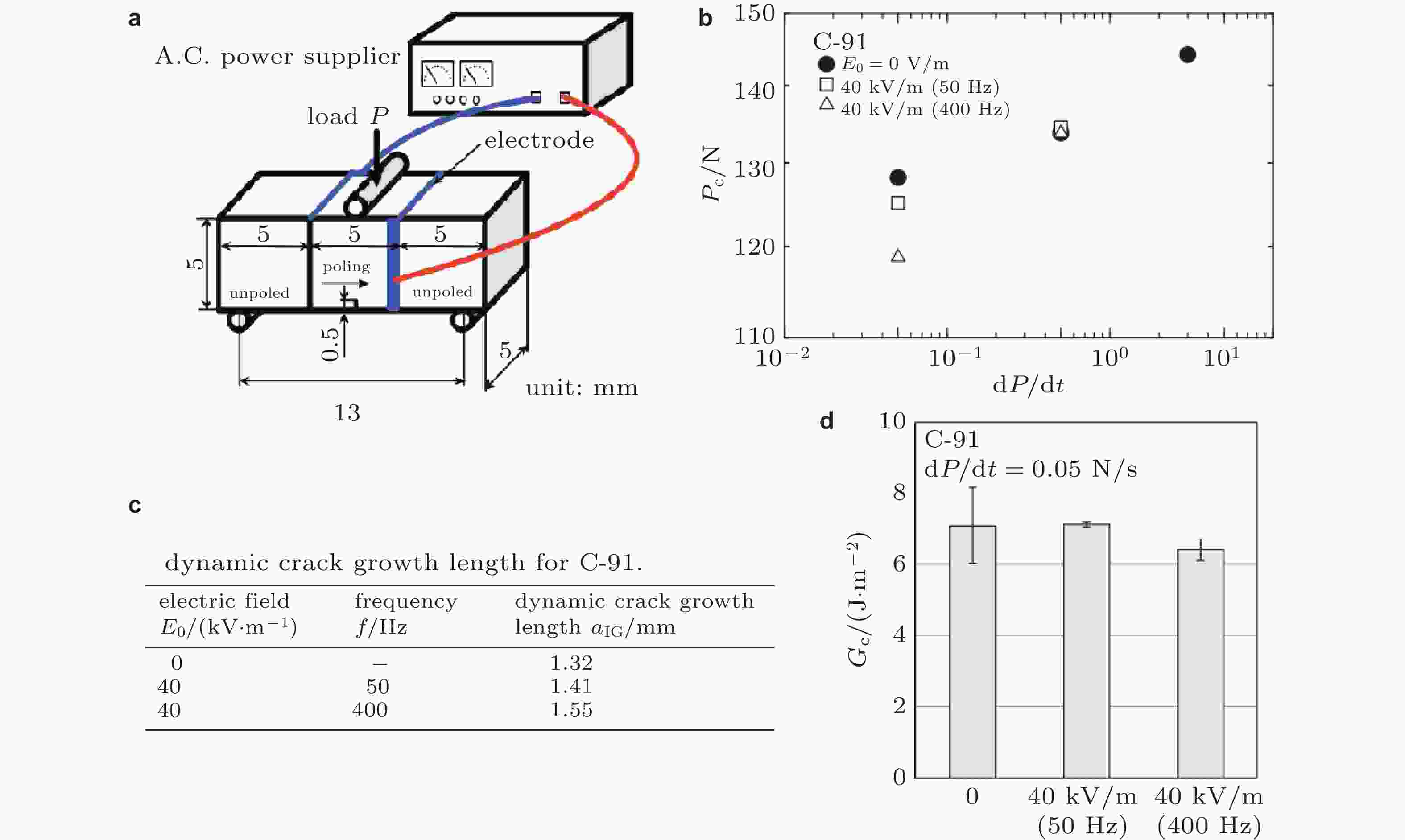

图 19 含预制裂纹的压电陶瓷在交流电场和三点弯曲载荷作用下的动态疲劳行为: (a)动态疲劳测试装置示意图, (b) C-91的断裂载荷与载荷速率的关系, (c) C-91的动态裂纹扩展长度, (d) C-91在交流电场作用下的临界能量释放率(Narita et al. 2012)

图 20 疲劳寿命作为标称场和厚度的函数: (a)计算值(所有情况下: E*f,th = E*cv), (b)实验值(样品均为PZT陶瓷), 损耗值为10% (Arias et al. 2006)

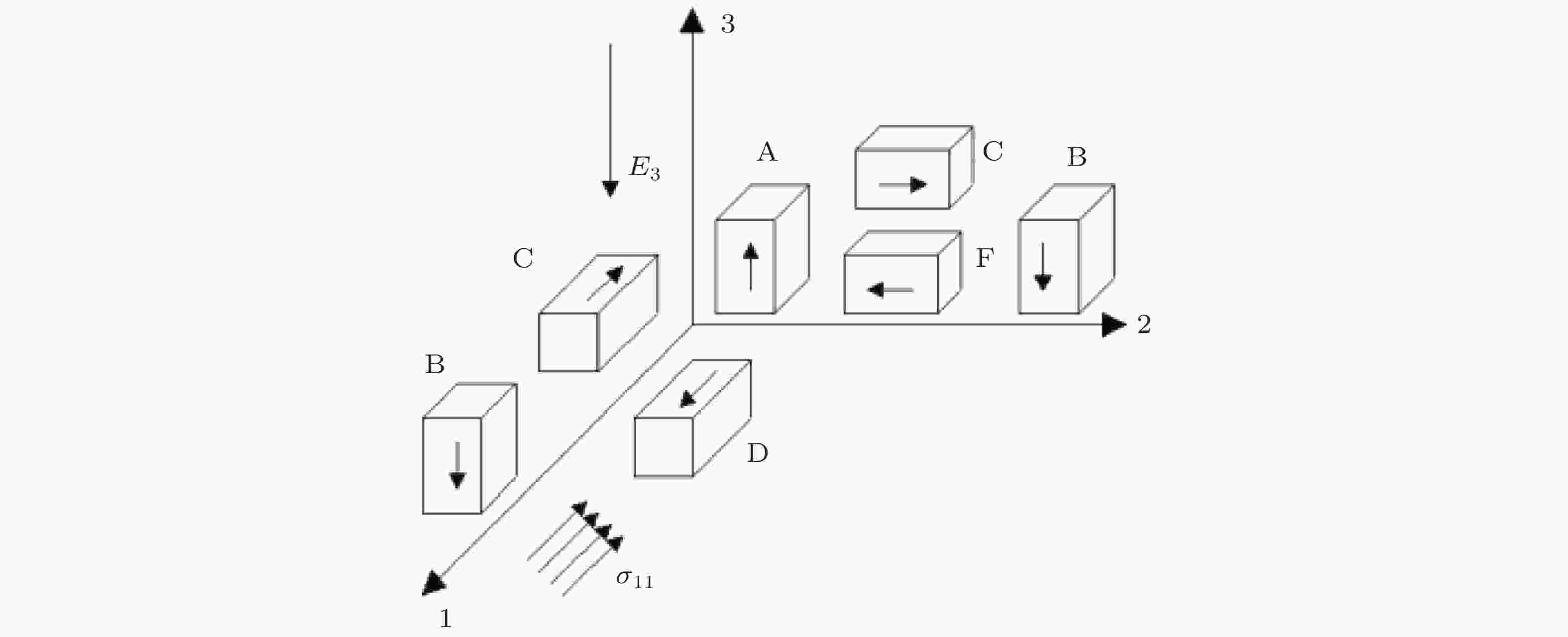

图 21 在正交力电载荷作用下两步连续的90°电畴翻转示意图(Li et al. 2005)

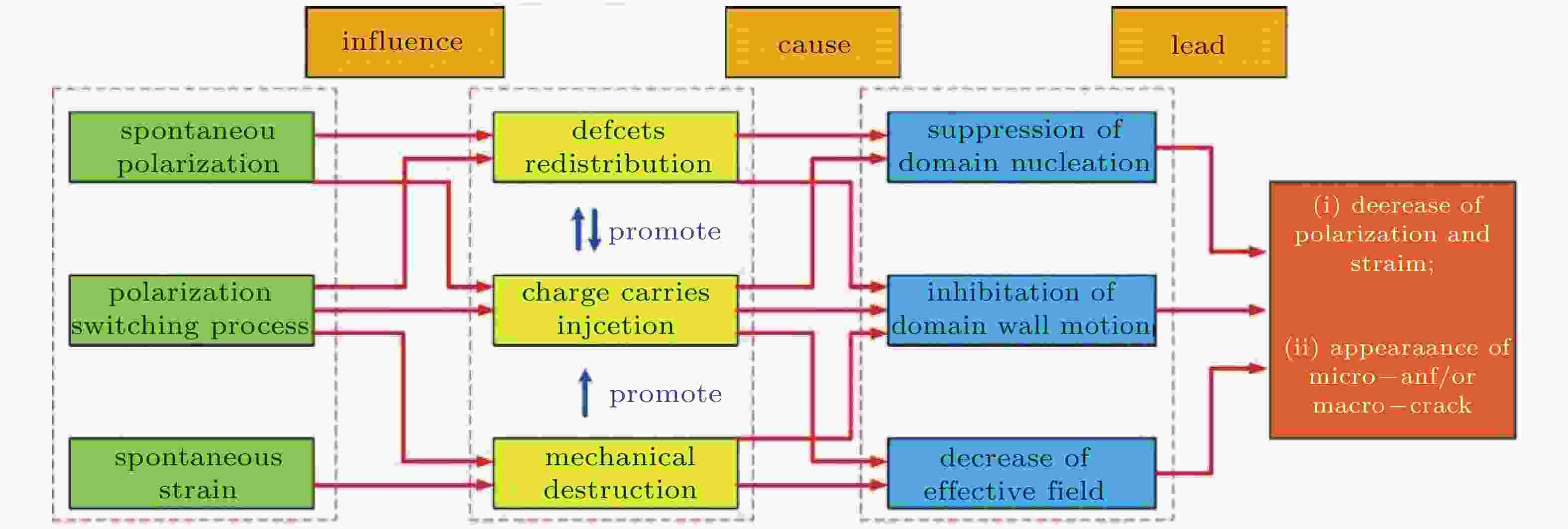

图 22 铁电体材料参数与疲劳机理的关系(Li Y W et al. 2020)

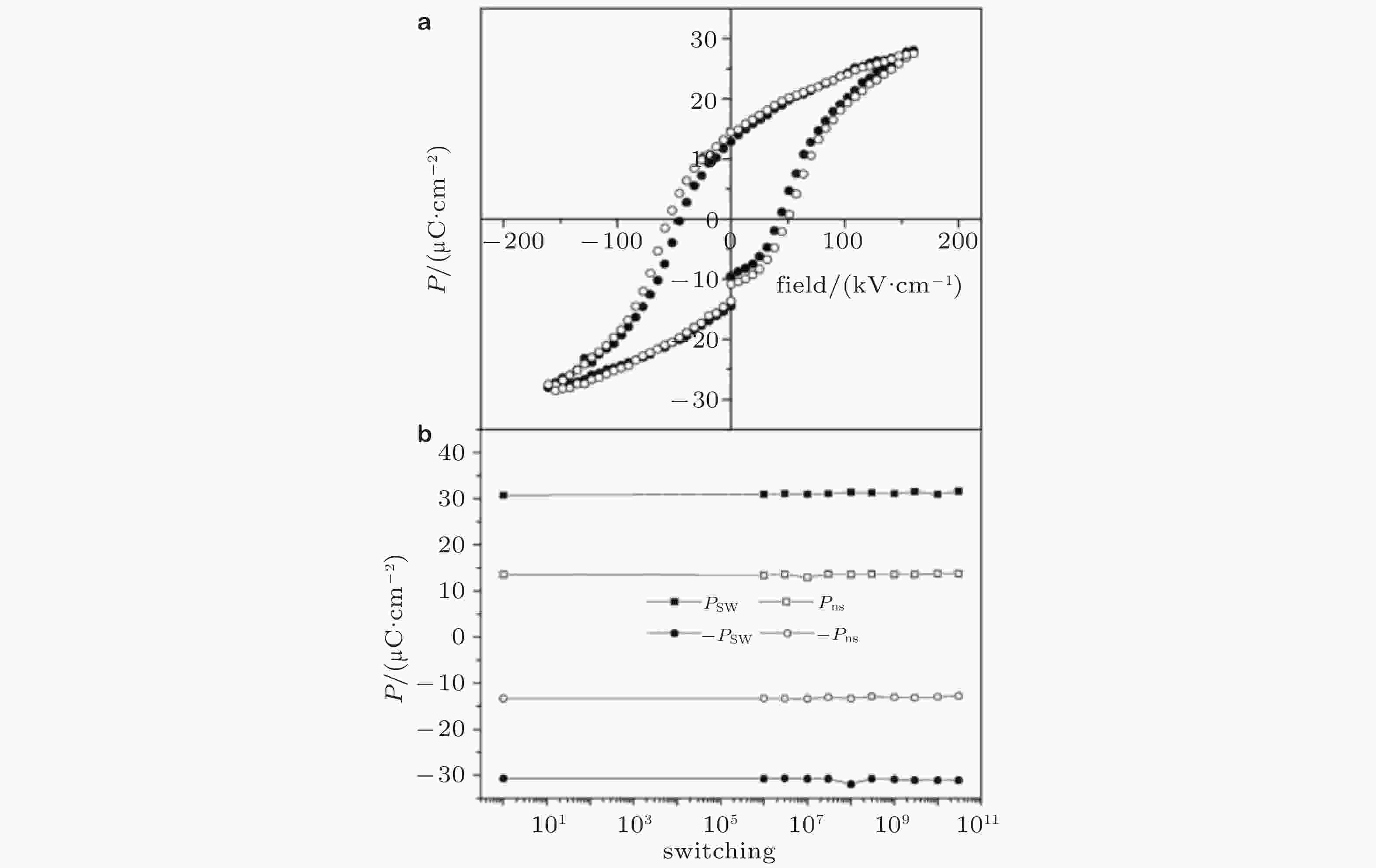

图 24 1 MHz下的疲劳测试(a) Au/BLT/Pt/Ti/SiO2/Si薄膜在3 × 1010次读写循环前(实心圆)后(空心圆)的P-E滞后回线, (b)Psw, Pns, −Psw和−Pns随循环次数的变化. 此处, −Psw和−Pns分别代表反向电场作用在这个电容时的翻转极化和线性非翻转极化(Park et al. 1999)

图 25 BiT陶瓷的3D-PFM图, 多个晶粒在VPFM 模式下的(a1)形貌与(a2)振幅; (a1)图中横向晶粒分别在VPFM, x-LPFM以及y-LPFM模式下的(b)形貌, (c1) (d1) (e1)振幅, (c2) (d2) (e2)相位以及(c3) (d3) (e3)极化矢量分布; (f) (g)铁电畴极化矢量的2D 与3D 模型, 插图表示对应的变体组合 (Xie et al. 2020a)

-

[1] 陈志武, 程璇, 张颖. 2004. 铁电陶瓷材料在交变电场作用下疲劳研究进展. 稀有金属材料与工程, 33: 673-678 (Chen Z W, Chen X, Zhang Y. 2004. Fatigue of ferroelectric ceramics under an alternative electric field. Rare Metal Materials and Engineering, 33: 673-678). doi: 10.3321/j.issn:1002-185X.2004.07.001 [2] 陈浩森. 2015. 铁电材料动态断裂力学研究. [博士论文]. 北京: 清华大学Chen H S. 2015. Research on the dynamic fracture mechanics of ferroelectric materials. [PhD Thesis]. Beijing: Tsinghua University [3] 耿黎明, 杨卫. 2007. 铁电陶瓷电致疲劳失效的研究进展. 力学进展, 37: 225-232 (Geng L M, Yang W. 2007. Research progress on electrical fatigue failure of ferroelectric ceramics. Advances in Mechanics, 37: 225-232). [4] 李卫国, 李定玉, 王如转等. 2012. 升温热冲击环境下超高温陶瓷材料抗热震性能的热-损伤模型. 应用力学学报, 29: 21-26 (Li W G, Li D Y, Wang R Z, et al. 2012. Thermal-damage model for thermal shock resistance of ultra-high temperature ceramic materials under heating and thermal shock environment. Chinese Journal of Applied Mechanics, 29: 21-26). doi: 10.11776/cjam.29.01.B043 [5] 李卫国, 邵家兴, 寇海波等. 2017. 材料高温力学性能理论表征方法研究进展. 固体力学学报, 02: 4-34 (Li W G, Shao J X, Kou H B, et al. 2017. Research progress of theoretical characterization methods for high temperature mechanical properties of materials. Acta Mechanica Solida Sinica, 02: 4-34). [6] 刘彬. 2000. 铁电晶体断裂与疲劳研究. [博士论文]. 北京: 清华大学Liu B. 2000. Research on fracture and fatigue of ferroelectric crystal. [PhD Thesis]. Beijing: Tsinghua University [7] 吕笑梅, 黄凤珍, 朱劲松. 2020. 铁电材料中的电畴: 形成, 结构, 动性及相关性能. 物理学报, 69: 27-44 (Lü X M, Huang F Z, Zhu J S. 2020. Electric domains in ferroelectric materials: formation, structure, mobility and related properties. Acta Physica Sinica, 69: 27-44). [8] 吴金根, 高翔宇, 陈建国等. 2018. 高温压电材料, 器件与应用. 物理学报, 67: 207701 (Wu J G, Gao Y X, Chen J G, et al. 2018. High-temperature piezoelectric materials, devices and applications. Acta Physica Sinica, 67: 207701). doi: 10.7498/aps.67.20181091 [9] 姚方周. 2016. 铌酸钾钠基无铅陶瓷的压电及其稳定性研究. [博士论文]. 北京: 清华大学Yao F Z. 2016. Study on piezoelectricity and stability of potassium sodium niobate-based lead-free ceramics. [PhD Thesis]. Beijing: Tsinghua University [10] 余寿文. 2008. 铁电材料在循环电载作用下的热效应与疲劳// 第十四届全国疲劳与断裂学术会议, 2008, 中国吉安, 80-85.Yu S W. 2008. Thermal effect and fatigue of ferroelectric materials under cyclic electric load//The 14th National Conference on Fatigue and Fracture, 2008, Ji’an, China, 80-85. [11] 张鸿, 周海涛, 李璐君等. 2007. PTCR铁电陶瓷热疲劳过程中的反常现象. 材料导报, 8: 133-135+139 (Zhang H, Zhou H T, Li L J, et al. 2007. Abnormal phenomena during thermal fatigue of PTCR ferroelectric ceramics. Materials Reports, 8: 133-135+139). doi: 10.3321/j.issn:1005-023X.2007.07.036 [12] 张晖辉, 刘峰. 2010. 铁电陶瓷微观电畴演化的成核率模型. 固体力学学报, 31: 193-197 (Zhang H H, Liu F. 2010. The nucleation rate model of the micro-domain evolution of ferroelectric ceramics. Acta Mechanica Solida Sinica, 31: 193-197). [13] 张阳军. 2013. 热力电耦合场下铁电薄膜非线性行为的畴变理论分析. [硕士论文]. 湘潭: 湘潭大学Zhang Y J. 2013. Theoretical analysis of domain switching of the nonlinear behavior of ferroelectric thin films in a thermo-electric coupled field. [Master Thesis]. Xiangtan: Xiangtan University. [14] 周普. 1977. 脆性陶瓷材料的裂缝扩展和热疲劳. 陶瓷, 3: 48-54 (Zhou P. 1977. Crack propagation and thermal fatigue of brittle ceramic materials. Ceramics, 3: 48-54). [15] 周志东, 杨凤娟, 柳听前等. 2011. 钙钛矿型铁电陶瓷的电致疲劳本构理论研究//2010全国压电, 声波和器件应用研讨会, 2010, 中国厦门, 111-115Zhou Z D, Yang F J, Liu T Q, et al. 2011. Study on the constitutive theory of electro-fatigue of perovskite ferroelectric ceramics//The 2010 Chinese Symposium on Piezoelectricity, Acoustic Waves and Device Applications, 2010, Xiamen, China, 111-115 [16] Arias I, Lagoudas D C, Serebrinsky S, et al. 2004. A cohesive model of fatigue of ferroelectric materials under electro-mechanical cyclic loading//Smart Structures and Materials, 2004, San Diego, CA, United States, 5387: 371-378. [17] Arias I, Serebrinsky S, Ortiz M. 2006. A phenomenological cohesive model of ferroelectric fatigue. Acta Material, 54: 975-984. doi: 10.1016/j.actamat.2005.10.035 [18] Ashby M F. Jones D R. 2012. Engineering Materials 1: An Introduction to Properties, Applications and Design. Oxford: Butterworth-Heinemann Elsevier. [19] Bathias C, Pineau A. 材料与结构的疲劳. 吴圣川, 李源, 王清远, 译. 2016. 北京: 国防工业出版社Bathias C, Pineau A. Fatigue of Materials and Structures. Wu S C, Li Y, Wang Q Y, Transl. 2016. Beijing: National Defense Industry Press. [20] Chaplya P M, Mitrovic M, Carman G P, et al. 2006. Durability properties of piezoelectric stack actuators under combined electromechanical loading. Journal of Applied Physics, 100: 124111. doi: 10.1063/1.2407269 [21] Chen Y, Pen Z H, Wang Q Y, et al. 2014. Crystalline structure, ferroelectric properties, and electrical conduction characteristics of W/Cr co-doped Bi4Ti3O12 ceramics. Journal of Alloys and Compounds, 612: 120-125. doi: 10.1016/j.jallcom.2014.05.136 [22] Chen X G, Song X J, Zhang Z X, et al. 2019. Two-dimensional layered perovskite ferroelectric with giant piezoelectric voltage coefficient. Journal of the American Chemical Society, 142: 1077-1082. [23] Chen Y, Xie S X, Wang H M, et al. 2017. Dielectric abnormality and ferroelectric asymmetry in W/Cr co-doped Bi4Ti3O12 ceramics based on the effect of defect dipoles. Journal of Alloys and Compounds, 696: 746-753. doi: 10.1016/j.jallcom.2016.11.322 [24] Chen Y, Xu J G, Xie S X, et al. 2018. Failure mode, ferroelastic behavior and toughening effect of bismuth titanate ferroelectric ceramics under uniaxial compression load. Materials & Design, 152: 54-64. [25] Chen Y, Xu J G, Xu Q, et al. 2020. Ferroelastic domain switching and R-curve behavior in lead zirconate titanate (Zr/Ti=52/48)-based ferroelectric ceramics. Journal of the American Ceramics Society, 103: 1067-1078. doi: 10.1111/jace.16722 [26] Damjanovic D. 1998. Ferroelectric, dielectric and piezoelectric properties of ferroelectric thin films and ceramics. Reports on Progress in Physics, 61: 1267-1324. doi: 10.1088/0034-4885/61/9/002 [27] De Araujo A P, Cuchiaro J D, Mcmillan L D, et al. 1995. Fatigue-free ferroelectric capacitors with platinum electrodes. Nature, 374: 627-629. doi: 10.1038/374627a0 [28] De U, Sahu K R, De A. 2015. Ferroelectric materials for high temperature piezoelectric applications. Solid state Phenomena, 232: 235-278. doi: 10.4028/www.scientific.net/SSP.232.235 [29] Ding Y, Liu J S, Qin H X, et al. 2001. Why lanthanum-substituted bismuth titanate becomes fatigue free in a ferroelectric capacitor with platinum electrodes. Applied Physics Letters, 78: 4175-4177. doi: 10.1063/1.1381038 [30] Do M T, Gauquelin N, Nguyen M D, et al. 2021. Interface degradation and field screening mechanism behind bipolar-cycling fatigue in ferroelectric capacitors. APL Materials, 9: 021113. doi: 10.1063/5.0038719 [31] Dong G, Li S, Yao M, et al. 2019. Super-elastic ferroelectric single-crystal membrane with continuous electric dipole rotation. Science, 366: 475-479. doi: 10.1126/science.aay7221 [32] Fang D N, Liu J X. 2013. Fracture Mechanics of Piezoelectric and Ferroelectric Solids. London: Springer. [33] Fang D N, Zhang Z K, Soh A K, et al. 2004. Fracture criteria of piezoelectric ceramics with defects. Mechanics of Materials., 36: 917-928. doi: 10.1016/j.mechmat.2003.08.011 [34] Fang D N, Zhang Y H, Mao G Z. 2010. Electric-field-induced fatigue crack growth in ferroelectric ceramics. Theoretical and Applied Fracture Mechanics, 54: 98-104. doi: 10.1016/j.tafmec.2010.10.004 [35] Fang D N, Zhang, Y H, Mao G Z. 2011. A cod fracture model of ferroelectric ceramics with applications in electric field induced fatigue crack growth. International Journal of Fracture, 167: 211-220. doi: 10.1007/s10704-010-9546-x [36] Fang D N, Liu B. 2004. Fatigue crack growth in ferroelectric ceramics driven by alternating electric fields. Journal of the American Ceramics Society, 87: 840-846. doi: 10.1111/j.1551-2916.2004.00840.x [37] Glaum J, Hoffman M. 2014. Electric fatigue of lead-free piezoelectric materials. Journal of the American Ceramics Society, 97: 665-680. doi: 10.1111/jace.12811 [38] Gotmare S W, Leontsev S O, Eitel R E. 2010. Thermal degradation and aging of high-temperature piezoelectric ceramics. Journal of the American Ceramics Society, 93: 1965-1969. [39] Genenko Y A, Glaum J, Hoffmann M J, et al. 2015. Mechanisms of aging and fatigue in ferroelectrics. Materials Science and Engineering B, 192: 52-82. doi: 10.1016/j.mseb.2014.10.003 [40] Haertling G H. 1999. Ferroelectric ceramics: History and technology. Journal of the American Ceramics Society, 82: 797-818. doi: 10.1111/j.1151-2916.1999.tb01840.x [41] Hao X H, Zhai J W, Yao X. 2009. Improved energy storage performance and fatigue endurance of Sr-doped PbZrO3 antiferroelectric thin films. Journal of the American Ceramics Society, 92: 1133-1135. doi: 10.1111/j.1551-2916.2009.03015.x [42] Hao X H, Zhai J W, Kong L B, et al. 2014. A comprehensive review on the progress of lead zirconate-based antiferroelectric materials. Progress in Materials Science, 63: 1-57. doi: 10.1016/j.pmatsci.2014.01.002 [43] Huang C C, Cai K, Wang Y Y. 2018. Revealing the real high temperature performance and depolarization characteristics of piezoelectric ceramics by combined in situ techniques. Journal of Materials Chemistry C, 6: 1433-1444. doi: 10.1039/C7TC04768A [44] Huang Q W, Chen Z B, Cabral M J, et al. 2021. Direct observation of nanoscale dynamics of ferroelectric degradation. Nature Communication, 12: 1234567890. [45] Ievlev A V, Santosh K C, Vasudevan R K, et al. 2019. Non-conventional mechanism of ferroelectric fatigue via cation migration. Nature Communication, 10: 3064. doi: 10.1038/s41467-019-11089-w [46] Ishiwara H. 2012. Ferroelectric random access memories. J. Nanosci. Nanotechnol., 12: 7619-7627. doi: 10.1166/jnn.2012.6651 [47] Ishibashi Y. 1989. Phenomenological theory of domain walls. Ferroelectrics, 98: 193-205. doi: 10.1080/00150198908217582 [48] Ji H F, Wang D W, Bao W C, et al. 2021. Ultrahigh energy density in short-range tilted NBT-based lead-free multilayer ceramic capacitors by nanodomain percolation. Energy Storage Materials, 38: 113-120. doi: 10.1016/j.ensm.2021.01.023 [49] Jiang X, Kim K, Zhang S, et al. 2014. High-Temperature Piezoelectric Sensing. Sensors, 14(1):144-169. [50] Kim S J, Jiang Q. 1999. Microcracking and electric fatigue of polycrystalline ferroelectric ceramics. Smart Materials and Structures, 5: 321. [51] Kuo Y C, Chien J T, Shih W T, et al. 2019. The fatigue behavior study of micro piezoelectric energy harvester under different working temperature//SPIE Smart Structures + Nondestructive Evaluation, 2019, Denver, Colorado, United States, Vol. 10967. [52] Kuroiwa Y, Ando A, Cho Y, et al. 2017. Ferroelectric materials and their applications. Japanese Journal of Applied Physics, 56: QT001-QT001. [53] Lebeugle D, Colson D, Forget A, et al. 2007. Very large spontaneous electric polarization in BiFeO3 single crystals at room temperature and its evolution under cycling fields. Applied Physics Letters, 91: 022907. doi: 10.1063/1.2753390 [54] Lee H N, Hesse D, Zakharov N, et al. 2002. Cheminform abstract: Ferroelectric Bi3.25La0.75Ti3O12 films of uniform a-axis orientation on silicon substrates. Science, 296: 2006-2009. doi: 10.1126/science.1069958 [55] Li L, Xie L, Pan X. 2019. Real-time studies of ferroelectric domain switching: a review. Reports on Progress in Physics, 82: 126502. doi: 10.1088/1361-6633/ab28de [56] Li F X, Li S, Fang D N. 2005. Domain switching in ferroelectric single crystal/ceramics under electromechanical loading. Materials Science and Engineering: B, 120: 119-124. doi: 10.1016/j.mseb.2005.02.037 [57] Li F X, Rajapakse R, Mumford D, et al. 2008. Quasi-static thermo-electro-mechanical behaviour of piezoelectric stack actuators. Smart Materials & Structures, 17: 015049. [58] Li Q, Wang B, He Q, et al. 2020. Ferroelastic nanodomain-mediated mechanical switching of ferroelectricity in thick epitaxial films. Nano Letters, 21: 445-452. [59] Li Y W, Li F X. 2012. In situ observation of electric field induced crack propagation in BaTiO3 crystals along the field direction. Scripta Material, 67: 601-604. doi: 10.1016/j.scriptamat.2012.06.020 [60] Li Y W, Cheng X Y, Zhu D P, et al. 2020. Influence of domain switching process on the electrical fatigue behavior of ferroelectrics. Ceramics International, 46: 24213-24224. doi: 10.1016/j.ceramint.2020.06.201 [61] Lu T, Tian Y, Studer A, et al. 2020. Structure-driven, ferroelectric wake-up effect for electrical fatigue relief. Chemistry of Materials, 32: 6456-6463. doi: 10.1021/acs.chemmater.0c01692 [62] Lou X J. 2009. Polarization fatigue in ferroelectric thin films and related materials. Journal of Applied Physics, 105: 024101. doi: 10.1063/1.3056603 [63] Luo Z H, Glaum J, Granzow T, et al. 2011. Bipolar and unipolar fatigue of ferroelectric BNT-based lead-free piezoceramics. Journal of the American Ceramics Society, 94: 529-535. doi: 10.1111/j.1551-2916.2010.04101.x [64] Lupascu D C. 2004. Fatigue in Ferroelectric Ceramics and Related Issues//Berlin Heidelberg: Springer. [65] Lupascu D C, Rödel J. 2005. Fatigue in bulk lead zirconate titanate actuator materials. Advanced Engineering Materials, 7: 882-898. doi: 10.1002/adem.200500117 [66] Mattingly M. 2006. Design and selection considerations for high-temperature aerospace accelerometers. NASA Tech. Briefs, 30: 52-54. [67] Martin L W, Rappe A M. 2016. Thin-film ferroelectric materials and their applications. Nature Reviews Materials, 2: 16087. [68] Narita F, Morikawa Y, Shindo Y, et al. 2012. Dynamic fatigue behavior of cracked piezoelectric ceramics in three-point bending under AC electric field. Journal of the European Ceramic Society, 32: 3759-3766. doi: 10.1016/j.jeurceramsoc.2012.05.033 [69] Noguchi Y, Miwa I, Goshima Y, et al. 2000. Defect control for large remanent polarization in bismuth titanate ferroelectrics−doping effect of higher-valent cations−. Japanese Journal of Applied Physics, 39: L1259. doi: 10.1143/JJAP.39.L1259 [70] Nuffer J, Lupascu D C, Glazounov A, et al. 2002. Microstructural modifications of ferroelectric lead zirconate titanate ceramics due to bipolar electric fatigue. Journal of the European Ceramic Society, 22: 2133-2142. doi: 10.1016/S0955-2219(02)00017-1 [71] Okayasu M, Ozeki G, Mizuno M. 2010. Fatigue failure characteristics of lead zirconate titanate piezoelectric ceramics. J. Eur. Ceram. Soc., 30: 713-725. doi: 10.1016/j.jeurceramsoc.2009.09.014 [72] Ortiz M, Pandolfi A. 1999. Finite-deformation irreversible cohesive elements for three-dimensional crack-propagation analysis. International Journal for Numerical Methods in Engineering, 44: 1267-1282. doi: 10.1002/(SICI)1097-0207(19990330)44:9<1267::AID-NME486>3.0.CO;2-7 [73] Panda P K, Sahoo B. 2015. PZT to lead free piezo ceramics: A review. Ferroelectrics, 474: 128-143. doi: 10.1080/00150193.2015.997146 [74] Panda P K. 2017. Piezoceramic materials and devices for aerospace applications//Aerospace Materials and Material Technologies, Singapore: Springer., 501-518. [75] Park B H, Kang B S, Bu S D, et al. 1999. Lanthanum-substituted bismuth titanate for use in non-volatile memories. Nature, 401: 682-684. doi: 10.1038/44352 [76] Paruch P, Guyonnet J. 2013. Nanoscale studies of ferroelectric domain walls as pinned elastic interfaces. Comptes Rendus Physique, 14: 667-684. doi: 10.1016/j.crhy.2013.08.004 [77] Pojprapai S, Jones J L, Studer A J, et al. 2008. Ferroelastic domain switching fatigue in lead zirconate titanate ceramics. Acta Material, 56: 1577-1587. doi: 10.1016/j.actamat.2007.11.044 [78] Qi L, Ruan S C, Zeng Y J. 2021. Review on recent developments in 2D ferroelectrics: Theories and applications. Advanced Materials, 33: 202005098. [79] Raghavan C M, Kim J W, Kim J W, et al. 2014. Effects of La- and V-doping on structural, electrical and multiferroic properties of Bi6Fe2Ti3O18 thin films. Ceramics International, 40: 10649-10655. doi: 10.1016/j.ceramint.2014.03.049 [80] Salazar R, Serrano M, Abdelkefi A. 2020. Fatigue in piezoelectric ceramic vibrational energy harvesting: a review. Applied Energy, 270: 115161. doi: 10.1016/j.apenergy.2020.115161 [81] Schneider G A. 2007. Influence of electric field and mechanical stresses on the fracture of ferroelectrics. Annual Review of Materials Science, 37: 491-538. doi: 10.1146/annurev.matsci.37.052506.084213 [82] Schneider G A, Petzow G. 2010. Thermal Shock and Thermal Fatigue Behavior of Advanced Ceramics. Netherlands: Springer. [83] Senousy M S, Rajapakse R, Mumford D, et al. 2009. Self-heat generation in piezoelectric stack actuators used in fuel injectors. Smart Materials & Structures, 18: 045008. [84] Sherrit S, Armstrong W D. 2005. Smart material/actuator needs in extreme environments in space. Proc. SPIE, 5761: 335-346. doi: 10.1117/12.606475 [85] Shieh J, Huber J E, Fleck N A. 2006. Fatigue crack growth in ferroelectrics under electrical loading. Journal of the European Ceramic Society, 26: 95-109. doi: 10.1016/j.jeurceramsoc.2004.10.002 [86] Schultheiß J, Liu L, Kungl H, et al. 2018. Revealing the sequence of switching mechanisms in polycrystalline ferroelectric/ferroelastic materials. Acta Material, 157: 355-363. doi: 10.1016/j.actamat.2018.07.018 [87] Su D, Zhu J S, Wang Y N, et al. 2003. Different domain structures and their effects on fatigue behavior in Bi3TiTaO9 and SrBi2Ta2O9 ceramics. Journal of Applied Physics, 93: 4784-4787. doi: 10.1063/1.1561992 [88] Su D, Ding Y, Zhu J S, et al. 2004. Morphology and mobility of 90° domains in La-substituted bismuth titanate. Journal of Physics: Condensed Matter, 16: 4549. doi: 10.1088/0953-8984/16/25/012 [89] Su L S, Lu X B, Chen L, et al. 2018. Flexible, fatigue-free, and large-scale Bi3.25La0.75Ti3O12 ferroelectric memories. ACS Applied Materials & Interfaces, 10: 21428-21433. [90] Subbarao E C. 1962. A family of ferroelectric bismuth compounds. Journal of Physics and Chemistry of Solids, 23: 665-676. doi: 10.1016/0022-3697(62)90526-7 [91] Tagantsev A K, Cross L E, Fousek J. 2010. Domains in Ferroic Crystals and Thin Films. New York: Springer. [92] Takenaka T. 2008. Bismuth-based piezoelectric ceramics//Piezoelectric and Acoustic Materials for Transducer Applications. Safari A, Akdo$\breve{{\rm{g}}} $an EK (eds) Boston: Springer. 103-130 [93] Troiler-McKinstry S. 2020. Impact of ferroelectricity. American Ceramic Society Bulletin, 99: 22-23. [94] Trolier-McKinstry S, Zhang S, Bell A J, et al. 2018. High-performance piezoelectric crystals, ceramics, and films. Annual Review of Materials Research, 48: 191-217. doi: 10.1146/annurev-matsci-070616-124023 [95] Uchino K. 2010. Advanced Piezoelectric Materials: Science and Technology. Woodhead Publishing Ltd. [96] Venkateshwarlu S, Venkataraman L K, Segouin V, et al. 2020. Large electromechanical strain and unconventional domain switching near phase convergence in a Pb-free ferroelectric. Communications Physics, 3: 1-14. doi: 10.1038/s42005-019-0260-3 [97] Wang B L, Han J C. 2007. An accumulation damage model for fatigue fracture of ferroelectric ceramics. Engineering Fracture Mechanics, 74: 1456-1467. doi: 10.1016/j.engfracmech.2006.08.007 [98] Xia X D, Wang Y, Zhong Z, et al. 2016. Theory of electric creep and electromechanical coupling with domain evolution for non-poled and fully poled ferroelectric ceramics. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences, 472: 20160468. doi: 10.1098/rspa.2016.0468 [99] Xiao S Y, Jin Y M, Lu X M, et al. 2020. Dynamics and manipulation of ferroelectric domain walls in bismuth ferrite thin films. National Science Review, 7: 278-284. doi: 10.1093/nsr/nwz176 [100] Xie S X, Chen Y, Liu W Y, et al. 2020a. Three-dimensional domain patterns in tetragonal-to-monoclinic Bi4Ti3O12 ceramics: Nonlinear analysis and piezoresponse force microscopy imaging. Acta Material, 188: 228-240. doi: 10.1016/j.actamat.2020.02.007 [101] Xie S X, Tan Z, Jiang L M, et al. 2020b. Ferroelastic properties and compressive stress-strain response of bismuth titanate based ferroelectrics. Ceramics International, 46: 1183-1188. doi: 10.1016/j.ceramint.2019.09.090 [102] Xie S X, Xu J G, Chen Y, et al. 2018a. Poling effect and sintering temperature dependence on fracture strength and fatigue properties of bismuth titanate based high-temperature piezoceramics. Ceramics International, 44: 20432-20440. doi: 10.1016/j.ceramint.2018.08.037 [103] Xie S X, Xu J G, Chen Y, et al. 2018b. Flexural fracture mechanisms and fatigue behaviors of Bi4Ti3O12-based high-temperature piezoceramics sintered at different temperatures. Ceramics International, 44: 16768-16765. [104] Xu Q, Xie S X, Chen Y, et al. 2021. Thermal shock resistance and crack growth behavior of Aurivillius phase Bi4Ti3O12-based ferroelectric ceramics. Progress in Natural Science: Materials International, 31: 248-254. doi: 10.1016/j.pnsc.2021.01.005 [105] Xue K H, Fonseca L R C, Nishi Y. 2014. First-principles study of A-site substitution in ferroelectric bismuth titanate. Journal of Materials Science, 49: 6363-6372. doi: 10.1007/s10853-014-8363-4 [106] Xue K H, Fonseca L R C, Miao X S. 2017. Ferroelectric fatigue in layered perovskites from self-energy corrected density functional theory. RSC Advances, 7: 21856-21868. doi: 10.1039/C7RA01650F [107] Yang C H, Han Y J, Qian J, et al. 2019. Flexible, temperature-resistant, and fatigue-free ferroelectric memory based on Bi(Fe0.93Mn0.05Ti0.02)O3 thin film. ACS Applied Materials & Interfaces, 11: 12647-12655. [108] Yang T T, Wei J, Guo Y X, et al. 2019. Manipulation of oxygen vacancy for high photovoltaic output in bismuth ferrite films. ACS Applied Materials & Interfaces, 11: 23372-23381. [109] Yimnirun R, Ananta S, Ngamjarurojana A, et al. 2005. Uniaxial stress dependence of ferroelectric properties of x PMN-(1-x) PZT ceramic systems. Applied Physics A, 81: 1227-1231. doi: 10.1007/s00339-005-3305-2 [110] Yoo I K, Desu S B. 2010. Mechanism of fatigue in ferroelectric thin films. Physica Status Solidi, 133: 565-573. [111] Yu Y, Wang X S, Li Y X, et al. 2014. Fatigue behaviors in PZT ceramics induced by mechanical cyclic load. Ferroelectrics Letters Section, 41: 123-128. doi: 10.1080/07315171.2014.956021 [112] Zhai J W, Li X, Yao Y, et al. 2003. Growth and characterization of PNZST thin films. Materials Science and Engineering B, 99: 230-233. doi: 10.1016/S0921-5107(02)00457-9 [113] Zhang S J, Yu F P. 2011. Piezoelectric materials for high temperature sensors. Journal of the American Ceramics Society, 94: 3153-3170. doi: 10.1111/j.1551-2916.2011.04792.x [114] Zheng X J, Deng S F, Zhou Y C, et al. 2005. Thermal shock and thermal fatigue of ferroelectric thin film due to pulsed laser heating. Advanced Materials Research, 9: 69-78. doi: 10.4028/www.scientific.net/AMR.9.69 [115] Zhukov S, Glaum J, Kungl H, et al. 2016. Fatigue effect on polarization switching dynamics in polycrystalline bulk ferroelectrics. Journal of Applied Physics, 120: 064103. doi: 10.1063/1.4960691 [116] Zou D, Liu S Y, Zhang C, et al. 2021. Flexible and translucent PZT films enhanced by the compositionally graded heterostructure for human body monitoring. Nano Energy , 85: 105984. doi: 10.1016/j.nanoen.2021.105984 -

下载:

下载: